Table of Contents

Advertisement

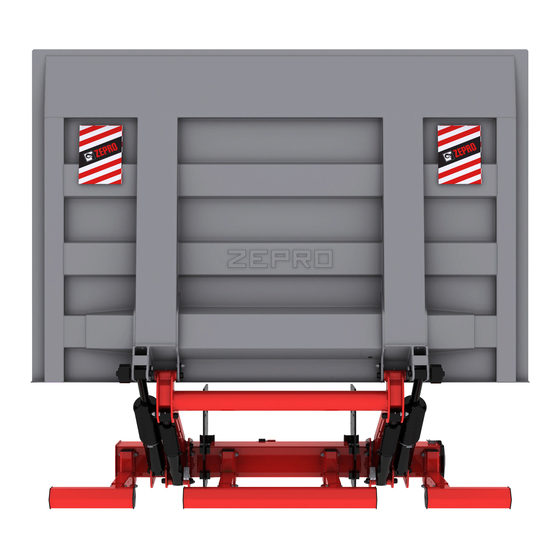

Z-LYFTEN PRODUKTION AB

INSTALLATION INSTRUCTIONS

ZHD 1500/2000-135/155/175

ZHDL 1500/2000-135/155/175

Sales

Mossvägen 8, 641 49 KATRINEHOLM, SWEDEN

Telephone:

+46 (0)150-489550

Fax:

+46 (0)150-489551

E-mail:

zepro@zepro.com

Internet:

www.zepro.com

Factory

Allévägen 4, 844 41 BISPGÅRDEN, SWEDEN

Telephone:

+46 (0)696-17200

Fax:

+46 (0)696-17242

E-mail:

info@zepro.com

Internet:

www.zepro.com

59581TL

01/05/2019

Advertisement

Table of Contents

Summary of Contents for Zepro ZHD 1500-135

- Page 1 INSTALLATION INSTRUCTIONS ZHD 1500/2000-135/155/175 ZHDL 1500/2000-135/155/175 01/05/2019 Sales Factory Mossvägen 8, 641 49 KATRINEHOLM, SWEDEN Allévägen 4, 844 41 BISPGÅRDEN, SWEDEN Telephone: +46 (0)150-489550 Telephone: +46 (0)696-17200 Fax: +46 (0)150-489551 Fax: +46 (0)696-17242 E-mail: zepro@zepro.com E-mail: info@zepro.com Internet: www.zepro.com Internet: www.zepro.com...

-

Page 3: Table Of Contents

6.10 Platform ....................25 6.11 Purging the cylinders ................30 6.12 Transport lock ..................30 Temporary operation of lift ................31 7.1 Connection ................... 31 7.2 Operation ....................31 7.3 Disconnection ..................31 Hydraulic unit and control card ..............32 www.zepro.com... - Page 4 15 Dismantling ..................... 58 16 Specifications ....................59 16.1 Weights ....................59 16.2 Maximum power consumption - Minimum recommended conductor cross sectional area ....................60 16.3 Battery maintenance ................60 16.4 Loading diagram ................... 61 16.5 Tightening torque .................. 62 www.zepro.com...

-

Page 5: Introduction

NOTE. Take care. Risk of damage to the product. WARNING! Take extra care. Risk of personal injury or damage to the product and the surroundings. www.zepro.com... -

Page 6: Ce Marking

ZHD 1500/2000-135/155/175 CE marking Zepro’s tail lifts on sale on the European market have been CE marked (Conformité Européenne) since 1/1/1995. The manufacturer guarantees that the product complies with the EU Machinery Directive. The aim of the Machinery Directive is to increase the safety of products throughout Europe. -

Page 7: Identification

Max. lifting capacity x 1 (kg) Max. lifting height -135 = 1340 mm -155 = 1530 mm -175 = 1710 mm Cylinder model, MA = Double acting Adjustable Tilt Single acting lift DA = Double acting Adjustable Tilt Double acting lift www.zepro.com... -

Page 8: Safety Rules

Fig. 1. Piston rods, cylinder covers and the hoses/cables and significantly boots must not be painted/coated impair durability. Fig. 2. Hydraulic hoses must not be painted/coated Fig. 3. Cables must not be painted/coated www.zepro.com... -

Page 9: Transport Plug

40 mm. WARNING! The platform must not be tilted down more than max. 10° from horizontal when people are on the platform. 10° Fig. 6. The platform must not be tilted down more than 10° from the horizontal www.zepro.com... -

Page 10: Third-Party Equipment Must Not Be Attached

Third-party equipment must not be attached WARNING! You must not attach third-party equipment (electric or hydraulic) to Zepro tail lifts. Attaching third-party equipment may interfere with the lift system and the safety functions. Risk of injury and damage. If it is necessary to install other equipment, check the vehicle manufacturer’s body instructions and use the attachment features on the vehicle. -

Page 11: Installation Workflow

Installing the control device cables • Installing the main power cable Installing the platform • Installing the platform • Installing seals and end stops • Installing the armstops Installing cylinders • Adjusting tilt cylinder • Test running Attaching decals www.zepro.com... -

Page 12: Calculating The Installed Dimensions

The A dimension is the space provided for the rear member, i.e. the space there will be between the lift arm and the vehicle floor with the lift in the raised position. The A dimension depends on the C dimension. H dimension The H dimension is the height from the ground (unloaded) to the vehicle floor level. The H dimen- sion must not be greater that the maximum lifting height of the lift. The platform must always be able to reach ground level. www.zepro.com... - Page 13 Calculating the installed dimensions ZHD 1500/2000-135/155/175 max. min. Fig. 7. ZHD/ZHDL 1500/2000-135 max. min. Fig. 8. ZHD/ZHDL 1500/2000-155 max. min. 1023 1051 Fig. 9. ZHD/ZHDL 1500/2000-175 www.zepro.com...

- Page 14 Calculating the installed dimensions ZHD 1500/2000-135/155/175 1435 1014 min. 750 - max. 930 1515 1870 2424 Fig. 10. ZHD 1500/2000 1669 1246 min. 982 - max. 1162 1749 2102 2481 Fig. 11. ZHDL 1500/2000 617-817 Fig. 12. ZHD/ZHDL 1500/2000 www.zepro.com...

-

Page 15: Rear Member Cut-Outs

2. Cut along the markings. 3. Grind away any burrs or sharp edges. A max. Fig. 13. ZHD 1500/2000 A max. 1226 Fig. 14. ZHDL 1500/2000 www.zepro.com... -

Page 16: Installation

Fig. 15. Measure and mark the midpoint of the rear member of the vehicle. WARNING! Zepro tail lifts are only approved for installation with Zepro installation kits. Support frame 1. Measure and mark the midpoint of the rear member of the vehicle. - Page 17 · the vehicle body is installed to reinforce the truck chassis. 15. Remove the mounting jig. Fig. 20. Install the chassis bracket with at least six M14x45 10.9 bolts www.zepro.com...

- Page 18 Do not place the lift under load until: · the correct number of bolts have been installed and torque-tightened. · the vehicle body is installed to reinforce the truck chassis. 20. Remove the mounting jig. www.zepro.com...

-

Page 19: Control Devices

Connect to the on-board electrical system via a 10 A (24 V), 15 A (12 V) fuse according the customer’s wishes. See the connec- tion diagram "9.6 Connecting cabin switch and open platform alarm" on page 39. www.zepro.com... -

Page 20: Main Power Cable

3. Check that the hydraulic unit is ef- fectively earthed. Certain commercial vehicle manufacturers provide spe- cial earth connection points. 4. Test all functions from all control Fig. 24. Quick connectors must be well protected devices. www.zepro.com... - Page 21 In general, care must be taken when laying all the cables in order to obtain a longer cable service life and to reduce the risk of unnecessary stoppages. Fig. 25. Earth and supply cables must be routed outside clamping yoke www.zepro.com...

-

Page 22: Underrun Protection

2x M12x100 8.8 80 Nm them firmly to secure. If necessary, tap carefully with a rubber hammer. 2x M12x80 8.8 2x M12x100 8.8 80 Nm 80 Nm 2x M12x80 8.8 80 Nm Fig. 29. Installing underrun protection www.zepro.com... - Page 23 25 mm. See illustration. • Each of the individual parts of the underrun protection must have a Min. area: 350 cm surface area of at least 350 cm See illustration. Max. 25 mm Max. 25 mm Fig. 32. Statutory dimensions www.zepro.com...

-

Page 24: Armstops

Fig. 35. Installing a sealing strip 2. Fit the rubber strip to the track. 3. Secure the rubber strips by swaging the tracks together at the bottom. NOTE. To fit an upper edge seal, create a 45° mitre against the vertical strips. www.zepro.com... -

Page 25: Platform

Ensure that the small holes on the inside of NOTE. Lubricate the bushings the bushings are filled with grease. See Fig. 36. Use Zepro lubricant or the equivalent. NOTE. Fig. 36. Carefully lubricate the metal bushings Carefully lubricate the metal bush- ings on the upper bearing of the arms. - Page 26 NOTE. Adjustment must always take place with full hydraulic pressure in the tilt cylinders. Lock screws, 3 pcs. 3. Loosen the three lock screws on the cylinder fitted to the platform. See illustration. Fig. 39. Adjusting the tilt angle www.zepro.com...

- Page 27 8. Tighten the bolts using a torque wrench. Tightening torque: 80 Nm. 9. Adjust the two cylinders alternately so that the platform meets the vehicle body. See Fig. 42 (B). Fig. 44. Fitting the tilt cylinder to the platform www.zepro.com...

- Page 28 30 mm. Fig. 45. Adjusting the tilt angle 11. Fit the cylinder boots. Fig. 46. ~ 10 mm Lift model 1500/2000-135 180 ±5 1500/2000-155 300 ±5 1500/2000-175 420 ±5 1500/2000-195 575 ±5 Fig. 46. Installing boots www.zepro.com...

- Page 29 (4). Fig. 48. 5. Tighten the lock screw in the end stop (5). Fig. 48. The tightening torque for lock screws is 3-5 Test all functions. Adjusting collar Lock screw Bolt End stop Washer Fig. 49. Tilt cylinder www.zepro.com...

-

Page 30: Purging The Cylinders

Electric hose rupture valves serve as locks for the platform. The lock opens automatically if the down function is actuated from the control device. The valves are non-return valves that let fluid in from the cylinders but not out be- fore they are actuated by the flow from the lowering valve. The platform is thus hydraulically locked during transport. www.zepro.com... -

Page 31: Temporary Operation Of Lift

Ctrl 2 CSPWR Jumper Ctrl 6 Di 6 Ctrl 3 Di 5 Radio Di 4 Lock Di 3 Di 2 Ctrl 5 Di 1 Ctrl 4 Ai 1 Spiral Ai 2 Lock Fig. 50. Temporary connection of lift control card www.zepro.com... -

Page 32: Hydraulic Unit And Control Card

Hydraulic unit and control card ZHD 1500/2000-135/155/175 Hydraulic unit and control card The hydraulic unit is built into the lift’s frame. The control card is housed in a separate enclosure. VALVE BODY TANK CAP OIL TANK SOLENOID MOTOR CONTROL CARD www.zepro.com... -

Page 33: Electrical And Hydraulic Drawings

Electrical and hydraulic drawings ZHD 1500/2000-135/155/175 Electrical and hydraulic drawings ZHD 1500/2000 NN www.zepro.com... -

Page 34: Zhd 1500/2000 Ce

Hydraulic unit and control card ZHD 1500/2000-135/155/175 ZHD 1500/2000 CE www.zepro.com... -

Page 35: Zhd 1500/2000 Dvx4 Nn

Hydraulic unit and control card ZHD 1500/2000-135/155/175 ZHD 1500/2000 DVx4 NN www.zepro.com... -

Page 36: Zhd 1500/2000 Dvx4 Ce

Hydraulic unit and control card ZHD 1500/2000-135/155/175 ZHD 1500/2000 DVx4 CE www.zepro.com... -

Page 37: Zhd 1500/2000 Hydraulic Autotilt Nn

Hydraulic unit and control card ZHD 1500/2000-135/155/175 ZHD 1500/2000 Hydraulic autotilt NN www.zepro.com... -

Page 38: Zhd 1500/2000 Hydraulic Autotilt Ce

Hydraulic unit and control card ZHD 1500/2000-135/155/175 ZHD 1500/2000 Hydraulic autotilt CE www.zepro.com... -

Page 39: Connecting Cabin Switch And Open Platform Alarm

Ctrl 2 CSPWR Brown Ctrl 6 Di 6 Black Ctrl 3 Di 5 Radio Green Di 4 Lock Di 3 White Di 2 Ctrl 5 Di 1 Ctrl 4 Ai 2 Spiral Yellow Ai 1 Lock Grey Orange Purple Pink www.zepro.com... -

Page 40: Connecting Control Devices

Ai 1 CD14 B Spiral Ai 2 Black (+) Lock Blue CD11 Brown CD12 Yellow Blue Grey Lock Black (+) White (-) Brown Brown Yellow CD10 Yellow Blue Black (+) Black (+) (White (-), (White (-), if available) if available) www.zepro.com... -

Page 41: Functional Schematic Drawings

Ctrl 1 45º Ctrl 2 Tilting up to ap- Tilt up B+C+Di2 U0+U3 Ctrl 3 proximately 45° 0º Ctrl 4 -10º Ctrl 6 90º 45º Close against Ctrl 1 Close B+C+2H U0+U3 vehicle body Ctrl 2 0º -10º * Only required at start of motion; after change of sensor, it is ignored until a re-run takes place. www.zepro.com... - Page 42 (+) signal comes in to Cs jumpered from (+) on nearby terminal. Control devices Two-hand Activated in connection with opening and closing of vehicle button body. Used for Quick opening. www.zepro.com...

-

Page 43: Zhd 1500-2000 (Config 3) Da

-10º 90º Ctrl 1 45º Ctrl 2 Tilting up to approxi- Tilt up B+C+Di2 U0+U3 Ctrl 3 mately 45° 0º Ctrl 4 -10º Ctrl 6 90º 45º Close against vehicle Ctrl 1 Close B+C+2H U0+U3 body Ctrl 2 0º -10º www.zepro.com... - Page 44 (+) signal comes in to Cs jumpered from (+) on nearby terminal. Control devices Two-hand Activated in connection with opening and closing of vehicle button body. Used for Quick opening. www.zepro.com...

-

Page 45: Connection Unit

- Active output (approved input signal from control device and sensors), the lift is operated. LED 1 LED 2 Display Flashing light Fig. 53. The control card is equipped with an alphanumerical display with a flashing light and 2 red LEDS www.zepro.com... - Page 46 On certain remote control models, the lift locks again as soon as a button on the remote control is pushed when the lift has been unlocked by the control power (CS) being switched Off/On. NOTE. Locking is retained if the lift loses power and then starts up again; the number 6 flashes on the control card’s display. Unlocking is performed in accordance with the above description. www.zepro.com...

- Page 47 Example of sequence of information codes: Program configuration: 01, Voltage detected: 12 V, Software version: 09 Example of sequence with sensor indication: Sensor indication: C, Detected sensor: Di1 Example of sequence with control device indication: Control device: 2, Detected button: B www.zepro.com...

- Page 48 Radio control device, external Coil control device Truck slider control device Radio control device, internal module CS (cabin switch) Segments B, C, E or X are il- luminated depending on which Segment button signal has locked the control device. www.zepro.com...

- Page 49 Fault code E is reset automatically if the control system has not received any signal from the relevant control device for 6 minutes. Example of sequence of fault codes: Output No. 3 short-circuited. www.zepro.com...

- Page 50 The lift is working but the voltage range outside the area marked with a heart is only recommended for operation for shorter periods of time. The lift works within the voltage range for the best functionality and service life. 8-15V 10-14V 0-7V 16-36V 18-30V 20-28V 0-16V 32-36V www.zepro.com...

-

Page 51: Marking And Decals

ZHD 1500/2000-135/155/175 Marking and decals 12.1 Summary The illustrations below show the positions of the various decals. Autotilt Autotilt Autotilt Autotilt www.zepro.com Phone +46 (0)150 48 95 50 76350TL 2017-02-02 Autotilt Autotilt www.zepro.com Phone +46 (0)150 48 95 50 76350TL 2017-02-02 Fig. -

Page 52: Load Diagram

A “work area” decal must be attached to the platform so that any drivers parking behind the vehicle know that 5 m clear- ance is needed for the platform to open and that sufficient space should be left for loading and unloading. Fig. 57. Work area www.zepro.com... -

Page 53: Driver's Instructions

Marking and decals ZHD 1500/2000-135/155/175 12.5 Driver’s instructions A driver’s instructions decal must be placed close to the fixed control device. Autotilt Autotilt www.zepro.com Phone +46 (0)150 48 95 50 76350TL 2017-02-02 Fig. 58. Driver’s instructions 12.6 Danger area A “danger area” decal warning about the danger zone between the platform and the rear edge of the vehicle. -

Page 54: Warning Flags

The marking below represents the Fig. 61. Warning flags manufacturer’s guarantee that the lift is designed and supplied in accordance with the EU Machinery Directive. This is the customer’s guarantee of high qual- ity and safety. Fig. 62. CE marking www.zepro.com... -

Page 55: Lubrication And Fluid Level Check

9. Lift arm right side, at upper bearing. 10. Right lift cylinder, at upper bearing. 11. Left lift cylinder, at upper bearing. 12. Lift arm left side, at upper bearing. 13.2 Oil level check Check the fluid level in the tank during service, top up if necessary. The marking on the hydrau- lic tank indicates the type of hydraulic fluid used. Mineral hydraulic fluid, product no. 21963 (1 litre), or biodegradable synthetic fluid, product no. 22235 (1 litre). Fig. 63. Lubrication points www.zepro.com... -

Page 56: Testing And Verification

Static load (Test load 1.25 x tail lift loading capacity). For tail lifts with load centre of 1000 mm Capacity Load 1500 kg Load 2000 kg Distance out in platform (L) 1500 kg 1250 mm 2000 kg 1625 mm 1250 mm Deformation Max. 15 mm Drift Max. 2° Fig. 64. Testing and verification www.zepro.com... -

Page 57: Dynamic Load Test

That all safety and operating decals are installed in their respective position. • That the platform’s mechanical lock is functioning correctly (where applicable). • That the instructions for using the tail lift have been left in the driver’s cabin. • That the CE declaration of conformity has been completed. www.zepro.com... -

Page 58: Dismantling

9. Support the support frame from beneath, for example with a car jack. 10. Remove the support frame from the vehicle chassis by loosening the bolts and carefully lowering the support frame to the ground with a car jack. www.zepro.com... -

Page 59: Specifications

The following is a list of selected components with their weight. Complete lift chassis (without platform) Lift components (included in complete lift chassis) ZHD 1500-135 334 kg Support frame ZHD 1500/2000 89 kg... -

Page 60: Maximum Power Consumption - Minimum Recommended Conductor Cross Sectional Area

When installing the lift and when carrying out service and repair work, when the lift is operated repeatedly without the vehicle being started and used, the battery charger must be used be- tween operations to maintain the battery’s charge level. NOTE. The battery charger must not be connected when operating the lift. Risk of damage. www.zepro.com... -

Page 61: Loading Diagram

Specifications ZHD 1500/2000-135/155/175 16.4 Loading diagram Fig. 66. Loading diagram www.zepro.com... -

Page 62: Tightening Torque

Specifications ZHD 1500/2000-135/155/175 16.5 Tightening torque 280 Nm 280 Nm 120 Nm 280 Nm 80 Nm Fig. 67. Tightening torque www.zepro.com...

Need help?

Do you have a question about the ZHD 1500-135 and is the answer not in the manual?

Questions and answers