Table of Contents

Advertisement

Z-LYFTEN PRODUKTION AB

INSTALLATION INSTRUCTIONS

Sales

Mossvägen 8, 641 49 KATRINEHOLM, SWEDEN

Telephone:

Fax:

0150 - 489551

E-mail:

zepro@zepro.com

Internet:

www.z-lyften.se

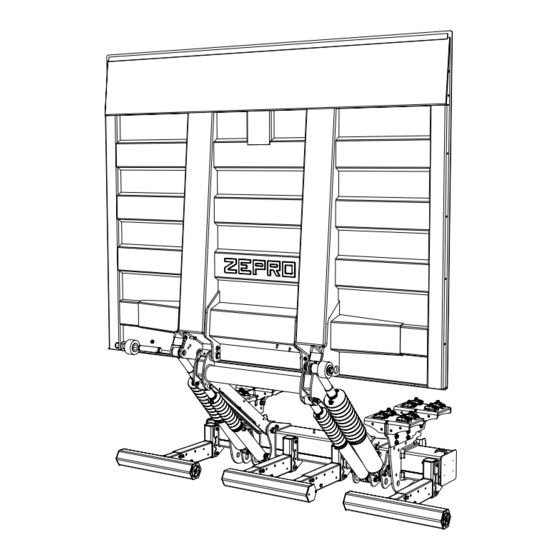

ZHDN 2500-150

0150 - 489550

Factory

Allévägen 4, 840 73 BISPGÅRDEN, SWEDEN

Telephone:

0696 - 17200

Fax:

0696 - 17242

E-mail:

info@zepro.com

Internet:

www.z-lyften.se

75354TL

2016-07-07

Advertisement

Table of Contents

Summary of Contents for Zepro ZHDN 2500-150

- Page 1 Z-LYFTEN PRODUKTION AB 75354TL INSTALLATION INSTRUCTIONS ZHDN 2500-150 2016-07-07 Sales Factory Mossvägen 8, 641 49 KATRINEHOLM, SWEDEN Allévägen 4, 840 73 BISPGÅRDEN, SWEDEN Telephone: 0150 - 489550 Telephone: 0696 - 17200 Fax: 0150 - 489551 Fax: 0696 - 17242 E-mail: zepro@zepro.com...

-

Page 3: Table Of Contents

Contents ZHDN 2500-150 Contents Introduction ...................... 5 General ......................5 Important .....................5 CE marking ....................6 1.4 Hydraulic fluid ....................6 1.5 Identification ....................7 Safety rules ......................8 2.1 Repainting .....................8 Transport plug ....................9 Moving parts - free movement ..............9 2.4 Third-party equipment must not be attached ..........10 2.5 Installation ....................10 Installation workflow .................. - Page 4 Temporary operation of lift................30 7.1 Connection ....................30 7.2 Operation ....................30 7.3 Disconnection .....................30 Electrical and hydraulic drawings ..............31 ZHDN 2500-150 ..................31 ZHD 2500-150, angle sensors ..............32 8.3 Connecting control device .................33 8.4 Connecting control device .................34 8.5 Connecting cabin switch and open platform alarm ........35 Connection unit ....................36 9.1 Operating information ................36...

-

Page 5: Introduction

Introduction ZHDN 2500-150 Introduction General Z-Lyften is electro-hydraulically driven. An electric motor which gets its power from the truck's ordinary battery drives a hydraulic pump which supplies fluid via hoses to the working hydraulic cylinders. The hdraulic system is controlled by electric valves which are controlled from push but- tons on the control devices. -

Page 6: Ce Marking

Introduction ZHDN 2500-150 CE marking Z-Lyften tail lifts on sale on the European market have been CE marked (CE stands for Conformité Européenne) since 1/1/1995. The manufacturer guarantees that the product complies with the EU Machinery Directive. The aim of the Machinery Directive is to increase the safety of products throughout Europe. -

Page 7: Identification

Introduction ZHDN 2500-150 Identification E.g. ZHDN 2500 - 135 MA ZHD = Standard model ZHDN = Narrow frame Max lifting capacity x 1 (kg) Max lifting height -135 = 1340 mm Cylinder model, MA = Double acting Adjustable Tilt Single acting Single speed Lift... -

Page 8: Safety Rules

Safety rules ZHDN 2500-150 Safety rules Repainting NOTE. Piston rods and cylinder covers must not be painted. Painting could dam- age the cylinder gaskets. Boots, hydraulic hoses and cables must not be painted/coated as the solvent in the paint could damage Image 1. -

Page 9: Transport Plug

Safety rules ZHDN 2500-150 54853 Transport plug NOTE. When the lift is installed, the trans- port plug in the hydraulic unit must be removed and replaced with the normal tank cap supplied with the hydraulic unit. Image 4. Replace the transport plug... -

Page 10: Third-Party Equipment Must Not Be Attached

Third-party equipment must not be attached WARNING! You must not attach third-party equipment (electric or hydraulic) to Zepro tail lifts. Attaching third-party equipment may interfere with the lift system and the safety functions. Risk of injury and damage. If it is necessary to install other equipment, check the vehicle manufacturer's body instructions and use the attachment features on the vehicle. -

Page 11: Installation Workflow

Installation workflow ZHDN 2500-150 Installation workflow Installing the support frame • Calculating the installed dimensions • Attaching the mounting jig to the rear beam • Aligning the support frame • Mounting the standard chassis brackets • Detaching the mounting jig Electrical connections •... -

Page 12: Calculating The Installed Dimensions

Calculating the installed dimensions ZHDN 2500-150 Calculating the installed dimensions For easier installation it is useful to calculate and specify the necessary dimensions in advance. Determine the C dimension first, then obtain the other dimensions from the relevant table. You should try to place the lift as high as possible within the specified C dimension in the table. The chassis brackets can be set to two different heights, which affects the C dimension, see section "5 Adjusting the chassis brackets"... - Page 13 Calculating the installed dimensions ZHDN 2500-150 567-817 Image 9. Installed dimensions 1094 1174 1200 - 1500 1870 2486 Image 10. Installed dimensions www.zepro.com...

-

Page 14: Adjusting The Chassis Brackets

Adjusting the chassis brackets ZHDN 2500-150 Adjusting the chassis brackets The chassis brackets can be set to two different heights. This affects the distance between the lift framework and the chassis (202 mm/242 mm). Take this into account when calculating the C dimension. The brackets must also be fitted differently depending on the chassis width, see the description below. -

Page 15: Installation

Consult the trailer manufacturer’s body instructions and Zepro’s instruction booklet before installation. WARNING! Zepro tail lifts are only approved for installation with Zepro installation kits. Chassis brackets 1. Place the chassis brackets on the support frame. 2. Adjust the distance between the brackets according to the chassis width and centre the frame so that the distance from the end of the frame to the bracket is the same on the left and the right. -

Page 16: Support Frame

Installation ZHDN 2500-150 Support frame 1. Measure and mark the midpoint of the rear beam of the trailer. See il- lustration. 2. Bolt or spot-weld the mounting jig (product no. 51724) to the rear beam so that both mid-points match. See illustration. - Page 17 Installation ZHDN 2500-150 platform. 7. The support frame should be positioned as high as possible within the specified C dimension. Adjust the frame to the ideal height under the trailer chassis. A car jack is useful. If necessary you can adjust the height of the bracket by installing its upper and lower parts in an alternative pattern of holes.

-

Page 18: Control Power Cable

Installation ZHDN 2500-150 Control power cable NOTE. See also the trailer manufacturer’s electrical instructions. 1. Route the control power cable from the driver’s cabin to the lift. NOTE. The cable must be protected with rubber grommets when it passes through beams or walls. If there are quick connectors, make sure Image 17. -

Page 19: Main Power Cable

Installation ZHDN 2500-150 Main power cable 1. Route the main power cable from the lift to the battery. Pull the cable through the plastic casing. NOTE. The cable must not be tied to brake lines or the normal on- board electrical system. The ca-... -

Page 20: Open Platform Alarm

Open platform alarm ZEPRO recommends installing a strobe lamp on the outside of the trailer body, where the driver can clearly see it in the rear view mirror. The lamp must be orange in colour. If the platform is not pressed against the vehicle body, the lamp lights up when the ignition is turned. -

Page 21: Underrun Protection

Installation ZHDN 2500-150 Underrun protection Test the position of the underrun protection without tightening the bolts to check that the statutory dimensions are obtained. Adjust if necessary then tighten the bolts with a torque wrench. 1. Fit the inner brackets at one of four Image 22. - Page 22 Installation ZHDN 2500-150 6.9.1 Statutory dimensions • Distance between the beam and the ground when the vehicle is unloaded: Max 550 mm See illustration. • Horizontal distance from the Max 375 mm outermost part of the platform to the underrun protection: Max 375 mm See illustration.

-

Page 23: Armstops

Installation ZHDN 2500-150 6.10 Armstops Fit end stops between the lift arms and the rear beam of the vehicle floor. The left and right end stops must be reached at the same time, as high up the lift arm as possible. -

Page 24: Platform

Installation ZHDN 2500-150 6.14 Platform 1. Check that all included components are clean, cleaning them where necessary. 2. Lubricate the metal bushings on the upper bearing of the arms. Ensure that the small holes on the inside of NOTE! Lubricate the bushings the bushings are filled with grease. - Page 25 Installation ZHDN 2500-150 Max 40 mm, Min 38 mm 5. Test the lift by carefully raising it to the vehicle floor level and tilting it to the vertical position. Check the position in relation to the rear beam and side posts of the vehicle.

- Page 26 Installation ZHDN 2500-150 4. Turn the adjusting collar so that the platform just meets the seal on the vehicle body, see Image 39 (A). Image 39. Adjusting the fit with the vehicle body. 5. Loosen the three lock screws on the other tilt cylinder, see illustration. 6. Loosen the three lock screws on the other tilt cylinder, see illustration. 7. Turn the adjusting collar so that the...

- Page 27 Installation ZHDN 2500-150 Max 30 mm 10. Tighten the lock screws of the ad- justing collar using a torque wrench. Tightening torque: 3-5 Nm. WARNING! After finishing the adjustment, make sure the distance between the adjust- ing collar and the end of the thread is no more than 30 mm.

- Page 28 Installation ZHDN 2500-150 6.14.2 Adjusting the downward tilt angle. NOTE. The tilt angle must be set at 90º to the vehicle body before the downward tilt angle is adjusted (see previous page). Image 43. The tilt angle must be ad- WARNING! justed to max.10º...

-

Page 29: Purging The Cylinders

Installation ZHDN 2500-150 6.15 Purging the cylinders Fully lower the platform a few times. You may have to lift the truck to fully lower the platform. For tilt cylinder model Tilt cylinders can be purged by closing the platform against the vehicle body and then opening and tilting all the way down. -

Page 30: Temporary Operation Of Lift

Temporary operation of lift ZHDN 2500-150 Temporary operation of lift When the lift is installed, it is sometimes necessary to operate the lift functions in order to change the position of the cylinders and the lift arms. To do this, the lift control card can be con- nected temporarily to run the functions. -

Page 31: Electrical And Hydraulic Drawings

Electrical and hydraulic drawings ZHDN 2500-150 8 Electrical and hydraulic drawings ZHDN 2500-150 www.zepro.com... -

Page 32: Zhd 2500-150, Angle Sensors

Electrical and hydraulic drawings ZHDN 2500-150 ZHD 2500-150, angle sensors www.zepro.com... -

Page 33: Connecting Control Device

Electrical and hydraulic drawings ZHDN 2500-150 Connecting control device Lift with 2H-button. For ZHDN 2500-150, use Config 13. www.zepro.com... -

Page 34: Connecting Control Device

Electrical and hydraulic drawings ZHDN 2500-150 Connecting control device Lift without 2H-button. For ZHDN 2500-150, use Config 13. www.zepro.com... -

Page 35: Connecting Cabin Switch And Open Platform Alarm

Ai 1 Lock ZEPRO recommends installing a strobe lamp on the outside of the trailer body, where the driver can clearly see it in the rear view mirror. The lamp must be orange in colour. Connect the lamp/indicator according to the electrical and hydraulic drawing. -

Page 36: Connection Unit

Connection unit ZHDN 2500-150 Connection unit Operating information All the lift's functions are controlled and monitored through the connection unit and its circuit board. The circuit board is equipped with an alphanumerical display with a flashing light and 2 red LEDs. These display current operating information. In the event of any operational distur- bances, fault codes are displayed to facilitate troubleshooting. - Page 37 Connection unit ZHDN 2500-150 9.1.1 Information codes Codes are shown on the display in a sequence. First a letter for identification of information, fol- lowed by figures or segments for further information and then ending with a pause: When the CS (cabin switch) is switched on, the current program configuration (P) is displayed first, followed by configuration number.

- Page 38 Connection unit ZHDN 2500-150 Information codes Code Code Identification Code 1 Information Other 00–99 Cancelled configuration (Program Dividers configuration) 12/24 Number of volts detected Version number 01–99 Software version Fixed light (1-7) displays active control 1.-7 (Fixed light) device during operation.

- Page 39 Connection unit ZHDN 2500-150 9.1.2 Fault codes If a fault arises, the fault code is shown in the display in the form of a letter for identifying the fault, followed by numbers and/or number segments for further information, followed by sensor indica- tion (C) in accordance with the previous page.

- Page 40 Connection unit ZHDN 2500-150 All fault codes can be reset manually by switching On/Off the CS (cabin switch) Fault codes F0-F7 and U0-U7 are reset automatically if the function in question is running (function verified). Fault codes L and H are reset automatically if the battery voltage becomes correct. Fault code E is reset automatically if the control system has not received any signal from the relevant control device for 6 minutes.

-

Page 41: Autotilt

Connection unit ZHDN 2500-150 Autotilt The lift uses Electrical Autotilt, which can have two different ways of working depending on the setting on the control card. Normal position, with jumper Di1 installed, or extended position (auto- levelling), without jumper Di1. See also the electrical and hydraulics diagrams in section "8.2 ZHD 2500-150, angle sensors"... -

Page 42: Functional Schematic Drawing

Connection unit ZHDN 2500-150 Functional schematic drawing Function Input signal Output Comment Illustration signal 90º 45º C+E+2H Open from vehicle body down Open U0+U1+U3+U5 C+E (Coil) to about 45º 0º -10º Lower (Manual) E+Di6 Without autotilt (Di6 jumpered) U1+U2+U4 Lower E+/Di5+/Di6... -

Page 43: Restriction Of Use Of Control Device

Connection unit ZHDN 2500-150 Restriction of use of control device Tilt up Tilt down 90º 90º Control device 1,2 (Ctrl Control device 1,2 (Ctrl 1 & 2) 45º 45º 1 & 2) Coil (Ctrl 4) Radio (Ctrl 3 & 6) Radio (Ctrl 3 & 6) Coil (Ctrl 4) 0º... -

Page 44: Sensor

Connection unit ZHDN 2500-150 Sensor Name Position Function Description (standard) Lift arm Angle sensor For autotilt, safety function. Platform Angle sensor For autotilt, platform angle. Platform Non-actuated Di3 disables Tilt up with the secondary control device so that the operator must use the two-hand button - 2H along with the primary control device in order to continue to maintain the tilt up function. -

Page 45: Hydraulic Unit

Connection unit ZHDN 2500-150 Hydraulic unit VALVE BODY TANK CAP TANK SOLENOID MOTOR Image 49. Hydraulic unit CIRCUIT BOARD CONNECTION UNIT Image 50. Connection unit www.zepro.com... -

Page 46: Marking And Decals

Marking and decals ZHDN 2500-150 Marking and decals 10.1 Summary The illustrations below show the positions of the various decals. Emergency closing when voltage is low. NB! Only the main control unit is functional. Nödstängning vid låg volt. OBS! Endast huvudmanöverdonet är användbart. Notsteuerung bei Unterspannung. ACHTUNG: Notsteuerung ist nur mit der Hauptsteuerung möglich! -

Page 47: Load Diagram

Marking and decals ZHDN 2500-150 10.2 Load diagram Load diagram decals are positioned close to control devices at a clearly vis- ible, suitable location on the platform. The decal clearly shows the nominal load and a load diagram describing the maximum permitted load at various places on the platform. -

Page 48: Driver's Instructions

Marking and decals ZHDN 2500-150 55056 10.5 Driver's instructions A driver’s instructions decal must be placed close to the fixed control device. Image 55. Driver's instructions 10.6 Danger area A “danger area” decal warning about the danger zone between the platform and the rear edge of the vehicle. -

Page 49: Ce Marking

Marking and decals ZHDN 2500-150 10.9 Warning flags Attach warning flags as close as possible to the top and edge of the platform, where there is no risk of them coming loose when the platform is lowered to the ground. Swage the tracks together to secure the warning flags. -

Page 50: Lubrication And Fluid Level Check

Lubrication and fluid level check ZHDN 2500-150 Lubrication and fluid level check The following lubrication points must be greased on installation. They must then be lubricated at least once a year. 11.1 Lubrication NOTE. Use LE lubricant 4622 or the equivalent. 1. Right tilt cylinder, at lower bearing. 2. Right lift cylinder, at lower bearing. 3. Lift arm right side, at lower bearing. -

Page 51: Testing And Verification

Testing and verification ZHDN 2500-150 Testing and verification Testing and verification of the tail lift takes place in accordance with the installation/delivery inspection. Verify that the tail lift is suitable for the vehicle in question and for the intended use. 12.1 Static load test 12.1.1... -

Page 52: Dynamic Load Test

Lubrication and fluid level check ZHDN 2500-150 12.2 Dynamic load test. 12.2.1 Test with max load Place a test load on the platform according to the table for the respective tail lift model and lifting capacity. Check that the lift operates correctly in the normal range of movement allowed i.e up, down, tilt- ing at the vehicle floor level. -

Page 53: Disassembly

Disassembly ZHDN 2500-150 Disassembly If the tail lift must be removed from the vehicle, for example to transfer it to another vehicle, for storage or for modification please follow these instructions. 1. Support the platform with a crane or similar equipment that can safely carry the platform's weight (NB. -

Page 54: Specifications

Complete lift chassis (without platform) Lift components (included in complete lift chassis) ZHDN 2500-150 340 kg Support frame ZHDN 2500 89 kg Lit arm ZHDN 2500-150 53 kg Steel platforms 3-part underrun protection 56 kg complete ZHDN Steel platform 2000x2540 mm... -

Page 55: Centre Of Gravity

Specifications ZHDN 2500-150 14.2 Centre of gravity ZHDN 2500-150, steel platform 2000x2560 mm C = 360 C = 485 C = 610 (mm) (mm) 1500 kg (mm) 2000 kg Image 62. Centre of gravity www.zepro.com... -

Page 56: Maximum Power Consumption - Minimum Recommended Conductor Cross Sectional Area

Specifications ZHDN 2500-150 14.3 Maximum power consumption - Minimum recommended conductor cross sectional area ZHDN 2500 (200 bar) Hydraulic unit 7100 12 volt 24 volt Pump - Motor unit 245 A 145 A Magnet (hydraulic unit) 4.2 A 2.1 A Magnet (electric safety valve) 1.5 A... -

Page 57: Loading Diagram

Specifications ZHDN 2500-150 14.4 Loading diagram Image 64. Loading diagram www.zepro.com... -

Page 58: Tightening Torque

Specifications ZHDN 2500-150 14.5 Tightening torque 80 Nm 180 Nm 80 Nm 180 Nm 260 Nm 80 Nm Image 65. Tightening torque www.zepro.com...

Need help?

Do you have a question about the ZHDN 2500-150 and is the answer not in the manual?

Questions and answers