Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK ROTA TB-TBS-EP

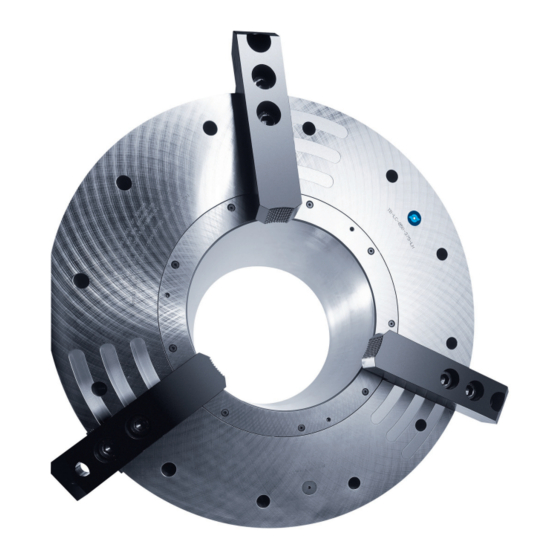

- Page 1 Translation of Original Operating Manual Pneumatic power chuck ROTA TB-TBS-EP Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 About this manual ....................5 1.1 Presentation of Warning Labels ................5 1.2 Applicable documents ....................6 2 Basic safety instructions ................... 7 2.1 Intended use ......................7 2.2 Not intended use ...................... 7 2.3 Notes on particular risks ................... - Page 4 Table of contents 8.2 Air transmission system ..................44 8.3 Pilot controlled check valve..................46 8.4 Clamping or jaw actuation ..................47 9 Commissioning and maintenance ................48 9.1 Commissioning ....................... 48 9.2 Maintenance ......................49 9.3 Maintenance intervals .................... 52 9.4 Hardened Reversible Jaws and Soft Top Jaws............

-

Page 5: About This Manual

About this manual About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

• Catalog data sheet of the purchased product * • Calculation of the jaw centrifugal forces, "Technology" chapter in the lathe chuck catalog * The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com 02.00|0889073_ROTA TB-TBS-EP |en... -

Page 7: Basic Safety Instructions

Only original SCHUNK spare parts may be used. Intended use The chuck is used to clamp workpieces on machine tools and other suitable technical facilities, paying particular attention to the technical data specified by the manufacturer. -

Page 8: Notes On Particular Risks

Basic safety instructions Notes on particular risks This product may cause danger to persons and damage to property if, for example - is not used as intended, - is improperly installed or maintained; - the safety and assembly instructions, the safety and accident prevention regulations valid at the place of use and the EC Machinery Directive are not observed. - Page 9 Basic safety instructions DANGER Possible risk of fatal injury to operating personnel if a jaw breaks or if the lathe chuck fails because the technical data have been exceeded and a workpiece is released or parts fly off • The technical data specified by the manufacturer for using the lathe chuck must never be exceeded.

- Page 10 Basic safety instructions CAUTION Danger of slipping and falling in case of dirty environment where the chuck is used (e.g. by cooling lubricants or oil). • Ensure that the working environment is clean before starting assembly and installation work. • Wear suitable safety shoes. •...

-

Page 11: Notes On Safe Operation

Basic safety instructions CAUTION Hazard from vibration due to imbalanced rotating parts and noise generation. Physical and mental strains due to imbalanced workpieces and noise during the machining process on the clamped and rotating workpiece. • Ensure the chuck's axial and concentric runout. •... - Page 12 (clamping force, coefficient of friction, wear characteristics). (For product information about LINOMAX plus, see the "Accessories" chapter of the SCHUNK lathe chuck catalog or contact SCHUNK). • Use a suitable high-pressure grease gun to ensure that you reach all the greasing areas.

- Page 13 Basic safety instructions lubricant back to the surfaces of the force transmission. This means that the clamping force is retained for longer). Caution Following a longer shutdown period (more than 6 hours), always retension the clamped lathe chuck in order to compensate for the setting properties of the clamping situation or possible pressure losses and the resulting loss of clamping force.

-

Page 14: Substantial Modifications

• If the chuck is involved in a collision, it must be subjected to a crack test before using it again. Replace damaged parts with original SCHUNK spare parts. • Replace the chuck jaw mounting screws if there are signs of wear or damage. -

Page 15: Using Personal Protective Equipment

Only allow specialists to remedy faults. Spare parts Only ever use original SCHUNK spare parts. Environmental regulations Comply with the applicable legal norms when disposing of waste. -

Page 16: Warranty

Scope of delivery Warranty If the product is used as intended, the warranty is valid for 24 months from the ex-works delivery date under the following conditions: ( 1.2, Page 6) • Observe the applicable documents, • Observe the ambient conditions and operating conditions •... -

Page 17: Technical Data

Technical Data Chuck data ROTA TB Size 400-115 400-140 470-185 500-160 500-205 500-230 600-275 630-265 Chuck Ø Chuck through bore [mm] Max. clamping force [kN] Max. rotation 1700 1700 1700 1300 1300 1300 1300 1000 speed [min-1] Stroke per jaw [mm] Serration of the 3/32"... - Page 18 Size 630-310 630-330 800-365 800-410 1000- 400- 470- 500- 140-LH 185-LH 205-LH Serration of the 3/32" x 90° jaws [mm] Distributor ring Ø [mm] Centrifugal 1.745 1.815 3.031 3.172 4.292 0.866 0.823 1.399 torque of base jaw [kgm] M Max. jaw eccentricity of center of gravity in axial direction...

- Page 19 ROTA EP Size 380-127 460-165 460-185 500-260 460-165- 460-185- Chuck Ø Chuck through bore [mm] 127 Max. clamping force [kN] 160 Max. rotation speed 2300 1600 1600 1000 1600 1600 [min-1] Stroke per jaw [mm] Serration of the jaws 3/32" x 90° 1/16"...

-

Page 20: Clamping Force / Speed Diagrams

SHB, SWB and SWB-AL. The maximum actuating force was introduced and the jaws were placed flush with the base jaw outer edge. The chuck is in perfect condition and lubricated with SCHUNK LINO MAX special grease. Should one or several of the above mentioned parameters be changed the diagrams are no longer valid. - Page 21 Clamping force-RPM-diagram ROTA TB 400-140 Clamping force-RPM-diagram ROTA TB 470-185 Clamping force-RPM-diagram ROTA TB 500-160 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 22 Clamping force-RPM-diagram ROTA TB 500-205 Clamping force-RPM-diagram ROTA TB 500-230 Clamping force-RPM-diagram ROTA TB 600-275 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 23 Clamping force-RPM-diagram ROTA TB 630-265 Clamping force-RPM-diagram ROTA TB 630-310 Clamping force-RPM-diagram ROTA TB 630-330 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 24 Clamping force-RPM-diagram ROTA TB 800-365 Clamping force-RPM-diagram ROTA TB 800-410 Clamping force-RPM-diagram ROTA TB 1000-534 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 25 Clamping force-RPM-diagram ROTA TB-LH 400-140 Clamping force-RPM-diagram ROTA TB-LH 470-185 Clamping force-RPM-diagram ROTA TB-LH 500-205 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 26 Clamping force-RPM-diagram ROTA TB-LH 500-230 Clamping force-RPM-diagram ROTA TB-LH 600-275 Clamping force-RPM-diagram ROTA TB-LH 630-265 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 27 Clamping force-RPM-diagram ROTA TB-LH 630-325 Clamping force-RPM-diagram ROTA TB-LH 850-375 Clamping force-RPM-diagram ROTA TB-LH 1000-560 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 28 Clamping force-RPM-diagram ROTA TB-LH 1200-640 Clamping force-RPM-diagram ROTA EP 380-127 Clamping force-RPM-diagram ROTA EP 460-165 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 29 Clamping force-RPM-diagram ROTA EP 460-185 Clamping force-RPM-diagram ROTA EP 500-260 Clamping force-RPM-diagram ROTA EP-LH 460-165 02.00|0889073_ROTA TB-TBS-EP |en...

-

Page 30: Calculations For Clamping Force And Speed

Clamping force-RPM-diagram ROTA EP-LH 460-185 Calculations for clamping force and speed Missing information or specifications can be requested from the manufacturer. Legend Total centrifugal force [N] Centrifugal torque of top jaws [Kgm] Effective clamping force [N] Centrifugal torque of base jaws [Kgm] minimum required clamping force Speed of rotation [RPM] spmin... - Page 31 (–) for gripping from the outside inwards (+) for gripping from the inside outwards DANGER Risk to life and limb of the operating personnel and significant property damage when the RPM limit is exceeded! With gripping from the outside inwards, and with increasing RPM, the effective clamping force is reduced by the magnitude of the increasing centrifugal force (the forces are opposed).

-

Page 32: Calculation Example: Required Initial Clamping Force For A Given Speed

CAUTION This calculated force must not be larger than the maximum clamping force ΣS engraved on the lathe chuck. See also "Lathe chuck data" table ( 6.1, Page 17) From the above formula it is evident that the sum of the effective clamping force F and the total centrifugal force F is multiplied by... - Page 33 • Machining force F = 3000 N (application-specific) • max. RPM n = 3200 RPM ("Lathe chuck data" table) • RPM n = 1200 RPM (application-specific) • Mass of one (!) top jaw m = 5.33 kg (application- specific) • Center of gravity radius of top jaw r = 0.107 m (application- specific) •...

-

Page 34: Calculation Of The Permissible Speed In Case Of A Given Initial Clamping Force

6.3.3 Calculation of the permissible speed in case of a given initial clamping force Calculation of the permissible RPM n in case of a given initial perm clamping force F The following formula can be used to calculate the permissible RPM for a given initial clamping force during shutdown: CAUTION For safety reasons, the calculated permissible RPM may not... -

Page 35: Grades Of Accuracy

Grades of Accuracy Tolerances for radial and axial run-out accuracy correspond to the Technical Supply Terms for lathe chucks as per DIN ISO 3442-3. Permissible imbalance DIN ISO 21940-11 The ROTA TB in ungreased state without T-nuts and top jaws corresponds to the balancing quality class 6.3 (according to DIN ISO 21940-11). -

Page 36: Pre-Assembly Measures

Mounting Pre-assembly measures Carefully lift the product (e.g. using suitable lifting gear) from the packaging. CAUTION Danger of injury due to sharp edges and rough or slippery surfaces Use personal protective gear, especially safety gloves. Check the delivery for completeness and for transport damage. CAUTION Always use the correct length of mounting screws when mounting the chuck and flange. -

Page 37: Mounting With Bracket

CAUTION The axial labyrinth gap between the chuck body and the distributor ring must be 1.5 mm on all TB chucks. This is the only way to ensure that the air is transmitted properly from the distributor ring to the chuck body. 1 Spacing console 4 Height dimension 2 Chuck... - Page 38 which have been drilled in at a 60° angle. When the threaded mounting holes in the headstock and the holes in the spacing console have been drilled, the spacing console is screwed onto the distributor ring. The chuck with the distributor ring and the bolted-on spacing console are now finally mounted on the spindle nose.

-

Page 39: Mounting With 2-Part Clamping Ring (D.r.m.b.)

Headstock mounting surface Height dimension Distributor ring mounting surface Type TB-400 TB-500 TB-630 TB-800/850 ØA ØB* ØC ØD * Example only (deviations possible) 7.2.2 Mounting with 2-part clamping ring (D.R.M.B.) The distributor ring can be clamped onto a rigid collar on the machine (at least 8 mm wide) using a two-piece clamping ring. -

Page 40: Attachment

Attachment 7.3.1 All TB 400 – 850, TB-LH 400 – 850, TB/TB-LH 1000 (2010 or later*) * TB/TB-LH 1000 for year of construction 2010 or later For power chuck types TB and TB-LH in size 400 – 850, a chuck flange is mounted on the spindle nose. - Page 41 (depth 8 mm) - i.e. only screwed in only 7 mm deep - to ensure that it touches the outer edge of the chuck. SCHUNK provides standard flanges that can be used to mount the pneumatic chuck on spindles in accordance with DIN 55026, DIN 55027 and DIN 55029.

-

Page 42: All Tb/Tb-Lh 1000 (Up To 2009*) And Ep/Ep-Lh

7.3.2 All TB/TB-LH 1000 (up to 2009*) and EP/EP-LH * TB/TB-LH 1000 for year of construction up to 2009 For power chuck types EP, EP-LH, TB and TB-LH in sizes of 1000 and larger, mounting is a several-step process. First, the chuck body is unscrewed and separated from the cylinder. - Page 43 1 Distributor ring 11 Locking screw 2 Profile gap 1.5 mm 12 Pilot-controlled check valve 3 Lubricating nipple 13 Piston cover 4 O-rings 14 Chuck body 5 Sealing disk 15 O-rings 6 Screw (for mounting chuck body on 16 Pneumatic connection cylinder) 7 Cylindrical screw with hexagon socket 17 Cylinder...

-

Page 44: Function

Function Function The item numbers specified for the corresponding individual components relate to chapter drawings.( 16, Page 64) Principle of Operation The problem of air supply was solved by a stationary distributor ring with profile ring seals arranged therein. Openings in the two elastic radially deformable profile seals allow the compressed air to flow through a non-return valve to one of the two pressure chambers. - Page 45 Function transfer point. This allows low-loss flow of the air through the openings in the profile seal into the cylinder chamber of the chuck. If the supply of compressed air is stopped, the double check valve closes and the pre-tensioned profile seal raises from the chuck body due to its elasticity and is not subjected to wear during rotation of the chuck.

-

Page 46: Pilot Controlled Check Valve

Function Pilot controlled check valve The pilot controlled check valve is a self-contained structural unit consisting of a valve body and two blocking pistons. It can easily be serviced from the face side of the chuck by means of a locking screw. -

Page 47: Clamping Or Jaw Actuation

Function Clamping or jaw actuation All three base jaws are centrically driven by a piston with a collar. The force is transmitted on the two-sided, extended and self- locking (10° wedge slant standard) wedge hook or base jaw. The clamping forces are absorbed by the diameter of the piston collar and braced against by the chuck body. -

Page 48: Commissioning And Maintenance

CAUTION Facing or skimming of the pneumatic power chuck is not permitted. Drilling of the chuck on the front face side may be performed only in accordance with the drilling patterns on the SCHUNK dimension sheets. 02.00|0889073_ROTA TB-TBS-EP |en... -

Page 49: Maintenance

Commissioning and maintenance Maintenance A WEH-type maintenance unit, consisting of a filter, a water separator and an oiler, must be connected upstream of the power chuck. The oil-enriched air provides all the sliding parts of the cylinder chamber with a film of oil. The oil level in the oil tank must be checked daily, and oil must be added if necessary. - Page 50 Commissioning and maintenance 1 Mounted directly from front: 2 bore 7 Required distance for removing the holes Ø L, depth C4 tank 2 Lateral mounting with two retaining 8 Automatic condensate drain can be brackets (accessories) connected using a hose with I.D. 6 3 Protective metal cage with transparent 9 Pressure gauge, Ø...

- Page 51 Commissioning and maintenance G 1/8” Weigh 0.760 t [kg] (weight without pressure gauge) 110.5 Basic setting for oiler Chuck type Air consumption/jaw Clamping Number of oil Oil quantity stroke at 6 bar strokes drops ROTA TB 400 to 5 – 11 liters approx.

-

Page 52: Maintenance Intervals

Commissioning and maintenance two to three times without a workpiece; the fully extended jaw stroke will then distribute the grease. The chuck valve system must occasionally be lightly lubricated with oil. In order to do this, the locking screw the face side of the chuck first needs to be removed. - Page 53 Commissioning and maintenance chuck. When installing and removing the reversible jaws numbered 1 to 3, make sure that the individual jaws are installed/removed on/from the base jaws with the same designation in order to ensure a high level run-out accuracy. The soft top jaws are turned on the chuck in the same clamping position and under the same operating pressure as are used for machining the workpiece.

-

Page 54: Disassembly And Assembly

TBS, TBS-LH stationary power chucks Disassembly and assembly The item numbers specified for the corresponding individual components relate to chapter drawings.( 16, Page 64) 10.1 TB 400 - 850, TB-LH 400 - 850, TB/TB-LH 1000 (year of construction 2010 or later) 10.1.1 Disassembly 1 Unscrew both the pneumatic quick coupling pieces from the... -

Page 55: Assembly

Lubricate the cylinder chamber of the chuck with oil. The jaw guides in the chuck body, the base jaws and the piston on the wedge hooks are greased with LINOMAX special grease paste. SCHUNK offers complete sealing kits for the O-rings. 10.1.2 Assembly The chuck is assembled in the same way, but in reverse order. -

Page 56: All Tb/ Tb-Lh Up To Size 1000 (Until Year Of Construction 2009) And All Ep/Ep-Lh

2-piece clamping ring" ( 7.2, Page 36)). CAUTION All parts of the SCHUNK power chuck move easily. As such, hard hammer blows should never be used during assembly. 10.2 All TB/ TB-LH up to size 1000 (until year of construction 2009) and all EP/EP-LH 10.2.1... - Page 57 The jaw guides in the chuck body, the base jaws and the piston on the wedge hooks are greased with LINOMAX special grease paste. SCHUNK offers complete sealing kits for the O-rings. 02.00|0889073_ROTA TB-TBS-EP |en...

-

Page 58: Assembly

TBS, TBS-LH stationary power chucks 10.2.2 Assembly The chuck is assembled in the same way, but in reverse order. Observe the following points when doing this: 1 Both the base jaws (2) and the base jaw guides in the chuck body (1) are numbered 1, 2, and 3. -

Page 59: Control Of Types Tb / Tb-Lh / Ep / Ep-Lh

Screw the locking screw (15) with the O-ring (45) into the chuck body. CAUTION All parts of the SCHUNK power chuck move easily. As such, hard hammer blows should never be used during assembly. Control of types TB / TB-LH / EP / EP-LH... -

Page 60: Power Chuck With Extended And Standard Jaw Stroke (Lh)

Power Chuck with extended and standard jaw stroke (LH) Power Chuck with extended and standard jaw stroke (LH) Lathe chucks with dual stroke system (LH-serie) are not allowed to be used for I.D. clamping. Moreover, no workpieces are allowed to be clamped on the fast jaw stroke, since due to the long jaw strokes the resulting clamping forces are lower (1). -

Page 61: Disposal

• Remove any identifiable plastic or aluminum parts installed in or on the chuck and dispose of them properly in line with the statutory provisions. • Dispose of the chuck's metal parts as scrap metal. Alternatively, you can return the chuck to SCHUNK for proper disposal. 02.00|0889073_ROTA TB-TBS-EP |en... -

Page 62: Spare Parts

Spare parts Spare parts When ordering spare parts, it is imperative to specify the type, size and above all the manufacturing no of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws and wiper bars plus parts coming into contact with the workpiece are not covered by the warranty. - Page 63 Spare parts Spare parts list for all TB / TB-LH from size 1000 and EP / EP-LH Item Designation Chuck body base jaw Piston Sleeve Sealing disk Piston cover Cylinder mount Distributor ring T-nuts Cylinder Double check valve Locking screw Filler plug Screw DIN EN ISO 4762 / 10.9 Screw DIN EN ISO 4762 / 10.9...

-

Page 64: Assembly Drawings

Assembly drawings Assembly drawings TB 400 – 850 02.00|0889073_ROTA TB-TBS-EP |en... - Page 65 Assembly drawings TB 400 – 850 (LH) * Item. for TB 400-115 and TB 400-140 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 66 Assembly drawings TB 400 – 850 LH 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 67 Assembly drawings Clamping stroke TB 1000 (LH) 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 68 Assembly drawings 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 69 Assembly drawings EP (LH) 02.00|0889073_ROTA TB-TBS-EP |en...

- Page 70 Assembly drawings 02.00|0889073_ROTA TB-TBS-EP |en...

-

Page 71: Translation Of Original Ec Declaration Of Incorporation

Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co.Spanntechnik KG Distributor Lothringer Str. 23 D-88512Mengen We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the directive 2006/42/EC of the European Parliament and of the Council on machinery. -

Page 72: Appendix On Declaration Of Incorporation, As Per 2006/42/Ec, Annex Ii, No. 1 B

Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, annex I, that apply to and are fulfilled for the scope of the partly completed machine: Product designation ROTA TB/TB-LH/TBS/TBS-LH/EP/EP-LH pneumatic chuck Type designation... - Page 73 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Required characteristics of guards and protective devices 1.4.1 General requirements 1.4.2 Special requirements for guards 1.4.2.1 Fixed guards 1.4.2.2 Interlocking movable guards 1.4.2.3 Adjustable guards restricting access 1.4.3 Special requirements for protective devices Risks due to other hazards...

Need help?

Do you have a question about the ROTA TB-TBS-EP and is the answer not in the manual?

Questions and answers

I'M LOOKING FOR FULL SET OS SEALS FOR CHUCK TB-630-310 & TB 630-275