Table of Contents

Advertisement

80

Boiler Manual

This manual must only be used by a qualified heating installer/service

technician. Read all instructions before installing. Follow all instructions

in proper order. Failure to comply could result in severe personal injury,

death or substantial property damage.

• Consider piping and installation when determining boiler location.

INSTALLER

• Any claims for damage or shortage in shipment must be filed immediately

against the transportation company by the consignee.

• This manual is for use only by your qualified heating installer/service

USER

technician.

• Boiler and burner must be installed by a qualified service technician.

• We recommend regular service by a qualified service technician, at least

annually.

When calling or writing about the boiler— Please have the boiler model

number from the boiler rating label and the CP number from the boiler

jacket.

Water & steam boilers

for use with Gas, Light Oil, &

Gas/Light Oil – Fired Burners

Part No. 550-141-935/0602

Advertisement

Table of Contents

Summary of Contents for Weil-McLain 80

- Page 1 Boiler Manual This manual must only be used by a qualified heating installer/service technician. Read all instructions before installing. Follow all instructions in proper order. Failure to comply could result in severe personal injury, death or substantial property damage. • Consider piping and installation when determining boiler location. INSTALLER •...

-

Page 2: Table Of Contents

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Contents Before installing boiler ... 3 Set boiler in place... 5 Assemble block ... 6 Perform hydrostatic pressure test ... 8 Complete block assembly ... 9 Install flue collector... 10 Connect water boiler piping ... -

Page 3: Before Installing Boiler

• Installation • Start-Up Before installing boiler Installation must comply with — • State, provincial and local plumbing, heating and electrical codes. • Regulations of servicing utilities. • National codes where applicable. Before selecting boiler location 1. Check for nearby connections to: a. - Page 4 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Before installing boiler Provide combustion and ventilation air openings: Do not install an exhaust fan in boiler room. Adequate combustion and ventilation air must be provided to assure proper combustion and prevent...

-

Page 5: Set Boiler In Place

• sealing rope not in place. • loose bolts or nuts. d. Correct all conditions and repeat step b. If unsealed areas still exist, contact your Weil-McLain distributor or sales office before continuing installation. 7. Proceed to "Perform hydrostatic pressure test," page 8. -

Page 6: Assemble Block

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Assemble block Sections are top heavy. Unbolted sections may fall if not supported, resulting in severe personal injury or death. Install back refractory blanket 1. Lay back section on floor with ports face up. - Page 7 If corrections are made and gap still exists, contact your Weil-McLain distributor or sales office before continuing installation. After erecting first intermediate section, check both sections for plumb.

-

Page 8: Perform Hydrostatic Pressure Test

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Perform hydrostatic pressure test Prepare boiler and test: 1. See pages 28 and 29 for tapping locations. Install: a. Boiler drain (not furnished). b. Water pressure gauge — for test only. Be sure gauge can handle test pressure — see step 3. -

Page 9: Complete Block Assembly

• Installation • Start-Up Complete block assembly Install burner mounting plate on front section 1. Install four ½" x 4¾" studs to secure burner mounting plate to section: a. Thread and lock together two nuts on rounded end of stud. Thread flat end of stud into one of four holes located around opening. -

Page 10: Install Flue Collector

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install flue collector Flue collector assembly 1. Figure 10, page 11, shows flue collector components and locations. Figure 11, page 13, shows collector hoods for all models. Follow all instructions in this manual to ensure correct installation of the flue collector. - Page 11 • Installation • Start-Up • Maintenance • Parts Install flue collector (continued) Figure 10 Flue collector components, typical (Model 880 collector configurations shown) Part No. 550-141-935/0602...

- Page 12 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install flue collector Before installing flue collector 1. See Figure 10, page 11, for general assembly of flue collector components. 2. See Figure 11, page 13 for the placement of flue collector hoods on each model.

- Page 13 • Installation • Start-Up Install flue collector Figure 11 Flue collector components by model (see Figure 10, page 11 for flue collector components not shown below) Part No. 550-141-935/0602 • Maintenance • Parts (continued)

-

Page 14: Connect Water Boiler Piping

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Connect water boiler piping General water piping information: • System water supply and return piping should be installed and piping connections attached to boiler before erecting jacket or installing controls. - Page 15 Gross output is in Btuh. Calculate only secondary piping circuit resistance. Boiler resistance will be about equal to three 90 degree elbows of secondary pipe size. Operate each boiler and its secondary pump from a Weil-McLain boiler control panel. Do not maintain boiler at predetermined water temperature.

-

Page 16: Connect Steam Boiler Piping

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Connect steam boiler piping General steam piping information: • Hartford loop piping arrangement and wet return are required for steam boilers. Use the Hartford loop for both pumped-return and gravity-return systems. - Page 17 • Installation • Start-Up Connect steam boiler piping Figure 15 Model 380 through 580 steam boiler piping — NOTE minimum 24 inches between boiler water line and bottom of header. Figure 16 Model 680 through 980 steam boiler piping — NOTE minimum 24 inches between boiler water line and bottom of header.

- Page 18 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Connect steam boiler piping (continued) Figure 17 Model 1080 through 1280 steam boiler piping — NOTE minimum 24 inches between boiler water line and bottom of header. Figure 18 Condensate piping to boiler...

- Page 19 E Construct common supply drop header with pipe size at least same size as largest boiler header size. F Use: • A Weil-McLain Boiler Control System (such as a BCP panel) with header-mounted pressure control(s) to sequence boilers, or . . . •...

-

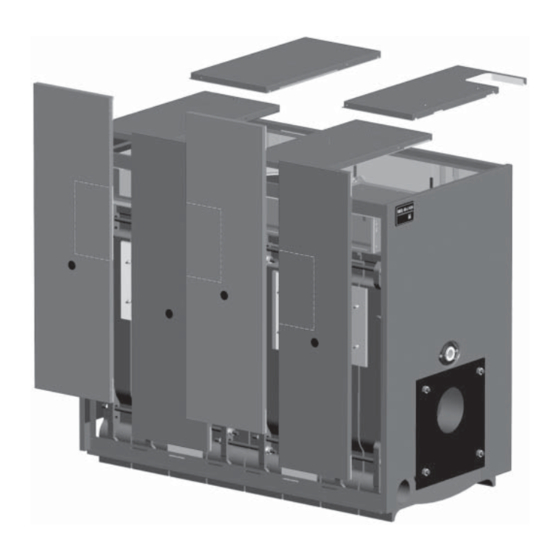

Page 20: Install Jacket

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install jacket Before installing jacket 1. Packaged boilers • Install top jacket panels per instructions in this manual. 2. Non-packaged boilers • Follow the instructions in this section to install all jacket panels. - Page 21 • Installation • Start-Up • Maintenance • Parts Install jacket (continued) Figure 20 Installing jacket support brackets and rails and jacket front and rear panels Part No. 550-141-935/0602...

- Page 22 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install jacket Install jacket side panels 1. Remove jacket side panels from cartons. 2. Insert a plastic plug (provided in jacket cartons) in the 1-inch hole in the center of each of the jacket side panels.

- Page 23 • Installation • Start-Up Install jacket Figure 22 Jacket side panel placement — Models 380, 480, 580 and 680 Part No. 550-141-935/0602 • Maintenance • Parts (continued)

- Page 24 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install jacket (continued) Figure 23 Jacket side panel placement — Models 780, 880 and 980 Part No. 550-141-935/0602...

- Page 25 • Installation • Start-Up Install jacket Figure 24 Jacket side panel placement — Models 1080, 1180, and 1280 Part No. 550-141-935/0602 • Maintenance • Parts (continued)

- Page 26 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install jacket (continued) Figure 25 Jacket top panel placement Part No. 550-141-935/0602...

-

Page 27: Pipe Tankless Heaters

• Installation • Start-Up Pipe tankless heaters To pipe tankless heaters: 1. Size piping no smaller than heater inlet and outlet. 2. Automatic mixing valve must be installed. See Figure 26. Follow manufacturer’s instructions to install. 3. Flow regulating valve must be installed. Size according to continuous draw of heater. -

Page 28: Install Water Boiler Controls

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install water boiler controls Install controls: 1. Install furnished controls where shown in Table 11 and Figure 27. Failure to properly install, pipe and wire boiler controls can result in severe damage to boiler, building and personnel;... -

Page 29: Install Steam Boiler Controls

• Installation • Start-Up Install steam boiler controls Install controls: 1. Install controls where shown in Table 12 and Figure 28. Failure to properly install, pipe and wire boiler controls can result in severe damage to boiler, building and personnel; and is not covered by boiler warranty. - Page 30 Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install steam boiler controls (continued) Figure 29 Table 13 Steam control siphon and fittings Water level control locations Figure 30 Water level control locations (see Table 13) Part No. 550-141-935/0602...

-

Page 31: Connect Breeching And Venting System

Connect breeching and venting systems General venting information • Model 80 boilers operate with positive overfire pressure. Adjust damper assembly (see page 33) during burner start-up to achieve 0.1" W.C. positive pressure at damper sample hole. Select type of venting system Forced draft Boiler, breeching and stub vent operate at positive pressure. -

Page 32: Install Burner

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Install burner To install burner: 1. Unpack burner. 2. Place gasket around air tube and against burner mounting flange. If sealing rope is used, apply " continuous bead of rope adhesive around burner mounting flange and apply sealing rope to make gas-tight seal. -

Page 33: Freeze Protection (When Used)

• Installation • Start-Up Make final adjustments Figure 35 Flue damper assembly, typical Skim steam boilers: Clean all newly installed steam boilers to remove oil. Failure to properly clean can result in violent water level fluctuations, water passing into steam mains, or high maintenance costs on strainers, traps and vents. -

Page 34: Dimensions And Ratings

Consult locat Weil-McLain representative. 7. Stack gas volume at outlet temperature. 8. With 0.10" W.C. positive pressure at flue collar. NOTICE: Boiler sections are tested for 80 PSIG working pressure. Water boilers are supplied with 30 PSIG relief valve standard. Part No. 550-141-935/0602... - Page 35 • Installation • Start-Up • Maintenance • Parts Dimensions and ratings (continued) Part No. 550-141-935/0602...

-

Page 36: Parts

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Parts Part No. 550-141-935/0602... - Page 37 • Installation • Start-Up • Maintenance • Parts Parts (continued) Part No. 550-141-935/0602...

-

Page 38: Handling Ceramic Fiber And Fiberglass Materials

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners Handling ceramic fiber and fiberglass materials This symbol is used in this addendum to indicate presence of hazards that can cause severe personal injury, death or substantial property damage. - Page 39 • Installation • Start-Up Propane boilers — propane gas odorant Propane boilers only — Your propane supplier mixes an odorant with the propane to make its presence detectable. In some instances, the odorant can fade and the gas may no longer have an odor.

- Page 40 Weil-McLain will furnish new part(s) to an authorized Weil-McLain distributor who, in turn will furnish the new part(s) to the heating contractor who installed the boiler. If you have any questions about the coverage of this warranty, contact Weil-McLain at the address above.

Need help?

Do you have a question about the 80 and is the answer not in the manual?

Questions and answers