Summary of Contents for Razorgage Cyclone RazorOptimal

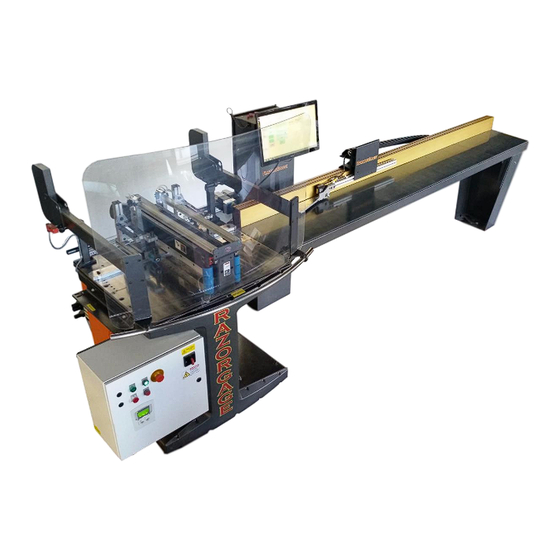

- Page 1 Cyclone RazorOptimal User Manual CYCLONE RAZOROPTIMAL SAW SYSTEM P a g e Technical Services, Inc.

-

Page 2: Table Of Contents

Cyclone RazorOptimal User Manual Table of Contents General Safety Rules for Woodworking Machinery ..........4 Safety Rules for Cut Off Saw .................. 6 Arrival Inspection ....................7 Installation ......................8 Leveling ..................... 9 Anchoring ....................9 Infeed/Outfeed Tables ................10 Electrical Power Connection .............. - Page 3 Cyclone RazorOptimal User Manual Guide Rollers ................... 33 Back Fence ....................34 Squaring Back Fence to Saw Blade ............35 Pusher Lift Height ..................36 Maintenance..................... 37 Lubrication ....................37 Saw Blade Access ..................38 Changing Out Saw Blade ................. 38 Replacement Parts List ................

-

Page 4: General Safety Rules For Woodworking Machinery

Cyclone RazorOptimal User Manual General Safety Rules for Woodworking Machinery WARNING The operator must thoroughly read and understand this manual before operating the saw or starting any servicing. All safety and warning instructions should be followed. This manual must be available to all operators. - Page 5 Cyclone RazorOptimal User Manual 8. Maintain and clean machine at recommend intervals. Intervals may need to be adjusted due to work load or material type to keep machine in top condition. Follow instructions for lubrication, setup, and changing accessories 9. Disconnect machine from power source before, changing accessories, or any servicing activity.

-

Page 6: Safety Rules For Cut Off Saw

Cyclone RazorOptimal User Manual Safety Rules for Cut-off Saw WARNING The operator must thoroughly read and understand this manual before operating the saw or starting any servicing. All safety and warning instructions should be followed. This manual must be available to all operators. -

Page 7: Arrival Inspection

The Cyclone Optimal ships with two items a pallet and a crate. The saw will be secured to a pallet. The RazorGage positioner, tables, legs, and tower control cabinet will be in the crate. Unpack the saw ensuring that all parts are present and free from damage. If any parts are missing or damaged contact your local distributor immediately. -

Page 8: Installation

Cyclone RazorOptimal User Manual Installation WARNING The operator must thoroughly read and understand this manual before operating the saw or starting any servicing. All safety and warning instructions should be followed. This manual must be available to all operators. Install saw with enough free space to conveniently allow workpiece to be brought into saw. If infeed and/or outfeed tables are required allow room for such. -

Page 9: Leveling

Cyclone RazorOptimal User Manual Leveling To ensure product moves freely through the saw system, it is important to level the saw. After the saw has been located the saw can be leveled. Place the level on top of the saw adjacent to the back fence to check for level side-to-side. -

Page 10: Infeed/Outfeed Tables

The saw has been factory wired to the requested voltage before shipment. The saw power requirements are either 208 / 230 VAC 3φ 30Amps OR 480 VAC 3φ 20Amps. The RazorGage tower requires a separate 120V 1φ 10A supply. Check that your supply lines match the labeled voltage and the circuit protection and wire gauge is adequate. -

Page 11: Electrical Interface Connections

DIN connector on the valve bank. The crayon and board sensor cables will need to be wired to the crayon optimal circuit board in the RazorGage tower. Follow the sensor type and color code of the cable conductors marked next to the terminals on the board. The printer has a power cord that plugs into the power strip at the bottom on the tower and also an ethernet cable that plugs into the crayon board. -

Page 12: Air Supply Connection

Pneumatic Connections The Cyclone Upcut Saw has all the valves for the Cyclone RazorOptimal System. The air lines for the pusher arm pop-up will need to be connected to the valve bank. The valve for the pusher is the first valve from the left. -

Page 13: Dust Collection

Cyclone RazorOptimal User Manual Dust Collection This saw requires dust collection to keep saw dust from collecting on the machine. Vacuum with the minimum capacity of 1200 CFM is recommended. There are two 4” dust collection on the saw. One port is located at the back of the saw and the other is underneath the saw carriage accessible from the left side of the saw. -

Page 14: Setup Procedure

Cyclone RazorOptimal User Manual Setup Procedure Set the Home Offset (PUSHER TO SAW AT LOW LIMIT). Follow the steps below after starting the software and homing the machine. Touch in the MOVE TO POSITION box, enter the number 16, touch the MOVE ONLY radio button, and press GO. - Page 15 Cyclone RazorOptimal User Manual Calibration Screen NOTE: The scale factor will be set at the factory and only needs to be modified if the parts get incrementally smaller or larger than nominal as the pusher advances. Now that you have set the Home Offset, the next step is to set the Scale Factor.

- Page 16 Cyclone RazorOptimal User Manual 16 | P a g e Technical Services, Inc.

- Page 17 PUSHER TO SAW AT LOW LIMIT – This value is the home offset and is set through the machine calibration process. Default is 0.5 inches LOW LIMIT – This value is the lowest position that the RazorGage is capable of moving. It does not need to be modified and cannot be selected from this screen. ...

- Page 18 Cyclone RazorOptimal User Manual Press the SAW button on the left-hand side of the screen and set the timer values as shown below. To determine the kerf, measure a short board with square ends, saw it in two, put the two pieces together and measure the overall length of the resulting two pieces.

- Page 19 AFTER SCAN IS DONE – This option changes the machine sequence after a scan. The first option moves the RazorGage to the Run Start position then dropped the pusher arm. The second (default) option is opposite. It drops the pusher arm and then move the RazorGage to the Run Start position.

- Page 20 Cyclone RazorOptimal User Manual If you have the Raz-Array option, press the RAZ-ARRAY button on the left-hand side of the screen. The description of the variables is below. Use APPLY CHANGES button to update changes to parameters. SELECT THE FIELD… – Use the dropdown list to select field in the cutlist that contains the Raz- Array bin numbers.

-

Page 21: Saw Capacity

Cyclone RazorOptimal User Manual Cyclone 600 Sawing Capacity Chart The vertical stroke of the upcut saw blade requires that the workpiece be centered over the center line of the blade to maximize thickness capacity. The fence is adjustable to accommodate the potential material sizes as shown in the chart above. -

Page 22: General Operation

Cyclone RazorOptimal User Manual General Operation 22 | P a g e Technical Services, Inc. - Page 23 Turn on tower control power using the green POWER ON button on the side. c. Start the Razor Optimal software and follow the instruction to home the RazorGage. d. Start the Cyclone saw by turning on the disconnect, resetting the E-stop, and pressing the START button.

- Page 24 Cyclone RazorOptimal User Manual c. Mark the trailing edge trim cut (Optional). d. If you prefer to cut out the crayon marks, press in order MORE, PARAMETERS, SCAN buttons. The CRAYON MARK OFFSET variable will change how much material is cut at the crayon marks.

- Page 25 Cyclone RazorOptimal User Manual 7. Once the scan has been accepted and the process initiated the RazorOptimal will cut the optimal parts from the board to minimize waste. While the machine is processing the board, you can begin defecting a new board. When the previous board is finished the pusher will return to the scan start position automatically.

-

Page 26: Machine Adjustments

Cyclone RazorOptimal User Manual Machine Adjustments WARNING The operator must thoroughly read and understand this manual before operating the saw or starting any servicing. All safety and warning instructions should be followed. This manual must be available to all operators. -

Page 27: Lockout/Tagout Points

If any assistance is needed contact your distributor or RazorGage. When removing any machine guards or panels properly lock-out tag-out machine power sources. See pictures above for electrical and pneumatic power source lock-out points. -

Page 28: Saw Feed Flow Controls

Cyclone RazorOptimal User Manual Saw Feed Flow Controls The saw blade feed rate is adjustable with pneumatic flow controls. This adjustment may be necessary if material thickness and/or width changes. Also, a saw timeout error may be a reason to make this adjustment. -

Page 29: Saw Stroke Distance

Cyclone RazorOptimal User Manual Saw Stroke Distance 29 | P a g e Technical Services, Inc. -

Page 30: Saw Blade Speed

Cyclone RazorOptimal User Manual Saw Blade Speed The saw blade speed is adjustable from the display on the front of the electrical enclosure. The selectable range is from 1380 to 3450 RPM. Use the up and down arrow to change the saw blade RPM set point. -

Page 31: Horizontal Clamps Flow Controls

Cyclone RazorOptimal User Manual Horizontal Clamps Flow Controls The horizontal clamp speed is adjustable with pneumatic flow controls. This adjustment may be necessary if material thickness or width changes. The flow controls for the horizontal clamps are located on the back of the saw. There are two flow controls per clamp with one being for extend and one for retract. -

Page 32: Vertical Clamp Flow Controls

Cyclone RazorOptimal User Manual Vertical Clamp Flow Controls The vertical clamp advance and retract speed is adjustable with pneumatic flow controls. This adjustment may be necessary if material thickness changes. The flow controls for vertical clamp are located a panel above the saw blade housing. There is a flow control for retract on the left and one for advance on the right. -

Page 33: Vertical Clamp Stroke Distance

Guide Rollers The Cyclone RazorOptimal is equipped with guide rollers to support the material as it is being feed through the saw. The guide rollers apply downward pressure to the material. The rollers are slightly angled toward the back fence to keep the material close to the fence while being advanced. -

Page 34: Back Fence

Cyclone RazorOptimal User Manual Back Fence The back fence on the Cyclone saw is set to the width of the material and also is squared to the saw blade from the factory. If adjustment is necessary (i.e. changes in material width) move the back fence to center the material on the saw blade. -

Page 35: Squaring Back Fence To Saw Blade

Cyclone RazorOptimal User Manual Squaring Back Fence to Saw Blade 35 | P a g e Technical Services, Inc. -

Page 36: Pusher Lift Height

Pusher Arm Lift Height The pusher arm lift height on the RazorGage is set to the thickness of the material. If adjustment is necessary (i.e. changes in material thickness) with the pusher arm down adjust the pusher so there is a 1/16”... -

Page 37: Maintenance

Cyclone RazorOptimal User Manual Maintenance WARNING The operator must thoroughly read and understand this manual before operating the saw or starting any servicing. All safety and warning instructions should be followed. This manual must be available to all operators. The operator must remove from and lock out all power sources to saw before servicing. -

Page 38: Saw Blade Access

Cyclone RazorOptimal User Manual Saw Blade Access To access the saw blade for inspection or replacement, locate the blade access cover the right side of the saw housing. Loosen the top two screws marked in the picture below. Remove the bottom right screw along with the thumb screw on the bottom left. -

Page 39: Replacement Parts List

Cyclone RazorOptimal User Manual Replacement Parts List RGX NO DESCRIPTION RGX00024 DOUBLE SOLENOID VALVE, 12VDC, MANIFOLD MOUNTED RGX00025 SINGLE SOLENOID VALVE, 12VDC, MANIFOLD MOUNTED RGX00506 DUMP VALVE, 24VDC RGX01124 SAW BLADE: 20″ FOR CUTTING WOOD RGX01220 SAW BLADE: 20″ FOR CUTTING ALUMINUM RGX00473 SAW BLADE: 24″... - Page 40 Cyclone RazorOptimal User Manual RGX00674 SPRING ROLLER SUPPORT RGX00482 END OF BOARD SENSOR RGX01533 CRAYON SENSOR RGX00805 CRAYON DEFECTING BOARD ASSEMBLY RGX00155 DIRECTLOGIC 06 PLC A full list of field replaceable parts can be accessed at our web site: https://razorgage.com/product-line/replacement-parts/...

-

Page 41: Troubleshooting

Cyclone RazorOptimal User Manual Troubleshooting Electrical Schematics (Page 1 of 4) 41 | P a g e Technical Services, Inc. - Page 42 Cyclone RazorOptimal User Manual Electrical Schematics (Page 2 of 4) 42 | P a g e Technical Services, Inc.

- Page 43 Cyclone RazorOptimal User Manual Electrical Schematics (Page 3 of 4) 43 | P a g e Technical Services, Inc.

- Page 44 Cyclone RazorOptimal User Manual Electrical Schematics (Page 4 of 4) 44 | P a g e Technical Services, Inc.

-

Page 45: Pneumatic Schematics

Cyclone RazorOptimal User Manual Pneumatic Schematics 45 | P a g e Technical Services, Inc. -

Page 46: Troubleshooting Guide

Saw Running signal is not on. the drive to the PLC X17 input. RazorGage Do Action signal Check that the I/O cable (largest of the three) on the RazorGage did not turn on. Mdrive is seated tightly. The connector needs to be wiggled while tightening otherwise it doesn’t tighten up enough to make... - Page 47 Cyclone RazorOptimal User Manual is ok and there is voltage to sensor and it doesn’t light when flagged replace the sensor. Saw didn’t complete cycle. Check sensor indicator or PLC input X16 if either is off and the...

- Page 48 Cyclone RazorOptimal User Manual input X16. Check all the connections for this input for an open circuit and replace cable if necessary. Proximity switch failed. If sensor indicator is off with the saw down and the cable &...

- Page 49 RE-SEND THE LAST MOVE button to PUSHER BAR RUN. resume operation. See figure #8. The RazorGage speed is set Press the RE-SEND THE LAST MOVE button to resume too high. operation. After bar is completed or if motion error reoccurs, go to the SETUP SCREEN and check the user parameter speed.

-

Page 50: Vfd Faults

RazorGage move. adjustment is ok, check the cable connection and wiring back to REQUESTED WHILE THE RazorGage tower enclosure. Press OK to recover from the SAW WAS NOT IN A error. The recovery from this error exits the runtime screen SAFE CONDITION FOR back to the setup screen. -

Page 51: Troubleshooting Reference Pictures

Cyclone RazorOptimal User Manual Troubleshooting Reference Pictures Figure #4 Figure #5 51 | P a g e Technical Services, Inc. - Page 52 Cyclone RazorOptimal User Manual Figure #6 Figure #7 Figure #8 52 | P a g e Technical Services, Inc.

-

Page 53: Troubleshooting E-Stop Faults

Cyclone RazorOptimal User Manual Troubleshooting E-Stop Faults 53 | P a g e Technical Services, Inc. - Page 54 E-Stop circuit changes from closed to open. This circuit cannot rely on software to drop power and air yet it is helpful if the software informs the user that an E-Stop condition is present. On RazorGage systems we use two normally unused pins on one of the serial communication connectors to trigger a software event that we use to display the E-Stop screen.

- Page 55 Make sure bare drain wire is hooked up to DB9 chassis. If you have more questions about RazorGage products visit our Downloads page and our You Tube channel. Both are accessible from the RazorGage home page, www.razorgage.com. If you would like to discuss an application, feel free to call us at (515) 232-3188.

Need help?

Do you have a question about the Cyclone RazorOptimal and is the answer not in the manual?

Questions and answers