Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BAC VTL-E

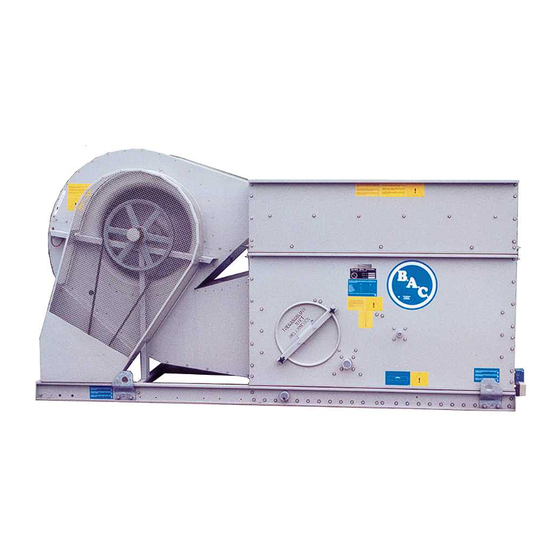

- Page 1 RVTL-Ev14EN VTL-E Open Cooling Towers RIGGING AND INSTALLATION INSTRUCTIONS...

- Page 2 Be sure to have a copy of the unit certified drawing available for reference. If you do not have a copy of this drawing or if you need additional information about this unit, contact the local BAC Balticare representative. His name and phone number can be found on the www.BaltimoreAircoil.eu.

- Page 3 Cleaning procedures Start-Up Weekly Monthly Quarterly Every 6 Annually Shutdown months Mechanical cleaning Disinfection** Drain basin ** depends on applied code of practice Notes 1. Water treatment and auxiliary equipment integrated in the cooling system may require additions to the table above.

-

Page 4: Table Of Contents

Table of contents RIGGING AND INSTALLATION INSTRUCTIONS General information About engineering and application practices Shipping Inspection before rigging Unit weights Anchoring Leveling Electrical connections Connecting pipework Freeze protection Bleed Line Installation Safety Precautions Non-walking surfaces Modifications by others Warranty Rigging General notes Rigging method discharge accessories Optional accessories assembly... -

Page 5: General Information

Shipping BAC cooling equipment is factory assembled to assure uniform quality and minimum field assembly. The models are shipped in one single section. CAUTION Do not cover units with PVC eliminators or fill with a plastic tarpaulin. - Page 6 An envelope with check-list is stored in a wooden no nail crate or a plastic container which is placed in the lower section. For safety reasons, access doors / panels may be sealed with bolts. The following table specifies which wrench is required to open them.

-

Page 7: Unit Weights

1. Heater Unit weights Before rigging any BAC equipment, the weight of each section should be verified on the unit certified drawing. These weights are approximate and should be confirmed by weighing before lifting when available hoisting capacity provides little margin for safety. -

Page 8: Electrical Connections

In such cases adapter pieces need to be installed. Freeze protection These products must be protected against damage and/or reduced effectiveness due to possible freeze-up by mechanical and operational methods. Please contact your local BAC Balticare representative for recommended protection alternatives. Bleed Line Installation On all open cooling towers, install a bleed line with valve between the system circulating pump discharge riser and a convenient drain. - Page 9 Failure to use designated lifting points can result in a dropped load causing severe injury, death and/or property damage. Lifts must be performed by qualified riggers following BAC published Rigging Instructions and generally accepted lifting practices. The use of supplemental safety slings may also be required if the lift circumstances warrant its use, as determined by the rigging contractor.

-

Page 10: Non-Walking Surfaces

BAC will guarantee all products to be free from manufactured defects in materials and workmanship for a period of 24 months from the date of shipment. In the event of any such defect, BAC will repair or provide a replacement. -

Page 11: Rigging

VTL-E RIGGING General notes 1. If the delivery consists of separate sections, do not assemble before lifting, as the lifting devices provided are not designed to support the weight of the entire assembly. When the unit is installed, all metal parts created by drilling, fastening self tapping screws, grinding, welding or other mechanical works must be removed from the unit. If they remain on the unit (typically on the double break... - Page 12 Model Unit Min. Spreader Discharge L & W "H " accessory (mm) (mm) length minimum (mm) "H" VTL-E-039-G to 3350 x 1250 3100 1250 3100 VTL-E-079-K VTL-E-058-G to 4560 x 1250 4300 1250 4300 VTL-E-117-M VTL-E-070-J to 5480 x 1250...

-

Page 13: Rigging Method Discharge Accessories

Rigging method and discharge accessory Discharge accessories can be: plume abatement coil, positive closure damper, tapered discharge hood, sound attenuation. Rigging method discharge accessories CAUTION When lowering a section, ensure nothing can be trapped between the upper and lower flanges. 2 Rigging 2 Rigging W W W . -

Page 14: Optional Accessories Assembly

VTL-E OPTIONAL ACCESSORIES ASSEMBLY General Information 1. Optional discharge accessories such as tapered hoods, positive closure dampers, discharge sound attenuators, desuperheaters, plume abatement coils and/or access plenums can be fitted. 2. Rigging method of optional accessories is indicated in the rigging tables.(see "General notes" on page 11 3. - Page 15 9. Remove the discharge accessory from the skid. Lift the discharge accessory and position it over the unit so that the flanges of the section are about 50 mm above the unit. Dot not let the section swing and damage the sealer.

-

Page 16: Clean Out Port

Clean out port Due to transport width limits, the cover flanges of the clean out port are mounted with flanges towards the inside (1). On site, the cover can be placed with flanges to the outside for easy access to hardware (2). Clean out port cover mounted for transport Final installation of clean out port cover W W W . -

Page 17: Inspection Prior To Start-Up

VTL-E INSPECTION PRIOR TO START-UP General Prior to start-up, the following services, which are described in detail in the Operating and Maintenance Manual (see table "Recommended maintenance and monitoring programme" ) must be performed. Proper start-up procedures and scheduled periodic maintenance will prolong the life of the equipment and ensure trouble-free performance for which the unit is designed. -

Page 18: Further Assistance & Information

FURTHER ASSISTANCE & INFORMATION Assistance BAC has established a specialized total care company called Balticare. The BAC Balticare offering involves all elements required to ensure a safe and efficient operation of your evaporative cooling products. For more details, contact your local BAC representative for further information and specific assistance at www.BaltimoreAircoil.eu... - Page 19 W W W . B A L T I M O R E A I R C O I L . E U...

- Page 20 W W W . B A L T I M O R E A I R C O I L . E U...

- Page 21 W W W . B A L T I M O R E A I R C O I L . E U...

- Page 22 COOLING TOWERS CLOSED CIRCUIT COOLING TOWERS ICE THERMAL STORAGE EVAPORATIVE CONDENSERS HYBRID PRODUCTS PARTS, EQUIPMENTS & SERVICES www.BaltimoreAircoil.eu info@BaltimoreAircoil.eu Please refer to our website for local contact details. Industriepark - Zone A, B-2220 Heist-op-den-Berg, Belgium © Baltimore Aircoil International nv...

Need help?

Do you have a question about the VTL-E and is the answer not in the manual?

Questions and answers