Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for BAC 3000 Series

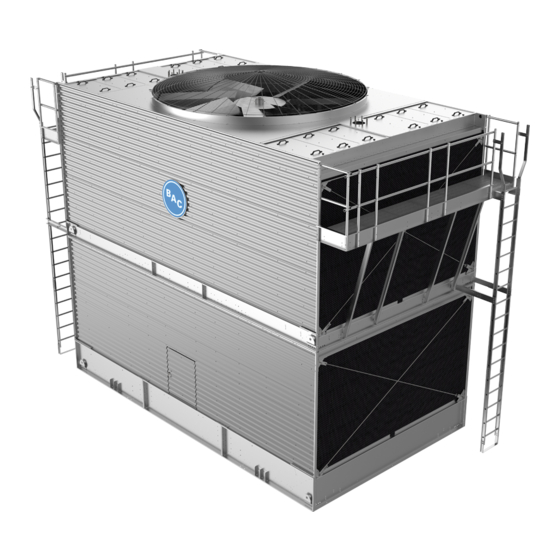

- Page 1 Series 3000 Series 3000 Cooling Tower RIGGING & ASSEMBLY INSTRUCTIONS...

- Page 2 Be sure to have a copy of the certified drawing available for reference. If you do not have a copy of this drawing, or if you need additional information about this unit, contact your local BAC Representative whose name and telephone number are on a label adjacent to the access door. The model...

-

Page 3: Table Of Contents

Table of Contents RIGGING & ASSEMBLY INSTRUCTIONS » SERIES 3000 COOLING TOWER Introduction Safety Shipping Pre-Rigging Checks Unit Weights Anchoring Cold Weather Operation Location Warranties Unit Operation Unit Rigging & Assembly Rigging Single-Cell Installation Two Piece Section Assembly Multi-Cell Installation Multi-Cell Unit Assembly Flume Box Installation Optional Positive Closure Plate Installation... -

Page 4: Introduction

Shipping lift circumstances warrant its BAC Cooling Towers are factory assembled to assure uniform quality and minimum field use, as determined by the rigging assembly. Models S3E/XES3E-8518-xxx, S3E/XES3E-1020-xxx, S3E/XES3E-1222-06x, contractor. -

Page 5: Unit Weights

Warranties only certified with standard anchorage locations. Using alternate anchorage locations or Unit Operation alternate steel supports will void any IBC wind or seismic ratings. Contact your local BAC Representative for details ATTENTION: Before an actual lift is undertaken, ensure no water,... -

Page 6: Unit Rigging & Assembly

All single cell and multi cell units must be rigged one section at a time. Models riggers following BAC published S3E/XES3E-8518-x, 1020-x, 1222-06x, 1222-07x, and 1424-07x ship in one section per cell. All other models ship in two sections per cell. -

Page 7: Single-Cell Installation

3. Wipe any moisture and dirt from the perimeter mating flanges of the lower section. 4. Install foam seal tape (BAC part # 270175) supplied with the unit, as illustrated in Figure 3, on the mating flanges of the lower section in a continuous line. -

Page 8: Multi-Cell Installation

2. Wipe any moisture and dirt from the perimeter mating flanges. 3. Install foam seal tape (BAC part # 270175) supplied with the unit, as illustrated in Figure 3, on page 5 on the mating flanges of the lower sections in a continuous line. - Page 9 Unit Rigging & Assembly 6. Apply two layers of flat butyl sealer tape to the other end of the flume box. Multi-Cell Installation 7. Wipe down the surface adjacent to the flume opening of Cell #2 to remove any Multi-Cell Unit Assembly dirt or moisture.

- Page 10 Positive Closure Plate Installation The optional positive closure plate and gasket can be furnished on multi-cell units to allow individual cells to be isolated for cleaning and routine maintenance. The plate ships loose inside the cold water basin. 1. Remove nuts and flat washer from the flume box. 2.

-

Page 11: Optional Positive Closure Plate Installation

Unit Rigging & Assembly Fan Guard Installation Multi-Cell Installation Due to height limitations on truck shipments, the fan guard may ship unmounted. Never Optional Positive Closure Plate step or walk on the fan guard when installed. Refer to Table 2 for the number of fan guard Fan Guard Installation pieces Series 3000 Cooling Towers will have . -

Page 12: Two-Piece Fan Guard

Two-Piece Fan Guard 1. Using six U-bolt assemblies, fasten the two halves of the fan guard together as DANGER: Fan guard must be illustrated in Figure 14, Detail B. Locate the U-bolt assemblies along the seam between the two guard halves per the X and Y dimension provided in Table 3, which securely in place before the cooling are based on the diameter of the supplied fan. -

Page 13: Four-Piece Fan Guard

Unit Rigging & Assembly Four-Piece Fan Guard Fan Guard Installation 1. Assemble fan guard supports as illustrated in Figure 15, Detail A. Two-Piece Fan Guard 2. Secure fan guard pieces to fan guard supports as shown in Figure 15, Detail B. Four-Piece Fan Guard 3. -

Page 14: Top Inlet Piping Installation

NOTES FOR FIGURE 16: Top Inlet Piping Installation 1. All piping shown by dashed lines is to be furnished by Use the following drawings, notes, and tables when installing top inlet piping. others. Refer to the certified Drawings shown are for multi-cell installations. For single cell installations, simply unit print for details on the ignore the additional cells and dimension “C”... - Page 15 (SEE N OTES 7 & 8) DET AIL “C” FACE OF WATER INLET AT H OT WATER Piping by others. Fl ow control valves availab le by BAC or others, a nd a lways install ed by others. DISTRIBUTION BASIN Figure 18. Piping Drawing Details...

-

Page 16: Motor Location And Conduit Installation

Motor Location and Conduit Installation NOTE: Use the following drawings and notes when installing electrical conduit for cooling towers 1. Weights given represent the additional weight when a supplied with the BALTIDRIVE Power Train, BALTIGUARD™ Fan System, gear drives, or ®... - Page 17 Number See Note 4 Configuration on Page 14 of Cells Motor Detail for Main Motor (BALTIDRIVE® Power Train) or BALTIGUARD™ Fan System (If Ordered) Face A CT-1 CT-1 & CT-4 Optional CT-1, CT-2 & CT-4 BALTIGUARD™ Fan System Motor Face B CT-1 through CT-4 Face B Connection End...

- Page 18 ENDURADRIVE™ Fan System Motor Detail Conduit Box Fan Motor Rigid Conduit Fan Motor Hole in Casing Panel Should be Large Enough to Accommodate Conduit Seal with Waterproof Sealant Rigid Conduit Outside Tower Turned Down to Junction Box or Safety Switch Plan View Typical for Single Disconnect/Safety Switch in Weatherproof Enclosure Cell or Multi Cell Installation...

-

Page 19: Optional Accessory Installation

SERIES 3000 COOLING TOWER Optional Accessory Installation ENDURADRIVE™ Fan System Installation (Optional) The ENDURADRIVE™ Fan System is an option for select Series 3000 Cooling Towers and is standard on S3E-1424-14U and S3E-1424-14W models. The ENDURADRIVE™ Fan System variable frequency drive (VFD) is to be installed per the ENDURADRIVE™ Fan System ACH550-UH HVAC User’s Manual. -

Page 20: Whisper Quiet Fan Installation

Whisper Quiet Fan Installation (Optional) NOTE: Refer to the “Customer The optional Whisper Quiet Fan will ship with blades assembled to the prescribed pitch Information Packet” for additional and hardware torque. Depending on the model number, the fan will ship installed or instructions for the specific cooling crated. - Page 21 Optional Accessory Installation Seal Disk Whisper Quiet Fan Installation Figure 24. Remove Seal Disk Figure 25. Attached to Blade Shanks Remove Nut Figure 26. Remove Shipping Restraint Hardware Figure 27. Lift Fan From Crate Figure 28. Fan Positioning Figure 29. Key Lineup FLAT WASHER FAN SEAL DISK SEAL WASHER...

-

Page 22: Side Outlet Depressed Sump Box Installation

1. Wipe the edges around the opening inside the cold water basin to remove any dirt or moisture that may have accumulated during shipment. 2. Apply a layer of trapezoidal butyl sealer tape (BAC part #554009) around the opening in the basin over the centerline of the holes. Do not stretch the sealer tape too thinly or overlap at the corners. -

Page 23: Factory Pre-Wired Terminal Box

(through flexible conduit and the mechanical equipment Factory Pre-Wired Terminal support) and terminated on the outside face of the BAC unit in a clearly marked, 304 Stainless Steel, NEMA 3R terminal box (see Figure 33 for the exterior location of the box Additional Optional on the cooling tower). - Page 24 COOLING TOWERS CLOSED CIRCUIT COOLING TOWERS ICE THERMAL STORAGE EVAPORATIVE CONDENSERS HYBRID PRODUCTS PARTS & SERVICES w w w . B a l t i m o r e A i r c o i l . c o m 7600 Dorsey Run Road, Jessup, MD 20794 ›...

Need help?

Do you have a question about the 3000 Series and is the answer not in the manual?

Questions and answers