Subscribe to Our Youtube Channel

Summary of Contents for Glendo Accu-Finish II Series

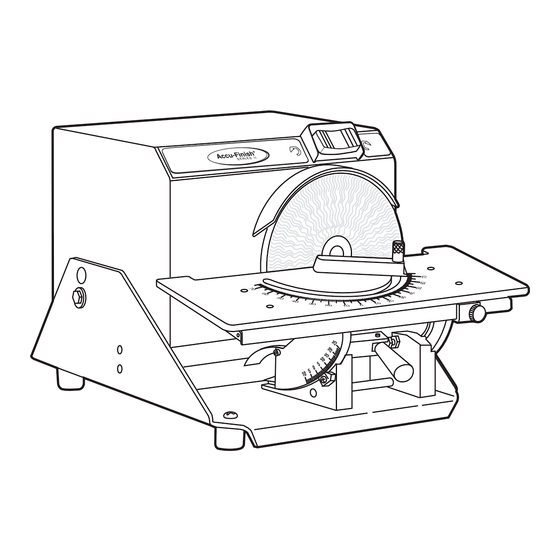

- Page 1 Accu-Finish SERIES II MANUAL & INSTRUCTIONS GLENDO CORPORATION For Rocker Switch Accu-Finish II Machines Serial Numbers begin with (115 V) AB08033 or (230 V) EB08015. Revised 08/2008.

- Page 2 This is best done on a high speed bench grinder or similar machine. Tool finishing or resharpening dull tools is the strength of Accu-Finish. Since Glendo will pay normal surface freight proper tool finishing is by far the most critical job, the Accu-Finish works back to the customer’s location.

-

Page 3: Installation

Accu-Finish SERIES II READ ALL DIRECTIONS before attempting setup or installation of this machine. Installation 4. Note there are four (4) ball 8. Replace the retainer bar with bearings mounted on the table the two Phillips head screws. 1. Unpack the machine and parts on support structure. -

Page 4: Tool Guide

Table Position 0° on the angle protractor. Loosen the locator block and align mark with the The vertical wheel position allows 0° mark on the protractor and tighten use of the calibrated table and the locator block (E). tool guide. Two tool angles can be simultaneously controlled. -

Page 5: Power Controls

“OFF” POSITION COUNTER CLOCKWISE Grinding on (CCW) CLOCKWISE Diamond Wheels (CW) Follow this recommended procedure. Approach the surface carefully with the tool. Apply cutting pressure smoothly. Be especially attentive when first cutting sharp points. Wet the diamond surface with the water soluble cutting Horizontal Wheel Use Power Controls fluid supplied with your Accu-Finish. - Page 6 ACCESSORIES Power Foot Switch Order #002-205 Turn the machine ON and OFF with both hands free. Especially useful for horizontal lapping. Comes prewired for standard 3-wire, 115 Volt grounded outlet. UL listed to 1/2 HP. Drive Belt Replacement Disconnect machine from electrical power.

-

Page 7: Wiring Diagram

WIRING DIAGRAM WARNING: ALWAYS DISCONNECT MACHINE FROM POWER BEFORE SERVICING. SHOCK HAZARD: ANY CAPACITOR CAN HOLD A CHARGE. DISCHARGE CAPACITOR BEFORE HANDLING. Yellow Jumper 011-400 Switch Motor 022-568 Yellow Wire 002-274 115 V, 60 Hz Blue Motor Wire Red Motor Wire Red Wire 011-401 Blue Wire 011-402 Fuse Holder... -

Page 8: Parts List

011-113 Toll Free: 1-800-835-3519 600 Grit Reverse Angle General 011-087 Phone: 620-343-1084 1200 Grit Reverse Angle Extra fine 011-088 Fax: 620-343-9640 Ceramic Lap E-mail: glendo@glendo.com Ultra-polishing “Mirror” Finish 001-671 Requires charging with diamond spray. www.accu-finish.com PAGE 7 of 7 001-193...

Need help?

Do you have a question about the Accu-Finish II Series and is the answer not in the manual?

Questions and answers