Table of Contents

Advertisement

Quick Links

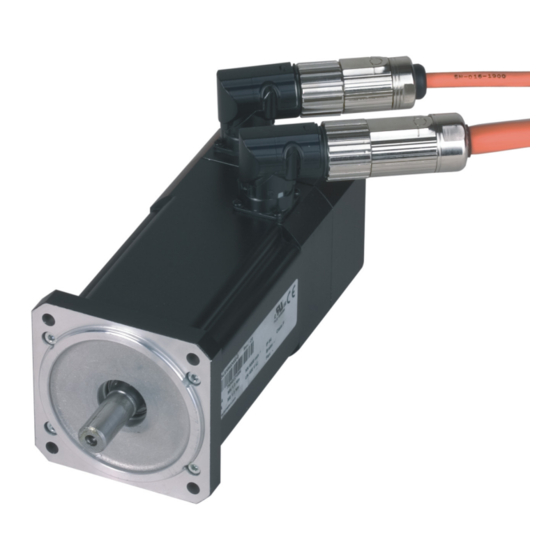

8LS...-3 three-phase

synchronous motors

User's manual

Version: 2.50 (2018-12-10)

Model no.: MAMOT2-ENG

All values in this manual are current as of its creation. We reserve the right to change the contents of this manual

without notice. B&R Industrial Automation GmbH is not liable for technical or editorial errors and defects in this

manual. In addition, B&R Industrial Automation GmbH assumes no liability for damages that are directly or indirectly

attributable to the delivery, performance or use of this material. We point out that the software and hardware

designations and brand names of the respective companies used in this document are subject to general trademark,

brand or patent protection.

Advertisement

Table of Contents

Summary of Contents for B&R 8LS 3 Series

- Page 1 8LS...-3 three-phase synchronous motors User's manual Version: 2.50 (2018-12-10) Model no.: MAMOT2-ENG All values in this manual are current as of its creation. We reserve the right to change the contents of this manual without notice. B&R Industrial Automation GmbH is not liable for technical or editorial errors and defects in this manual.

-

Page 2: Table Of Contents

Table of contents 1 General information....................5 1.1 Manual history..............................5 1.2 About this user's manual..........................5 1.3 Safety................................5 1.3.1 Organization of safety notices........................5 1.3.2 Intended use..............................6 1.3.3 Reasonably foreseeable misuse....................... 6 1.3.4 General sources of danger........................6 1.3.5 Provisions and safety guidelines.......................8 1.3.6 Responsibilities of the operator.........................9 1.3.7 Qualified personnel............................9 1.3.8 Safety notices............................ - Page 3 Table of contents 2.13.1 8LSA25...-3 - Standard motors......................43 2.13.2 8LSAA2...-3 / 8LSAA4...-3 - Standard motors..................44 2.13.3 8LSA35...-3 - Standard motors......................45 2.13.4 8LSA37...-3 - Standard motors......................46 2.13.5 8LSA44...-3 - Standard motors......................47 2.13.6 8LSA46...-3 - Standard motors......................48 2.13.7 8LSA55...-3 / 8LSA57...-3 - Standard motors..................

- Page 4 Table of contents 6.2.3 Freely rotating motors........................... 290 6.2.4 Holding brake............................290 6.3 Verification..............................291 6.3.1 To verify before commissioning......................291 6.3.2 To verify during commissioning......................292 6.3.3 During operation............................ 292 6.4 Faults during operation..........................292 7 Inspection and maintenance................294 7.1 Safety................................294 7.1.1 General sources of danger........................

-

Page 5: General Information

General information 1 General information 1.1 Manual history Version Date Notes 2.00 2016-04-29 First edition for motor version V3 2.10 2016-04-29 Updated ring core design (see "Ring core design" on page 278). 2.50 2018-12-10 General revision Updates: Motors (8LSAA, 8LSA5A/B/C, 8LSC5A/B/C, 8LSO9, 8LSP9). 8LSC fan kit (see "replacement parts, connection direction, assembly"... -

Page 6: Intended Use

General information 1.3.2 Intended use B&R motors and gear motors are components designed for installation in electrical systems or machines. They were designed, developed and manufactured for general industrial use. They are intended to be operated in covered rooms and under normal climatic conditions, which is usually the case in modern production halls. When used in residential areas, commercial areas or small businesses, additional filtering measures are required or must be provided by the user. - Page 7 General information Danger! Risk of injury due to electric shock! If live parts are touched, there is immediate danger of fatal electric shock. If connections are connected or disconnected in the wrong order or when the power is switched on, electric arcs can occur and persons and contacts can be damaged.

-

Page 8: Provisions And Safety Guidelines

General information Danger! Danger of injury due to rotating or moving elements and loads! By rotating or moving elements, body parts can be drawn in or severed or subjected to impacts. • Do not stay in the danger zone during operation and secure it against access by unauthorized persons. -

Page 9: Responsibilities Of The Operator

General information • National, local and plant-specific regulations for your end product • Relevant regulations for electrical installations (e.g. wire cross section, fuses, protective conductor connec- tion). The values provided in chapter "Technical data" must also be taken into account here. The operator is solely responsible for these and all other regulations applicable at the place of use. -

Page 10: 8Ls Three-Phase Synchronous Motors

General information 1.4 8LS three-phase synchronous motors B&R's 8LS three-phase synchronous motors have been specially developed for use in high-performance appli- cations. Today, they are used to manufacture consumer goods and products in the plastics industry, packaging industry, metalworking industry, beverage and food industry and to palletize these products with handling systems. Complete solutions from a single source requires the right components as well as the right configuration for the application environment. -

Page 11: Nameplate

General information Information: The conditions of acceptability per UL file E360421 must be observed when using motors within the scope of UL! 1.4.2 Nameplate The nameplate clearly identifies each motor. The serial number ensures traceability. Note: • The nameplate must be visible at all times. •... -

Page 12: Technical Data

Technical data 2 Technical data 2.1 General description Three-phase synchronous motors from the 8LS series are permanent magnet, electronically commutated synchro- nous motors for applications that require excellent dynamic characteristics and positioning precision as well as compact size and reduced weight. •... -

Page 13: 8Ls Order Key

Technical data 2.2 8LS order key ee nnn gg - Cooling / Construction type A ... Built-in connector, self-cooling C ... Built-in connector, attached fan module ... Built-in connector, liquid cooled A-side flange O ... Terminal box, self-cooling P ... Terminal box, built-in fan module see "Cooling / Construction type (b)"... - Page 14 Technical data Note: Order codes only provide information about possible combinations in exceptional cases. Information about possible combinations is available in the CAD configurator under cad.br-automation.com. 8LS...-3 user's manual V2.50...

-

Page 15: Example Order 1

Technical data 2.2.1 Example order 1 A three-phase synchronous motor of type 8LSA45 with a nominal speed of 3000 rpm was selected for an appli- cation. Because of the construction, the cables can only be connected on the top of the motor ("top" connection direction). -

Page 16: Cooling / Construction Type (B)

Technical data 2.3 Cooling / Construction type (b) gg - see "Order key" on page 13 8LS three-phase synchronous motors are available in cooling types 8LSA, 8LSC, 8LSO and 8LSP. Cooling type 8LSE is only available upon request. All motors are based on cooling type A (elongated, slim) and can deviate in this, the cable connection or mounting type. -

Page 17: Size (C)

Technical data 2.4 Size (c) gg - see "Order key" on page 13 8LS three-phase synchronous motors are available in various sizes (2, A, 3 ... 9). These differ in dimensions (especially flange dimensions) and power data. The sizes are distinguished by a character (c) in the model number. The larger this number, the larger the flange dimensions and power data of the respective motor. -

Page 18: Motor Encoder System (Ee)

Technical data 2.6 Motor encoder system (ee) gg - see "Order key" on page 13 8LS three-phase synchronous motors are available with EnDat encoders as well as resolvers. The motor encoder system is listed as part of the model number in the form of a 2-character code (ee). Analog and digital transfer A resolver is an analog encoder system. -

Page 19: Resolver

Technical data 2.6.4 Resolver Order code (ee) Technical data Precision ['] Vibration during operation [m/s 10 < f ≤ 500 Hz: ≤196 55 < f ≤ 2000 Hz: <500 Shock during operation [m/s ] (11 ms duration) ≤981 ≤1000 Available resolvers / Order code (ee) Availability 8LSA2...-3 8LSAA...-3... -

Page 20: Inductive Endat Encoders For Sizes 3 - 9

Technical data Available encoders / Order code (ee) Availability 8LSx2...-3 8LSAA...-3 2.6.7 Inductive EnDat encoders for sizes 3 - 9 Encoder type / Order code (ee) Technical data Operating principle Inductive EnDat protocol Functional safety Single-turn / Multi-turn Revolutions 4096 4096 4096 Resolution... -

Page 21: Nominal Speed (Nnn)

Technical data Available encoders / Order code (ee) Availability 8LSx2...-3 8LSx3/4/5/6/7/8...-3 8LSx5A/B/C...-3 8LSO...-3 8LSP...-3 2.7 Nominal speed (nnn) gg - see "Order key" on page 13 8LS three-phase synchronous motors are available with different nominal speeds. The nominal speed is listed as part of the model number in the form of a 3-digit code (nnn). Order code (nnn) Nominal speed n [rpm]... -

Page 22: Availability - 8Lsc

Technical data 8LSA6 Available nominal speeds n [rpm] 1100 1300 1500 2000 2200 3000 4000 4500 6000 8LSA63 8LSA64 8LSA65 8LSA66 8LSA7 Available nominal speeds n [rpm] 1100 1300 1500 2000 2200 3000 4000 4500 6000 8LSA73 8LSA74 8LSA75 8LSA76 8LSA77 8LSA78 8LSA8... -

Page 23: Availability - 8Lso

Technical data 8LSC8 Available nominal speeds n [rpm] 1100 1300 1500 2000 2200 3000 4000 4500 6000 8LSC83 8LSC84 8LSC85 8LSC86 2.7.3 Availability - 8LSO...-3 / 8LSP...-3 8LSO9 Available nominal speeds n [rpm] 1300 1500 2200 8LSO93 8LSO94 8LSO95 8LSO96 8LSP9 Available nominal speeds n [rpm]... -

Page 24: Motor Options (Ff) 8Lsa / 8Lsc

Technical data 2.8 Motor options (ff) 8LSA / 8LSC gg - see "Order key" on page 13 See the following table for the corresponding code (ff) in the order key. The first position in the code (ff) defines the connection direction with options Cx, Dx and Sx. The second position (e.g. -

Page 25: Connection Direction (Ff) 8Lsa / 8Lsc

Technical data 2.8.1 Connection direction (ff) 8LSA / 8LSC Power connection and encoder connection 8LSA and 8LSC three-phase synchronous motors are available with 3 different connection options. Straight built-in connector Connection direction: Straight (top) Encoder and power cable: Separated with own connections Angled built-in connector Connection direction: Angled (swivel connector) Encoder and power cable: Separated with own connections... -

Page 26: Availability - Single-Cable Solution (Hybrid) (Ff) 8Lsa / 8Lsc

Technical data 2.8.2 Availability - Single-cable solution (hybrid) (ff) 8LSA / 8LSC The single-cable solution (hybrid) is only possible for motors with connector size 1.0 (built-in connector on the motor side) and therefore generally up to size/length 65. The following exceptions apply to individual motors with size/length 5A, 5B and 5C. The listed motors are therefore not available as a single-cable solution (hybrid). -

Page 27: Oil Seal (Ff) 8Lsa / 8Lsc

Technical data 2.8.3 Oil seal (ff) 8LSA / 8LSC All 8LS three-phase synchronous motors are available with a form A oil seal per DIN 3760. When equipped with an oil seal, the motors have IP65 protection per EN 60034-5. Motor options (ff) - Overview (order code) see "Motor options (ff) 8LSA / 8LSC"... -

Page 28: Holding Brake (Ff) 8Lsa / 8Lsc

Technical data 2.8.4 Holding brake (ff) 8LSA / 8LSC Operating principle The holding brake is a permanent magnet brake and can be controlled by the B&R drive system. Based on principle, this type of holding brake exhibits a minimal amount of backlash. The brake is designed as a holding brake. -

Page 29: Shaft End (Ff) 8Lsa / 8Lsc

Technical data Technical data - Reinforced holding brake 8LSA3 8LSA4 8LSA5 8LSA6 8LSA7 8LSC3 8LSC4 8LSC5 8LSC6 8LSC7 Holding torque M [Nm] Connected load P 18.0 25.0 25.0 36.5 Supply current I 0.63 0.75 1.04 1.04 1.52 Supply voltage U [VDC] 24 (+10% / -10%) 24 (+6% / -10%) -

Page 30: Motor Options (Ff) 8Lso / 8Lsp

Technical data 2.9 Motor options (ff) 8LSO / 8LSP gg - see "Order key" on page 13 See the following table for the corresponding code (ff) in the order key. Applies to all options: The terminal box is always located on top; the cable outlet / connection direction is shown in the options table. The encoder connection is straight and facing the connection direction. -

Page 31: Connection Direction (Ff) For 8Lso / 8Lsp

Technical data Mounting types Mounting flange Mounting flange and mounting base 8LSO 8LSO 8LSP 2.9.2 Connection direction (ff) for 8LSO / 8LSP 8LSO and 8LSP three-phase synchronous motors are available with a terminal box and 4 different connection directions Motor options (ff) - Overview (order code) see "Motor options (ff) 8LSO / 8LSP"... -

Page 32: Oil Seal (Ff) 8Lso / 8Lsp

Technical data 2.9.3 Oil seal (ff) 8LSO / 8LSP All 8LS three-phase synchronous motors are available with a form A oil seal per DIN 3760. When equipped with an oil seal, the motors have IP65 protection per EN 60034-5. Motor options (ff) - Overview (order code) see "Motor options (ff) 8LSO / 8LSP"... - Page 33 Technical data Special option see "Special motor options (gg) 8LSO / 8LSP" on page 37 Toothed shaft The toothed shaft manufactured per ANSI B 92.1 is only available for 8LSO/8LSP motors as a special motor option. 8LS...-3 user's manual V2.50...

-

Page 34: Special Motor Options (Gg) 8Lsa / 8Lsc

Technical data 2.10 Special motor options (gg) 8LSA / 8LSC gg - see "Order key" on page 13 The respective special motor option is specified as part of the model number in the form of a 2-digit code (gg). The code (ff) for the motor options is limited by the special motor option (gg), or further codes (ff) are necessary when using the special-purpose holding brake. -

Page 35: Special-Purpose Holding Brake For Reinforced A-Side Bearing

Technical data Order code Options (ff) Special motor options (gg) (ff) (gg) (gg) Connection direction Oil seal Shaft end 8LSA 8LSC Straight (top connector) Smooth shaft Keyed shaft Smooth shaft Keyed shaft Angled (swivel connector) Smooth shaft Keyed shaft Reinforced A- (self-cooling) (standard fan 24 VDC) side bearing... - Page 36 Technical data Special-purpose holding brake - Technical data 8LSA4 8LSA5 8LSA6 8LSA7 8LSA8 8LSC4 8LSC5 8LSC6 8LSC7 8LSC8 Holding torque M [Nm] Connected load P Supply current I 0.67 1.08 1.08 1.51 Supply voltage U 24 (+6% / -10%) Moment of inertia J [kgcm²] 1.84 10.2...

-

Page 37: Special Motor Options (Gg) 8Lso / 8Lsp

Technical data 2.11 Special motor options (gg) 8LSO / 8LSP gg - see "Order key" on page 13 The special motor option is specified as part of the model number in the form of a 2-character code (gg). No special motor option If no special motor option is desired, the two-character code (gg) as part of the model number only provides information about the cooling type. -

Page 38: General Motor Data

Technical data 2.12 General motor data General information 8LSA 8LSC 8LSO 8LSP C-UR-US listed UL file number E235396 Electrical properties 8LSA 8LSC 8LSO 8LSP Mains input voltage on servo drive 3x 400 VAC ... 3x 480 VAC ±10% Connection type - Conventional: speedtec circular connector from Intercontec Terminal box Power connection:... -

Page 39: Fan Modules

Technical data 2.12.1 Fan modules Fan 24 VDC (standard) The fan components used depend on the size. 8LSC4 8LSC5 / 8LSC6 8LSC7 / 8LSC8 8LSP9 Manufacturer ebm-papst Manufacturer's product ID 4184 NXH 7114 N 6424 M W1G250-HH37-52 C-UR-US listed Fan type DC fan with electronically commutated external rotor motor Rotor bearings... -

Page 40: Formula Symbols

Technical data 2.12.2 Formula symbols Term Symbol Unit Description Nominal speed Nominal speed of the motor Nominal torque The nominal torque is output by the motor (n = n ) when the nominal current is being drawn. This is possible for any length of time if the ambient conditions are correct. Nominal power The nominal power is supplied by the motor when n = n . -

Page 41: Power Dissipation

Technical data 2.12.3 Power dissipation Power from the servo motors is dissipated via the motor flange and the surface of the motor. The following factors are important to ensure optimal heat dissipation: • Thermally open installation • Free convection The motor data specified for the nominal operating point apply to a motor installed in a thermally open system. The dimensions of the flange plates used for the measurement are shown in the table below. -

Page 42: Standard Motors

Technical data 2.13 Standard motors The most commonly used 8LSA series motors are available as standard motors (preferred motors). If required, these motors are available on short notice using express delivery. Overview of standard motors Cooling type Size Length Nominal speed nN [rpm] Motor version Availability / Technical data 6000... -

Page 43: 8Lsa25

Technical data 2.13.1 8LSA25...-3 - Standard motors Holding Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA25.R0060D000-3 Smooth shaft 8LSA25.R0060D200-3 Angled (swivel connector) 8LSA25.R0060D100-3 Keyed shaft 8LSA25.R0060D300-3 8LSA25.D8060S000-3 2.2 single-turn 8LSA25.D8060S200-3 6000 Smooth shaft 8LSA25.D9060S000-3 2.2 multi-turn 8LSA25.D9060S200-3 Single-cable solution (hybrid) Angled, swivel connector... -

Page 44: 8Lsaa2

Technical data 2.13.2 8LSAA2...-3 / 8LSAA4...-3 - Standard motors Holding 8LSAA2...-3 Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSAA2.D8045S000-3 2.2 single-turn 8LSAA2.D8045S200-3 Smooth shaft 8LSAA2.D9045S000-3 2.2 multi-turn 8LSAA2.D9045S200-3 Single-cable solution (hybrid) 4500 Angled, swivel connector 8LSAA2.D8045S100-3 2.2 single-turn 8LSAA2.D8045S300-3... -

Page 45: 8Lsa35

Technical data 2.13.3 8LSA35...-3 - Standard motors Holding Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA35.EA030D000-3 3000 8LSA35.EA030D200-3 2.1 single-turn 8LSA35.EA060D000-3 6000 8LSA35.EA060D200-3 8LSA35.EB030D000-3 3000 8LSA35.EB030D200-3 2.1 multi-turn Smooth shaft 8LSA35.EB060D000-3 6000 8LSA35.EB060D200-3 Angled (swivel connector) 8LSA35.R2030D000-3 3000 8LSA35.R2030D200-3... -

Page 46: 8Lsa37

Technical data 2.13.4 8LSA37...-3 - Standard motors Holding Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA37.R2030D000-3 3000 8LSA37.R2030D200-3 Smooth shaft 8LSA37.R2060D000-3 6000 8LSA37.R2060D200-3 Angled (swivel connector) 8LSA37.R2030D100-3 3000 8LSA37.R2030D300-3 Keyed shaft 8LSA37.R2060D100-3 6000 8LSA37.R2060D300-3 8LSA37.DA030S000-3 3000 8LSA37.DA030S200-3 2.2 single-turn... -

Page 47: 8Lsa44

Technical data 2.13.5 8LSA44...-3 - Standard motors Holding Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA44.EA030D000-3 3000 8LSA44.EA030D200-3 2.1 single-turn 8LSA44.EA060D000-3 6000 8LSA44.EA060D200-3 8LSA44.EB030D000-3 3000 8LSA44.EB030D200-3 2.1 multi-turn Smooth shaft 8LSA44.EB060D000-3 6000 8LSA44.EB060D200-3 Angled (swivel connector) 8LSA44.R2030D000-3 3000 8LSA44.R2030D200-3... -

Page 48: 8Lsa46

Technical data 2.13.6 8LSA46...-3 - Standard motors Holding Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA46.R2030D000-3 3000 8LSA46.R2030D200-3 Smooth shaft 8LSA46.R2060D000-3 6000 8LSA46.R2060D200-3 Angled (swivel connector) 8LSA46.R2030D100-3 3000 8LSA46.R2030D300-3 Keyed shaft 8LSA46.R2060D100-3 6000 8LSA46.R2060D300-3 8LSA46.DA030S000-3 3000 8LSA46.DA030S200-3 2.2 single-turn... -

Page 49: 8Lsa55

Technical data 2.13.7 8LSA55...-3 / 8LSA57...-3 - Standard motors Holding 8LSA55...-3 Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA55.EA030D000-3 2.1 single-turn 8LSA55.EA030D200-3 8LSA55.EB030D000-3 2.1 multi-turn Smooth shaft 8LSA55.EB030D200-3 Angled (swivel connector) 8LSA55.R2030D000-3 8LSA55.R2030D200-3 8LSA55.R2030D100-3 Keyed shaft 8LSA55.R2030D300-3 3000 8LSA55.DA030S000-3... -

Page 50: 8Lsa73

Technical data 2.13.8 8LSA73...-3 / 8LSA75...-3 - Standard motors Holding 8LSA73...-3 Nominal speed nN [rpm] Resolver EnDat (inductive) Connection direction Shaft end brake 8LSA73.R2030D000-3 Smooth shaft 8LSA73.R2030D200-3 Angled (swivel connector) 8LSA73.R2030D100-3 Keyed shaft 8LSA73.R2030D300-3 8LSA73.DA030S000-3 2.2 single-turn 8LSA73.DA030S200-3 3000 Smooth shaft 8LSA73.DB030S000-3 2.2 multi-turn 8LSA73.DB030S200-3... -

Page 51: 8Lsa - Technical Data

Technical data 2.14 8LSA - Technical data 2.14.1 8LSA2...-3 - Technical data Model number 8LSA23. 8LSA24. 8LSA25. 8LSA25. 8LSA26. 8LSA26. ee060ffgg-3 ee060ffgg-3 ee045ffgg-3 ee060ffgg-3 ee045ffgg-3 ee060ffgg-3 Motor Nominal speed n [rpm] 6000 4500 6000 4500 6000 Number of pole pairs Nominal torque M [Nm] 0.17... - Page 52 Technical data 2.14.1.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA23.eennnffgg-3 (0/0.8) (785/0.8) = 6000 min (0/0.2) (5099/0.1) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ...

- Page 53 Technical data 8LSA26.eennnffgg-3 (0/3.2) (0/3.2) (1225/3.2) (1752/3.2) = 4500 min = 6000 min (0/0.8) (0/0.8) (4224/0) (5230/0) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K 8LS...-3 user's manual V2.50...

- Page 54 Technical data 2.14.1.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA23.eennnffgg-3 (0/0.8) (3150/0.8) = 6000 min (6000/0.4) (0/0.2) (6000/0.2) (8865/0.1) 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 55 Technical data 8LSA26.eennnffgg-3 (0/3.2) (0/3.2) (3123/3.2) (4005/3.2) = 4500 min = 6000 min (6000/1.8) (4500/2) (0/0.8) (0/0.8) (4500/0.8) (6000/0.7) (9000/0.1) (7347/0) 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 56 Technical data 2.14.1.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA23.eennnffgg-3 (0/0.8) = 6000 min (4680/0.8) (6000/0.7) (9000/0.3) (0/0.2) (6000/0.2) 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 57 Technical data 8LSA26.eennnffgg-3 (0/3.2) (0/3.2) (4725/3.2) (5895/3.2) = 4500 min (4500/3.2) (6000/3.2) = 6000 min (9000/1.5) (0/0.8) (0/0.8) (4500/0.8) (6000/0.7) (9000/0.3) 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 58 Technical data 2.14.1.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.1.4.1 8LSA2...-3 - Standard bearing 8LSA24 (standard bearing) 8LSA23 (standard bearing) 1000 1000 1500 1500 3000 3000...

- Page 59 Technical data 2.14.1.5 8LSA2...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depend- ing on motor option [mm] Model number Holding brake Oil seal Encoder assignments E4, E5, D4, D5, D8, D9, S4, S5, S8, S9 E8,E9 8LSA23.eennnffgg-3 8LSA24.eennnffgg-3 8LSA25.eennnffgg-3 8LSA26.eennnffgg-3 IMPORTANT: Extension of encoder cover for certain encoders, see dimension "K...

- Page 60 Technical data 2.14.1.6 8LSA2...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 61: 8Lsaa

Technical data 2.14.2 8LSAA...-3 - Technical data Model number 8LSAA2. 8LSAA2. 8LSAA2. 8LSAA3. 8LSAA3. 8LSAA3. ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 Motor Nominal speed n [rpm] 3000 4500 6000 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 1.27 1.23 2.11... - Page 62 Technical data Model number 8LSAA4.ee030ffgg-3 8LSAA4.ee045ffgg-3 8LSAA4.ee060ffgg-3 Motor Nominal speed n [rpm] 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 2.96 Nominal power P 1319 1696 Nominal current I 2.05 2.89 Stall torque M [Nm] Stall current I 2.21 4.38 Maximum torque M...

- Page 63 Technical data 2.14.2.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSAA2.eennnffgg-3 (0/4.5) (0/4.5) (0/4.5) (929/4.492) (1726/4.492) (2589/4.491) = 3000 rpm = 4500 rpm = 6000 rpm (0/1.4) (0/1.4) (0/1.4) (5073/0.025) (2550/0.024) (3825/0.013) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ...

- Page 64 Technical data 2.14.2.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSAA2.eennnffgg-3 (0/4.5) (0/4.5) (0/4.5) (2251/4.5) (3650/4.5) (5075/4.5) = 3000 min = 4500 min = 6000 min (6000/3.4) (4500/3.2) (3000/3) (7000/2.1) (0/1.4) (0/1.4) (0/1.4) (3000/1.3) (4500/1.3) (6000/1.3) (4434/0.1) (6651/0.1) 1000 2000 3000...

- Page 65 Technical data 2.14.2.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSAA2.eennnffgg-3 (0/4.5) (0/4.5) (0/4.5) (3420/4.5) (5390/4.5) (7000/4.5) (7000/4.5) (3000/4.5) (4500/4.5) (6000/4.5) = 3000 rpm = 4500 rpm = 6000 rpm (7000/2.5) (0/1.4) (0/1.4) (0/1.4) (3000/1.3) (4500/1.3) (6000/1.3) (5568/0.1) 1000 2000 3000...

- Page 66 Technical data 2.14.2.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.2.4.1 8LSAA...-3 - Standard bearing 8LSAA2 (standard bearing) 8LSAA3 (standard bearing) 1000 1000 1500 1500 2000 2000...

- Page 67 Technical data 2.14.2.5 8LSAA...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on motor option [mm] Holding brake Encoder assignments R0, D8, D9 E4, E5, D4, D5 8LSAA2...-3 150.5 111.5 8LSAA3...-3 170.5 131.5 8LSAA4...-3 195.5 156.5 IMPORTANT: Dimensions K and K depend on the length of the encoder cover.

-

Page 68: 8Lsa3

Technical data 2.14.3 8LSA3...-3 - Technical data Model number 8LSA33. 8LSA33. 8LSA33. 8LSA34. 8LSA34. 8LSA34. ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 Motor Nominal speed n [rpm] 3000 4500 6000 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 0.67 1.44 Nominal power P... - Page 69 Technical data Model number 8LSA34. 8LSA35. 8LSA35. 8LSA35. 8LSA35. 8LSA36. ee060ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 ee022ffgg-3 Motor Nominal speed n [rpm] 6000 2200 3000 4500 6000 2200 Number of pole pairs Nominal torque M [Nm] Nominal power P 1005 Nominal current I 1.37 Stall torque M [Nm]...

- Page 70 Technical data Model number 8LSA36. 8LSA36. 8LSA36. 8LSA37. 8LSA37. 8LSA37. 8LSA37. ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 Motor Nominal speed n [rpm] 3000 4500 6000 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] Nominal power P 1037 1131 1068...

- Page 71 Technical data 2.14.3.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA33.eennnffgg-3 = 3000 min (0/3) (0/3) (0/3) (746/3) (1236/3) (1700/3) = 4500 min = 6000 min (0/0.8) (0/0.8) (0/0.8) (2615/0) (3883/0.1) (5230/0) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ...

- Page 72 Technical data 8LSA36.eennnffgg-3 = 2200 min (0/12) (0/12) (0/12) (0/12) (968/12) (1589/12) (640/12) (2328/12) = 3000 min = 4500 min = 6000 min (0/3) (0/3) (0/3) (0/3) (1872/0.1) (5152/0.1) (2615/0) (3923/0) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 73 Technical data 2.14.3.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA33.eennnffgg-3 = 3000 min (0/3) (0/3) (0/3) (1683/3) (2558/3) (3330/3) = 4500 min = 6000 min (3000/1.4) (4500/1.4) (6000/1.3) (0/0.8) (0/0.8) (0/0.8) (3000/0.7) (4500/0.7) (6000/0.6) (6753/0.1) (9000/0.1) (4548/0) 1000 2000 3000...

- Page 74 Technical data 8LSA36.eennnffgg-3 = 2200 min (0/12) (0/12) (0/12) (0/12) (1910/12) (2934/12) (4275/12) (1379/12) = 3000 min = 4500 min = 6000 min (3000/6) (6000/6.8) (2200/5.8) (4500/5.9) (0/3) (0/3) (0/3) (0/3) (2200/2.7) (3000/2.7) (4500/2.2) (6000/1.8) (4548/0) (6822/0) (9095/0) (3255/0.1) 1000 2000 3000 4000...

- Page 75 Technical data 2.14.3.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA33.eennnffgg-3 = 3000 min (0/3) (0/3) (0/3) (2374/3) (3646/3) (4770/3) = 4500 min = 6000 min (4500/2.3) (3000/2.3) (6000/2.3) (9000/1.1) (0/0.8) (0/0.8) (0/0.8) (3000/0.7) (4500/0.7) (6000/0.6) (5653/0) (8479/0) 1000 2000 3000...

- Page 76 Technical data 8LSA36.eennnffgg-3 = 2200 min (0/12) (0/12) (0/12) (0/12) (2827/12) (4324/12) (6210/12) (2023/12) = 3000 min = 4500 min (6000/12) (4500/11.5) (3000/11.2) = 6000 min (2200/10.8) (9000/5.9) (0/3) (0/3) (0/3) (0/3) (2200/2.7) (3000/2.7) (4500/2.2) (6000/1.8) (8479/0) (5653/0) (4088/0.2) 1000 2000 3000 4000...

- Page 77 Technical data 2.14.3.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 8LS...-3 user's manual V2.50...

- Page 78 Technical data 2.14.3.4.1 8LSA3...-3 - Standard bearing 8LSA34 (standard bearing) 8LSA33 (standard bearing) 1000 1000 1500 1500 3000 3000 4500 4500 6000 6000 (smooth shaft rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm] Distance x [mm] maximum allowed axial force: F = 62 N amax...

- Page 79 Technical data 2.14.3.5 8LSA3...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Reinforced A-side bearing 8LSA33.eennnffgg-3 8LSA34.eennnffgg-3 8LSA35.eennnffgg-3 8LSA36.eennnffgg-3 8LSA37.eennnffgg-3 IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 80 Technical data 2.14.3.5.1 8LSA4...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 81: 8Lsa4

Technical data 2.14.4 8LSA4...-3 - Technical data Model number 8LSA43.ee022ffgg-3 8LSA43.ee030ffgg-3 8LSA43.ee045ffgg-3 8LSA43.ee060ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] Nominal power P 1272 1257 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M... - Page 82 Technical data Model number 8LSA44.ee022ffgg-3 8LSA44.ee030ffgg-3 8LSA44.ee045ffgg-3 8LSA44.ee060ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 4.62 Nominal power P 1198 1451 1696 1885 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M [Nm]...

- Page 83 Technical data Model number 8LSA45.ee022ffgg-3 8LSA45.ee030ffgg-3 8LSA45.ee045ffgg-3 8LSA45.ee060ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 6.16 Nominal power P 1613 1935 2262 2513 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M [Nm]...

- Page 84 Technical data Model number 8LSA46.ee022ffgg-3 8LSA46.ee030ffgg-3 8LSA46.ee045ffgg-3 8LSA46.ee060ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] Nominal power P 2004 2419 2827 3142 Nominal current I Stall torque M [Nm] Stall current I 12.3 Maximum torque M [Nm]...

- Page 85 Technical data 2.14.4.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA43.eennnffgg-3 = 2200 rpm (0/15.2) (0/15.2) (0/15.2) (0/15.2) (447/15.2) (806/15.2) (1400/15.2) (1940/15.2) = 3000 rpm = 4500 rpm = 6000 rpm (0/4) (0/4) (0/4) (0/4) (4627/0.1) (1699/0.1) (2337/0) (3507/0.1) 1000 1500...

- Page 86 Technical data 8LSA46.eennnffgg-3 = 2200 rpm (0/38) (0/38) (0/38) (0/38) (532/38) (783/38) (1293/38) (1799/38) = 3000 rpm = 4500 rpm = 6000 rpm (0/10) (0/10) (0/10) (0/10) (2302/0.3) (3472/0.3) (4673/0) (1699/0.3) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 87 Technical data 2.14.4.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA43.eennnffgg-3 = 2200 rpm (0/15.2) (0/15.2) (0/15.2) (0/15.2) (1030/15.2) (1626/15.2) (2711/15.2) (3657/15.2) = 3000 rpm = 4500 rpm = 6000 rpm (4500/6.8) (6000/6.6) (3000/5.7) (2200/4.9) (0/4) (0/4) (0/4) (0/4) (3000/3.1) (4500/2.7)

- Page 88 Technical data 8LSA46.eennnffgg-3 = 2200 rpm (0/38) (0/38) (0/38) (0/38) (1119/38) (1544/38) (2434/38) (3373/38) = 3000 rpm = 4500 rpm = 6000 rpm (6000/15.3) (4500/14.3) (3000/13.5) (2200/13.9) (0/10) (0/10) (0/10) (0/10) (3000/7.7) (4500/6) (2200/8.7) (6000/5) (4003/0.4) (8127/0) (6038/0.5) (2955/0.4) 1000 2000 3000 4000...

- Page 89 Technical data 2.14.4.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA43.eennnffgg-3 = 2200 rpm (0/15.2) (0/15.2) (0/15.2) (0/15.2) (1521/15.2) (2450/15.2) (3752/15.2) (5152/15.2) = 3000 rpm = 4500 rpm = 6000 rpm (6000/12.4) (4500/12.1) (3000/11.8) (2200/9.8) (0/4) (0/4) (0/4) (0/4) (2200/3.5) (3000/3.1)

- Page 90 Technical data 8LSA46.eennnffgg-3 = 2200 rpm (0/38) (0/38) (0/38) (0/38) (1595/38) (2223/38) (3408/38) (4596/38) = 3000 rpm = 4500 rpm = 6000 rpm (4500/26.5) (6000/26.6) (3000/25.9) (2200/25.5) (0/10) (0/10) (0/10) (0/10) (2200/8.7) (3000/7.7) (4500/6) (6000/5) (7543/1.2) (5001/1) (10102/0) (3710/0) 2000 4000 6000 8000...

- Page 91 Technical data 2.14.4.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.4.4.1 8LSA4...3 / 8LSC4...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA44 (standard bearing) 8LSA43 (standard bearing) 1300...

- Page 92 Technical data 2.14.4.4.2 8LSA4...-3 / 8LSC4...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA44 (special option "reinforced A side bearing") 8LSA43 (special option "reinforced A side bearing") 2400 2400 2200 2200 2000 2000 1800 1800 1600 1600 1000...

- Page 93 Technical data 2.14.4.5 8LSA4...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on motor option [mm] Encoder assignments DA,DB,EA,EB,SA,SB,R2 D0,D1,E0,E1,S0,S1 Model number Holding brake Heavy-duty holding brake Reinforced A- side bearing 8LSA43.eennnffgg-3 8LSA44.eennnffgg-3 8LSA45.eennnffgg-3 8LSA46.eennnffgg-3 IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 94 Technical data 2.14.4.5.1 8LSA4...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 95: 8Lsa5

Technical data 2.14.5 8LSA5...-3 - Technical data Model number 8LSA53.ee022ffgg-3 8LSA53.ee030ffgg-3 8LSA53.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] Nominal power P 1257 1838 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M [Nm]... - Page 96 Technical data Model number 8LSA54.ee022ffgg-3 8LSA54.ee030ffgg-3 8LSA54.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] Nominal power P 1797 2419 3440 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M [Nm] 27.6 Maximum current I...

- Page 97 Technical data Model number 8LSA55.ee022ffgg-3 8LSA55.ee030ffgg-3 8LSA55.ee045ffgg-3 8LSA56.ee022ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 Number of pole pairs Nominal torque M [Nm] 11.8 11.6 14.4 Nominal power P 2719 3644 4477 3318 Nominal current I Stall torque M [Nm] 12.5 Stall current I...

- Page 98 Technical data Model number 8LSA56.ee030ffgg-3 8LSA56.ee045ffgg-3 8LSA57.ee022ffgg-3 8LSA57.ee030ffgg-3 8LSA57.ee045ffgg-3 Motor Nominal speed n [rpm] 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 13.9 12.7 17.5 Nominal power P 4367 5985 4147 5498 7069 Nominal current I 11.6 10.7 13.7...

- Page 99 Technical data 2.14.5.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (1052/13.8) (584/13.8) (1604/13.8) = 2200 rpm = 3000 rpm = 4500 rpm (0/4.5) (0/4.5) (0/4.5) (1673/0.1) (3434/0.1) (2337/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 100 Technical data 8LSA56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (815/55.2) (1274/55.2) (1848/55.2) = 2200 rpm = 3000 rpm = 4500 rpm (0/16) (0/16) (0/16) (1699/0.3) (2313/0.2) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 101 Technical data 2.14.5.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (1224/13.8) (1991/13.8) (3002/13.8) = 2200 rpm = 3000 rpm = 4500 rpm (4500/6.3) (3000/6.3) (2200/5.1) (0/4.5) (0/4.5) (0/4.5) (4500/3.9) (2200/4.2) (3000/4) (2910/0.1) (4064/0) (5972/0.1) 1000 2000 3000...

- Page 102 Technical data 8LSA56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (1552/55.2) (2317/55.2) (3335/55.2) = 2200 rpm = 3000 rpm = 4500 rpm (3000/30.4) (4500/29.5) (2200/27.8) (0/16) (0/16) (0/16) (2200/14.4) (3000/13.9) (4500/12.7) (4023/0.4) (6063/0) (2955/0.4) 1000 2000 3000 4000 5000 6000 7000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 103 Technical data 2.14.5.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (1781/13.8) (2930/13.8) (4296/13.8) = 2200 rpm (3000/13.4) (4500/13) = 3000 rpm = 4500 rpm (2200/10.4) (0/4.5) (0/4.5) (0/4.5) (2200/4.2) (4500/3.9) (3000/4) (7461/0.6) (3635/0.4) (5051/0) 1000 2000 3000...

- Page 104 Technical data 8LSA56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (4824/55.2) (2244/55.2) (3384/55.2) = 2200 rpm (4500/55.2) (2200/55.2) (3000/55.2) = 3000 rpm = 4500 rpm (0/16) (0/16) (0/16) (3000/13.9) (4500/12.7) (2200/14.4) (7537/0) (3710/0) (5051/0) 1000 2000 3000 4000 5000 6000 7000 8000 9000 TChar Version:0124 dT ...

- Page 105 Technical data 2.14.5.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.5.4.1 8LSA5...-3 / 8LSC5...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 106 Technical data 8LSA54 (standard bearing) 8LSA53 (standard bearing) 1400 1300 1200 1200 1100 1000 1000 1000 1000 1500 1500 3000 3000 4500 4500 6000 (smooth shaft 6000 rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm] Distance x [mm] maximum allowed axial force: F = 114 N...

- Page 107 Technical data 2.14.5.4.2 8LSA5...-3 / 8LSC5...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA54 (special option "reinforced A side bearing") 8LSA53 (special option "reinforced A side bearing") 4500 4500 4000 4000 3500 3500 3000 3000 1000 1000 2500...

- Page 108 Technical data 2.14.5.5 8LSA5...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Encoder assignments DA,DB,SA,SB,R2 EA,EB D0,D1,E0,E1,S0,S1 Model number Holding Reinforced hold- Reinforced A-side brake ing brake bearing 8LSA53.eennnffgg-3 8LSA54.eennnffgg-3 8LSA55.eennnffgg-3 8LSA56.eennnffgg-3 8LSA57.eennnffgg-3 IMPORTANT: Motor option "oil seal"...

- Page 109 Technical data 2.14.5.5.1 8LSA5...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 110: 8Lsa5A/B/C

Technical data 2.14.6 8LSA5A/B/C...-3 - Technical data Model number 8LSA5A. 8LSA5A. 8LSA5A. 8LSA5B. 8LSA5B. 8LSA5B. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee022ffgg-3 ee030ffgg-3 ee040ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 3000 4000 Number of pole pairs Nominal torque M [Nm] Nominal power P 4147 4398... - Page 111 Technical data Model number 8LSA5C.ee015ffgg-3 8LSA5C.ee022ffgg-3 8LSA5C.ee030ffgg-3 Motor Nominal speed n [rpm] 1500 2200 3000 Number of pole pairs Nominal torque M [Nm] Nominal power P 6283 7833 8482 Nominal current I 12.3 15.3 16.6 Stall torque M [Nm] Stall current I 14.7 21.6 29.5...

- Page 112 Technical data 2.14.6.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA5A.eennnffgg-3 (0/84) (0/84) (0/84) (755/84) (1075/83.986) (1726/83.973) = 2200 rpm = 3000 rpm = 4500 rpm (0/24) (0/24) (0/24) (1699/0.46) (2313/0.3) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 113 Technical data 2.14.6.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA5A.eennnffgg-3 (0/84) (0/84) (0/84) (1433/84) (1951/84) (3150/84) = 2200 min = 3000 min = 4500 min (4500/42.3) (2200/38.9) (3000/37.7) (0/24) (0/24) (0/24) (2200/18) (3000/14) (4500/8) (6000/1.4) (2955/0.8) (4023/0.6) 1000 2000 3000...

- Page 114 Technical data 2.14.6.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA5A.eennnffgg-3 (0/84) (0/84) (0/84) (2040/84) (2829/84) (4470/84) = 2200 min = 3000 min (4500/83.5) (3000/77.5) = 4500 min (2200/76) (6000/47.2) (0/24) (0/24) (0/24) (2200/18) (3000/14) (4500/8) (3710/0) (5051/0) 1000 2000 3000...

- Page 115 Technical data 2.14.6.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.6.4.1 8LSA5A/B/C...-3 - Standard bearing 8LSA5A (standard bearing) 8LSA5B (standard bearing) 2000 2000 1800 1800 1600 1600...

- Page 116 Technical data 2.14.6.5 8LSA5A/B/C...-3 - Dimensions Motor EnDat/Resolver feedback Extension of K and M depending on motor option [mm] Holding Increased brake Reinforced bearing brake Encoder assign- R2, DA, DB, SA, SB E0, E1, D0, D1, S0, S1 All encoders ments Connector size 8LSA5A...-3...

-

Page 117: 8Lsa6

Technical data 2.14.7 8LSA6...-3 - Technical data Model number 8LSA63.ee022ffgg-3 8LSA63.ee030ffgg-3 8LSA63.ee045ffgg-3 8LSA64.ee022ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 Number of pole pairs Nominal torque M [Nm] 11.8 11.6 Nominal power P 2719 3644 4477 4147 Nominal current I Stall torque M [Nm] 12.5... - Page 118 Technical data Model number 8LSA64.ee030ffgg-3 8LSA64.ee045ffgg-3 8LSA65.ee022ffgg-3 8LSA65.ee030ffgg-3 8LSA65.ee045ffgg-3 Motor Nominal speed n [rpm] 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 17.5 15.1 12.2 Nominal power P 5498 7116 5068 6597 5749 Nominal current I 10.7 13.8 12.9...

- Page 119 Technical data Model number 8LSA66.ee022ffgg-3 8LSA66.ee030ffgg-3 8LSA66.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 24.5 23.5 Nominal power P 5644 7383 7069 Nominal current I 11.1 14.4 13.7 Stall torque M [Nm] Stall current I 12.6...

- Page 120 Technical data 2.14.7.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA63.eennnffgg-3 = 2200 rpm = 3000 rpm = 4500 rpm (0/47) (0/47) (0/47) (695/47) (1040/47) (1761/47) (0/12.5) (0/12.5) (0/12.5) (1691/0.3) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 121 Technical data 8LSA66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (1110/114.3) (1761/114.3) (730/114.2) = 4500 min (0/28) (0/28) (0/28) (1699/0.7) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 122 Technical data 2.14.7.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA63.eennnffgg-3 = 2200 rpm = 3000 rpm = 4500 rpm (0/47) (0/47) (0/47) (1388/47) (1971/47) (3244/47) (4500/24.6) (3000/21.6) (2200/20.9) (0/12.5) (0/12.5) (0/12.5) (2200/11.8) (3000/11.6) (4500/9.5) (2940/0.5) (4064/0) (6064/0) 1000 2000 3000...

- Page 123 Technical data 8LSA66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (2093/114.3) (3184/114.3) (1418/114.2) = 4500 min (3000/58.8) (4500/57.1) (2200/53.8) (0/28) (0/28) (0/28) (2200/24.5) (3000/23.5) (4500/15) (2955/1.2) (6064/0) (4064/0) 1000 2000 3000 4000 5000 6000 7000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 124 Technical data 2.14.7.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA63.eennnffgg-3 = 2200 rpm = 3000 rpm = 4500 rpm (0/47) (0/47) (0/47) (2003/46.9) (2854/47) (4500/47) (4673/47) (3000/44.3) (2200/41.3) (0/12.5) (0/12.5) (0/12.5) (2200/11.8) (3000/11.6) (4500/9.5) (3673/1.4) (7537/0) (5051/0) 1000 2000 3000...

- Page 125 Technical data 8LSA66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (2980/114.3) (4635/114.3) (1985/114.1) = 4500 min (3000/114.1) (4500/114.3) (2200/99) (0/28) (0/28) (0/28) (2200/24.5) (3000/23.5) (4500/15) (7537/0) (3710/0) (5051/0) 1000 2000 3000 4000 5000 6000 7000 8000 9000 TChar Version:0124 dT ...

- Page 126 Technical data 2.14.7.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.7.4.1 8LSA6...-3 / 8LSC6...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 127 Technical data 8LSA64 (standard bearing) 8LSA63 (standard bearing) 1400 1400 1300 1200 1200 1100 1000 1000 1000 1000 1500 1500 3000 3000 4500 4500 6000 6000 (smooth shaft rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm] Distance x [mm] maximum allowed axial force: F = 125 N...

- Page 128 Technical data 2.14.7.4.2 8LSA6...-3 / 8LSC6...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA64 (special option "reinforced A side bearing") 8LSA63 (special option "reinforced A side bearing") 5000 5000 4500 4500 4000 4000 3500 3500 1000 1000 3000...

- Page 129 Technical data 2.14.7.5 8LSA6...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the mo- tor option [mm] Encoder assignments DA,D- EA,EB D0,D1,E0,E1,S0,S1 B,SA,SB,R2 Model number Holding Heavy-duty Reinforced A-side brake holding brake bearing 8LSA63.eennnffgg-3 8LSA64.eennnffgg-3 8LSA65.eennnffgg-3 8LSA66.eennnffgg-3 8LSA66.ee045ffgg-3, power connec- tor size 1.5 IMPORTANT: Motor option "oil seal"...

- Page 130 Technical data 2.14.7.5.1 8LSA6...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

- Page 131 Technical data 2.14.7.5.2 8LSA6...-3 - Dimensions of connector options (size 1.5) 8LS...-3 user's manual V2.50...

-

Page 132: 8Lsa7

Technical data 2.14.8 8LSA7...-3 - Technical data Model number 8LSA73.ee022ffgg-3 8LSA73.ee030ffgg-3 8LSA73.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 21.9 20.5 Nominal power P 5045 6440 7540 Nominal current I 9.86 12.58 14.68 Stall torque M... - Page 133 Technical data Model number 8LSA74.ee022ffgg-3 8LSA74.ee030ffgg-3 8LSA74.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 27.5 Nominal power P 6336 7854 8482 Nominal current I 12.39 15.34 16.51 Stall torque M [Nm] Stall current I 14.86 20.25...

- Page 134 Technical data Model number 8LSA75.ee022ffgg-3 8LSA75.ee030ffgg-3 Motor Nominal speed n [rpm] 2200 3000 Number of pole pairs Nominal torque M [Nm] Nominal power P 7833 9425 Nominal current I 15.32 18.4 Stall torque M [Nm] Stall current I 19.37 26.38 Maximum torque M [Nm] Maximum current I...

- Page 135 Technical data Model number 8LSA76.ee015ffgg-3 8LSA76.ee022ffgg-3 8LSA76.ee030ffgg-3 8LSA77.ee030ffgg-3 8LSA78.ee030ffgg-3 Motor Nominal speed n [rpm] 1500 2200 3000 Number of pole pairs Nominal torque M [Nm] 48.5 42.5 Nominal power P 7618 9791 10996 12566 13823 Nominal current I 14.88 19.2 21.47 24.5 Stall torque M...

- Page 136 Technical data 2.14.8.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA73.eennnffgg-3 (0/107) (0/107) (0/107) (584/107) (853/107) (1290/107) = 2200 min = 3000 min = 4500 min (0/26) (0/26) (0/26) (1716/0) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 137 Technical data 8LSA76.eennnffgg-3 (0/230) (0/230) (0/230) (421/230) (661/230) (935/230) = 1500 rpm = 2200 rpm = 3000 rpm (0/60) (0/60) (0/60) (1699/0.9) (1169/0) (2337/0) 1000 1500 2000 2500 3000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 138 Technical data 2.14.8.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA73.eennnffgg-3 (0/107) (0/107) (0/107) (1105/107) (1585/107) (2340/107) = 2200 min = 3000 min = 4500 min (3000/39.2) (4500/37.3) (0/26) (0/26) (0/26) (2200/36.1) (3000/20.5) (2200/21.9) (4500/16) (6000/1.6) (4064/0) (2985/0) 1000 2000 3000...

- Page 139 Technical data 8LSA76.eennnffgg-3 (0/230) (0/230) (0/230) (803/230) (1224/230) (1727/230) = 1500 rpm = 2200 rpm = 3000 rpm (3000/92.4) (1500/84.7) (2200/84.9) (0/60) (0/60) (0/60) (1500/48.5) (3000/35) (2200/42.5) (2032/0) (2955/1.5) (4064/0) 1000 1500 2000 2500 3000 3500 4000 4500 TChar Version:0124 dT ...

- Page 140 Technical data 2.14.8.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA73.eennnffgg-3 (0/107) (0/107) (0/107) (1577/107) (2197/107) (3330/107) = 2200 min = 3000 min = 4500 min (4500/71.8) (3000/71.3) (2200/69.3) (6000/40.5) (0/26) (0/26) (0/26) (2200/21.9) (3000/20.5) (4500/16) (5051/0) (3710/0) 1000 2000 3000...

- Page 141 Technical data 8LSA76.eennnffgg-3 (0/230) (0/230) (0/230) (1124/230) (1744/229.9) (2430/230) = 1500 rpm = 2200 rpm = 3000 rpm (3000/172.1) (2200/167.9) (1500/157.8) (4500/63.5) (0/60) (0/60) (0/60) (2200/42.5) (1500/48.5) (3000/35) (2526/0) (3710/0) 1000 1500 2000 2500 3000 3500 4000 4500 5000 TChar Version:0124 dT ...

- Page 142 Technical data 2.14.8.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.8.4.1 8LSA7...-3 / 8LSC7...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 143 Technical data 8LSA74 (standard bearing) 8LSA73 (standard bearing) 2800 2600 2500 2400 2200 2000 2000 1800 1000 1000 1500 1600 1500 1500 1400 3000 3000 1200 1000 4500 4500 6000 1000 (smooth shaft 6000 rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm]...

- Page 144 Technical data 2.14.8.4.2 8LSA7...-3 / 8LSC7...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA74 (special option "reinforced A side bearing") 8LSA73 (special option "reinforced A side bearing") 4500 4500 4000 4000 3500 3500 3000 3000 1000 1000 2500...

- Page 145 Technical data 2.14.8.5 8LSA73/74/75...-3 - Dimensions EnDat/Resolver feedback Extension of K and K depending on the mo- tor option [mm] Encoder assignments DA,DB,EA,EB,R2, D0,D1,E0,E1,S0,S1 SA,SB Model number Holding brake Heavy-duty Reinforced A- holding brake side bearing 8LSA73.eennnffgg-3 8LSA73.ee045ffgg-3, power connector size On request 8LSA74.eennnffgg-3 8LSA74.ee045ffgg-3, power connector size...

- Page 146 Technical data 2.14.8.5.1 8LSA73/74/75...-3 - Dimensions of connector options (size 1.0) 8LS...-3 user's manual V2.50...

- Page 147 Technical data 2.14.8.5.2 8LSA73/74/75...-3 - Dimensions of connector options (size 1.5) 8LS...-3 user's manual V2.50...

- Page 148 Technical data 2.14.8.6 8LSA76/77/78...-3 - Dimensions EnDat/Resolver feedback Extension of K depending on motor option [mm] Model number Holding brake Heavy-duty Special brake Reinforced A- holding brake side bearing 8LSA76.eennnffgg-3 8LSA77.eennnffgg-3 8LSA78.eennnffgg-3 IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 149 Technical data 2.14.8.6.1 8LSA76/77/78...-3 - Dimensions of connector options (size 1.5) 8LS...-3 user's manual V2.50...

-

Page 150: 8Lsa8

Technical data 2.14.9 8LSA8...-3 - Technical data Model number 8LSA83.ee015ffgg-3 8LSA83.ee022ffgg-3 8LSA83.ee030ffgg-3 8LSA84.ee015ffgg-3 Motor Nominal speed n [rpm] 1500 2200 3000 1500 Number of pole pairs Nominal torque M [Nm] Nominal power P 5498 7142 8482 9111 Nominal current I 10.7 16.6 17.8... - Page 151 Technical data Model number 8LSA84.ee022ffgg-3 8LSA84.ee030ffgg-3 8LSA85.ee015ffgg-3 8LSA85.ee020ffgg-3 Motor Nominal speed n [rpm] 2200 3000 1500 2000 Number of pole pairs Nominal torque M [Nm] 51.5 48.4 Nominal power P 11865 15205 12095 15080 Nominal current I 23.2 29.7 23.6 29.4 Stall torque M [Nm]...

- Page 152 Technical data Model number 8LSA86.ee015ffgg-3 8LSA86.ee020ffgg-3 Motor Nominal speed n [rpm] 1500 2000 Number of pole pairs Nominal torque M [Nm] Nominal power P 15237 17802 Nominal current I 29.8 32.9 Stall torque M [Nm] Stall current I 35.3 44.6 Maximum torque M [Nm] Maximum current I...

- Page 153 Technical data 2.14.9.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSA83.eennnffgg-3 = 1500 rpm (0/120) (0/120) (0/120) (649/120) (927/120) (1262/120) = 2200 rpm = 3000 rpm (0/40) (0/40) (0/40) (1699/0.5) (2313/0.6) (1169/0) 1000 1500 2000 2500 TChar Version:0124 dT ...

- Page 154 Technical data 8LSA86.eennnffgg-3 = 1500 min (0/345) (678/345) (0/115) (1169/0) 1000 1200 1400 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...

- Page 155 Technical data 2.14.9.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSA83.eennnffgg-3 = 1500 rpm (0/120) (0/120) (0/120) (1230/120) (2304/120) (1686/120) = 2200 rpm = 3000 rpm (1500/78.4) (3000/69.8) (2200/66.5) (0/40) (0/40) (0/40) (1500/35) (3600/30.4) (2200/31) (3000/27) (2955/0.8) (2032/0) 1000 1500 2000...

- Page 156 Technical data 8LSA86.eennnffgg-3 = 1500 min (0/345) (1240/345) (1500/216.5) (0/115) (1500/97) (2032/0) 1000 1500 2000 2500 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...

- Page 157 Technical data 2.14.9.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSA83.eennnffgg-3 (0/120) (0/120) (0/120) (1793/120) (2448/119.9) (3294/119.9) (1500/120) (2200/119.9) (3000/119.9) (3600/102.2) = 1500 rpm = 2200 rpm = 3000 rpm (0/40) (0/40) (0/40) (1500/35) (2200/31) (3000/27) (3600/23.1) (2526/0) 1000 1500 2000...

- Page 158 Technical data 8LSA86.eennnffgg-3 = 1500 min (0/345) (1806/345) (1500/345) (0/115) (1500/97) (2526/0) 1000 1500 2000 2500 3000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...

- Page 159 Technical data 2.14.9.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.14.9.4.1 8LSA8...-3 / 8LSC8...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA84 (standard bearing) 8LSA83 (standard bearing) 5500...

- Page 160 Technical data 2.14.9.4.2 8LSA8...-3 / 8LSC8...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA84 (special option "reinforced A side bearing") 8LSA83 (special option "reinforced A side bearing") 11000 10000 10000 9000 9000 8000 8000 7000 1000 7000 1000...

- Page 161 Technical data 2.14.9.5 8LSA8...-3 - Dimensions Optical EnDat feedback Extension of K depending on motor option [mm] Model number Holding brake Oil seal Reinforced A-side bear- 8LSA83.eennnffgg-3 16.5 8LSA84.eennnffgg-3 16.5 Inductive EnDat/resolver feedback Extension of K depending on motor option [mm] Model number Holding brake Oil seal...

- Page 162 Technical data Optical EnDat feedback Extension of K depending on motor option [mm] Model number Holding brake Oil seal Reinforced A-side bear- 8LSA85.eennnffgg-3 16.5 8LSA86.eennnffgg-3 16.5 Inductive EnDat/resolver feedback Extension of K depending on motor option [mm] Model number Holding brake Oil seal Reinforced A-side bear- 8LSA85.eennnffgg-3...

- Page 163 Technical data 2.14.9.5.1 8LSA8...-3 - Dimensions of connector options 8LSA83...-3 / 8LSA84...-3 8LSA85...-3 / 8LSA86...-3 8LS...-3 user's manual V2.50...

- Page 164 Technical data 8LS...-3 user's manual V2.50...

-

Page 165: 8Lsc - Technical Data

Technical data 2.15 8LSC - Technical data 2.15.1 8LSC4...-3 - Technical data Model number 8LSC43. 8LSC43. 8LSC43. 8LSC43. 8LSC44. 8LSC44. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 ee022ffgg-3 ee030ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 2200 3000 Number of pole pairs Nominal torque M [Nm] 4.55... - Page 166 Technical data Model number 8LSC44. 8LSC44. 8LSC45. 8LSC45. 8LSC45. 8LSC45. ee045ffgg-3 ee060ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee060ffgg-3 Motor Nominal speed n [rpm] 4500 6000 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 4.68 8.01 6.24 Nominal power P 2205 2450 2096...

- Page 167 Technical data Model number 8LSC46.ee022ffgg-3 8LSC46.ee030ffgg-3 8LSC46.ee045ffgg-3 8LSC46.ee060ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 6000 Number of pole pairs Nominal torque M [Nm] 11.31 10.01 Nominal power P 2606 3145 3676 4084 Nominal current I Stall torque M [Nm] Stall current I Maximum torque M...

- Page 168 Technical data 2.15.1.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC43.eennnffgg-3 = 2200 min (0/15.2) (447/15.2) (0/15.2) (0/15.2) (0/15.2) (806/15.2) (1400/15.2) (1940/15.2) = 3000 min = 4500 min = 6000 min (0/5.2) (0/5.2) (0/5.2) (0/5.2) (3490/0.1) (1656/0.1) (2337/0) (4673/0) 1000 2000...

- Page 169 Technical data 8LSC46.eennnffgg-3 = 2200 min (0/38) (532/38) (0/38) (0/38) (0/38) (783/38) (1293/38) (1799/38) = 3000 min = 4500 min = 6000 min (0/13) (0/13) (0/13) (0/13) (3490/0.2) (1716/0) (2337/0) (4673/0) 1000 2000 3000 4000 5000 6000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 170 Technical data 2.15.1.2 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC43.eennnffgg-3 = 2200 min (0/15.2) (0/15.2) (0/15.2) (0/15.2) (2450/15.2) (3752/15.2) (5152/15.2) = 3000 min (1540/15.1) = 4500 min = 6000 min (6000/12.4) (4500/12.1) (3000/11.9) (2200/9.7) (0/5.2) (0/5.2) (0/5.2) (0/5.2) (2200/4.6) (4500/3.6)

- Page 171 Technical data 8LSC46.eennnffgg-3 = 2200 min (0/38) (0/38) (0/38) (0/38) (1595/38) (2223/38) (3408/38) (4596/38) = 3000 min = 4500 min = 6000 min (6000/26.7) (3000/25.9) (4500/26.5) (2200/25.5) (0/13) (0/13) (0/13) (0/13) (2200/11.4) (4500/7.8) (3000/10.1) (6000/6.5) (7581/0.7) (3710/0) (5051/0) (10102/0) 2000 4000 6000 8000...

- Page 172 Technical data 2.15.1.3 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC43.eennnffgg-3 = 2200 min (0/15.2) (0/15.2) (0/15.2) (0/15.2) (1646/15.2) (2711/15.2) (3657/15.2) (1030/15.2) = 3000 min = 4500 min = 6000 min (4500/6.8) (6000/6.7) (0/5.2) (0/5.2) (0/5.2) (0/5.2) (2200/4.7) (3000/5.6) (2200/4.6) (3000/4.1)

- Page 173 Technical data 8LSC46.eennnffgg-3 = 2200 min (0/38) (0/38) (0/38) (0/38) (1119/38) (1544/38) (2434/38) (3373/38) = 3000 min = 4500 min = 6000 min (4500/14.4) (6000/15.3) (0/13) (0/13) (0/13) (0/13) (2200/14) (3000/13.6) (4500/7.8) (2200/11.4) (3000/10.1) (6000/6.5) (6068/0.3) (8127/0) (2985/0) (4064/0) 1000 2000 3000 4000...

- Page 174 Technical data 2.15.1.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.15.1.4.1 8LSA4...3 / 8LSC4...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA44 (standard bearing) 8LSA43 (standard bearing) 1300...

- Page 175 Technical data 2.15.1.4.2 8LSA4...-3 / 8LSC4...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA44 (special option "reinforced A side bearing") 8LSA43 (special option "reinforced A side bearing") 2400 2400 2200 2200 2000 2000 1800 1800 1600 1600 1000...

- Page 176 Technical data 2.15.1.5 8LSC4...-3 - Dimensions Shaft option - Smooth shaft Shaft option - Smooth shaft EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Heavy-duty holding Reinforced A-side brake bearing 8LSC43.eennnffgg-3 8LSC44.eennnffgg-3 8LSC45.eennnffgg-3 8LSC46.eennnffgg-3...

- Page 177 Technical data 2.15.1.5.1 8LSC4...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 178: 8Lsc5

Technical data 2.15.2 8LSC5...-3 - Technical data Model number 8LSC53. 8LSC53. 8LSC53. 8LSC54. 8LSC54. 8LSC54. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 5.46 5.07 10.14... - Page 179 Technical data Model number 8LSC55. 8LSC55. 8LSC55. 8LSC56. 8LSC56. 8LSC56. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 15.34 15.08 12.35 18.72 18.07 16.51 Nominal power P 3534...

- Page 180 Technical data Model number 8LSC57.ee022ffgg-3 8LSC57.ee030ffgg-3 8LSC57.ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 23.4 22.75 19.5 Nominal power P 5391 7147 9189 Nominal current I 10.6 17.9 Stall torque M [Nm] Stall current I 11.7...

- Page 181 Technical data 2.15.2.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (1052/13.8) (1604/13.8) (584/13.8) = 2200 rpm = 3000 rpm = 4500 rpm (0/5.9) (0/5.9) (0/5.9) (1665/0.1) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 182 Technical data 8LSC56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (815/55.2) (1274/55.2) (1848/55.2) = 2200 rpm = 3000 rpm = 4500 rpm (0/20.8) (0/20.8) (0/20.8) (1716/0) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 183 Technical data 2.15.2.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (1224/13.8) (1991/13.8) (2971/13.8) = 2200 rpm = 3000 rpm = 4500 rpm (4500/6.5) (3000/6.3) (0/5.9) (0/5.9) (0/5.9) (2200/5.5) (3000/5.2) (2200/5) (4500/5.1) (2895/0.1) (4064/0) (6064/0) 1000 2000 3000...

- Page 184 Technical data 8LSC56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (1552/55.2) (2317/55.2) (3335/55.2) = 2200 rpm = 3000 rpm = 4500 rpm (3000/30.7) (4500/29.5) (2200/28) (0/20.8) (0/20.8) (0/20.8) (2200/18.8) (3000/18.1) (4500/16.6) (2985/0) (4064/0) (6064/0) 1000 2000 3000 4000 5000 6000 7000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 185 Technical data 2.15.2.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC53.eennnffgg-3 (0/13.8) (0/13.8) (0/13.8) (4296/13.8) (1781/13.7) (2930/13.8) = 2200 rpm (3000/13.5) = 3000 rpm (4500/13) = 4500 rpm (2200/10.3) (0/5.9) (0/5.9) (0/5.9) (2200/5.5) (3000/5.2) (4500/5.1) (3635/0.2) (5051/0) (7537/0) 1000 2000 3000...

- Page 186 Technical data 8LSC56.eennnffgg-3 (0/55.2) (0/55.2) (0/55.2) (2244/55.2) (3384/55.2) (4824/55.2) = 2200 rpm = 3000 rpm (2200/55.2) (3000/55.2) (4500/55.2) = 4500 rpm (0/20.8) (0/20.8) (0/20.8) (2200/18.8) (4500/16.6) (3000/18.1) (3710/0) (7537/0) (5051/0) 1000 2000 3000 4000 5000 6000 7000 8000 9000 TChar Version:0124 dT ...

- Page 187 Technical data 2.15.2.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.15.2.4.1 8LSA5...-3 / 8LSC5...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 188 Technical data 8LSA54 (standard bearing) 8LSA53 (standard bearing) 1400 1300 1200 1200 1100 1000 1000 1000 1000 1500 1500 3000 3000 4500 4500 6000 (smooth shaft 6000 rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm] Distance x [mm] maximum allowed axial force: F = 114 N...

- Page 189 Technical data 2.15.2.4.2 8LSA5...-3 / 8LSC5...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA54 (special option "reinforced A side bearing") 8LSA53 (special option "reinforced A side bearing") 4500 4500 4000 4000 3500 3500 3000 3000 1000 1000 2500...

- Page 190 Technical data 2.15.2.5 8LSC5...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Heavy-duty Reinforced A-side holding brake bearing 8LSC53.eennnffgg-3 8LSC54.eennnffgg-3 8LSC55.eennnffgg-3 8LSC56.eennnffgg-3 8LSC57.eennnffgg-3 IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 191 Technical data 2.15.2.5.1 8LSC5...-3 - Dimensions of connector options 8LS...-3 user's manual V2.50...

-

Page 192: 8Lsc5A/B/C

Technical data 2.15.3 8LSC5A/B/C...-3 - Technical data Model number 8LSC5A.ee022ffgg-3 8LSC5A.ee030ffgg-3 8LSC5A.ee045ffgg-3 8LSC5B.ee020ffgg-3 8LSC5B.ee022ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2000 2200 Number of pole pairs Nominal torque M [Nm] 27.5 26.4 45.5 Nominal power P 6336 8294 9425 9844 10482... - Page 193 Technical data Model number 8LSC5B.ee030ffgg-3 8LSC5B.ee040ffgg-3 8LSC5C.ee015ffgg-3 8LSC5C.ee022ffgg-3 8LSC5C.ee030ffgg-3 Motor Nominal speed n [rpm] 3000 4000 1500 2200 3000 Number of pole pairs Nominal torque M [Nm] Nominal power P 13195 15080 10524 14975 18221 Nominal current I 25.8 29.3 20.6 29.3 35.6...

- Page 194 Technical data 2.15.3.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC5A.eennnffgg-3 (0/84) (0/84) (0/84) (755/84) (1075/83.989) (1726/83.995) = 2200 rpm = 3000 rpm = 4500 rpm (0/31) (0/31) (0/31) (2313/0.361) (1716/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 195 Technical data 2.15.3.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC5A.eennnffgg-3 (0/84) (0/84) (0/84) (1433/84) (1951/84) (3150/84) = 2200 min = 3000 min = 4500 min (4500/42.5) (2200/39.1) (3000/37.7) (0/31) (0/31) (0/31) (2200/27.5) (3000/26.4) (4500/20) (6000/2) (4023/0.7) (2985/0) 1000 2000 3000...

- Page 196 Technical data 2.15.3.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC5A.eennnffgg-3 (0/84) (0/84) (0/84) (2040/84) (2829/84) (4470/84) = 2200 min (4500/83.5) = 3000 min (2200/76) (3000/77.5) = 4500 min (6000/47.4) (0/31) (0/31) (0/31) (2200/27.5) (3000/26.4) (4500/20) (3710/0) (5051/0) 1000 2000 3000...

- Page 197 Technical data 2.15.3.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.15.3.4.1 8LSC5A/B/C...-3 - Standard bearing 8LSC5A (standard bearing) 8LSC5B (standard bearing) 2000 2000 1800 1800 1600 1600...

- Page 198 Technical data 2.15.3.5 8LSC5A/B/C...-3 - Dimensions Motor EnDat/Resolver feedback Extension of K and M depending on motor option [mm] Holding brake Increased brake Reinforced bearing Encoder assign- All encoders All encoders ments Connector size 8LSC5A...-3 229.5 8LSC5B...-3 425.5 294.5 8LSC5C...-3 364.5 IMPORTANT: Dimension K depends on the length of the encoder cover.

-

Page 199: 8Lsc6

Technical data 2.15.4 8LSC6...-3 - Technical data Model number 8LSC63. 8LSC63. 8LSC63. 8LSC64. 8LSC64. 8LSC64. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 15.34 15.08 12.35... - Page 200 Technical data Model number 8LSC65. 8LSC65. 8LSC65. 8LSC66. 8LSC66. 8LSC66. ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 ee022ffgg-3 ee030ffgg-3 ee045ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 3000 4500 Number of pole pairs Nominal torque M [Nm] 28.6 27.3 15.86 31.85 30.55 19.5 Nominal power P 6589...

- Page 201 Technical data 2.15.4.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC63.eennnffgg-3 = 2200 min = 3000 min = 4500 min (0/47) (0/47) (0/47) (695/47) (1040/47) (1761/47) (0/16.3) (0/16.3) (0/16.3) (1699/0.2) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 202 Technical data 8LSC66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (1110/114.3) (1761/114.3) (730/114.3) = 4500 min (0/36.4) (0/36.4) (0/36.4) (1716/0) (2337/0) (3487/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 203 Technical data 2.15.4.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC63.eennnffgg-3 = 2200 min = 3000 min = 4500 min (0/47) (0/47) (0/47) (1388/47) (1971/46.9) (3244/47) (3000/21.6) (4500/24.6) (2200/21.1) (0/16.3) (0/16.3) (0/16.3) (3000/15.1) (2200/15.4) (4500/12.4) (2955/0.3) (4064/0) (6064/0) 1000 2000 3000...

- Page 204 Technical data 8LSC66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (2093/114.3) (3184/114.3) (1418/114.2) = 4500 min (3000/59) (4500/57.2) (2200/54) (0/36.4) (0/36.4) (0/36.4) (2200/31.9) (3000/30.6) (4500/19.5) (6064/0) (4064/0) (2985/0) 1000 2000 3000 4000 5000 6000 7000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 205 Technical data 2.15.4.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC63.eennnffgg-3 = 2200 min = 3000 min = 4500 min (0/47) (0/47) (0/47) (2003/47) (2854/46.9) (4500/47) (4673/47) (3000/44.3) (2200/41.4) (0/16.3) (0/16.3) (0/16.3) (2200/15.4) (3000/15.1) (4500/12.4) (3710/0) (5051/0) (7537/0) 1000 2000 3000...

- Page 206 Technical data 8LSC66.eennnffgg-3 = 2200 min = 3000 min (0/114.3) (0/114.3) (0/114.3) (2980/114.3) (3000/114.1) (4635/114.3) = 4500 min (1985/114.2) (4500/114.3) (2200/99.2) (0/36.4) (0/36.4) (0/36.4) (2200/31.9) (3000/30.6) (4500/19.5) (3710/0) (5051/0) (7537/0) 1000 2000 3000 4000 5000 6000 7000 8000 9000 TChar Version:0124 dT ...

- Page 207 Technical data 2.15.4.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.15.4.4.1 8LSA6...-3 / 8LSC6...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 208 Technical data 8LSA64 (standard bearing) 8LSA63 (standard bearing) 1400 1400 1300 1200 1200 1100 1000 1000 1000 1000 1500 1500 3000 3000 4500 4500 6000 6000 (smooth shaft rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm] Distance x [mm] maximum allowed axial force: F = 125 N...

- Page 209 Technical data 2.15.4.4.2 8LSA6...-3 / 8LSC6...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA64 (special option "reinforced A side bearing") 8LSA63 (special option "reinforced A side bearing") 5000 5000 4500 4500 4000 4000 3500 3500 1000 1000 3000...

- Page 210 Technical data 2.15.4.5 8LSC6...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Heavy-duty holding brake Reinforced A-side bearing 8LSC63.eennnffgg-3 8LSC64.eennnffgg-3 8LSC65.eennnffgg-3 8LSC66.eennnffgg-3 8LSC66.ee045ffgg-3, power connector size 1.5! IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 211 Technical data 2.15.4.5.1 8LSC6...-3 - Dimensions of connector options Size 1 8LS...-3 user's manual V2.50...

- Page 212 Technical data Size 1.5 8LS...-3 user's manual V2.50...

-

Page 213: 8Lsc7

Technical data 2.15.5 8LSC7...-3 - Technical data Model number 8LSC73.ee022ffgg-3 8LSC73.ee030ffgg-3 8LSC73.ee045ffgg-3 8LSC74.ee022ffgg-3 Motor Nominal speed n [rpm] 2200 3000 4500 2200 Number of pole pairs Nominal torque M [Nm] 28.5 26.8 21.5 36.8 Nominal power P 6566 8419 10132 8478 Nominal current I 12.84... - Page 214 Technical data Model number 8LSC74.ee030ffgg-3 8LSC74.ee045ffgg-3 8LSC75.ee022ffgg-3 8LSC75.ee030ffgg-0 Motor Nominal speed n [rpm] 3000 4500 2200 3000 Number of pole pairs Nominal torque M [Nm] 24.6 45.5 Nominal power P 10681 11592 10482 12252 Nominal current I 20.86 22.57 20.5 23.93 Stall torque M [Nm]...

- Page 215 Technical data Model number 8LSC76.ee015ffgg-3 8LSC76.ee030ffgg-3 8LSC77.ee030ffgg-3 8LSC78.ee030ffgg-3 Motor Nominal speed n [rpm] 1500 3000 Number of pole pairs Nominal torque M [Nm] 47.3 53.6 Nominal power P 10367 14860 16839 18535 Nominal current I 20.25 32.9 36.2 Stall torque M [Nm] 91.2 Stall current I...

- Page 216 Technical data 2.15.5.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC73.eennnffgg-3 (0/107) (0/107) (0/107) (584/107) (853/107) (1290/107) = 2200 min = 3000 min = 4500 min (0/33.8) (0/33.8) (0/33.8) (3435/0.3) (1716/0) (2337/0) 1000 1500 2000 2500 3000 3500 4000 TChar Version:0124 dT ...

- Page 217 Technical data 8LSC76.eennnffgg-3 (0/230) (0/230) (421/230) (935/230) = 1500 rpm = 3000 rpm (0/75) (0/75) (1169/0) (2337/0) 1000 1500 2000 2500 3000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K 8LSC77.eennnffgg-3 (0/270) (970/270) = 3000 min (0/91.2) (2337/0) 1000...

- Page 218 Technical data 2.15.5.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC73.eennnffgg-3 (0/107) (0/107) (0/107) (1105/107) (1585/107) (2370/106.9) = 2200 min = 3000 min = 4500 min (3000/39.3) (0/33.8) (0/33.8) (0/33.8) (2200/36.1) (4500/36.8) (3000/26.8) (2200/28.5) (4500/21.5) (2985/0) (6064/0) (4064/0) 1000 2000 3000...

- Page 219 Technical data 8LSC76.eennnffgg-3 (0/230) (0/230) (803/230) (1727/230) = 1500 rpm = 3000 rpm (1500/84.8) (3000/92.4) (0/75) (0/75) (1500/66) (3000/47.3) (2032/0) (4064/0) 1000 1500 2000 2500 3000 3500 4000 4500 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 220 Technical data 2.15.5.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC73.eennnffgg-3 (0/107) (0/107) (0/107) (1577/107) (2197/107) (3360/106.9) = 2200 min = 3000 min = 4500 min (3000/71.3) (4500/71.9) (2200/69.4) (6000/40) (0/33.8) (0/33.8) (0/33.8) (2200/28.5) (3000/26.8) (4500/21.5) (5051/0) (3710/0) 1000 2000 3000...

- Page 221 Technical data 8LSC76.eennnffgg-3 (0/230) (0/230) (1124/230) (2430/230) = 1500 rpm = 3000 rpm (3000/172.2) (1500/158) (0/75) (0/75) (1500/66) (4500/63.5) (3000/47.3) (2526/0) 1000 1500 2000 2500 3000 3500 4000 4500 5000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ...

- Page 222 Technical data 2.15.5.4 Maximum shaft load Note the information in section "Load capacity of the shaft end and bearing" on page 268 of chapter "Installation conditions". 2.15.5.4.1 8LSA7...-3 / 8LSC7...-3 - Standard bearing Shaft load values apply to both 8LSA and 8LSC! 8LS...-3 user's manual V2.50...

- Page 223 Technical data 8LSA74 (standard bearing) 8LSA73 (standard bearing) 2800 2600 2500 2400 2200 2000 2000 1800 1000 1000 1500 1600 1500 1500 1400 3000 3000 1200 1000 4500 4500 6000 1000 (smooth shaft 6000 rmax (smooth shaft and shaft key) rmax and shaft key) Distance x [mm]...

- Page 224 Technical data 2.15.5.4.2 8LSA7...-3 / 8LSC7...-3 - Reinforced bearing Shaft load values apply to both 8LSA and 8LSC! 8LSA74 (special option "reinforced A side bearing") 8LSA73 (special option "reinforced A side bearing") 4500 4500 4000 4000 3500 3500 3000 3000 1000 1000 2500...

- Page 225 Technical data 2.15.5.5 8LSC73/74/75...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Heavy-duty holding Reinforced A-side brake bearing 8LSC73.eennnffgg-3 137.8 8LSC73.ee045ffgg-3, power connector size 1.5 On request 8LSC74.eennnffgg-3 340.5 137.8 8LSC74.ee045ffgg-3, power connector size 1.5 353.5 141.8...

- Page 226 Technical data 2.15.5.6 8LSC76/77/78...-3 - Dimensions EnDat/Resolver feedback Extension of K and M depending on the motor option [mm] Model number Holding brake Heavy-duty holding Reinforced A-side brake bearing 8LSC76.eennnffgg-3 8LSC77.eennnffgg-3 8LSC78.eennnffgg-3 IMPORTANT: Motor option "oil seal" has no effect on the motor length. 8LS...-3 user's manual V2.50...

- Page 227 Technical data 2.15.5.7 8LSC7...-3 - Dimensions of connector options Size 1 8LS...-3 user's manual V2.50...

- Page 228 Technical data Size 1.5 8LS...-3 user's manual V2.50...

-

Page 229: 8Lsc8

Technical data 2.15.6 8LSC8...-3 - Technical data Model number 8LSC83.ee015ffgg-3 8LSC83.ee022ffgg-3 8LSC83.ee030ffgg-3 8LSC84.ee015ffgg-3 Motor Nominal speed n [rpm] 1500 2200 3000 1500 Number of pole pairs Nominal torque M [Nm] 45.5 40.3 35.1 75.4 Nominal power P 7147 9284 11027 11844 Nominal current I 18.2... - Page 230 Technical data Model number 8LSC84.ee022ffgg-3 8LSC84.ee030ffgg-3 8LSC85.ee015ffgg-3 8LSC85.ee020ffgg-3 Motor Nominal speed n [rpm] 2200 3000 1500 2000 Number of pole pairs Nominal torque M [Nm] 66.95 62.92 100.1 93.6 Nominal power P 15424 19767 15724 19604 Nominal current I 30.2 38.6 30.7 38.2...

- Page 231 Technical data Model number 8LSC86.ee015ffgg-3 8LSC86.ee020ffgg-3 Motor Nominal speed n [rpm] 1500 2000 Number of pole pairs Nominal torque M [Nm] 126.1 110.5 Nominal power P 19808 23143 Nominal current I 38.7 42.8 Stall torque M [Nm] 149.5 Stall current I 45.9 57.9 Maximum torque M...

- Page 232 Technical data 2.15.6.1 Speed-torque characteristic curves at 325 VDC DC bus voltage 8LSC83.eennnffgg-3 = 1500 rpm (0/120) (0/120) (0/120) (649/120) (927/120) (1262/120) = 2200 rpm = 3000 rpm (0/52) (0/52) (0/52) (1169/0) (1716/0) (2337/0) 1000 1500 2000 2500 3000 TChar Version:0124 dT ...

- Page 233 Technical data 8LSC86.eennnffgg-3 = 1500 min (0/345) (678/345) (0/149.5) (1169/0) 1000 1200 1400 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...

- Page 234 Technical data 2.15.6.2 Speed-torque characteristic curves at 560 VDC DC bus voltage 8LSC83.eennnffgg-3 = 1500 rpm (0/120) (0/120) (0/120) (1230/120) (1686/120) (2304/120) = 2200 rpm = 3000 rpm (1500/78.9) (2200/67.1) (3000/70.2) (0/52) (0/52) (0/52) (1500/45.5) (2200/40.3) (3600/30.8) (3000/35.1) (2032/0) (2985/0) 1000 1500 2000...

- Page 235 Technical data 8LSC86.eennnffgg-3 = 1500 min (0/345) (1240/345) (1500/217.2) (0/149.5) (1500/126.1) (2032/0) 1000 1500 2000 2500 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...

- Page 236 Technical data 2.15.6.3 Speed-torque characteristic curves at 750 VDC DC bus voltage 8LSC83.eennnffgg-3 (0/120) (0/120) (0/120) (3294/120) (1793/120) (2448/120) (1500/120) (3000/120) (2200/120) (3600/102.5) = 1500 rpm = 2200 rpm = 3000 rpm (0/52) (0/52) (0/52) (1500/45.5) (2200/40.3) (3000/35.1) (3600/25.1) (2526/0) 1000 1500 2000...

- Page 237 Technical data 8LSC86.eennnffgg-3 = 1500 min (0/345) (1806/345) (1500/345) (0/149.5) (1500/126.1) (2526/0) 1000 1500 2000 2500 3000 TChar Version:0124 dT ... 100K Speed [rpm] DB Version:2018 06 12 dT ... 60K dT ... 60K 8LS...-3 user's manual V2.50...