Summary of Contents for ADENDORFF VLS8TS-1

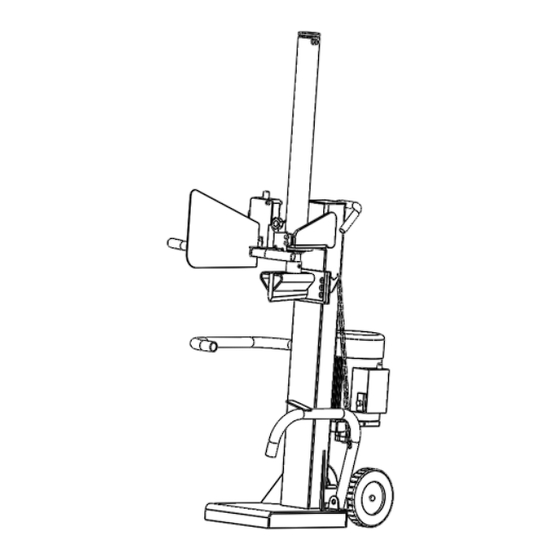

- Page 1 Original Instructions Instruction Manual For Hydraulic Log Splitter VLS8TS-1 Read and understand the entire manual before operating machine. Save this manual for future reference.

-

Page 2: Safety Instructions

Instruction manual 1. Read Carefully the instruction manual before operation. Do not allow person to operate until they have read the safe operating instruction contained this manual This warning sticker is to remind the operator to read the manual and make himself familiar with all safe instructions before starting to work on the machine. -

Page 3: Prevent Fires

-NEVER operate the machine without wearing protective shoes , glasses tight-fitting gloves and apparels -NEVER remove from your log splitter the safety tools and devices mounted on the machine by the manufacturer. -NEVER leave the machine unattended with the running motor . Assure full compliance with all applicable and traffic and safety rules in your country and especially with applicable health and safety previsions on the workplace. - Page 4 maintenance/repair instructions in order to avoid happening of any injury or dangerous condition . BEWARE: this unit has a log capacity of min 80 mm and max 350 mm diameter. Danger! Keep clear of moving parts! Danger! Keep clear of moving parts! ●...

-

Page 5: Application Conditions

• Before using the product, make sure the two hands controls function! • Before starting work, inspect the hydraulic connections:no damages, no leakage and etc affect the normal operation. • Make sure a suitable working area free from obstructions e.g. logs, split wood ect •... - Page 6 3.3 Hydraulic specs The machine is equipped with own hydraulic oil tank located inside the main table pipe and is supplied by the manufacturer with a first oil fill. BEWARE: a leaning splitter position during transport may result into oil leakage from the oil plug. At low ambient temperature the oil in the hydraulic circuit will thicken.

- Page 7 3.6 WARNING The location you choose for your machine should be flat, dry, and sold. Check around log splitter for hazards. Make sure that the area is free of slippery surfaces and objects to over. Slippery and icy floor conditions must be duly treated to assure solid standing conditions. 1)Never reach with your hands at pinch points where they can get caught by the traveling wedge! 2)Never try to split such hard Across-the-Grain wood and never try to split such...

- Page 8 Wood clamping before splitting: 3.7 Operation Firstly place the log on the working table and lean it against the log fixing device; Secondly press down the two operation handles to let the wedge run towards the log with wedge pressing on the top of the log. DO NOT RELEASE THE CONTROL LEVERS UNTIL THE CYCLE IS COMPLETELY OVER AND THE LOG IS SPLIT.

-

Page 9: Maintenance Instructions

(2)Unscrew the two bolts from the cylinder fixing part on both sides. Moving handle (2) Then start machine again to press down operation handles again to make the cylinder going down. After all above 2 steps are taken,operator can move the log splitter by the moving handle. 5.Maintenance instructions Do not install, repair, clean or handle the log splitter when the machine is still running and without having securely clamped the wedge. - Page 10 Make maintenance regular part of daily operation. The daily maintenance routine needs to include -Cleaning of the machine and cleaning of all parts from residual wood debris. chips, dust, bark pieces and eventual other waster. -Greasing of the sliding pads inside the sliding casing(ram) -Hydraulic oil check and(in case of leakage)hydraulic hose and fittings check-up to detect eventual oil leaks -Lubrication of all moving parts...

- Page 11 6.2 Electric diagram BEWARE: only let expert skilled staff do electric repair/maintenance works! As for all electric tools and equipment we strongly recommend use a portable residual current device (PRCD).unless you already have a residual current device (RCD)in your house assuring safety and Protection up to max 0.03Anominal fault current.

- Page 12 6.4 HYDRAULIC DIAGRAMM 7.Risk factors 7.1Mecnanical dangers The special two –hands control mechanisms minimizes risks and dangers related to moving parts on the machine An additional safety provided on the machine in order to prevent working with only one handle while the other...

-

Page 13: Troubleshooting Chart

one is being engaged (held down) by some mechanical tool or system . DO NOT EVER ATTEMPT to remove or by-pass the two-hands control Danger operating the splitter without the safety two-hands control will increase your risk of having your hands pinched during the splitting cycle Do not remove any other safety and protection device the machine. - Page 14 Steel stud Wedge Move back wedge towards steel stud and fit the screws on the steel stud. Then tighten the two nuts M8. Protection guard Fix the protection guard with 2 screws M6x8, 2 spring washers ø6, 2 flat washers ø6.

- Page 15 Control lever 1.Rotate the control lever upwards and make it match the hole on the valve seat. 2.Fit the control lever into position using the bolt supplied as shown . The bolt should pass through the hole on the valve seat . 3.Then tighten the nut.

- Page 16 Wood lifting frame Hook chain Fix the wood lifting frame with screws M12*50,spring washer ø12,flat washer ø12. Put the chain on the hook. Technicai specifications Model number VLS8TS-1 Voltage 230V/50Hz Max Log splitting length 700mm Min log diameter 80mm Max log diameter...

Need help?

Do you have a question about the VLS8TS-1 and is the answer not in the manual?

Questions and answers