Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SilverStone ES14-3300

- Page 1 E S 1 4 - 3 3 0 0 / E S 1 6 - 5 0 0 0...

- Page 2 WARNING WARNING! ! ! ! WARNING WARNING PREVENT PREVENT SETIOUS SETIOUS RISK RISK INJURY INJURY TO PREVENT PREVENT SETIOUS SETIOUS RISK RISK OF OF INJURY INJURY TO YOUORSELF YOUORSELF YOUORSELF YOUORSELF AND AND OTHERS OTHERS OTHERS OTHERS OBSERVE OBSERVE OBSERVE OBSERVE THE FOLLOWING SAFETY...

- Page 3 9. All hydraulic systems shall be regularly inspected and maintained in conformance with good practice. Cylinders, valves and other similar parts shall be checked to assure that "drift" has not developed to the extent that it would create a hazard. 10.

-

Page 4: Table Of Contents

catalog catalog catalog catalog Correct Correct application application ................... 1 1 1 1 Correct Correct use use and and application application......................................................... 1. 1. 1. 1. Truck Truck Truck Truck Description Description Description Description..........................................2 2 2 2 ...................... -

Page 5: Correct Correct Use Use Use And And And Application Application

Correct Correct Correct Correct use use and and application application application application The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are supplied with the truck. The guidelines form part of these operating instructions and must be observed. National regulations apply in full. The truck described in the present operator manual is an industrial truck designed for lifting and transporting load units. -

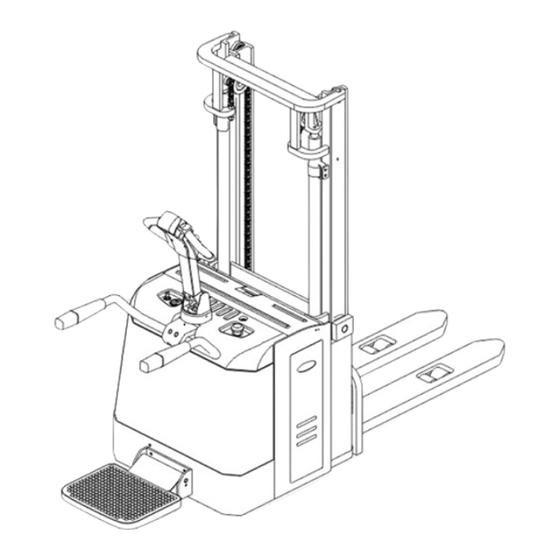

Page 6: 1. 1. 1. 1. Truck

1. 1. 1. 1. Truck Truck Truck Truck Description Description Description Description 1.1Assemblies Assemblies Assemblies Assemblies Item Component Item Component Folding operator pedal Control Handle Side arm Emergency brake swich Battery discharge indicator Mast Key switch Lift mechanism... - Page 7 1.1.1 1.1.1 Folding Folding operator operator pedal pedal 1.1.1 1.1.1Folding Folding operator operator pedal pedal Folding operator pedal have two state: fold and unfold. While the state of Folding operator pedal changed the Travel speed (Max) changed too. Because of gas spring the folding operator pedal can fold self-motion.

- Page 8 Power Power Power Power up up test test test test On power up the display shows: – the operating hours – the charge status 1.1.4 1.1.4 switch switch 1.1.4 1.1.4Key Key switch switch Switches control current on and off. Removing the key prevents the truck from being switched on by unauthorised personnel.

-

Page 9: Identification Points And Data Plates

1.2 Identification Identification Identification Identification points points points points and and data data data data plates plates plates plates Item Description Suspend direction EP decal “Never stand under the forks” and “Never stand or ride on forks for any reason” warning “Never put your hands in inner and outer mast.“... -

Page 11: 1.3Specifications

1.2.1 1.2.1 Truck Truck data data plate plate 1.2.1 1.2.1Truck Truck data data plate plate Item Description Item Description Model name Max. allowable battery weight(kg) Type Min. allowable battery weight(kg) Serial no. load-lift height table Nominal load centre(mm) Manufacturer Weight without battery(kg) adress Nominal voltage(V)... - Page 12 Raise lift speed(Max) Fully load mm/s 115 Non-load Lowering lift speed Fully load mm/s Travel speed (Max) Fully load Km/h Non-load Max. grade ability (5 min Fully load rating) Non-load Turning radius Pedal folded (w1) 1665 Pedal unfold (w2) 2130 Ground clearance(m2) Fork dimension Length (l)

-

Page 14: Transport 2.Transport And And And Commissioning Commissioning

2. 2. 2. 2.Transport Transport Commissioning Transport Transport and and Commissioning Commissioning Commissioning Transport Transport 2.1Transport Transport 2.1.1 2.1.1 Lifting Lifting truck truck crane crane 2.1.1 2.1.1Lifting Lifting the the truck truck by by crane crane 1.Only use crane lifting gear with sufficient capacity. -

Page 15: During Brake-In

than 6 m . Preparing the truck for operation after delivery or transport Procedure – Check the equipment is complete. – Check the hydraulic oil level. – Install the battery if necessary, (see "4.4 Battery removal and installation" on page 19). -

Page 16: Operation 3.Operation

3. 3. 3. 3.Operation Operation Operation Operation 3.1Safety 3.1Safety Regulations Regulations Operation Operation Operation of of of of Forklift Forklift Forklift Trucks Trucks 3.1Safety 3.1Safety Regulations Regulations for for the the Operation Forklift Trucks Trucks Driver Driver authori authori authoris s s s ation: ation: ation: Driver... - Page 17 Checks Checks Checks Checks and and operations operations operations operations to to to to be be performed performed performed performed before before before before starting starting starting starting daily daily daily daily work work work work – Visually inspect the entire truck (in particular wheels and load handler) for obvious damage.

- Page 18 – Make sure the battery is connected Warning! Warning! Warning! Warning! – Insert the key in the key switch ( 4 ) Before operating the truck, check all and turn it to the right as far as it will go. controls and warning devices for –...

- Page 19 Travel Travel Travel Travel Do not reach between the operator pedal and the truck panel when you fold up the pedal. We distinguish between two travel modes: Truck with a folding operator pedal and moving handle. – Pedestrian mode: Push the side arms in, fold up the operator pedal (1). The truck can only be operated at the reduced travel speed.

-

Page 20: Safety Regulations For Truck Operation

3.2.4Parking 3.2.4Parking truck truck securely securely 3.2.4Parking 3.2.4Parking the the truck truck securely securely When you leave the truck it must be securely parked even if you only intend to leave it for a short time. – Do not park the truck on an incline. –... -

Page 21: Collecting And Depositing Loads

Persons riding in the lift with the forklift truck must only enter the lift after the truck has come to a rest and must leave the lift before the truck. Collecting Collecting depositing depositing loads loads 3.4 Collecting Collecting and and depositing depositing loads loads... -

Page 22: Maintenance

4.Battery Maintenance Maintenance & & & & Charging Charging 4.Battery 4.Battery 4.Battery Maintenance Maintenance Charging Charging Safety Safety regulations regulations handling handling acid acid batteries batteries 4.1 Safety Safety regulations regulations for for handling handling acid acid batteries batteries Park the truck securely before carrying out any work on the batteries. Maintenance personnel personnel : : : :... -

Page 23: Battery Type & Dimension

Battery Battery Disposal: Disposal: Battery Battery Disposal: Disposal:Batteries may only be disposed of in accordance with national environmental protection regulations or disposal laws.The manufacturer’s disposal instructions must be followed. Before closing the battery cover make sure that the battery lead cannot be damaged. Batteries contain an acid solution which is poisonous and corrosive . -

Page 24: Battery Removal And Installation

4.3.2Charging 4.3.2Charging battery battery 4.3.2Charging 4.3.2Charging the the battery battery Safety Safety regulations regulations Charging Charging battery battery Safety Safety regulations regulations for for Charging Charging the the battery battery – To charge the battery, the truck must be parked in a closed and properly ventilated room. - Page 25 – Expose the battery ( see 4.3.1 Exposing the battery Page 18 ). – Remove the battery connector (3). – Strap the crane lifting gear to the eyes (8). –Drawing back the emergency brake switch. When replacing a battery always use the same battery type. Extra weights must not be removed and must remain in the same position.

-

Page 26: Forklift 5.Forklift Truck Truck Truck Maintenance Maintenance Maintenance

5.Forklift 5.Forklift Truck Truck Maintenance Maintenance 5.Forklift 5.Forklift Truck Truck Maintenance Maintenance 5.1Operational 5.1Operational safety safety environmental environmental protection protection 5.1Operational 5.1Operational safety safety and and environmental environmental protection protection – The servicing and inspection operations contained in this chapter must be performed in accordance with the intervals indicated in the servicing checklists. -

Page 27: Servicing And Inspection

and electronic components must be carefully covered beforehand as moisture can cause malfunctions. Do not clean with pressurised water. After cleaning the truck, carry out the activities detailed in the “ Recommission (on page 27)” section. Electrical Electrical System System Electrical Electrical System System... - Page 28 C = Every 2000 operating hours, or at least annually W service intervals are to be performed by the customer. In the run-in period - after approx. 100 service hours - or after repair work, the owner must check the wheel nuts/bolts and re-tighten if necessary. 5.3.1Maintenance 5.3.1Maintenance Checklist...

- Page 29 Standard = ★ Cold Store = ☆ ★ Truck design Test the operator’s platform and check for damage. ★ Check chassis for damage and screw connections. ★ Check labels. ★ Hydraulic Check operation, wear and setting. operation ★ Check forks for wear and damage. ☆...

- Page 30 5.3.2 5.3.2 Lubrication Lubrication Schedule Schedule 5.3.2 5.3.2 Lubrication Lubrication Schedule Schedule...

- Page 31 Fuels, Fuels, coolants coolants lubricants lubricants Fuels, Fuels, coolants coolants and and lubricants lubricants Handling Handling consumables: consumables: Handling Handling consumables: consumables: Consumables must always be handled correctly. Follow the manufacturer’s instructions. Improper handling is hazardous to health, life and the environment. Consumables must only be stored in appropriate containers.

- Page 32 The drive wheel must only be replaced by authorised service personnel. Checking Checking hydraulic hydraulic level level Checking Checking the the hydraulic hydraulic oil oil level level – Prepare the truck for maintenance and repairs ( See 5.3.3 Maintenance Instructions Page26 ). –...

-

Page 33: Decommissioning The Industrial Truck

The truck may only be recommissioned after cleaning or repair work, once the following operations have been performed. – Test horn. – Test Emergency brake swich. – Test brake. – Lubricate the truck in accordance with the maintenance schedule. 5.4Decommissioning 5.4Decommissioning industrial industrial... -

Page 34: Safety Checks To Be Performed At Regular Intervals And Following Any Unusual Incidents

– Clean the battery, grease the terminals and connect the battery. – Charge the battery (See 4.3Charging the battery P18). – Check transmission oil for condensed water and replace if necessary. – Check hydraulic oil for condensed water and replace if necessary. –... -

Page 35: Troubleshooting 6.Troubleshooting

6.Troubleshooting 6.Troubleshooting 6.Troubleshooting 6.Troubleshooting This chapter is designed to help the user identify and rectify basic faults or the results of incorrect operation. When locating a fault, proceed in the order shown in the table. Fault Possible cause Action Truck does –...

Need help?

Do you have a question about the ES14-3300 and is the answer not in the manual?

Questions and answers