Table of Contents

Advertisement

Quick Links

Visit the SoundLok

Installation Video on the Wenger Youtube.com channel.

Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Important User Information . . . . . . . . . . . . . . . . . . . . . . .2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Fastener Parts List - Floor Frame . . . . . . . . . . . . . . . . . .4

Fastener Parts List - Door . . . . . . . . . . . . . . . . . . . . . . . .4

Fastener Parts List - Ceiling . . . . . . . . . . . . . . . . . . . . . .4

Fastener Parts List - Closures. . . . . . . . . . . . . . . . . . . . .4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Floor Frame and Door Assembly . . . . . . . . . . . . . .6

Floor Frame Leveling . . . . . . . . . . . . . . . . . . . . . . .10

Wall Panel Installation . . . . . . . . . . . . . . . . . . . . . . .11

Communication Conduit . . . . . . . . . . . . . . . . .13

Communication Conduit . . . . . . . . . . . . . . . . .13

Extended Height Option . . . . . . . . . . . . . . . . . . . . .14

Ceiling Frame Rail Beam Option . . . . . . . . . . . . . .15

Ceiling Frame Rails . . . . . . . . . . . . . . . . . . . . . . . . .16

Note: Please read and understand the SoundLok

before starting the installation.

Note: Remove all items from the shipping containers and sort the components by type, size, etc.

Refer to the illustrations on the following pages. If you need additional information,

contact the Wenger Corporation using the information below.

©Wenger Corporation 2019

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: (800) 4WENGER (493-6437) • Worldwide: +1-507-455-4100 • wengercorp.com

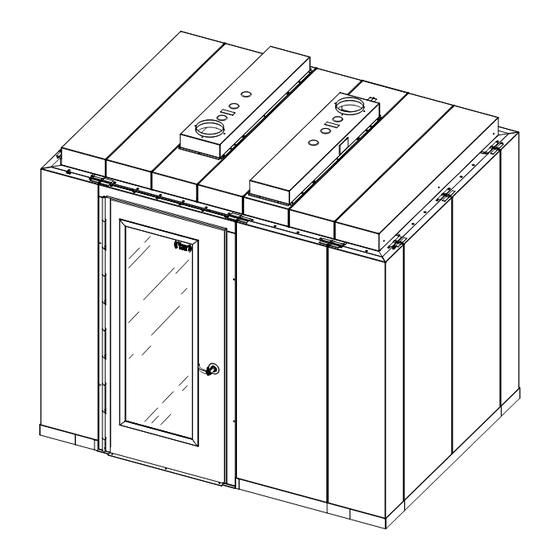

SoundLok

Sound-Isolation Room

®

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Horizontal Closures . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Vertical Closures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

®

Printed in USA 2019-01

Assembly Instructions

Sound-Isolation Room

®

Ceiling Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

HVAC Ceiling Panels . . . . . . . . . . . . . . . . . . . . . . .19

Inside Ceiling Trim . . . . . . . . . . . . . . . . . . . . . . . . .20

Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door Seal Adjustment . . . . . . . . . . . . . . . . . . . . . . .26

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Hole Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Door Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Clean the Panels . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Electrical Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Optional Communications Panel . . . . . . . . . . . . . . .28

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Door Hinge Lubrication . . . . . . . . . . . . . . . . . . . . . .34

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Horizontal Window Glass Replacement . . . . . . . . .35

Magnetic Gasket Replacement . . . . . . . . . . . . . . . .36

Sweep Seal Gasket Replacement . . . . . . . . . . . . .36

Key Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .36

Sound-Isolation Room Assembly Instructions

Part #270A673-09

Advertisement

Table of Contents

Summary of Contents for Wenger SoundLok

-

Page 1: Table Of Contents

Refer to the illustrations on the following pages. If you need additional information, contact the Wenger Corporation using the information below. ©Wenger Corporation 2019 Printed in USA 2019-01 Part #270A673-09 Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448 Questions? Call..USA: (800) 4WENGER (493-6437) • Worldwide: +1-507-455-4100 • wengercorp.com... -

Page 2: Safety Precautions

In no event will Wenger Corporation be liable for technical or editorial omissions made herein, nor for direct, indirect, special, incidental, or consequential damages resulting from the use or defect of this manual. -

Page 3: Before You Begin

Moving doors requires four electrician. with local electrical codes. people working together. Required Tools The following tools are required to assemble the SoundLok Sound-Isolation Room. The following tools are required to assemble the Inset Floor Option. · Mallet Flat Head Screwdriver ·... -

Page 4: Fastener Parts List - Floor Frame

Fastener Parts List - Floor Frame Machine Screw, ¼-20 x .590 Fastener Parts List - Door Machine Screw, Machine Screw, Set Screw, Allen. Socket Screw, ¼-20 x .590 ¼-20 x ⅝" -18 x ½" -16 x 1" Hole Plug, " HOLE PLUG,3/4",PAINTED,C Fastener Parts List - Ceiling Washer, Neoprene,... -

Page 5: Electrical Connections

Electrical Connections Wenger will supply the customer with a power panel kit prior to the SoundLok installation date. This hardware will allow Wenger to connect the ETL Classified electrical system to the customer's house service using the following steps. 1. A certified electrician must wire the outlet to house power. House power requirements are 120V, 60 HZ, 20 amp circuit for each connector. -

Page 6: Installation

The SoundLok door frame is shipped fully assembled in a wooden crate. 3. Remove the screws holding the side and top panels of the door crate. - Page 7 Installation (continued) Floor Frame and Door Frame Assembly (continued) 5. Adjust the levelers on the underside of the door assembly so that when it is upright, it will stand vertical, level and square to the floor. Leveler Leveler Note: Do not extend levelers beyond the gaskets attached to the underside of the door frame assembly.

- Page 8 Installation (continued) Floor Frame and Door Frame Assembly (continued) 8. According to the layout plan drawing, ¼-20 x 0.59 attach the appropriate floor frame side Machine Screws piece to each door connect bracket using two ¼-20 x 0.59 machine ¼-20 x 0.59 screws as shown.

- Page 9 Installation (continued) Floor Frame and Door Frame Assembly (continued) 11. With the door frame in it's permanent location, check the door frame Vertical to be sure that the vertical frame edges stand plumb to be able to Frame Edge mate with the wall panels when they are installed. 12.

-

Page 10: Floor Frame Leveling

Installation (continued) Floor Frame Leveling and Adjustment 1. With the floor frame and door frame connected, check that the entire frame assembly is the correct distance from the wall according to the layout plan drawing. Also check that the frame assembly is square by measuring diagonally from corner to corner. -

Page 11: Wall Panel Installation

Installation (continued) Wall Panel Installation If the optional Inset Floor has been installed, the Inset Floor Door Trim should now be installed following the procedure in 271A210. 1. Locate and identify all of the wall panels sections. These must be installed exactly as indicated in the layout plan drawing. - Page 12 Installation (continued) Wall Panel Installation (continued) 5. Work in a clockwise direction and continue to install the remaining wall panel sections according to the layout plan drawing. a. Repeat Steps 3 and 4, locking the roto locks in the next wall panel section to the previously installed wall panel section.

-

Page 13: Horizontal Window Option With Offset Communication Conduit

Installation (continued) Horizontal Window Option With Offset Communication Conduit The horizontal window wall panel is attached in three sections. Top Panel Section 1. Place the bottom panel section in position on the floor frame. Attach it to the adjacent panel sections by turning the roto locks. 2. -

Page 14: Extended Height Option

Installation (continued) Extended Height Option Rooms taller than 7'6" (2286 mm) will require a header panel over the door to close off the space. If this is a standard height room, this step is not required. Continue on to "Ceiling Frame Rails". 1. -

Page 15: Ceiling Frame Rail Beam Option

Installation (continued) Ceiling Frame Rail Beam Option Larger rooms may require a ceiling frame rail beam to support the ceiling panels. Check the layout plan drawing to determine if this is required and attach it as follows. If it is not required, continue on with the assembly. 1. -

Page 16: Ceiling Frame Rails

Installation (continued) Ceiling Frame Rails 1. Position the first ceiling frame rail on top of the wall panel section that was installed first. 2. Loosely attach the ceiling frame rail to the top of the wall panel section using a "... -

Page 17: Ceiling Panels

Installation (continued) Ceiling Panels 1. Position the first end ceiling panel at the end of the room with the roto locks facing inside the room. 2. Loosely attach the ceiling panel to the frame rail using a " flat washer and a -20 x "... - Page 18 Installation (continued) Ceiling Panels (continued) 3. Locate the next inside ceiling panel in the order according to the layout plan drawing. IMPORTANT: Male roto locks must be used in all end ceiling panels. Switching roto lock configuration between male and female may be required on mating panels.

-

Page 19: Hvac Ceiling Panels

Installation (continued) HVAC Ceiling Panels If the ceiling contains HVAC ceiling panels, ceiling vent adapters are installed to them as follows. 1. Position the ceiling vent adapter on top of the HVAC ceiling panel by aligning the pre-drilled holes. 2. Attach the ceiling vent adapter to the HVAC ceiling panel through the pre-drilled holes using #8-15 x "... -

Page 20: Inside Ceiling Trim

Installation (continued) Inside Ceiling Trim The inside ceiling trim covers the ceiling rail frame inside of the room. 1. Hook the upper lip of the inside ceiling trim over the top of the ceiling rail frame tab. Install the straight sections first followed by the corner sections. 2. -

Page 21: Door Assembly

Installation (continued) Door Assembly This procedure is described for a 36" (914 mm) or 48" (1219 mm) door. For 90" (2286 mm) Double Doors, see the instructions in 270A837. 1. Inspect the dust box in the door frame to be sure that it is properly recessed behind the strike plate and will not interfere with the door latch bolt as it passes through the strike plate. - Page 22 Installation (continued) Door Assembly (continued) 2. Lift the door assembly from the crate and transport it to the set-up position. Use of a SoundLok Door Dolly and Leaf Adjustment Tool is recommended. CAUTION CAUTION Do not slide the door The door assembly is heavy.

- Page 23 Installation (continued) Door Assembly (continued) 4. Loosely attach the door assembly to the door frame using a -16 x 1" socket screw in the five sets of aligned pre-drilled holes. -16 x 1" Socket Screw...

- Page 24 Installation (continued) Door Assembly (continued) 5. Position the door assembly to leave " (19 mm) between the hinge barrels and the outside face of the door frame. See Detail A This should result in a 1- " (44 mm) space between the inside face of the door frame and the inside of the door.

- Page 25 Installation (continued) Door Assembly (continued) 6. Close and latch the door. Inspect the compression of the foam seal on the latch side of the door. It should be approximately equal from the top to the bottom of the door. If adjustment is necessary, use a pry bar or shim to hold the door hinge at it's current elevation and loosen the top and bottom mounting screws.

-

Page 26: Door Seal Adjustment

Installation (continued) Door Seal Adjustment If instaling a double door, resume the procedure at this point after the doors been assembled according to the instructions in 270A837. If necessary, the sweep seal can be adjusted to ensure proper fit and to prevent sound leaks. 1. -

Page 27: Lights

Installation (continued) Door Seal Adjustment (continued) 7. Continue checking and making adjustments until the door and sweep seal pass the adjustment checks. Then make certain all four sweep seal screws are tight. 8. Inspect the fit between the magnetic seals and the door stops. They should be approximately parallel. -

Page 28: Electrical Connections

3. Connect the house service connector cable from the electrical panel to the connector on the wall (preinstalled by electrician). Turn on the lights and fans to ensure that they are working. For more information, refer to the "SoundLok Electrical Panel Interconnection" Installation Manual. Optional Communications Panel... -

Page 29: Horizontal Closures

Horizontal Closures To install horizontal closures across the top front surface of the sound-isolation room, proceed with the following steps: 1. Install closure brackets along the top surface of the wall panel sections at the front of the room. a. Space the brackets a maximum of 2-feet (610 mm) apart. b. - Page 30 Horizontal Closures (continued) 3. Cut pvc closure extrusions and the closure panel board to fit the length of the area being covered. a. Secure the bottom of the closure panel to the closure bracket using #12 x 1¾" self-tapping screws leaving ⅛" (3 mm) space under the closure board to accomodate the thickness of the pvc closure t-extrusions.

-

Page 31: Vertical Closures

Vertical Closures To install vertical closures along front surface of the sound-isolation room, proceed with the following steps: 1. Install 2 x 4" metal studs offset from the front surface of the wall panel sections at the front of the room. a. - Page 32 Vertical Closures (continued) 2. Attach the closure panels to the 2 x 4" metal studs. a. Cut the closure panel boards to fit the areas being covered. b. Secure the closure panels to the 2 x 4" metal studs using #12 x 1¾" self-tapping screws leaving ⅛"...

- Page 33 Vertical Closures (continued) 3. Attach pvc closure extrusions and floor rail pvc extrusions to the closure panels. a. Cut the length of the pvc closure l-extrusions to fit along the side edges of the closure panels. b. Cut the length of the pvc closure t-extrusions to fit along the top edge of the closure panels. c.

-

Page 34: Maintenance

Maintenance Cleaning Painted Surfaces — Any commercial non-abrasive cleaner. Glass — Any commercial glass cleaner. Floor — Standard floor cleaner. Vent Grille — Remove, clean in a commercial detergent and replace. Perforated Surfaces — Only slightly dampen a sponge or rag with water. (Chemicals or excessive water can promote corrosion. -

Page 35: Horizontal Window Glass Replacement

Maintenance (continued) Horizontal Window Glass Replacement 1. Inner Most Glass Panel a. Remove the glass retainers on the inside of the room. b. Remove the pane of glass. Note: Glass can be heavy. c. Remove the upper and lower horizontal separators (perforated metal). d. -

Page 36: Magnetic Gasket Replacement

Maintenance (continued) Magnetic Gasket Replacement 1. Open the top leg of the aluminum gasket retainer with a wide flat bladed screwdriver. Do not destroy basic shape of lip. 2. Open the legs of the vertical retainers at the extreme bottom where the gasket is held from dipping below the retainer.

Need help?

Do you have a question about the SoundLok and is the answer not in the manual?

Questions and answers