Reliable QRM2 Series Installation, Operation And Maintenance Manual

Riser and tank mounted quiet oil-less air compressors, 60hz

Hide thumbs

Also See for QRM2 Series:

- Installation, operation and maintenance manual (15 pages) ,

- Installation, operation and maintenance manual (14 pages)

Table of Contents

Advertisement

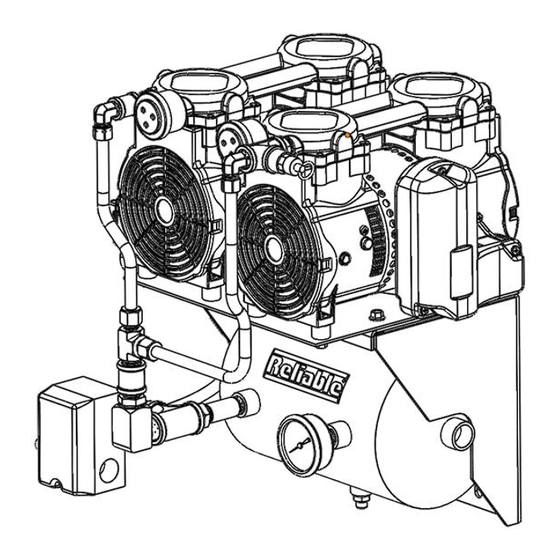

QRM2- Series

Riser and Tank Mounted

Quiet Oil-less Air Compressors

Installation, Operation and

Maintenance Manual

For 60Hz Models Only

Reliable Automatic Sprinkler Co., Inc.

103 Fairview Park Drive, Elmsford, New York 10523

800-55-RASCO (800-557-2726) Technical Support

www.reliablesprinkler.com

Reliable QRM2- Series IOM_Rev 1.7_2-4-20

Advertisement

Table of Contents

Summary of Contents for Reliable QRM2 Series

- Page 1 Riser and Tank Mounted Quiet Oil-less Air Compressors Installation, Operation and Maintenance Manual For 60Hz Models Only Reliable Automatic Sprinkler Co., Inc. 103 Fairview Park Drive, Elmsford, New York 10523 800-55-RASCO (800-557-2726) Technical Support www.reliablesprinkler.com Reliable QRM2- Series IOM_Rev 1.7_2-4-20...

-

Page 2: Table Of Contents

Table of Contents Section 1 - Safety & Warnings 1.1 - Safety Guidelines 1.2 - General Information 1.3 - General Safety Information 1.4 - Safety Notes Section 2 - Receiving Section 3 - Installation Location Section 4 - Mounting 4.1 - General Information 4.2 - Basic Instructions - Riser Mounting Bracket 4.3 - Basic Instruction - QRM2- Mounting Bracket Section 5 - Lubrication... -

Page 3: Section 1 - Safety & Warnings

Section 1 - Safety & Warnings 1.1 Safety Guidelines This manual contains information that is very important to know and understand. This information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols. - Danger indicates an imminently hazardous situation which, if not avoided, WILL DANGER result in death or serious injury. -

Page 4: Section 2 - Receiving

Compressed air contains liquid water and is saturated with water vapor, which can WARNING freeze when surrounding temperatures are lower than 32 F (0 C). Component selection to minimize the effects of water vapor must be considered. - Do not touch any component inside compressor enclosure or on the discharge piping WARNING when the compressor is operating or immediately after it has stopped. -

Page 5: Basic Instructions - Riser Mounting Bracket

4.2 Basic Instructions - Riser Mounting Bracket Riser Mounting Kit (RMK) Contents: A - Mounting Straps: Each RMK comes with 3 mounting straps. B - Riser Mounting Plate C - Nuts, Bolts, and Washers. Necessary for mounting the QRM2- Bracket. D - Mounting Hooks Riser Mounting Kit (RMK) Mounting: Bring the mounting straps in from the back side... -

Page 6: Section 5 - Lubrication

Section 5 - Lubrication - This compressor is designed for non-lubricated service. Bearings are permanently NOTICE lubricated. Do not lubricate any part of the compressor or motor. Section 6 - Piping 6.1 Piping Instructions - Compressed air contains liquid water and is saturated with water vapor, which can WARNING freeze when surrounding temperatures are lower than 32°F (0°C). -

Page 7: Qrm2- Series Riser Mounted Quiet Oilless Air Compressor Installation Drawing

Section 6 - Piping 6.2 QRM2- Series Riser Mounted Oilless Air Compressor Installation Drawing... -

Page 8: Qrm2-T Series Tank Mounted Quiet Oilless Air Compressor Installation Drawing

6.3 QRM2-T Series Tank Mounted Oilless Air Compressor Installation Drawing... -

Page 9: Section 7 - Wiring

Section 7 - Wiring 7.1 Wiring Instructions - Wiring should be in accordance with the National Electrical Code (NEC) and any local WARNING codes or regulations. Have a licensed and competent electrician ensure that the voltage supplied matches the compressor voltage. CAUTION - Inadequate wiring size can cause insufficient voltage at the compressor during start-up. -

Page 10: Oilless Air Compressor Single Phase Wiring Drawing

7.2 Oilless Air Compressor Single Phase Wiring Drawing... -

Page 11: Section 8 - Adjusting The Pressure Switch

*Differential Pressure is defined as the difference between cut-out and cut-in pressure. Turning the differential pressure screw clockwise increases the differential pressure, which increases the cut-out pressure without changing the cut-in pressure. QRM2- Replacement Parts Without Tank Reliable P/N 6990021904 Pressure Switch With Tank Reliable P/N 6990021905 Check Valve... -

Page 12: Section 9 - Maintenance Instructions

3. Air flow to fan blocked 3. Clean air flow to fan or relocate unit 1. Damaged bearings 2. Worn piston cup Excessive noise in Contact Reliable for technical support 3. Broken valves operation 4. Loose fan 5. Damaged fan guard 1. -

Page 13: Section 11 - Warranty Policy

Replacement parts provided under the terms of the warranty are warranted which may vary from those in neighboring areas. While Reliable Automatic for the remainder of the Warranty Period of the product upon which Sprinkler Co., Inc.

Need help?

Do you have a question about the QRM2 Series and is the answer not in the manual?

Questions and answers