Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Carbide3D SHAPEOKO XXL

- Page 1 X X L A S S E MB L Y G U I D E...

- Page 2 Have Questions? Need Help? We have a fully-staffed support department waiting to help you if you run into trouble while assembling your Shapeoko XXL. Just send us an email at support@carbide3d.com and we’ll get back to you on the quick! 3/27/2020 Version 5.0...

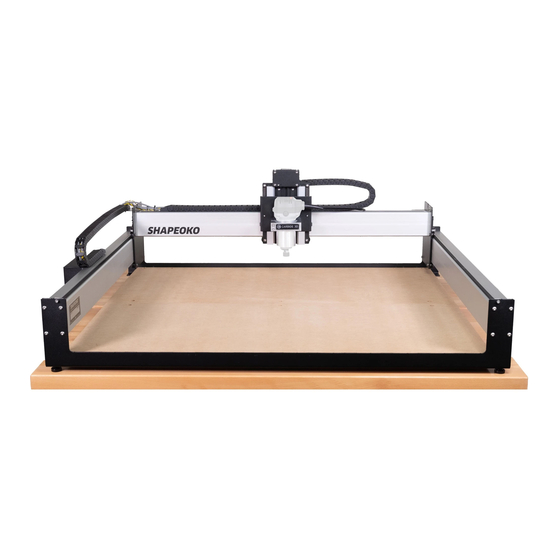

- Page 3 You are now the proud owner of the Shapeoko XXL, an incredibly powerful and easy-to-use CNC machine. In this guide we will walk you through the assembly of your Shapeoko XXL, step-by-step. If you run into problems as you go, send us an email at support@carbide3d.com...

- Page 4 Outlet Requirements Plug the router into an outlet that has a dedicated on/off switch. Be sure this is accessible while the machine is running, in case you should need to shut the Shapeoko XXL off immediately. End Mill Safety Use care when handling end mills—both to avoid being cut and to avoid damaging them. Handling end mills with suitable gloves, or using a cloth to avoid contaminating them, is recommended.

- Page 5 Start Carbide Motion 5 on your computer. d. Turn the Shapeoko XXL on by flipping the in-line rocker switch on the power supply cord to the ON position. Once powered on, you will be able to see a steady blue LED light on the controller unit.

- Page 6 V-wheels to slide smoothly along the v-rails, which as you’ll see as we begin to assemble the Shapeoko XXL, that this allows the carriages to slide easily along the rail system. End Mill or End Mill Cutter: End mills (or cutters) are the cutting tools used by a CNC machine. End mills are similar to drill bits, though, typically they can cut in all directions.

- Page 7 Once verified, carefully set aside until needed for assembly. PRO TIP: Your Shapeoko XXL kit has been carefully packaged by hand and double checked for accuracy. However, sometimes errors are made. If, after completing your inventory, you find that something is missing or damaged, contact us at support@carbide3d.com and we’ll ship it to you ASAP.

- Page 8 Carefully open the box labeled XXL Final Assembly and inspect its contents. Many parts are packaged in small plastic bags, and smaller bags may be inserted into larger bags for shipping purposes. This box should contain all of the items shown in Figure 1-2 and listed in the table on the next page. Figure 1-2 docs.carbide3d.com...

- Page 9 Assembly and visually verify they match the carriages as shown in Figure 1-3. The Right and Left Assembly components are mirror images. NOTE: We’ll need these two boxes and the two foam blocks inside them to help with assembling the gantry. Set them aside for later use. Figure 1-3 support@carbide3d.com...

- Page 10 Figure 1-5. Figure 1-5 Item Description Z-Plus Carriage with Z-Axis Stepper Motor and Z-Axis Proximity Switch Attached X-Axis Stepper Motor M5 x 10mm Socket Head Cap Screw Tramming Plate and Hardware: M5 x 8mm Socket Head Cap Screws (4) docs.carbide3d.com...

- Page 11 Figure 1-8 Cross Straps The three (3) cross straps are identical and are packed together in a cardboard shell. Remove the packaging and identify the three cross straps pictured in Figure 1-9. Figure 1-9 support@carbide3d.com...

- Page 12 Figure 1-10 Carbide Compact Router Box You will only have this box among your items if you ordered a separate router with your Shapeoko XXL kit. This box should contain all of the items shown in Figure 1-11. Additional Required Tools...

- Page 13 In addition to adopting a front view perspective, it is very helpful to familiarize yourself with the machine’s directional axes: the X-Axis moves left and right, the Y-Axis moves front and back, and the Z-Axis moves up and down. See Figure 1-14. Figure 1-14 support@carbide3d.com...

- Page 14 Step 2: Baseframe Figure 2-2 docs.carbide3d.com...

- Page 15 Adjustable Leveling Foot XXL Final Assembly Box Required Tools See Figure 2-3: Item Description 3mm Hex Key Level (not included) Recommended Tools See Figure 2-3: Item Description Spare Hex Key (included) 2 or 3 Figure 2-3 Flashlight Tape Measure support@carbide3d.com...

- Page 16 The completed dimensions of the Shapeoko XXL are 44.8" W x 40.3" L x 16.6" H. We recommend that you assemble the machine on a table slightly larger than the machine itself.

- Page 17 NOTE: If you are having trouble getting any of these screws started, make sure the machine is square and apply a little bit more downward pressure. However, be very careful not to cross thread any of the screws. Figure 2-9 support@carbide3d.com...

- Page 18 If you are still having trouble getting the holes to Figure 2-11 line up, contact us at support@carbide3d.com. Attach the Front Endplate 1. Place the other endplate along the front of the machine and slide it under the three cross straps as shown in Figure 2-11.

- Page 19 See Figure 2-14. Approximates are acceptable at this stage as the machine is not fully tightened. A final and more comprehensive leveling and squaring of the machine will be completed in Step 11: Level and Square. Figure 2-14 support@carbide3d.com...

- Page 20 Step 3: Carriages Figure 3-2 docs.carbide3d.com...

- Page 21 M6 x 12mm Button Head Cap Screw XXL Final Assembly Box Required Tools See Figure 3-3: Item Description 3 and 4mm Hex Key 10mm Wrench Recommended Tools See Figure 3-3: Item Description 10mm Combination Wrench Figure 3-3 Masking Tape support@carbide3d.com...

- Page 22 Reach under and spin the V-wheel with your finger. If it rotates freely, keep tightening the eccentric nut until you feel some friction against the v-rail. The carriage should be free from slop and travel smoothly without bumps. Figure 3-4 Figure 3-5 docs.carbide3d.com...

- Page 23 Z-motor and the idlers with the Carbide 3D label facing down (toward the idlers). See Figure 3-8. 3. Use the 4mm hex key and four (4) M5x10mm socket head cap screws to secure the X-motor to the Z-Plus. Figure 3-8 support@carbide3d.com...

- Page 24 1. Position the tramming plate with the short legs extending up in a “U” shape. 2. Carefully inspect the top two holes shown in Figure 3-10. 3. Determine which of the holes is smaller and position the tramming plate with this hole at TOP-LEFT. This is the FRONT of the plate. Figure 3-10 docs.carbide3d.com...

- Page 25 (4) available M5 screw holes on the front of the Z-Plus. 3. Use the 4mm hex key and the four (4) M5x8mm socket head cap screws to secure the router mount and tramming plate to the Z-Plus and Figure 3-12 tighten. Figure 3-12. support@carbide3d.com...

- Page 26 Y-Axis right aluminum extrusion rail (Y2-rail): has two (2) pre-drilled M6 screw holes along the outside. It will be installed on the right side of the machine, running front to back, with the v-rail facing to the inside. Figure 3-15 docs.carbide3d.com...

- Page 27 When properly attached, the motor body will be to the inside and behind the X-rail. The V-wheels, idlers, and motor pulley will be facing out as shown in Figure 3-18. 3. Snug the Y1-carriage to the X-rail, but do not fully tighten the screws. Figure 3-18 support@carbide3d.com...

- Page 28 When properly attached, the motor body will be to the inside and behind the X-rail. The V-wheels, idlers, and motor pulley will be facing out as shown in Figure 3-20. 3. Snug the Y2-carriage to the X-rail, but do not fully tighten the screws. Figure 3-20 docs.carbide3d.com...

- Page 29 Step 4: Gantry Figure 4-2 support@carbide3d.com...

- Page 30 M6 x 12mm Button Head Cap Screw XXL Final Assembly Box Required Tools See Figure 4-3: Item Description 4mm Hex Key 10mm Wrench Foam Packing Block (From the Two Y-Carriage Boxes) Recommended Tools See Figure 4-3: Item Description Figure 4-3 10mm Combination Wrench docs.carbide3d.com...

- Page 31 (12) screws holding the MDF baseplates to the endplates to give you more room to “tilt” the endplates apart. See Figure 4-5. Figure 4-5 Positioning the X-Rail 1. Position the X-rail with attached carriages diagonally across the baseframe. See Figure 4-6. Figure 4-6 support@carbide3d.com...

- Page 32 The Y1- and Y2- rails will be raised into place one at a time. The first rail to be lifted (the Y1-rail) is loosely attached to the endplates with two (2) screws, one front and one back. This creates a pivot point for rotating the Y2-rail up and into place Figure 4-9 docs.carbide3d.com...

- Page 33 (Z-Plus, Y1, and Y2) clockwise until the V-wheels engage with the v-rails. See Figure 4-12. Refer back to the eccentric nut information on page 20 and Figures 3-4 and 3-5, if needed. Figure 4-12 support@carbide3d.com...

- Page 34 Step 5: Belting Figure 5-2 docs.carbide3d.com...

- Page 35 3 and 4mm Hex Key Tape Measure or Ruler (not included) Belts and Belt Clips The Shapeoko XXL ships with three 1200mm steel-core toothed Figure 5-3 belts. These belts engage with the stepper motors to drive the gantry. Belts are secured to the rail using belt clips. Each right-angle belt clip has an integrated PEM nut on the short leg and two parallel slots on the long leg.

- Page 36 5. Slide the 3mm hex key under the belt, between the two idlers. Use the hex key as a lever against the X-rail to push a loop of belt up between the two idlers as shown in Figure 5-7. Figure 5-7 docs.carbide3d.com...

- Page 37 Y2-carriage. Ensure the teeth of the bottom few inches of belt interlock with the top. See Figure 5-10. NOTE: The belt should be tight enough to snap against the Y1-rail when gently lifted. Figure 5-10 support@carbide3d.com...

- Page 38 Y1-carriage. Make sure the belt does not twist and the teeth remain facing down all the way to the rear endplate. See Figure 5-13. Do not attach the other end of the belt just yet. Figure 5-13 docs.carbide3d.com...

- Page 39 Install the Y2-Rail Belt PRO TIP: The Y2-belt installation process is a mirror image of the Y1-belt installation process. 1. Install the remaining belt on the Y2-rail, following steps 1-11 of the “Install the Y1-Rail Belt” section above. Figure 5-16 support@carbide3d.com...

- Page 40 Step 6: Drag Chains Figure 6-2 docs.carbide3d.com...

- Page 41 Wiring Harness Box M3 x 4mm Flat Head Screw Wiring Harness Box Required Tools See Figure 6-3: Item Description 2, 3, and 4mm Hex Key 8mm Wrench Recommended Tools See Figure 6-3: Item Description 8mm Combination Wrench Figure 6-3 support@carbide3d.com...

- Page 42 Y1-carriage with four (4) M5x10mm socket head cap screws. However, to attach the drag chain head bracket to the Shapeoko XXL, the top two (2) motor-mount screws will need to be replaced by two (2) longer M5x16mm socket head cap screws. Once replaced, the shorter screws will no longer be needed. See Figure 6-6.

- Page 43 Figure 6-8. 4. Use the 3mm hex key and two (2) M4x6mm socket head cap screws to attach the tail bracket (single PEM nut) to the outside of the Y1-rail closest to the rear endplate. See Figure 6-8. Figure 6-8 support@carbide3d.com...

- Page 44 Also, the drag chains will only curl in one direction. Do not force the drag chain to bend; if it doesn’t curl easily, simply turn it over and try again. Important Wiring Harness Information Figure 6-9 docs.carbide3d.com...

- Page 45 Installing the Y-Axis Drag Chain 1. Unroll and lay out the wiring harness on the baseframe, move the X-rail all the way to the FRONT, and move the Z-Plus 8 to 10-inches from the Y2-carriage as shown in Figure 6-10. Figure 6-10 support@carbide3d.com...

- Page 46 5. Use the 2mm hex key and one (1) M3x4mm flat head screw to attach the drag chain to the single PEM nut in the tail bracket at the rear. Use the center through-hole closest to the end of the drag chain. See Figure 6-14. Figure 6-14 docs.carbide3d.com...

- Page 47 4. Use the 2mm hex key and one (1) M3x4mm flat head screw to attach the tail of the drag chain to the single PEM nut in the tail bracket. Use the center through-hole closest to the end of the drag chain. See Figure 6-16. Figure 6-16 support@carbide3d.com...

- Page 48 Step 7: Proximity Switches Figure 7-2 docs.carbide3d.com...

- Page 49 2.5 and 4mm Hex Key Install the Proximity Switches Figure 7-3 The Shapeoko XXL includes three inductive proximity switches. The Z-Axis proximity switch is pre-installed on the front of the Z-Plus. The X- and Y-Axis switches are pre-installed in the wiring harness. See Figure 7-4.

- Page 50 3. Use the 2.5mm hex key and two (2) M3x18mm socket head cap screws to attach the switch to the plate. Make sure the front edge of the proximity Figure 7-7 switch and plate stay flush. See Figure 7-7. docs.carbide3d.com...

- Page 51 Do not force a connection. If you encounter resistance, make sure you have the correct orientation. See Figure 7-11. 2. Properly align and connect the two cables. See Figure 7-9 Figures 7-10 and 7-11. Figure 7-11 Figure 7-10 support@carbide3d.com...

- Page 52 Step 8: Wiring Figure 8-2 docs.carbide3d.com...

- Page 53 3. Carefully remove the controller unit cover. Inside the controller unit you will find two (2) M6x12mm button head cap screws which are used to mount the controller unit to the Y1-rail. Set these aside for a later step. Figure 8-4 support@carbide3d.com...

- Page 54 “X,” “Y,” and “Z” into their respective ports on the PCB riser board. Be sure to match the labels on the cables with those of the board. The “P,” and “F” ports to the right remain empty. See Figure 8-7. Figure 8-7 docs.carbide3d.com...

- Page 55 Figure 8-8 Connect the Stepper Motors Shapeoko XXL comes equipped with four stepper motors: X, Y1, Y2, and Z. Each motor connects to the controller unit via a gray extension cable installed in the wiring harness at the factory.

- Page 56 Y-Axis drag chain. 1. Unravel the Y2-motor leads. 2. Extend the long gray 4-pin extension cable labeled “Y2” about 3/4 of the way across the machine and connect it to the Y2-motor leads as shown in Figure 8-13. Figure 8-13 docs.carbide3d.com...

- Page 57 Step 9: Cleanup Figure 9-2 support@carbide3d.com...

- Page 58 1. One at a time insert the cables, beginning with the three Y-cables, followed by the four X/Z-cables. See Figure 9-4. 2. Use two (2) cable ties, one on each side of the cutout, to secure the cables in place as shown in Figure 9-4. Figure 9-4 docs.carbide3d.com...

- Page 59 5. Use flush cut pliers or scissors (not included) to trim the ends of all the cable ties Figure 9-7 Apply the Shapeoko Owner’s Decal 1. Write your name on the decal with the included permanent marker and apply it to the inside of the Y1-rail. support@carbide3d.com...

- Page 60 Step 10: Compact Router Figure 10-2 docs.carbide3d.com...

- Page 61 M5x55mm socket head cap screws on the front of the router mount 2. Insert the router into the mount until the taper of the router’s body meets the adapter ring. Ensure the power cord extends to the right. See Figure 10-4 Figure 10-4. support@carbide3d.com...

- Page 62 1-inch loop. Finally, use a third cable tie to secure the router power cable to the cable tie chain. See Figure 10-7. 5. Route the power cord through the circular cutout at the top of the Y2-carriage. See Figure 10-7. Figure 10-7 docs.carbide3d.com...

- Page 63 Figure 10-10. NOTE: Plug the compact router into an outlet that has a dedicated on/off switch. Be sure this is accessible while the machine is running, in case you should need to shut the Shapeoko off immediately. Figure 10-10 support@carbide3d.com...

- Page 64 See Figure 10-13. Alternatively, you can press and hold the shaft lock while tightening with the 22mm collet nut wrench. Removing the End Mill 1. To remove the end mill, follow the installation procedure in reverse. Figure 10-13 docs.carbide3d.com...

- Page 65 Squaring ensures the X-rail and Y-rails are perpendicular and that the Y1- and Y2-rails are parallel. 1. Use the 4mm hex key to loosen the eight (8) M6x12mm button head cap screws securing the X-rail to the Y1-carriage and Y2-carriage. Do not remove the screws; a 1/4 to 1/2 turn will suffice. support@carbide3d.com...

- Page 66 Optional: Use a tape measure to confirm square by comparing measurements corner to corner. Your assembly is now complete! Next Steps On the following pages you will find helpful information to get you ready to use your Shapeoko XXL. 1. Connect to Power 5. Workholding 2.

- Page 67 See Figure 12-2. Figure 12-2 Download the Software 1. Download Carbide Motion 5 from: carbide3d.com/carbidemotion/download. 2. Download Carbide Create from: carbide3d.com/carbidecreate. 3. Install both programs to your computer. Carbide Motion lets you control your machine by jogging it around, setting zeroes, and loading and running G-code.

- Page 68 3. Start Carbide Motion 5 on your computer. 4. Flip the in-line rocker switch on the power cord to the ON position to turn on the Shapeoko XXL. 5. In Carbide Motion, click Connect to Cutter button. Upload Your Settings Figure 13-2 1.

- Page 69 Figure 14-1 Letter-Sized, A4, Paper (not included) Masking Tape (not included) Piece of Cardboard (not included) Complete the Test Project To complete this test project (see Figure 14-2) on your Shapeoko XXL, follow the project instructions at: docs.carbide3d.com/tutorials/hello-world. Figure 14-2 support@carbide3d.com...

- Page 70 DIY Workholding Projects Hold-Down Solution: Make a DIY hold-down solution to put on top of your baseplates: cutrocket.com/p/5df928247387d. Hold-Down Clamps: Make a set of clamps to use with the DIY hold-down: docs.carbide3d.com/tutorials/shapeoko-clamps. Workholding Solutions Available in the Carbide 3D Store...

- Page 71 Once you have implemented a workholding solution, you’re ready to tackle some beginner tutorials and projects! The Star Wars Coaster Project is an excellent crash course on how to use your Shapeoko XXL. The tutorial walks you through designing a simple set of coasters in Carbide Create and then executing the project with Carbide Motion. Follow the complete project tutorial at: docs.carbide3d.com/tutorials/project-coaster.

Need help?

Do you have a question about the SHAPEOKO XXL and is the answer not in the manual?

Questions and answers