Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Rockinger RO 400

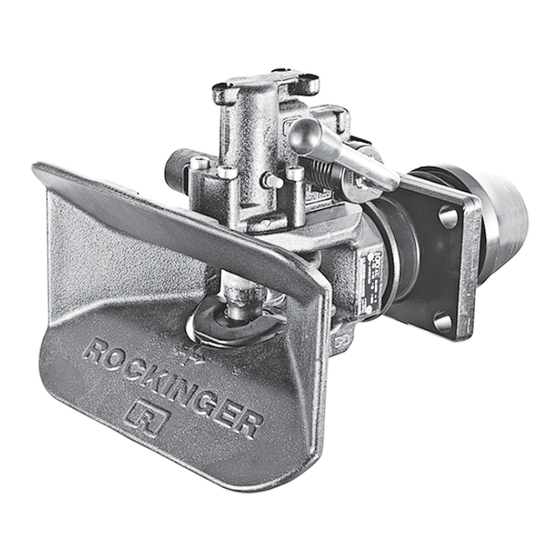

- Page 1 Montage- und Betriebsanleitung Installation and operating instructions Instructions de montage et d’utilisation Member of JOST-World Modellreihe Series Type Vollautomatische Anhängekupplung Automatic Trailer Coupling Attelage de remorque entièrement automatique...

-

Page 2: Table Of Contents

Appendix 7 of Directive Technical data 28 – 29 ECE R 55 and the national regulations for commercial vehicles must be observed. Upgrade kits Subject to technical changes without prior notice ROCKINGER Member of JOST-World... -

Page 3: Safety Instructions

Alterations of any kind shall cause the warranty to lapse and invalidate the vehicle and the trailer must be checked. type approval, which in turn invalidates the vehicle operation permit. ROCKINGER Member of JOST-World... -

Page 4: Fitting

02b Spacer bushing (2) 02c Hexagon nut 03 Hexagon nut 04 Conical cap 05 Rubber buffer 06 Protective buffer cap 07 Bearing T Vehicle cross member 08 Protective buffer cap 09 Rubber buffer 10 Jaw with drawbar Fig. 1 ROCKINGER Member of JOST-World... -

Page 5: Before Installation

Note: Observe manufactures’ instructions in case different bolts and nuts are recommended! ATTENTION: Mount bolt heads on the side directed towards the jaw (outside the cross member) to avoid impairing movability of the hitch (see Fig. 2) (UVV Fahrzeuge, VBG 12, KBA-Merkblatt) ROCKINGER Member of JOST-World... - Page 6 1. Fitting Torque of bolts on the bearing Size of Size of Width Tightening ROCKINGER hitch bolts across flats torque set of bolts S (mm) (Nm) part no. M 20 70971 M 16 70952 M 14 70970 Tightening torque for screws use a torque meter to fix according to DIN ISO 6789, class A or B Grip (thickness) of cross member (s.

- Page 7 Note: Before painting, it is essential to close hitch and grease or cover coupling pin. After painting clean and regrease the coupling pin. Tightening torque, screws are to fix with a torque wrench at DIN EN ISO 6789, classe A or B ROCKINGER ROCKINGER ROCKINGER Member of JOST-World...

-

Page 8: Operation

Driving a trailer in that condition is not allowed. If not correctly coupled: – move the prime mover forward (approximately 1 m) – check again Fig. 4 In-cab status indicator upgrade kit available for retrofitting. ROCKINGER ROCKINGER Member of JOST-World Member of JOST-World... -

Page 9: Closing Coupling Manually

– intervals: 6 months or 50,000 km x Lubricate lower funnel bearing (F) with EP3 grease. Note: Close coupling before cleaning with high-pressure washers Fig. 5 (see para. 2.2). x After cleaning, relubricate coupling pin and support ring with EP3 grease. ROCKINGER Member of JOST-World... -

Page 10: Inspection

Vertical play may not exceed 3 mm measured at coupling head (centre axis of coupling pin). Coupling pin: Check wear using ROCKINGER reference gauge (order no. 57026) (see Fig. 8): Coupling pin may be used until diameter of crowned section has worn to less than 36.5 mm, after which it must be replaced. - Page 11 3. Maintenance Vertical play in coupling pin (see fig. 9) may not exceed 2mm. Lower bush: Check wear using ROCKINGER reference gauge (order no. 57290). Max. admissible internal diameter of lower bush is 31.5 mm. Passage below pin must be free.

- Page 12 (M) (see fig. (S = 0). x Please, check the lock and movement of the funnel again Tightening torque for screws use a torque meter to fix according to DIN ISO 6789, class A or B ROCKINGER Member of JOST-World...

-

Page 13: Series Ro I 400

1 55 R-01 0352 Typ RO 400-G 135 or drawbar eyes 40 Flange size to DIN 74053 und ECE-Class S ECE R 55-01 Size KL max. (mm) (mm) (mm) (mm) (mm) (mm) (mm) Nameplate position ROCKINGER Member of JOST-World... -

Page 14: Upgrade Kits

Electronical remote indicator RI-BE ROE 71546 Pneumatic remote operation power assistent opening Electrical remote indicator RI-BC ROE 71654 and closing ROE 71461 Repair instructions and parts list to be obtained upon request! Mechanical remote operation ROE 71676 ROCKINGER Member of JOST-World... - Page 15 ROCKINGER Member of JOST-World...

- Page 16 JOST-Werke · Siemensstr. 2, D-63263 Neu-Isenburg · Telefon +49 (0) 61 02 2 95 - 0 · Fax +49 (0) 61 02 2 95 -298 · www.jost-world.com MuB 016 007 M20 (REV--) 05-2015 (PG)

Need help?

Do you have a question about the RO 400 and is the answer not in the manual?

Questions and answers