Heyl Testomat 808 Operating Instructions Manual

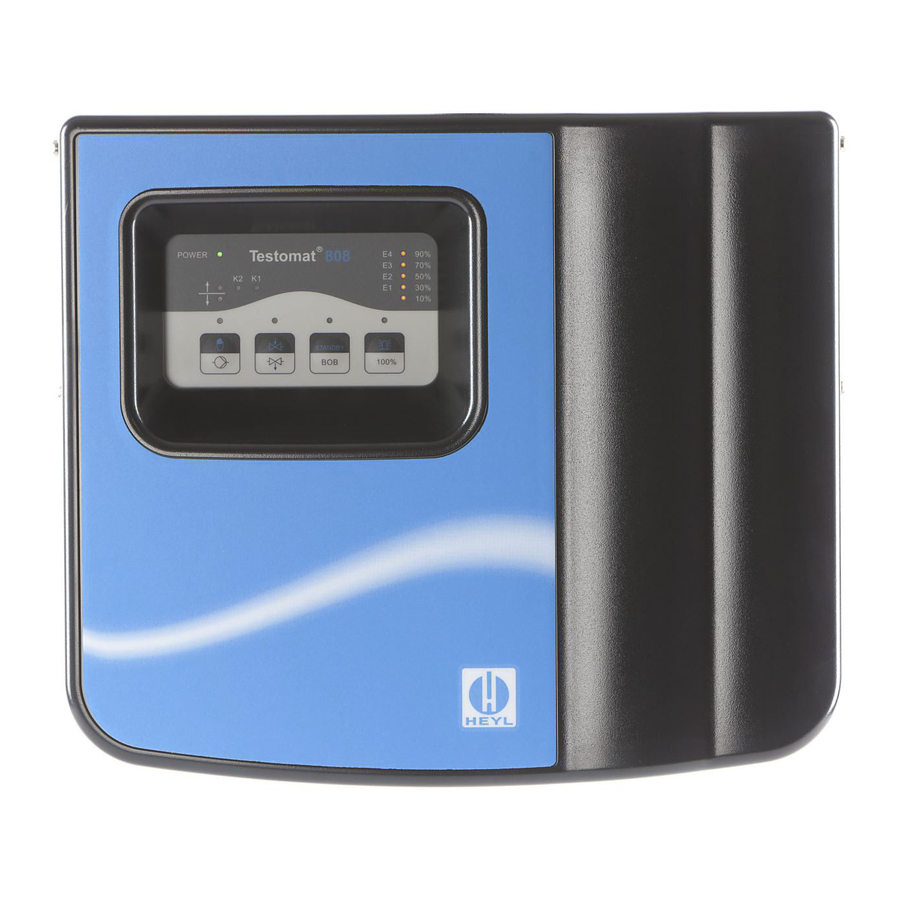

Online analysis instrument for water hardness

Hide thumbs

Also See for Testomat 808:

- Maintenance and service instructions (56 pages) ,

- Replacing instructions (2 pages) ,

- Replacing (2 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Heyl Testomat 808

- Page 1 Operating Instructions ® Testomat 2019 Online Analysis Instrument for Water Hardness...

-

Page 2: Table Of Contents

Content Content Content ....................2 Important safety information ............. 4 Intended use ..................4 Qualification of the staff ................ 4 Warning notices in these instructions ........... 5 Notes and instructions to be observed ..........5 General instructions ................5 Installation ..................... 6 Operation .................... - Page 3 Content Serial interface RS232 ................ 24 Description of the relay outputs ............24 Relay 3 – fault message ..............24 Relays 1 and 2 ..................24 Switching functions of the relays 1 and 2 ........... 24 Commissioning ................. 26 Inserting the indicator bottle ..............26 Bleeding the indicator lines ..............

-

Page 4: Important Safety Information

Always adhere to hazard warnings and safety information when using reagents, chemicals and cleaning agents. Please adhere to the respective safety data sheet! Download the safety data sheets for the supplied reagents at http://www.heyl.de. Intended use ® Testomat 808 has been designed for use in the field of water treatment (e.g. -

Page 5: Warning Notices In These Instructions

Notes and instructions to be observed Warning notices in these instructions The warning notices in these instructions warn the user about potential dangers to individuals and property resulting from incorrect handling of the instrument. The warning notices are structured as follows: Description of the type or source of danger Description of the consequences resulting from non-observance... -

Page 6: Installation

Use to the enclosed error log to describe the error and return it to us together with the instrument. If the error log is no longer available, download it at www.heyl.de. Disposal • Dispose of the instrument in accordance with national regulations. -

Page 7: Operating Requirements

Operating requirements • ® In order for Testomat 808 to operate reliably, use Heyl indicators in the pH-range 4 – 10.5! CAUTION ® Testomat • Only operate the instrument with the parameters specified under “Technical data”. • Attention! Water that is too cold can lead to foggy viewing windows. -

Page 8: Scope Of Delivery

Special accessories (available separately): Filter inlet, candle filter as well as pressure regulator Required hose connections and supply lines for Testomat ® 808 are available from Heyl. Performance specifications ® Testomat 808 is used for the automatic monitoring of residual total hardness (water hardness) in water. -

Page 9: Functions Of The Operating And Display Elements

Functions of the operating and display elements Functions of the operating and display elements ® Operating statuses and measuring results are displayed at Testomat 808 via LEDs. The input keys for operating the instrument are positioned below the LEDs. ® Switching Testomat 808 on/off (1) External power switch... -

Page 10: Operating Elements/Function Keys

Functions of the operating and display elements Operating elements/Function keys All operating elements/function keys are assigned twice. The respective function is triggered by a short or long (min. 2 seconds) key press. Key 1 Short key press: Starts an analysis (manual start), (manual) the respective LED flashes. -

Page 11: Display Elements/Leds

Functions of the operating and display elements Display elements/LEDs All measuring results as well as activated functions are displayed at ® Testomat 808 via LEDs. The LEDs above the function keys illuminate/flash when the respective function is activated. The LED lights up when the device is supplied with power and is in operation. -

Page 12: Installation

Installation Installation Risks resulting from incorrect installation! WARNING ® Install Testomat 808 at a location where it is protected against dripping or splash water, dust and aggressive substances – e.g. in a control cabinet or on a suitable wall. NOTE Information for trouble-free operation ... -

Page 13: Operating Testomat 808 In The Pressure Range 4 To 8 Bar

Installation ® Operating Testomat 808 in the pressure range 4 to 8 bar Prior to installation, please check whether a higher operating pressure (between 4 and 8 bar) is required. Use a pressure controller (art. no. 37602) for ranges between 4 and 8 bar. Optimum operation of Testomat ®... -

Page 14: Water Outlet

Installation When using a cooler CAUTION The hot water can cause burns and damage wetted parts of ® Testomat 808. Water outlet The feed water flows through the measuring chamber to the drain via the outlet hose. Remove the red plug from the outlet connection. ... -

Page 15: Plant Example Testomat 808

Installation Risk of damages caused by electromagnetic fields! ® If Testomat 808 or the connecting cables are installed parallel to power cables or in close proximity to strong electromagnetic fields, NOTE the instrument may be damaged or measurements incorrect. ... -

Page 16: Internal Design Testomat 808

Installation ® Internal design Testomat Rear of the controller board Keys 1 to 4 are located at the front of the board. Please refer to the section entitled “Functions of the operating and display elements” page 9 for a detailed description of its operating system and the display elements. -

Page 17: Slide Switch T1

If your instrument requires a firmware update, Heyl will provide you with further detailed information. Switch position NOTE ... -

Page 18: Base Circuit Board Testomat 808

Installation ® Base circuit board Testomat The illustration above provides an overview of the design of the base circuit board. Plug connector J2 The connection to the controller board is established via the plug ... -

Page 19: Inputs Ext. Lösch. And Stopp

Installation Inputs EXT. LÖSCH. and STOPP “Description of the signal Please refer to the section entitled inputs” on page 23 for a description of the inputs “Ext. lösch. (delete externally)” and “Stopp” Terminal block “Connecting the mains Please refer to the sections entitled voltage”... - Page 20 Installation Loosen the cable ducting strain relief (union nut). Remove the closing plugs. Lay the cable through the cable ducting underneath the housing into the terminal box. Tighten the union nut of the cable ducting and so establish the strain relief.

-

Page 21: Connecting The Inputs And Outputs

Installation Connecting the inputs and outputs Connecting the inputs CAUTION Do not connect external voltage to these connections! ® Testomat 808 has the following connections for control and monitoring functions. Ensure that the strands are held securely in the terminals. ... - Page 22 Installation “Technical data” on page 44 for * Please refer to the section entitled the maximum contact load of the relays. Mark external voltage on the device! In the event you connect system components that are not powered DANGER by the device voltage, you may apply external voltage to the relay contacts.

-

Page 23: Description Of The Signal Inputs

Description of the signal inputs Description of the signal inputs Connecting the signal inputs Only connect the signal inputs “Delete externally” and “Stop” to CAUTION volt-free contacts! The connection of external voltages would damage the instrument! (EXT. LÖSCH. of relay 3 The input “EXT. -

Page 24: Serial Interface Rs232

Description of the relay outputs Current interface load NOTE The current interface is galvanically decoupled. A maximum load of 500 Ohms should not be exceeded! For faults and when using very long cables (approx. 20 m), a screened cable should be used if possible. Serial interface RS232 ®... - Page 25 Description of the relay outputs The following switch positions are possible: Switch Relay 2 Relay 1 Comment position (message poor analysis) (external flush) for relay 2 Normally open – closes in Normally open – closes after a Continuous contact can be deleted via key 4 (horn) or “Delete case of 1 poor analysis, poor analysis for 1 minute...

-

Page 26: Commissioning

Please adhere to the respective safety data sheet! CAUTION ® Trouble-free operation of Testomat 808 is only guaranteed when ® using Heyl Testomat indicators! Inserting the indicator bottle Open the housing cover to access the housing. ... -

Page 27: Instrument Settings And Analysis

Instrument settings and analysis Instrument settings and analysis Please read the following information before carrying out the required settings at the instrument. Instrument settings The required instrument settings for executing analyses, e.g. measuring interval pause, indicator bottle size and behaviour of relays 1 and 2, are carried out on the controller board using the “Internal function keys and slide switches. -

Page 28: Selecting The Indicator Type And Bottle Size

Instrument settings and analysis Selecting the indicator type and bottle size ® Specifying the measuring/monitoring range of Testomat NOTE The measuring/monitoring range of Testomat ® 808 is specified by the selected indicator type only. “Testomat ® Please refer to the section entitled 808 2019 spare parts and accessories”... -

Page 29: Analysis Process

Instrument settings and analysis Automatic interval mode can be interrupted via standby and analyses started manually. Operating mode Function/Process Standby The instrument is switched on and in standby. Short press key 3 (pause) to switch standby on/off. Note: During an interval pause, the instrument immediately switches to standby;... -

Page 30: Further Basic Functions And Settings

Further basic functions and settings Further basic functions and settings Internal flushing To ensure that the analysed sample represents the current value, the sampling line must be sufficiently flushed. Duration of the internal flush time The duration of the internal flush time is preset (10 s before and NOTE after a measurement) and cannot be influenced by the operator. -

Page 31: Interval Pause

Further basic functions and settings External flush process: Long press (approx. 2 seconds) key 2 (Flush) to activate the external flush valve. The external valve is activated via relay 1 and the line is flushed. Long key press (approx. 2 seconds) key 2 (Flush) again to terminate the external flush process. -

Page 32: 72 H Operation (Operation Without Permanent Supervision)

Error messages/Troubleshooting 72 h operation (operation without permanent supervision) If the instrument should run for a longer period of time without supervision (e.g. at the weekend), use this function to check whether sufficient indicator is available for a continuous measurement. On the basis of the still available indicator, the set indicator pause and indicator quantity consumed per measurement, the instrument calculates whether the residual indicator quantity is sufficient for the... - Page 33 Error messages/Troubleshooting Activate the red alarm LED above key 4 (horn) as follows: Cause • Flashes Calculation shows that the indicator filling level is zero • No or insufficient indicator in the measuring chamber after dosing • Optical fault • The instrument is operated outside of the specification (e.g.

- Page 34 Error messages/Troubleshooting The following errors are displayed for 4 seconds: Cause Remedy Insufficient LED power, Check whether the water is turbid. Strong turbidity can insufficient light (or hardware negatively influence the measurement. error) Check whether the measuring chamber/sight glass is soiled.

-

Page 35: Low Water Level

Error messages/Troubleshooting Low water level The LED above key 4 (horn) illuminates if the water level is low. The low water level is also registered via relay 3. Contacts C and NC are connected for this purpose. Press key 4 (horn) or close the contacts of the “EXT. LÖSCH.” input to confirm the alarm. -

Page 36: Further Possible Instrument Errors

Insert a transportation plug into the outlet pipe to prevent leakage. Use to the enclosed error log to describe the error and return it to us together with the instrument. If the error log is no longer available, download it at www.heyl.de. -

Page 37: Maintenance

Maintenance Maintenance Required maintenance measures NOTE Regular maintenance is necessary to ensure trouble-free operation of the instrument (every six to twelve months)! At least carry out the maintenance work described in the following section on a regular basis when ... -

Page 38: Description Of Maintenance Work

Maintenance Description of maintenance work Carry out the maintenance work described below on a regular basis. Bleeding the lines NOTE Bleed the lines after each mechanical step to ensure trouble-free operation of the instrument. To achieve this, proceed as described in the section entitled “Replacing the indicator bottle”... -

Page 39: Cleaning The Measuring Chamber And The Sight-Glass Windows

Maintenance Resetting the analysis counter ® Testomat 808 automatically calculates the number of analyses CAUTION depending on the set bottle size. The instrument cannot measure the actual filling level of the indicator bottle! Only reset the analysis counter to 100% after inserting a new indicator bottle! Cleaning the measuring chamber and the sight- glass windows... - Page 40 Maintenance Once the measuring chamber has been fully cleaned, it can be reinstalled. Reassemble in reverse order to disassembly. Removal and installation of the sight glass windows ATTENTION If the sight glass windows cannot be removed from the measurement chamber, open the measurement chamber cover (4) and then carefully push them out from the inside.

-

Page 41: Pump Head Maintenance Message

Maintenance Pump head maintenance message The effective runtime of the pump head is counted during operation. After 150 hours of operation, the LED E4 flashes with the maintenance message for the pump head. This runtime for the pump will be reached during normal operation (analysis interval every 10 minutes) after approx. -

Page 42: Testomat 808 2019 Spare Parts And Accessories

O-ring 1.78x1.78 Art. no. Spare parts - instrument 37321 Controller board Testomat 808, SMD 37324 Base circuit board Testomat 808, 230V 37570 Solenoid valve Testomat 808 Full set with optics board and LED holder for 40393 Testomat 808 2019 37562... -

Page 43: Accessories - Indicators

Candle filter Testomat 808 complete 37584 Filter insert 37593 Plug D = 6 Conversion set for water inlet and water outlet 37576 from Testomat BOB to Testomat 808 37602 Pressure regulator, complete for Testomat 270342 Maintenance case Testomat 808* 270351 Service set Testomat 808*... -

Page 44: Technical Data

Technical data Technical data (24 / 115)* 230V, 50 / 60 Hz Power supply: Instrument protection 230 – 240 V: T0.1 A Instrument protection: 115 V: T0.2 A Instrument protection: 24 V: T0.8 A max. 4 A (n , l) Mains protection for consumers: Power consumption:... -

Page 45: Checkliste Testomat 808 2019

® Checkliste Testomat 808 2019 Dear customers and service technicians, This check list cannot replace your expertise or extensive experience in fault resolution. It is intended to support fast and systematic error diagnosis and error documentation. This list does not claim to be complete. We are therefore always grateful for any advice and information you may be able to provide. - Page 46 This could compromise its function. Operation/Indicator ® The proper operation of Testomat instruments can only be assured where original Heyl Testomat indicators are used. These indicators permit an exact analytic measurement of the smallest quantities of substances. As for all reactive chemical substances, their effectiveness is also influenced by environmental conditions.

-

Page 47: Ec Conformity Declaration

Technical data EC conformity Declaration... - Page 48 Gebrüder Heyl Analysentechnik GmbH & Co. KG Orleansstraße 75b D 31135 Hildesheim Testomat_808-2019_GB_190710.docx www.heyl.de Scan the code and visit us on our website!

Need help?

Do you have a question about the Testomat 808 and is the answer not in the manual?

Questions and answers