Table of Contents

Advertisement

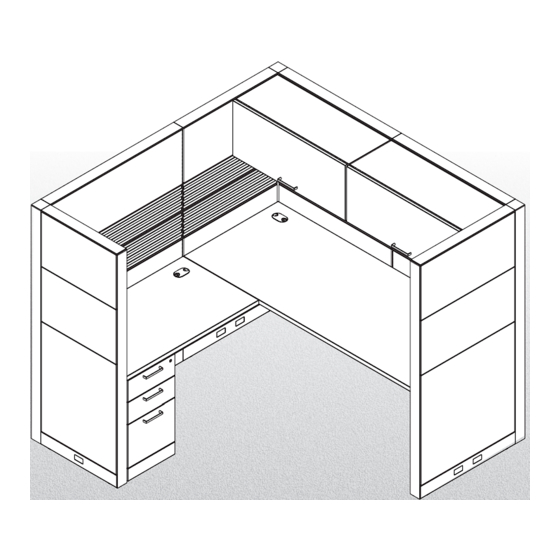

Stride

Installation Instructions

Allsteel Inc.

Muscatine, Iowa 52761-0071

www.allsteeloffice.com

Contents

System Guidelines. . . . . . . . . . . . . . . . . . . . . 1

Panel Frame Connections . . . . . . . . . . . . . . . 4

Base Raceway Cover Removal . . . . . . . . . . 12

Footed Panel Adjustment . . . . . . . . . . . . . . 13

Low Profile Glass Installation . . . . . . . . . . . 14

Trim Installation . . . . . . . . . . . . . . . . . . . . . . 25

Panel Tile Installation. . . . . . . . . . . . . . . . . . 33

Non-Rail Based Off Modular Installation . . . 43

Door Panel Installation . . . . . . . . . . . . . . . . 52

Power Pole And Trim Installation . . . . . . . . . 53

8-Wire Electrical Installation . . . . . . . . . . . . 55

Data Terminal Installation . . . . . . . . . . . . . . 60

Overhead Storage Installation . . . . . . . . . . . 60

Permanent Wall Hanger Installation . . . . . . 68

Worksurface Supports Installation . . . . . . . . 69

Countertop Installation. . . . . . . . . . . . . . . . . 80

Spanning Tile Installation. . . . . . . . . . . . . . . 84

ZAPE-E

Stride

Index

System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 1 thru 3

Panel Frame Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 4 thru 11

Base Raceway Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Footed Panel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Low Profile Glass Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 14 thru 23

Panel Mounted Screen Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 24 thru 26

Glass Panel Mounted Screen Installation . . . . . . . . . . . . . . . . . . . . . . Pages 27 thru 28

Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 29 thru 33

Panel Tile Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 34 thru 45

Non-Rail Based Off-Modular Installation . . . . . . . . . . . . . . . . . . . . . . . Pages 46 thru 55

Worksurfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 46 thru 47

Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 48 thru 52

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 53 thru 55

Rail Based Off-Modular Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 56 thru 68

Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 59 thru 65

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 66

Worksurfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 67 thru 68

Door Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 69 thru 70

Power Pole and Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 71 thru 72

8-Wire Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 73 thru 77

Data Terminal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 78

Overhead Storage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 78 thru 85

Permanent Wall Hanger Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 86

Worksurface Supports Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 87 thru 97

Pour des instructions en francais, appeler le 800-822-7653

Countertop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 98 thru 101

Para instrucciones en espanol, llame al 800-822-7653

Spanning tile installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 102 thru 108

Worksurfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 67 thru 68

Door Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 69 thru 70

Power Pole and Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 71 thru 72

8-Wire Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 73 thru 77

Data Terminal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 78

Overhead Storage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 78 thru 85

Permanent Wall Hanger Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 86

Worksurface Supports Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 87 thru 97

Countertop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 98 thru 101

Spanning tile installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 102 thru 108

343-2152G

Allsteel Inc.

Muscatine, Iowa 52761-0071

www.allsteeloffice.com

3430215200 J

343-2152G

(8/12)

Advertisement

Table of Contents

Summary of Contents for Allsteel Stride

- Page 1 Data Terminal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 78 Stride Overhead Storage Installation .

- Page 2 Return panels may also have the have the effect of dividing space . effect of dividing space. FOR ADEQUATE STABILITY of the Allsteel Stride FOR ADEQUATE STABILITY of the Allsteel Stride FOR ADEQUATE STABILITY of the Allsteel Stride...

- Page 3 Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 4 Illustration 4 Illustration 4. StACKInG lIMItAtIOnS StACKInG lIMItAtIOnS Stack-on frames do not have a hang slot Stack-on frames do not have a hang slot STACKING LIMITATIONS: at the bottom of the vertical tube .

- Page 4 Stride Stride Installation Packet Installation Packet Illustration 6 OVErhEAd StOrAGE GuIdElInES: Refer to Illustration 6 . In a panel run, only two overhead storage cabinets or open storage Overhead shelves are recommended per side, per panel . If storage unit...

- Page 5 Stride Stride Installation Packet Installation Packet WArnInG refer to Pages 1-3 for Failure to install product as instructed, use of hardware other than that which is provided with product, or failure to Installation Guidelines comply with instructions can result in product failure, personal injury, or property damage.

- Page 6 Stride Stride Installation Packet Installation Packet Illustration 9. Stack-On Frame Installation IMPOrtAnt: Tiles must be removed from stack-on Step 1 - Remove top cap, top cap retainers, and frame and base panel frame prior to center clip block from base panel frame stack-on frame installation .

- Page 7 Stride Stride Installation Packet Installation Packet Illustration 10. Frame-to-Frame Connection at 90°, “t”, “X” and Extended Straight Panel Junctures (common height) Step 1 - Determine the configuration of the panels at the connector juncture and ensure that the connector block for that juncture has the correct number of spacers .

- Page 8 Stride Stride Installation Packet Installation Packet Illustration 10a. Frame-to-Frame Connection at 90°, “t”, “X” and Extended Straight Panel Junctures (common height) Step 2 - Attach the connector blocks to panel frames with one screw per block, per panel . Start on the left hole of the lowest position on the panel frame .

- Page 9 Stride Stride Installation Packet Installation Packet Illustration 11. Installing Connector Blocks with Stack-On Frames Step 1 - Refer to Illustration 10 for the correct connector block configuration and orientation Step 2 - Ensure that there is one connector block at the top and bottom of each stack-on frame, and at the top of each base frame .

- Page 10 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 12. Light Block Installation Illustration 12. light Block Installation “L” Light Block Step 1 - If light block is being used in a variable height application, cut the light block to the same height as the shortest panel it will be adjacent to .

- Page 11 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 13. Frame-to-Frame Variable height Connection Illustration 13. Frame-to-Frame Variable Height Connection Step 1 - In variable height applications, place connector blocks on shortest base panel, according to the table in Illustration Step 1 - In variable height applications, place connector blocks on shortest base panel, according to the table in 10a .

- Page 12 Stride Stride Installation Packet Installation Packet Illustration 14. Permanent Wall Mount Connection Notch identifies Wall Mount Top Cap top of wall mount . Trim Connector Panel Top Cap Panel Frame Larger diameter holes are used for fastening wall mount to the wall .

- Page 13 Stride Stride Installation Packet Installation Packet Illustration 15. Baserail Cover removal Step 1 - Insert flat blade screwdriver between Baserail cover and bottom frame horizontal . Pivot screwdriver upward to free Baserail cover from glide towers . Step 2 - Repeat Step 1 on opposite end of panel frame .

-

Page 14: Footed Panel Adjustment

Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 16. Footed Panel Adjustment Illustration 16. Footed Panel Adjustments nOtE: Footed panels are shipped ready to be installed in an in-line application . Step 1 - Extend leveler about Step 2 -Lower panel foot... - Page 15 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 17. low Profile Glass - Support Brackets Illustration 17. Low Profile Glass - Support Brackets IMPOrtAnt - When spanning multiple frames, mount support brackets to all base panels . Ensure panels are level .

- Page 16 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 18. low Profile Glass (lPG) Installation Illustration 18. Low Profile Glass (LPG) Installation IMPOrtAnt: • Review Illustrations 19-27 to determine proper assembly based on end connection . • Top tile on each side of base panel must be removed prior to LPG installation .

- Page 17 Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 19. low Profile Glass - In-line Connection - lPG to Panel Illustration 19. low Profile Glass - In-line Connection - lPG to Panel Illustration 19. Low Profile Glass - In-Line Connection - LPG to Panel Step 1 - Install LPG (see Illustration 18) .

- Page 18 Stride Stride Installation Packet Installation Packet Illustration 21. low Profile Glass - In-line Connection - lPG to lPG Step 1 - Install first LPG (see Illustration 18) . Step 2 - Remove vertical rib from each LPG . Step 3 - Reattach both vertical ribs to the first LPG using 1 .5" screw provided as shown .

- Page 19 Stride Stride Installation Packet Installation Packet Illustration 22. low Profile Glass - Connector Block Pre-Assembly When LPG is used at a connector block connection, it is necessary to pre-assemble 1 or 2 LPG vertical rib components to the connector blocks prior to LPG installation .

- Page 20 Stride Stride Installation Packet Installation Packet Illustration 24. low Profile Glass - 1 lPG at Connector Block Connection These instructions cover configurations with 1 LPG and 1 to 3 base panels at a connector block connection . nOtE: If multiple base panels are already installed with connector blocks, connector blocks for LPG must be removed prior to Step 1 .

- Page 21 Stride Stride Installation Packet Installation Packet Illustration 25. low Profile Glass - 2 lPG “l” or 120 degree 2-Way These instructions cover configurations with 2 LPG that create: A) “L” (may have additional 1 or 2 base panels, creating “T” or “X”)

- Page 22 Stride Stride Installation Packet Installation Packet Illustration 26. low Profile Glass - 2 lPG “Extended Straight” These instructions cover configurations with 2 LPG that create an “extended straight” (may have additional 1 or 2 base panels) . Step 1 - Remove vertical rib from one end of one LPG...

- Page 23 Stride Stride Installation Packet Installation Packet Illustration 27. low Profile Glass - lPG create a “t”, “X”, or 120 degree 3-Way These instructions cover configurations with more than 2 LPG . Step 1 - Install “L” (or 120 Degree 2-Way) by following Steps 1-5 from Illustration 25 .

- Page 24 Stride Stride Installation Packet Installation Packet Illustration 28. low Profile Glass - tie Brackets nOtE: Tie brackets are required unless: A) All vertical ribs are fastened to respective LPG assemblies . B) All vertical ribs are fastened to adjacent LPG assembly or connector blocks at the connection nOtE: Only consider LPG assemblies at each connection (with tops at same height) when determining which tie bracket to use .

- Page 25 Stride Installation Packet Illustration 29. Glass Panel Mounted Screen Installation Illustration 29a . Positioning glass assembly Step 1 – Snap glass retainer to bottom of aluminum glass channel . Ensure glass retainers line up with electrical cutouts in panel frame horizontal .

- Page 26 Stride Stride Installation Packet Installation Packet Illustration 30. Vertical trim Installation and removal 90° Filler trim- Step 1 - To install 90° filler trim, snap one side into the connector blocks, then rotate other side around and snap it in .

- Page 27 Stride Stride Installation Packet Installation Packet Illustration 31. Installing top Caps and top Cap transition Pieces Step 1 - If panel frames were shipped without top caps, install the top caps by snapping the legs of the top cap into the plastic retainer .

- Page 28 Stride Stride Installation Packet Installation Packet Illustration 32. top Cap retainer removal and Installation Step 1 - Step 2 - Step 3 - Remove top cap . Use flat blade screwdriver to While squeezing the sides of unsnap one side of the top cap...

- Page 29 Stride Stride Installation Packet Installation Packet Illustration 33. Connector top Cap transition Configuration Examples “L” Transition Tab can be broken off for use with panel mounted screens . “S” Transition (Extended Straight) “T” Transition 3430215200 J Page 28 of 90...

- Page 30 Stride Stride Installation Packet Installation Packet Illustration 33a. Connector top Cap transition Configuration Examples “X” Transition 120° 2-Way Transition 120° 3-Way Transition 3430215200 J Page 29 of 90 PAGE 33 OF 108 (8/12) (09/19)

- Page 31 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 36. locating Segment horizontal Illustration 34. Locating Segment Horizontal nOtE: Segment horizontals are required between tiles . The only exception is the 22 .5" segment at the bottom of the NOTE: Segment horizontals are required between tiles.

- Page 32 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 35. Segment Horizontal Installation Illustration 37. Segment horizontal Installation Step 1 - Slip ends of the segment horizontal over IMPOrtAnt: It may be necessary to install electrical panel frame verticals .

- Page 33 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 38. tile Clip Identification Illustration 36. Tile Clip Identification Center Clip - Included on 36" and wider tiles (top and bottom of tile) . Clip engages into center clip block or segment horizontal .

- Page 34 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 37. Tile Attachment Illustration 39. tile Attachment The following describes typical attachment of the following tiles: Tackable Acoustic, Landscape, Steel, Perforated Steel, Marker Board, Hard Surface, Veneer, Glass, and Pass-Thru .

- Page 35 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 40. to the Floor tile Installation note: If installing veneer or Illustration 3 8. To the Floor Tile Installation remove Baserail Cover and Prepare Bottom Center Clip Block laminate to the floor tiles, skip Step 2-4 and 6-10 .

- Page 36 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 39. To the Floor Tile Installation Illustration 41a. to the Floor tile Installation 39a. Attach To the Floor Tile Hardware Attach to the Floor tile hardware Step 5 - Install the side brackets as illustrated below based on whether it is being used at the end of a run or at an inline connection .

- Page 37 Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 41b. to the Floor tile Installation Illustration 39. To the Floor Tile Installation Install to the Floor tile 39b. Install To the Floor Tile Step 7 - By tilting the top of the tile away from the panel frame, insert the bottom...

- Page 38 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 40. Anti-Dislodgement Brackets Illustration 42. Anti-dislodgement Brackets Step 1 – Install glass tile (see Illustration 37) . For pass thru kits, install pass-thru tile . Anti-Dislodgement Bracket Step 2 - Position anti-dislodgement bracket behind glass tile vertical shroud .

- Page 39 Stride Stride Installation Packet Installation Packet Illustration 41. tool tile Installation Illustration 41a. tool tile Installation at Standard Segment Bar Step 1 – Refer to Illustration 35 to ensure correct installation of segment horizontal . Step 2 - Tilt top of tool tile towards the panel frame...

- Page 40 Stride Stride Installation Packet Installation Packet Illustration 41. tool tile Installation Illustration 41b. tool tile Installation at top of Panel Frame Step 1 - Remove half of the center clip block, as described in Illustration 24 . Step 2 - Attach top-of-panel bracket to the panel frame horizontal, ensuring it is centered, with the supplied self-drilling screws .

- Page 41 Stride Stride Installation Packet Installation Packet Illustration 41. tool tile Installation Illustration 41c. tool tile Installation On Wall track Wall Track Middle Segment Horizontal Top of Offset Bracket Push tile up, Step 1 - Refer to Illustration 71 to ensure correct...

- Page 42 Stride Installation Packet Stride Stride Stride Stride Installation Packet Installation Packet Installation Packet Installation Packet Illustration 42. Off-Modular Worksurface Bracket Application Illustration 44. Illustration 44. Off-Modular Worksurface Bracket Applications Off-Modular Worksurface Bracket Applications 42a. Off-Modular Worksurface Bracket Kit - Used to attach one end of worksurface(s) to a Illustration 44a.

- Page 43 Stride Installation Packet Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Illustration 43. 3” (76.2 mm) Lower ‘C’ Worksurface Bracket Installation Illustration 45. 3" lower ‘C’ Worksurface Bracket Installation nOtE: Standard height worksurfaces that Illustration 45. 3" lower ‘C’ Worksurface Bracket Installation nOtE: Standard height worksurfaces that 43a.

- Page 44 Stride Stride Installation Packet Installation Packet Illustration 44. non-rail Based Off-Modular Mid Panel Connection Illustration 44a. Install Brackets to Off-Modular Panel Top Bracket Self-Drilling Sheet Metal Step 1 - Install top bracket by inserting two sheet metal screws (line up with frame vertical holes) .

- Page 45 Stride Stride Installation Packet Installation Packet Illustration 44b. Mount lower Bracket to Parent run Panel Step 6 - Remove top cap and top cap retainer (only on the side that the off-modular panel will be located) . IMPOrtAnt: Off-modular panel CANNOT be mounted in...

- Page 46 Stride Stride Installation Packet Installation Packet Illustration 44c. Attach Off-Modular Panel to Parent run Panel Step 8 - Attach tiles per Illustration 37 on parent run frame before attaching off-modular panel . Step 9 - Insert parent run’s bottom bracket into bracket/vertical of off-modular panel (see Section View) .

- Page 47 Stride Stride Installation Packet Installation Packet Illustration 44d. Modifying top Cap retainer Step 12 - Use a hacksaw to cut the top cap retainer to fit around the top bracket . Remove approximately 1-1/8”(28.575 mm) Remove approximately 1 1/8" to to clear the top bracket clear the top bracket .

- Page 48 Stride Stride Installation Packet Installation Packet Illustration 45. non-rail Based Off-Modular End Panel Bracket Kit Illustration 45a. Attach Support Bracket: Step 1 - Determine placement of support bracket on lowest panel horizontal, attach with four self-drilling screws . Illustration 45b. Attach End Panel: Step 2 - Install tile per Illustration 37 and, if necessary, install off-modular worksurface bracket per Illustration 42 .

-

Page 49: Storage

Stride Stride Installation Packet Installation Packet Illustration 46. non-rail Based Overhead Off-Modular Connection Illustration 46a. Install tile Support Bracket Step 1 - Remove top cap and top cap retainer(s) per Illustration 31 and 32 . Step 2 - Assemble vertical support bracket in the center of where the... - Page 50 Stride Stride Installation Packet Installation Packet Illustration 46c. Install Modified top Cap retainer, Center Clip Block and top Cap Step 6 - Top cap retainer(s) will need to be cut with a hacksaw at location of brackets to fit on top frame horizontal .

- Page 51 Stride Stride Installation Packet Installation Packet Illustration 46e. Secure Overhead to Off-Modular Brackets Step 10 - Thread machine screws through the hole in each off-modular bracket until they secure the location of the overhead . 3430215200 J 343-2152G Page 50 of 90...

- Page 52 Stride Stride Installation Packet Installation Packet Illustration 47. Panel door Installation Illustration 47a. Connect Panel Door to 87.5"(2222.5 mm) High Panels Note: Door is factory assembled as right- hand orientation Factory Assembled as Right-Hand Install panel door between Factory Assembled as Right-Hand Install panel door between two two panel configurations 87.5"...

- Page 53 Stride Stride Installation Packet Installation Packet Illustration 47. Panel door Installation (cont) Illustration 47c. lower threshold to Floor After door is installed and leveled, loosen (do not remove) bottom screw on each side of door frame. Push threshold down until threshold rests on floor.

- Page 54 Stride Stride Installation Packet Installation Packet Illustration 48. Power Pole and trim Illustration 48b. remove top Cap and top Cap retainer Illustration 48a. remove top Cap and top Cap retainer Step 3 - Reinstall top cap retainer per Illustration 32,...

-

Page 55: Trim Installation

Terrace 2.6 Installation Packet ® Stride Stride Installation Packet Installation Packet Terrace 2.6 Installation Packet Illustration 59. Power Pole and Trim Installation (cont): ® Terrace 2.6 Installation Packet ® Illustration 59e. Install Power Pole Top Caps: Illustration 59f. Junction Box: Illustration 48. - Page 56 Stride Stride Installation Packet Installation Packet Illustration 49. Electrical Mounting Bracket Kits (8988EBZS) (8988EBZS) Mounting on Segment Horizontal Mounting on Segment horizontal: Place spacer under electrical mounting bracket and Place spacer under electrical mounting bracket and Segment insert screw through both into segment horizontal...

- Page 57 Stride Stride Installation Packet Installation Packet WArnInG Connection to a power source, by a licensed electrician, and quantity of receptacles used for a given circuit must be in compliance with all national and local electrical codes. Connect a maximum of 13 receptacles (12 in Canada, and fewer in certain u.S.

- Page 58 Stride Stride Installation Packet Installation Packet to facilitate ease of configuration of electrical components: • At least one power harness should be used at a Tee connection, when all 3 panels are powered . • At least two power harnesses should be used at a Cross connection, when all 4 panels are powered .

- Page 59 Screw Stride Stride Installation Packet Installation Packet Mounting bracket Power CAUTION block Spacer • The interior of panels is NOT to be used for routing electrical cords or extension cords. DO NOT route cords through panel junctions. Illustration 58. Illustration 57. Panel Beltline Area Electrical Installation:...

- Page 60 Stride Stride Installation Packet Installation Packet Illustration 61. Base or Ceiling Side In-Feed Installation: WArnInG Improperly installed electrical components can fail resulting in personal injury and/or property damage. Connection of the in-feed device to the power source should be performed by a licensed electrician in compliance with all national and local electrical codes.

- Page 61 Stride Stride Installation Packet Installation Packet Illustration 62. data terminal location Options Monolithic tile assembly Grommet Commercially available Modular data Face Plate - snap into vacant receptacle grommets in monolithic tile or vacant receptacle openings in note: Grommet can also be field Baserail covers .

- Page 62 Stride Installation Packet Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Illu stration 64. Shelf divider (optional acce ssory) Illustration 78. Shelf divider (optional accessory): Illustration 78. Shelf divider (optional accessory): Step 1 - Position shelf divider at an angle, as shown, and insert flange underneath lip of storage shelf back stop.

- Page 63 Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 80. 15" h Overhead Storage Cabinet Installation: Illustration 80. 15" h Overhead Storage Cabinet Installation: Illustration 66. 15” (381 mm) H Overhead Storage Cabinet Installation Illustration 80a.

- Page 64 Stride Stride Installation Packet Installation Packet Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 80. 15" h Overhead Storage Cabinet Installation: Illustration 66. 15” (381 mm) H Overhead Storage Cabinet Installation Contiuned Illustration 80. 15" h Overhead Storage Cabinet Installation: Illustration 80c.

- Page 65 Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 81. Ganging 15" h Overhead Storage Cabinets: Illustration 81. Ganging 15" h Overhead Storage Cabinets: Illustration 67. Ganging 15” (381 mm) H Overhead Storage Cabinets:...

- Page 66 Stride Stride Installation Packet Installation Packet Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 83. 15" h Overhead Storage Cabinet Easy Assist Mechanism Installation Illustration 69. 15” (381 mm) h Overhead Storage Cabinet Easy Assist Mechanism Installation Illustration 83a. Install Easy Assist Mechanism Mounting Plate onto Each Side of Cabinet: Illustration 83.

- Page 67 Stride Installation Packet Stride Stride Installation Packet Installation Packet Stride Stride Installation Packet Installation Packet Illustration 69. 15” (381 mm) h Overhead Storage Cabinet Easy Assist Mechanism Continued Illustration 83. 15" h Overhead Storage Cabinet Easy Assist Mechanism Installation Illustration 83. 15" h Overhead Storage Cabinet Easy Assist Mechanism Installation 69c.

- Page 68 Stride Stride Stride Stride Installation Packet Installation Packet Installation Packet Installation Packet Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 70. 15” h Overhead Storage Cabinet up-Mount Kit Installation Continued Illustration 84. 15" h Overhead Storage Cabinet up-Mount Kit Installation Illustration 84.

-

Page 69: Permanent Wall Hanger Installation

Stride Stride Installation Packet Installation Packet • Customers must provide attachment hardware. Either: • Customers must provide attachment hardware. Either; 1 . #10 screws with metal “Molly” or “Toggle” type fasteners of an appropriate size for " (or thicker) drywall, 1 #10 screws with metal “Molly” or “Toggle” type fasteners of an appropriate size for 5/8” (15.875 mm) (or thicker) drywall,... - Page 70 Stride Stride Installation Packet Installation Packet WArnInG Failure to install product as instructed, use of hardware other than that which is provided with the product, or failure to comply with all instructions can result in product failure, personal injury, or property damage.

- Page 71 Stride Stride Installation Packet Installation Packet Illustration 73. Cantilever Bracket Installation Step 1 - Tilt the front of the cantilever up and insert the top hook into desired slot of panel frame . Step 2 - Rotate the cantilever down so the remaining hooks engage the slots of the vertical .

- Page 72 Stride Stride Installation Packet Installation Packet Illustration 74. Support Panel (use to support adjacent worksurfaces, can not be used at the end of a single worksurface) Illustration 74a. Preassemble Support Panel Illustration 74b. hang Support onto Panel Support panel flat bracket...

- Page 73 Stride Stride Installation Packet Installation Packet Illustration 75. End Support Panel (use to support the end of a run of worksurfaces, or single worksurface where no return panel is positioned) Illustration 75a. Preassemble End Support Panel Illustration 75b. hang End Support Panel onto Panel...

- Page 74 Stride Installation Packet Illustration 76. Flat Bracket Primary worksurface (supported at each end) Return worksurface Position with notche toward rear of return worksurface Flat Bracket 2 Wood screws into return worksurface locator holes for alignment. 4x additional wood screws into return worksurface 6x wood screws into primary worksurface Illustration 77.

- Page 75 Stride Installation Packet Stride Stride Installation Packet Installation Packet Illustration 78. Support Column (Use with Peninula and D-shaped worksurfaces) Illustration 92. Support Column (use with peninsula and D-shaped worksurfaces) Leveling glide Leveling glide Support column Support Column Machine screw - install four...

- Page 76 Stride Stride Installation Packet Installation Packet Illustration 80. Pedestal to Panel Attachment Illustration 80a. Anti-dislodgment bracket Align top of bracket with top of pedestal case Self-drilling screw - insert four screws through bracket into pedestal Align outside edge of bracket with...

- Page 77 Step 2 - Push worksurface bracket over the edge of the unit note: The “Y” should face outward if installing the side access unit on Align, Stride, or Terrace DNA panel system . The “Y” should be inside the unit if installing for Terrace 2 .6, or Concensys...

- Page 78 Stride Stride Installation Packet Installation Packet Illustration 81b Side Access Worksurface Installation Step 4 - (only if installing on Terrace 2 .6, and Concensys) Install the two shelf clips into the false back Shelf Clips Step 5 - Insert the bottom shelf back...

- Page 79 Stride Stride Installation Packet Installation Packet Illustration 81c Side Access Worksurface Installation Wood Screws Step 6 - Make sure the side access unit is level and the worksurface bracket is even with the worksurface . Line up the front edge of the worksurface with the front edge of the side access unit . Insert the three wood screws into the worksurface .

- Page 80 Stride Stride Installation Packet Installation Packet Illustration 82. Wall Mounted tackboard Installation Customer provides appropriate note: Correct orientation of wall attachment hardware - wood mounted bracket . screws into studs, or Molly-type fastener into drywall . Horizontal Mounting Horizontal Mounting...

-

Page 81: Countertop Installation

Stride Installation Packet Illustration 83. Countertop Installation Illustration 83a. Countertop Exploded View Transition Piece Countertop Top Cap Countertop Support Bracket Top Cap Retainer Attachment Bracket NOTE: Corner countertop shown. Straight countertops up to 48” (1249.2 mm) wide require only two attachment and countertop support brackets, while 54”... - Page 82 Stride Installation Packet Illustration 83. Countertop Installation Continued Illustration 83b. Modifying Top Cap Retainers Step 2 - Cut top cap reatainers with hacksaw per dimensions below. Cut two for straight countertops ane three for corner or 120 degree countertops. 2 - 5/8 3 - 3/8 (66.675 mm)

- Page 83 Stride Installation Packet Illustration 83. Countertop Installation Continued Illustration 83d. Install Support Brackets Step 4 - Reinstall modified top cap retainers Step 5 - Position support brackets onto attachment brackets and secure with four #8- 18 x 1/2” hex head self drilling screws.

- Page 84 Stride Installation Packet Illustration 83. Countertop Installation Continued Illustration 83f. Attach Countertop wood screws Step 7 - Insert eight wood screws through each bracket into bottom of worksurface. 3430215200 J Page 83 of 90 (09/19)

-

Page 85: Spanning Tile Installation

Stride Stride Installation Packet Installation Packet Stride Installation Packet Illustration 98. Spanning tile Installation Illustration 84. Spanning tile Installation Illustration 98a. Modify/remove Center Clip Blocks 84a. Modify/remove Center Clip Blocks Step 1 – If installing spanning tiles on both sides of the frame, remove center clip blocks (only on 36" or wider frames) and recycle . - Page 86 Stride Stride Installation Packet Installation Packet Illustration 84. Spanning tile Installation Illustration 84b. Installing Spanning tile top Segment Kit. (Only used With Monolithic tiles Or tiles Installed In the top location Of Panel Frame) Step 3 – Insert sheetmetal vertical brackets into both ends of the aluminum top segment extrusion .

- Page 87 Stride Stride Installation Packet Installation Packet Illustration 84. Spanning tile Installation Illustration 84c. Installing Spanning tile Mid/Bottom Segment Kit At Bottom location Of Frame. (Only used With Monolithic Or Segmented tiles Installed At Base location) Step 6 – Insert sheetmetal vertical brackets into both ends of the aluminum segment extrusion .

- Page 88 Stride Stride Installation Packet Installation Packet Illustration 84. Spanning tile Installation Illustration 84d. Installing Spanning tile Mid/Bottom Segment Kit At Segment location On Frame. note: Segment Kit Is Only Installed If Segmented tiles Are Being Installed. If Monolithic tile Is Being Installed, Proceed Onto next Step Of Installing the tiles.

- Page 89 Stride Stride Installation Packet Installation Packet Illustration 84. Spanning tile Installation Illustration 84f. removing Side Clips. Step 1 – Pry up side clip with flat head screwdriver at locations 1a and 1b . nOtE: Be sure not to damage tile while removing clips.

- Page 90 Stride Installation Packet Stride Installation Packet Illustration 85. to-the-Floor Spanning tile Installation Illustration 85b. Assemble to-the-Floor tile Segment Kit. Step 6 - Attach the to-the- floor bracket assembly to the spanning segment extrusion by sliding the assembled brackets in from the side Brackets should be approximately 1" (25.4mm) from the ends when installed.

- Page 91 Stride Stride Installation Packet Installation Packet Illustration 85. to-the-Floor Spanning tile Installation Illustration 85d. Installing to-the-Floor Spanning tiles to Panel Frame. Step 8 – By tilting the top of the tile away from the panel, insert the bottom clips into their proper locations in each bracket (1st) Step 9 –...

Need help?

Do you have a question about the Stride and is the answer not in the manual?

Questions and answers