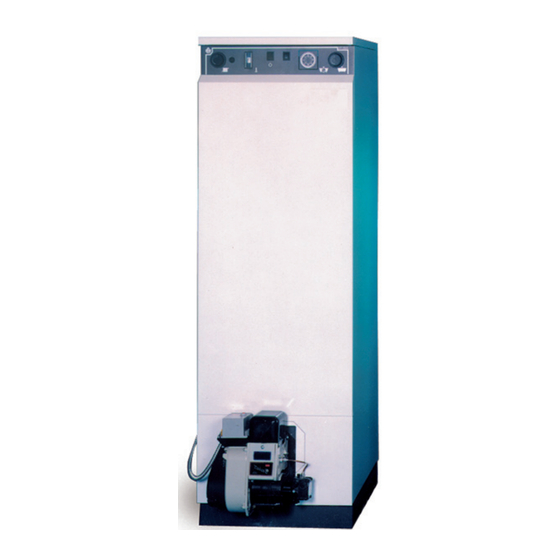

Summary of Contents for TriangleTube Delta Elite Series

-

Page 1: Trouble Shooting Guide

F-25/30/35/40 & 45 SERVICE TECHNICIAN’S TROUBLE SHOOTING GUIDE 2006-15 EliteTSG-PG-4/06... - Page 3 WARNING Indicates a potentially hazardous situation, if ignored, can result in death, serious injury or sub- stantial property damage. NOTICE Indicates special instructions on installation, operation or maintenance, which are important to the equip- ment/product, but not related to personal injury hazards. WARNING This guide is to be used in conjunction with the ELITE Installation and Maintenance manual.

- Page 4 Introduction This guide is to be used in conjunction with the Triangle Tube ELITE Combination Water Heater Installation and Maintenance Guide. Good Troubleshooting Practices Before leaving for the job site: - Check your parts and tools. • Test equipment and tools that you will need: Electrical meter that can measure voltage and continuity.

-

Page 5: Service Check List

Service Check List No Heat Call - Unit Cold & Burner Not Firing - Page 5-7 - Check Manual Reset Limit - Check the LED Code on Burner Control No Heat Call - Check the Incoming Power Supply Unit is Cold & Burner Not Firing - Check the Transformer / 24V Circuit - Check the Safety Limits - Check “Relay 1”... - Page 6 Servicing Tips and Instructions Service Instruction 1 - Accessing the Electrical Control Panel 1. Disconnect power supply to the ELITE prior to proceeding with the instructions. WARNING Failure to disconnect the power supply prior to proceeding with the instructions could lead to pos- sible electrical shock hazard and cause severe personal injury or death.

- Page 7 Servicing Tips and Instructions 8. To reassemble the front jacket panel, insert the lower tabs into the side panels. Lift the panel up to align the locking pins with the retaining clips and snap the panel into place. 9. Align the top jacket panel with the locking pins and snap downward into place. Service Instruction 2 - Removing Front or Top Jacket Panel and Burner Panel 1.

- Page 8 No Heat Call - Unit is Cold & Burner Not Firing Check the Manual Reset Safety Limit. - The Manual Reset Safety Limit reset button is located on the center of the front control panel. - If the Manual Reset Limit had tripped then check the following items: •...

- Page 9 No Heat Call - Unit is Cold & Burner Not Firing • If voltage is not present, and 120V is supplied to the unit replace the Transformer. Proceed to Check the Safety Limits. Check the Safety Limits. - Complete the procedures for checking Incoming Power Supply and for checking the Transformer and 24V Circuit.

- Page 10 No Heat Call - Unit is Cold & Burner Not Firing - If the system temperature is above 160ºF, initiate a “call for heat” within the system and attempt to cool the unit down. If the unit cools down and the Automatic Reset limit does not reset, replace the limit.

- Page 11 No Heat Call - Unit is Hot & Burner Fires Check for System Component Problems. - Check the room thermostats for proper function. - Check zone valves or circulators for proper function. - Check zone panels or relays for proper function. Check for System Electrical Problems.

- Page 12 Insufficient Domestic Hot Water Temperature Is the ELITE properly sized for the domestic water application? • There are many methods of sizing various domestic hot water applications, i.e ASHRAE sizing tables, or ASPE domestic water heating design manual. Re-confirm the domestic hot water demand required for the application.

- Page 13 Insufficient Domestic Hot Water Temperature Does the mixing valve require cleaning due to scaling deposits? 1. Isolate the domestic water supply to the ELITE and relieve any existing pressure. 2. Remove the main valve body from the ELITE using the union connections. 3.

- Page 14 Excessive Domestic Hot Water Temperature Is the thermostatic mixing valve properly set? • The operating range of the mixing valve is 90ºF to 120ºF. • The mixing valve is equipped with a cap that may be locked into position. Adjust the mixing valve setting to the desired temperature prior to locking the cap.

- Page 15 Pressure Relief Valve Lifting or Weeping Is the expansion tank on the primary system properly sized? • Each ELITE unit contains approximately 20 gallons of primary water that needs to be accounted for in the sizing of an expansion tank. Conventional Expansion Tank Capacity Gallons = Heat Loss Btu/hr 5,000...

- Page 16 Temperature/Pressure Relief Valve Lifting or Weeping Is there a thermal expansion tank installed on the domestic supply piping and is it properly sized? • A thermal expansion tank is required if the domestic supply piping includes a backflow preventer or pressure reducing valve.

- Page 17 Water Found on the Floor Near the Unit Is the source of the water from the ELITE? • Check for possible water seepage through foundation cracks. Did the water appear after a heavy rain? • Check overhead pipes for leaking connections or excessive condensation. Is the source of the water from the T&P Relief Valve? •...

-

Page 18: Water Quality Problems

Water Quality Problems The water smells like “rotten eggs”. The most common cause of water to smell like “rotten eggs” is a non-toxic sulfate reducing bacteria. The bacteria usually enters into the water system through a break in the supply piping or during construc- tion/maintenance of the supply piping. - Page 19 Water Quality Problems As the water system pressure increases, the amount of gas that the water can hold in a solution decreas- es. When air and gases are forced out of the heated water, the problem may be evident in one or both of the following conditions •...

- Page 20 Start Up Items WARNING The start up of the ELITE should be performed by a qualified installer, service agency or the gas or oil supplier. The start up procedure should include a complete combustion test. A complete com- bustion test must also be performed after any adjustments to the burner factory setting. Failure to comply with these requirements can result in severe personal injury, death or substantial property damage.

- Page 21 Start Up Items The motor is lockout on thermal overload Check for: Seized motor bearing Seized fuel pump Fan locked against housing Start winding burned out Defective starter switch Defective wiring If the burner motor starts, but there is no flame: There may be insufficient oil flow.

- Page 22 Start Up Items If the burner starts and has a smoky flame: Check for: Insufficient combustion air Improper mixing of oil and air Insufficient draft Flame impingement on the combustion walls Nozzle afterdrip due to faulty solenoid or cutoff valve If you hear mechanical noise from the burner: Check for: Loose fan...

- Page 23 Start Up Items General Troubleshooting Guidelines for the Carlin G3B Gas Burner NOTICE The following is a list of general guidelines for troubleshooting the Carlin G3B Gas Burner. It is recom- mended to reference the Carlin burner installation manual or contact Carlin or local burner representative for additional assistance.

- Page 24 Start Up Items General Troubleshooting Guidelines for the Riello 200 / 400 Gas Burner NOTICE The following is a list of general guidelines for troubleshooting the Riello Gas Burner. It is recommend- ed to reference the Riello burner installation manual or contact Riello or local burner representative for additional assistance.

- Page 25 Appendix ELITE Factory Wire Connection Diagram...

- Page 26 Appendix ELITE Factory Ladder Wiring Diagram...

- Page 27 Notes For additional Technical Assistance Contact: Triangle Tube Engineering Department Tel: (856) 228 8881 Fax: (856) 228 3584 E-mail: Eng@TriangleTube.com R.W. Beckett Corporation Tel: (800) 645 2876 Fax: (440) 327 1064 Carlin Combustion Technology Inc. Tel: (413) 525 7700 Fax: (413) 525 83 00...

- Page 28 Member of Triangle Tube/Phase III Co., Inc. Freeway Center - 1 Triangle Lane - Blackwood, NJ 08012 Tel: (856) 228 8881 - Fax: (856) 228 3584 E-mail: Info@triangletube.com http://www.triangletube.com Group...

Need help?

Do you have a question about the Delta Elite Series and is the answer not in the manual?

Questions and answers