Advertisement

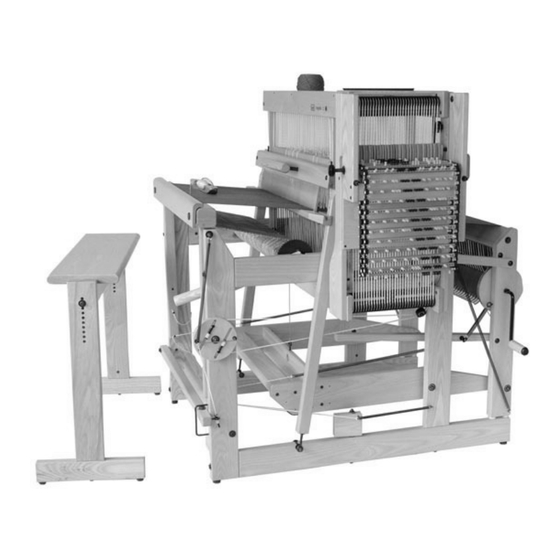

Megado 70 / 110 / 130

Instructions

Introduction .......................................................................................................................................... 1

Assembling the loom ............................................................................................................................ 2

Assembling the mechanical dobby system ......................................................................................... 21

Installing the electronic interface ........................................................................................................ 29

Tips and tricks for using the loom ....................................................................................................... 33

Maintenance ...................................................................................................................................... 37

Trouble shooting ................................................................................................................................ 37

Contact .............................................................................................................................................. 41

Version: I-ME-EN-V3

Advertisement

Summary of Contents for Louet Megado 70

-

Page 1: Table Of Contents

Megado 70 / 110 / 130 Instructions Introduction ............................1 Assembling the loom ..........................2 Assembling the mechanical dobby system ..................21 Installing the electronic interface ......................29 Tips and tricks for using the loom ....................... 33 Maintenance ............................37 Trouble shooting .......................... -

Page 3: Introduction

Introduction Megado’s countermarch action produces a perfect shed automatically The Megado is not literally a countermarch loom although it has all the advantages of one. In countermarch looms, the shafts move both up and down so that tension on both raised and lowered warp threads is equal. -

Page 4: Assembling The Loom

Assembling the loom Ask a friend During the assembly of the loom, there will be some moments that you will need assistance. The middle section or the assembled loom is difficult to move by oneself. For these tasks, we advise you to ask a friend or a family member for help. Barrel nuts For the assembly of the looms, we use many barrel nuts and bolts to connect two parts. - Page 5 Tools All parts used for the loom are metric. To facilitate the assembly, we have included two wrenches (10 mm for m6, 13 mm for m8) and a pz2 cross head screwdriver (not a Phillips head!). Together with hardware bags 1, 2 and 5, these tools are located in box B. Bolts, washers, bushings and nuts, packed in the hardware bags are assembled in the correct sequence.

- Page 6 Take one of the hinged arms and assemble it to side rail JND, using an m8 x 65 mm carriage bolt, washers, and cap nut. Make sure that the screw hooks of the arm are located as shown on the picture. One big washer and two small washers have to be placed onto the bolt between the arm and the ball bearing;...

- Page 7 Now assemble both bottom side rails below the already assembled vertical posts by sliding them over the wooden pegs. Tighten these joints (A-A and B- B) with an m8 x 130 mm bolt, large washer, and barrel nut. Slide the front posts over the wooden pegs of the upper and lower side rails and make the connections I-I, J-J, F-F, and E-E with the four remaining m8 x...

- Page 8 Apply pressure to the side where the foot rail pegs rest so that the side moves out, allowing the pegs of the foot rail to fall into place. Connect and tighten at both sides with m8 x 70 mm bolts, large washer, and barrel nut.

- Page 9 4. Assembling the treadle arms Open hardware bag 2: 4 carriage bolts 8 x 75 mm with • large washer, small washer, spacer, and cap nut. 2 bolts m8 x 70 mm with large • washer and barrel nut. 1 threaded hook m6 x 60 mm with •...

- Page 10 Turn the hinged arm, which rests on the side rail, backwards and connect it into the other ball bearing hole in the back post. Remember to put the three washers onto the bolt, in between the hinged arm and the ball bearing. 5.

- Page 11 Connect the left back post with the treadle arm in the same manner as you did on the other side. Take the back beam, marked P O out of box D. First insert the wooden pegs of the back beam on side P into the holes in the right back post.

- Page 12 6. Assembling the treadle Now you will attach the treadle rail and the connection rail (from Box C) to the treadle arms. There are four holes in each treadle arm for the attaching of the connection rail. You will only use two on each side: The two holes farthest from the front of the loom are used for the 16- shaft loom.

- Page 13 Carefully lift the treadle bar on the opposite side and slide it into its place between the arms. Place the screws into the holes of the treadle arm and find the pilot holes by adjusting the treadle bar. Now tighten all screws of the treadle bar with the screwdriver and then tighten the screws that hold the connecting rail.

- Page 14 8. Installing the cloth beam Open hardware Bag 3, which is in Box C: 10 beam cords (if your Megado is a 70 or 110, 1 carriage bolt m8 x 75 mm with • • you only need 6 or 8 of them) large washer, 33 mm bushing, small washer, and cap nut 1 ratchet wheel...

- Page 15 Take the cloth beam out of Box C. Slide the ratchet wheel over the long shaft and install with the four 4 x 30 mm screws. Make sure the countersunk holes for the screws are facing out so that the screw heads fit. Slide the cloth advance handle over the shaft against the ratchet wheel and install the cloth beam into the slots in...

- Page 16 Insert the m8 x 50 mm carriage bolt through the back post after you have lifted up the back part of the loom (to prevent the hinged arm from interfering with the installation of the carriage bolt). Slide the large washer, bushing, and small washer onto the bolt and tighten with the cap nut.

- Page 17 The threaded hook for the brake cable has to be installed now on the short end of the brake pedal. Insert the barrel nut into the hole and place the thread of the hook into the groove of the treadle. Now, screw the hook into the barrel nut until the threaded end protrudes about 3/4"...

- Page 18 Hang this hook into the eye of the brake pedal with the cord around the neck of the eye. Later on we’ll explain how this hook can be used to block the brake pedal in a position such that the brake is released.

- Page 19 Screw three screws into each of the spring arms. The heads have to protrude about ¼" (5 mm). Hook the Texsolv cord onto the middle screw of each spring arm. Insert a screw through the second last hole on the other end of each cord and screw them into the holes of the backside of the front posts.

- Page 20 Hook the ends of the spring cords onto the bottom screw heads of the spring arms (see page 37: the moving breast beam). Place the breast beam (from box C) onto the pins of the spring arms. Use the nail, again, to screw the screw eyes into the holes on the rear of the back posts.

- Page 21 Screw the hinges into the bottom of the uprights. The exact height of the beater can be adjusted later on by screwing the hinges further in or out. Attach the reed support (out of Box D) in the notches of the uprights, using the two m6 x 75 mm bolts, washers, and barrel nuts.

- Page 22 Assemble the top beater bar, placing the bolts into the grooves on top of the uprights. Be sure that the washers are installed in between the uprights and the wing nuts! Tighten the wing nuts, so that the top beater bar is high enough, allowing the reed to be inserted from the side.

-

Page 23: Assembling The Mechanical Dobby System

Assembling the mechanical dobby system This section only applies if the loom is provided with a mechanical dobby system. The mechanical dobby head has a wooden roller driven by a treadle. A chain of program bars (also called dobby bars) runs along this roller. Each time you push the treadle, the roller makes a quarter turn to bring the next program bar into the proper position for selecting the shafts for the next shed. - Page 24 2. Assembling the dobby treadle Screw the guide block for the dobby treadle with the two 5 x 55 mm screws into the pilot holes on the inside of the right hand front post of the loom. Insert the dobby treadle from the right side through the brace of the previously installed guide block.

- Page 25 Replace washer and nut onto the threaded rod that now protrudes under the side rail. Tighten nut and cap nut securely using two 13 mm wrenches and then remove the book(s). A spring and a cord are attached to the screw eye in the blocking block.

- Page 26 4. Installing the bar with the rollers for the cords You have to attach this bar with the guide rollers, using the hole that you will find on the right side of the shaft section of the loom in the lower cross bar that is farthest back.

- Page 27 Remove the plastic hooks from the cord ends. Slide these ends through the back into the holes of the reversing disk. Replace the plastic hooks and press them into the black holders on the disk, the tips of the hooks pointing towards the bottom of the groove.

- Page 28 Adjust the cords so they are taut and so that the metal guide on the reversing disk is horizontal. There is some play in the position of this guide, but it is important that the average position is horizontal. Check as follows: You pick up the guide on the left side and while you move it up and down,...

- Page 29 You can evaluate whether the adjustment has been done accurately by turning the black plastic knob on front of the dobby mechanism. In both positions of the spring, you must be able to turn the knob both ways with equal ease. If this is not the case, recheck the adjustments.

- Page 30 Reconnect the ends of the chain of bars with the grey pegs. Connecting the links of the chain requires some skill, because the right and the left sides have to be done at the same time. You can place stickers on the side chain joints in order to number the program bars.

-

Page 31: Installing The Electronic Interface

Installing the electronic interface This section only applies if the loom is provided with an electronic interface. If your Megado has a mechanical dobby system, you have to disassemble this system first, using the instructions of the previous pages. Parts included with the interface: Power cable (North American, •... - Page 32 Place the magnet onto the dobby knife as shown in the picture and insert the barrel nuts into the holes in the sides of the middle section. Make sure the slots are facing outwards. Insert the threaded rods into the holes in the side of the middle section and screw them into the barrel nuts, keeping the slot of the nuts in line with...

- Page 33 (select Spinning & weaving, Weaving looms, Megado and follow the instructions described in the paragraph “Louet Dobby USB Files”. If you use the USB cable you need to make sure that the interface is connected with the COM-port that you have selected in the weaving program.

- Page 34 Both PC’s and Mac computers will communicate with the Louët interface. Warranty Louet North America offers a 2-year complete warranty for our Electronic Interface. For all warranty issues, contact Louet North America at info@louet.com...

-

Page 35: Tips And Tricks For Using The Loom

Tips and tricks for using the loom Installing the heddles to the shafts Texsolv heddles consist of a double polyester cord that is connected at specific distances. This chain of heddles is folded in a zigzag fashion into bundles of one hundred. With a sharp pair of scissors, cut the loops between the heddles. - Page 36 Slide the bundle of heddles onto the shaft bar, replace the shaft side into the groove, reinsert the bent end into its hole, and replace the cord into the groove. Remove the two ties that hold the top part of the heddles. To install the heddles onto the lower shaft bar, we recommend placing the shaft in a higher position:...

- Page 37 While pushing the brake pedal down, you can attach the hook to the bolt of the hinge point located on the treadle where it is connected to the back part of the loom. By changing the length of the Texsolv cord, you can adjust the friction of the brake.

- Page 38 the rod to check whether the cords are equally tight. If required, correct them by loosening the loops and then tightening them again by pulling on the rod. When you are ready to tie on the warp to the apron rod, remove the cloth protector on the breast beam by unscrewing the plastic knurled bolts at both sides.

-

Page 39: Maintenance

Points of attention 1. Do not remove the ties from the bundles of heddles before the shafts bars or something else has been put into the heddle openings. The ties are required to keep the heddles properly organized. 2. With some weave structures there are many warp threads on the first two shafts. To help these two first shafts moving down when the shed closes, we have added some additional weight to them. - Page 40 A shaft that should stay down, comes up when you make a shed Possible cause: The dobby hook of the faulty shaft did not come high enough after the previous shed. The • screw head should snap back above the blocking plate. Because the screw head stays against the blocking plate, the dobby hook remains extended forward and will be picked up by the knife, making next shed.

- Page 41 When you push the shed treadle, there is no shed Possible causes: The cable of the treadle has become undone. • To prevent overheating of the interface, it becomes inactive if you wait a while before • making next shed. Activate the interface again with your software. There are no pegs in the program bar that you just put into position.

- Page 42 You do not push in the dobby treadle far enough. • The cord between the treadle and the reversing disk is too loose or too tight. • The position of the reversing disk is not properly adjusted. • The cords connecting the reversing disk to the anchor are not properly positioned over •...

-

Page 43: Contact

Contact If you still have a problem after reading this section, please contact your dealer or Louët directly. For problems with the electronic interface you can contact Louet North America. Louët BV Louet North America Kwinkweerd 139...

Need help?

Do you have a question about the Megado 70 and is the answer not in the manual?

Questions and answers