York ZR Series Installation Manual

15 - 25 ton 60 hertz

Hide thumbs

Also See for ZR Series:

- Technical manual (104 pages) ,

- Wiring diagrams (95 pages) ,

- Installation manual (72 pages)

Table of Contents

Advertisement

R-410A

ZR SERIES

15 - 25 Ton

60 Hertz

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging And Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compressors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power And Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 13

Optional Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional Gas Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Options/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Damper Set Point Adjustment. . . . . . . . . . . . . . . . . . . . . . 27

Optional Variable Air Volume (VAV) . . . . . . . . . . . . . . . . . 27

Optional Hot Gas Bypass (HGBP) . . . . . . . . . . . . . . . . . . 29

Air Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1 ZR180-300 Unit Limitations . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 ZR180-300 Unit Accessory Weights . . . . . . . . . . . . . . . . . 9

4 Utilities Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Supply Fan VFD Weights, In Lbs. . . . . . . . . . . . . . . . . . . . 9

6 ZR180-300 Unit Clearances . . . . . . . . . . . . . . . . . . . . . . 11

7 Control Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 ZR180-300 Physical Data . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Electric Heat Minimum Supply Air . . . . . . . . . . . . . . . . . . 23

11 Gas Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

12 Gas Pipe Sizing - CapacIty of Pipe . . . . . . . . . . . . . . . . . 24

13 Gas Heat Minimum Supply Air . . . . . . . . . . . . . . . . . . . . 24

14 Altitude/Temperature Correction Factors . . . . . . . . . . . . 32

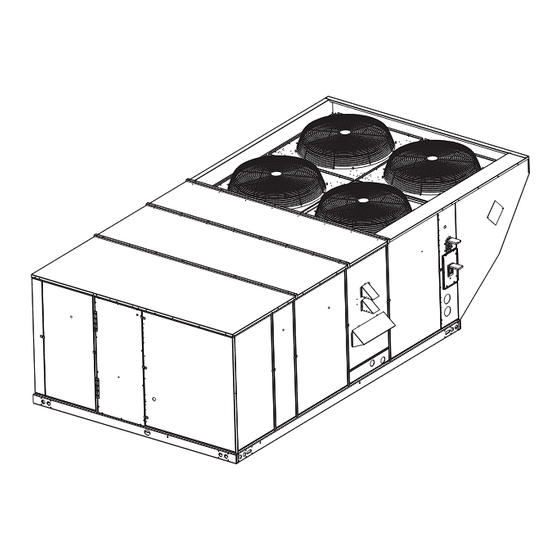

1 ZR180-300 Component Location . . . . . . . . . . . . . . . . . . . 6

2 Unit 4 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Unit 6 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Center of Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 ZR180-300 Unit Dimensions Front View . . . . . . . . . . . . . 9

6 ZR180-300 Unit Dimensions Rear View . . . . . . . . . . . . 10

7 ZR180-300 Unit Dimensions Rain Hood . . . . . . . . . . . . 11

8 ZR180-300 Roof Curb . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Fixed Outdoor Air Damper . . . . . . . . . . . . . . . . . . . . . . . 13

10 Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12 Typical Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 External Supply Connection External Shut-Off . . . . . . . 24

14 Bottom Supply Connection External Shut-Off . . . . . . . . 24

15 Vent and Combustion Air Hood . . . . . . . . . . . . . . . . . . . 26

16 Enthalpy Set Point Chart . . . . . . . . . . . . . . . . . . . . . . . . 30

17 Honeywell Economizer Control W7212 . . . . . . . . . . . . . 30

TABLE OF CONTENTS

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cooling Sequence Of Operation . . . . . . . . . . . . . . . . . . . . 39

No Outdoor Air Options . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cooling Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . 41

Reheat Mode Sequence Of Operation . . . . . . . . . . . . . . . 42

Electric Heating Sequence Of Operations. . . . . . . . . . . . . 45

Electric Heat Operation Errors . . . . . . . . . . . . . . . . . . . . 46

Gas Heating Sequence Of Operations . . . . . . . . . . . . . . . 46

Gas Heating Operation Errors . . . . . . . . . . . . . . . . . . . . 47

Start-Up (Cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Start-Up (Gas Heat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Checking Gas Heat Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Charging The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Unit Control Board Option Setup . . . . . . . . . . . . . . . . . . . . . . 60

Option Byte Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Heat Delay Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Optional VAV Control Board Flash Codes . . . . . . . . . . . . 60

LIST OF TABLES

15 Air Flow Performance - Side Duct Application . . . . . . . . 34

16 Air Flow Performance - Bottom Duct Application . . . . . . 36

17 RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

18 Indoor Blower Specifications . . . . . . . . . . . . . . . . . . . . . . 38

19 Power Exhaust Specifications . . . . . . . . . . . . . . . . . . . . . 38

20 Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . 39

21 Limit Control Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

22 Electric Heat Anticipator Setpoint . . . . . . . . . . . . . . . . . . 46

23 Gas Heat Limit Control Setting . . . . . . . . . . . . . . . . . . . . 48

24 Gas Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . . . . 48

25 Gas Rate Cubic Feet Per Hour . . . . . . . . . . . . . . . . . . . . 50

26 Unit Control Board Flash Codes . . . . . . . . . . . . . . . . . . . 59

27 Heat Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

28 VAV Control Board Flash Codes . . . . . . . . . . . . . . . . . . 60

LIST OF FIGURES

18 Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

19 Altitude/Temperature Correction Factors . . . . . . . . . . . . 32

20 Pressure Drop Across A Dry Indoor Coil Vs. Supply

Air CFM For All Unit Tonnages . . . . . . . . . . . . . . . . . . . 38

21 Reheat Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . 43

22 Reheat Controls - Part 1 . . . . . . . . . . . . . . . . . . . . . . . . 44

23 Reheat Controls - Part 2 . . . . . . . . . . . . . . . . . . . . . . . . 44

24 System Piping Schematic . . . . . . . . . . . . . . . . . . . . . . . 45

25 Gas Valve Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

26 Gas Valve and Controls . . . . . . . . . . . . . . . . . . . . . . . . . 48

27 Proper Pilot Flame Adjustment . . . . . . . . . . . . . . . . . . . 50

28 Typical Flame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

29 Typical Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

30 ZR180 (15 Ton) Charging Chart . . . . . . . . . . . . . . . . . . 52

31 ZR240 (20 Ton) Charging Chart . . . . . . . . . . . . . . . . . . 52

32 ZR300 (25 Ton) Charging Chart . . . . . . . . . . . . . . . . . . 53

33 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

275864-YIM-F-0213

Advertisement

Table of Contents

Summary of Contents for York ZR Series

-

Page 1: Table Of Contents

R-410A ZR SERIES 15 - 25 Ton 60 Hertz TABLE OF CONTENTS General ......... . 2 Operation . -

Page 2: General

275864-YIM-F-0213 General ® YORK Model ZR units are either single package air conditions equipped with optional factory installed electric heaters, or single Before performing service or maintenance operations on package gas-fired central heating furnaces with cooling unit. unit, turn off main power switch to unit. Electrical shock Both are designed for outdoor installation on a rooftop or slab. - Page 3 Wear safety glasses and work gloves. Use quenching cloth and Renewal Parts have a fire extinguisher available during brazing operations. ® Contact your local York parts distribution center for authorized replacement parts. Inspection As soon as a unit is received, it should be inspected for possible Approvals damage during transit.

- Page 4 275864-YIM-F-0213 Nomenclature 15-25 Ton MagnaDRY™ Model Number Nomenclature Z R 180 N24 A 2 A AA 1 0 1 2 4 A Product Category Product Style Z = A/C, Single Pkg., R-410A A = Style A Product Identifier Configuration Options (not required for all units) These four digits will not be assigned until a quote is requested, or an order placed.

-

Page 5: Installation

275864-YIM-F-0213 Installation Limitations These units must be installed in accordance with the following: Installation Safety Information In U.S.A.: Read these instructions before continuing this appliance National Electrical Code, ANSI/NFPA No. 70 - Latest installation. This is an outdoor combination heating and cooling Edition unit. - Page 6 275864-YIM-F-0213 ® Simplicity Control Board 110 Volt Convenience Outlet 2” Disposable Filters (“Powered” or “Non-Powered” Optional) (4” Filters Optional) Disconnect Location (Optional Disconnect Switch) Bottom Power and Control Wiring Entry Copper Tube/Aluminum Power Ventor Motor Fin Evaporator Coils Electric Heater Location Slide In/Plug In Internal (Optional Electric/Electric Units) Economizer (Optional)

-

Page 7: Location

If a unit is to be installed on a roof curb other than a personal injury. Typical contaminates include: ® York roof curb, gasketing must be applied to all permanent wave solution, chlorinated waxes and surfaces that come in contact with the unit underside. -

Page 8: Center Of Gravity

275864-YIM-F-0213 All panels must be secured in place when the unit is lifted. The condenser coils should be protected from rigging cable damage with plywood or other suitable material. Figure 3: Unit 6 Point Load Weight FRONT LEFT Figure 4: Center of Gravity Figure 2: Unit 4 Point Load Weight Table 2: Weights and Dimensions Size... -

Page 9: Zr180-300 Unit Dimensions Front View

275864-YIM-F-0213 Table 3: ZR180-300 Unit Accessory Weights Weight (lbs.) Unit Accessory Shipping Operating Economizer Power Exhaust Electric Heat Gas Heat Double Wall Motorized Damper Barometric Damper Econ./Motorized Damper Rain Hood Econ./Power Exhaust Rain Hood Wood Skid Roof Curb Hot Gas Bypass Supply Fan VFD See Table 5 1. -

Page 10: Zr180-300 Unit Dimensions Rear View

275864-YIM-F-0213 Dot Plug (for Pressure Evaporator Drop Reading) Section 40-3/8” Supply Outdoor Return 18-5/8” 40-1/2” Supply Air 27-3/4” Access Filter 5-1/8” Access 39-5/8” 1” NPT Female Dimensions listed are for side duct Return Air Outdoor Air Cond. Drain flange opening; see Field Accessories Access Compartment Connector... -

Page 11: Zr180-300 Unit Dimensions Rain Hood

275864-YIM-F-0213 Economizer Motorized Power Exhaust Damper Rain Hood Rain Hood Supply Air (on Outdoor (on Return Compartment Economizer/Motorized Damper Air Compartment) Air Compartment) and Power Exhaust Rain Hood Fixed Outdoor Air Intake Hood (Located on 36-5/8” Return Air 1” Condensate Compartment) Drain (Must be 16-1/8”... -

Page 12: Ductwork

275864-YIM-F-0213 25-1/4" Figure 8: ZR180-300 Roof Curb Ductwork Gasketing and mounting screws are provided in a parts bag attached to the hood assembly. Apply gasketing to the three Ductwork should be designed and sized according to the flange surfaces on the hood prior to installing the hood. Extend methods in Manual D of the Air Conditioning Contractors of gasketing 1/4 inch beyond the top and bottom of the two side America (ACCA) or as recommended by any other recognized... -

Page 13: Condensate Drain

275864-YIM-F-0213 designed for HCFC and CFC refrigerants. Take all necessary precautions to avoid exposure of the oil to the atmosphere. Side Supply Air Access Panel Do not leave the system open to the atmosphere. Unit Damper Baffle damage could occur due to moisture being absorbed by the POE oil in the system. - Page 14 A disconnect must be utilized for these units. Factory installed disconnects are available. If installing a disconnect (field Power Wiring Detail ® supplied or York International supplied accessory), refer to Units are factory wired for the voltage shown on the unit Figure 1 for the recommended mounting location.

-

Page 15: Field Wiring Disconnect - Cooling Unit With/Without

275864-YIM-F-0213 TERMINAL BLOCK TB1 FACTORY OR FIELD GROUND SUPPLIED DISCONNECT THREE PHASE POWER SUPPLY Figure 11: Field Wiring Disconnect - Cooling Unit With/Without Electric Heat Thermostat Wiring Space Sensor The thermostat should be located on an inside wall approximately The space sensor, if used, should be located on an inside wall 56 inch above the floor where it will not be subject to drafts, sun approximately 56 inches above the floor where it will not be exposure or heat from electrical fixtures or appliances. - Page 16 275864-YIM-F-0213 THERMOSTAT ( RCB ) TERMINALS REHEAT CONTROL BOARD 208/230-3-60 and 380/415-3-50 units control transformers are factory wired for 230v and 415v power supply respectively. Change tap on transformer for 208- 3-60 or 380-3-50 operation. See unit wiring diagram. TERMINAL BLOCK DEHUMIDISTAT TO REMOTE SENSOR 2ET04701324 IF USED...

- Page 17 275864-YIM-F-0213 Table 8: Electrical Data ZR180-300 - Standard Drive Without Powered Convenience Outlet OD Fan Supply Max Fuse Compressors Motors Blower Conv Electric Heat Option Size Breaker (each) Volt (each) Motor Outlet (Tons) (Amps) Size (Amps) RLA LRA MCC Model Stages Amps None...

- Page 18 275864-YIM-F-0213 ZR180-300 - Standard Drive With Powered Convenience Outlet OD Fan Supply Max Fuse Compressors Motors Blower Conv Electric Heat Option Size Breaker (each) Volt (each) Motor Outlet (Tons) (Amps) Size (Amps) RLA LRA MCC Model Stages Amps None 90.1 13.5 37.5 90.1...

- Page 19 275864-YIM-F-0213 ZR180-300 - High Static Drive Without Powered Convenience Outlet OD Fan Supply Max Fuse Compressors Motors Blower Conv Electric Heat Option Size Breaker (each) Volt (each) Motor Outlet (Tons) (Amps) Size (Amps) RLA LRA MCC Model Stages Amps None 84.7 13.5 37.5...

- Page 20 275864-YIM-F-0213 ZR180-300 - High Static Drive With Powered Convenience Outlet OD Fan Supply Max Fuse Compressors Motors Blower Conv Electric Heat Option Size Breaker (each) Volt (each) Motor Outlet (Tons) (Amps) Size (Amps) RLA LRA MCC Model Stages Amps None 94.7 13.5 37.5...

- Page 21 275864-YIM-F-0213 ZR300 - Low Static Drive Without Powered Convenience Outlet OD Fan Supply Max Fuse Compressors Motors Blower Conv Electric Heat Option Size Breaker (each) Volt (each) Motor Outlet (Tons) (Amps) Size (Amps) RLA LRA MCC Model Stages Amps None 143.0 13.5 37.5...

- Page 22 275864-YIM-F-0213 Table 9: ZR180-300 Physical Data Models Component ZR180 ZR240 ZR300 Nominal Tonnage AHRI COOLING PERFORMANCE Gross Capacity @ AHRI A point (Btu) AHRI net capacity (Btu) 11.6 12.1 10.0 SEER IEER 12.4 12.9 10.5 Nominal CFM 6000 8000 7600 System power (KW) 14.40 20.10...

-

Page 23: Optional Electric Heat

275864-YIM-F-0213 Table 9: ZR180-300 Physical Data (Continued) Models Component ZR180 ZR240 ZR300 Nominal Tonnage CONDENSER FAN DATA Quantity Fan diameter (Inch) Type Prop Prop Prop Drive type Direct Direct Direct No. speeds Number of motors Motor HP each Nominal total CFM 4000 5000 5000... -

Page 24: Optional Gas Heat

275864-YIM-F-0213 Optional Gas Heat These gas-fired heaters have aluminized-steel or optional stainless steel, tubular heat exchangers with spark ignition with proven pilot. Table 11: Gas Application Data Unit Input Temp Rise Output (MBH) (MBH) (°F) Size Opt. Main Manual 20-50 Shut-off 30-60 Valve... - Page 25 275864-YIM-F-0213 Gas Connection The gas supply line can be routed within the space and roof curb, exiting through the unit’s basepan. Refer to Figure 5 for the gas The furnace and its individual shut-off valve must be piping inlet location. Typical supply piping arrangements are disconnected from the gas supply piping system during shown in Figures 13 and 14.

-

Page 26: Options/Accessories

275864-YIM-F-0213 Options/Accessories Check all connections for leaks when piping is completed using a soap solution. NEVER USE A FLAME. Electric Heat Electric heaters are available as a factory-installed option. These heaters mount in the heat compartment with the heating elements extending into the supply air chamber. All electric FIRE OR EXPLOSION HAZARD heaters are fused and intended for use with single point power Failure to follow the safety warning exactly could result... -

Page 27: Optional Bas-Ready Economizer Power Exhaust Damper Set Point Adjustment

275864-YIM-F-0213 the “A”, “B”, “C” or “D” setting corresponding to the lettered Duct Static Pressure Transducer curve of the Enthalpy Set Point Adjustment Figure 17. A 0-5" WC pressure transducer, located in the control box • For a dual enthalpy operation, carefully turn the set point compartment, is used to sense static (gauge) pressure in the adjusting screw fully clockwise past the "D"... - Page 28 275864-YIM-F-0213 • RH - a 0-10 VDC analog input provided by a field-installed or PDA and a down-loaded copy of the Simplicity® return air relative humidity sensor for dual enthalpy software available at the UPGnet Commercial Product economizer configuration (used with OH). Catalog website.

-

Page 29: Optional Hot Gas Bypass (Hgbp)

275864-YIM-F-0213 'VFD-Ready' For Customer-installation Units configured as 'VFD-ready' provide provisions for a customer-installed drive. The physical dimensions of VFDs can If the unit is operated with the manual bypass switch in vary greatly among manufacturers, horsepower ratings and the LINE (BYPASS) position and there are VAV boxes voltage requirements. -

Page 30: Enthalpy Set Point Chart

275864-YIM-F-0213 CONTROL POINT CONTROL APPROX. CURVE (29) (32) (35) (38) (41) (43) AT 50% RH 73 (23) 70 (21) (27) 67 (19) 63 (17) (24) (21) (18) (16) (13) (10) (10) (13) (16) (21) (24) (27) (29) (32) (38) (41) (43) (18) (35) - Page 31 275864-YIM-F-0213 Phasing ® York Model ZR units are properly phased at the factory. Check for proper compressor rotation. If the blower or compressors rotate in the wrong direction at start-up, the electrical Procedure for adjusting belt tension: connection to the unit is misphased. Change the phasing of the 1.

-

Page 32: Altitude/Temperature Correction Factors

275864-YIM-F-0213 Table 14: Altitude/Temperature Correction Factors Altitude (Ft.) Temp. 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 1.060 1.022 0.986 0.950 0.916 0.882 0.849 0.818 0.788 0.758 0.729 1.039 1.002 0.966 0.931 0.898 0.864 0.832 0.802 0.772 0.743 0.715 1.019 0.982... -

Page 33: Rpm Selection

275864-YIM-F-0213 Drive Selection Determine side or bottom supply duct application. Determine desired airflow Calculate or measure the amount of external static pressure. Using the operating point determined from steps 1, 2 & 3, locate this point on the appropriate supply air blower performance table. -

Page 34: Air Flow Performance - Side Duct Application

275864-YIM-F-0213 Table 15: Air Flow Performance - Side Duct Application ZR180 (15 Ton) Side Duct Available External Static Pressure - IWG Air Flow (CFM) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP Standard 5 HP &... - Page 35 275864-YIM-F-0213 ZR300 (25 Ton) Side Duct Available External Static Pressure - IWG Air Flow (CFM) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP Low Static 7.5 HP & Low Static 7.5 HP & Drive Field Supplied Drive 6600 758 3.03 790 3.47 822 3.88 854 4.27 885 4.65 916 5.00 948 5.34 981 5.66...

-

Page 36: Air Flow Performance - Bottom Duct Application

275864-YIM-F-0213 Table 16: Air Flow Performance - Bottom Duct Application ZR180 (15 Ton) Bottom Duct Available External Static Pressure - IWG Air Flow (CFM) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP Standard 5 HP &... - Page 37 275864-YIM-F-0213 ZR300 (25 Ton) Bottom Duct Available External Static Pressure - IWG Air Flow (CFM) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP Low Static 7.5 HP & Drive Standard 10 HP &...

-

Page 38: Air Balance

275864-YIM-F-0213 Table 18: Indoor Blower Specifications Motor Motor Sheave Blower Sheave Size Model Belt Datum Dia. Datum Dia. (Tons) Eff. Frame Bore (in.) Model Bore (in.) Model (in.) (in.) 1725 0.89 1.15 184T 5.2 - 6.4 1 1/8 1VP65 10.4 BK110 BX83 (15) -

Page 39: Electric Heat

275864-YIM-F-0213 Supply Air Drive Adjustment High static drive accessories (containing a smaller blower pulley and a shorter belt) are available for applications requiring The RPM of the supply air blower will depend on the required the supply air blower to produce higher CFM's and/or higher CFM, the unit accessories or options and the static resistances static pressures. -

Page 40: No Outdoor Air Options

275864-YIM-F-0213 Optional VAV Startup and Control When the Return Air Temp (RAT) is above the "VAV Supply Air Temp Reset Set point" the SAT will be maintained at +/- 5 degrees of the "VAV Cooling Supply Air Temp Lower Set point". When the Return Air Temp (RAT) is below the "VAV Supply Air Temp Reset Set point"... - Page 41 275864-YIM-F-0213 room thermostat is set in the "AUTO" position) and drives the or if free-cooling is unavailable, the control opens the economizer dampers to the minimum position setting. economizer dampers from fully closed to their minimum position. If the enthalpy of the outdoor air is below the setpoint Free-cooling is available if the outdoor air temperature meets of the enthalpy controller (previously determined), "Y1"...

-

Page 42: Cooling Operation Errors

275864-YIM-F-0213 Economizer With Optional Intelli-comfort II™ With Power If the call for cooling is still present at the conclusion of the ASCD, the UCB will re-energize the halted compressor. Exhaust The power exhaust motor is energized via the exhaust relay based Should a low-pressure switch open three times within one hour on the position of the economizer actuator's auxiliary switch of operation, the UCB will lock-out the associated compressor... -

Page 43: Reheat Mode Sequence Of Operation

275864-YIM-F-0213 controlled. On any fault, only the associated system will be When the room thermostat calls for first stage cooling, with or affected by any safety/preventive action. The other refrigerant without a call for dehumidification, the RCB senses a signal system will continue in operation unless it is affected by the through "Y1", de-energizing the HGR, which de-energizes SOL fault as well. -

Page 44: Reheat Control Board

275864-YIM-F-0213 HGRR DEHUMIDISTAT MODE HARNESS SELECTION CONNECTION JUMPER Figure 22: Reheat Control Board Johnson Controls Unitary Products... - Page 45 275864-YIM-F-0213 UNIT CONTROL REHEA CONTROL BOARD BOARD HUMIDIFY TERMINAL REHEAT RELAY RHTB REHEAT TERMINAL BLOCK Figure 23: Reheat Controls - Part 1 REHEAT SOLENOID REHEAT REHEAT SOLENOID SOLENOID UNIT CONTROL BOARD REHEAT CONTROL BOARD Figure 24: Reheat Controls - Part 2 Johnson Controls Unitary Products...

-

Page 46: Electric Heating Sequence Of Operations

275864-YIM-F-0213 Check Valve Piping T Condenser Check Valve Air Flow Air Flow Condenser Indoor Blower Coil Refrigerant flow in cooling mode Evaporator Hot Gas Coil Coil Refrigerant flow in reheat mode Open in Bleed Line to clear Suction line Cooling the Hot Gas Coil bleed when it is not in use... -

Page 47: Electric Heat Operation Errors

275864-YIM-F-0213 Electric Heat Operation Errors Flash Codes The UCB will initiate a flash code associated with errors within Temperature Limit the system. Refer to UNIT CONTROL BOARD FLASH CODES If the UCB senses zero volts from the high temperature limit, Table 26. -

Page 48: Gas Heating Operation Errors

275864-YIM-F-0213 speed of the draft motor reaches approximately 2500 RPM, the Redundant valve Main valve centrifugal switch contact, located on the end of the draft motor shaft, closes to power the first stage ignition module “IC1”, thru the “RW1-1” contacts. Gas main Ignition module “IC1”... -

Page 49: Gas Heat Anticipator Setpoints

275864-YIM-F-0213 Safety Controls The ICB monitors the Pressure and Rollout switches of gas heat units. The UCB monitors the temperature limit switch of gas heat units. The control circuit includes the following safety controls: The control circuit includes the following safety controls: Limit Switch (LS) This control is located inside the gas heat compartment and is Ignitor Control #2... -

Page 50: Start-Up (Cooling)

275864-YIM-F-0213 Start-Up (Cooling) Operating Instructions Prestart Check List After installation has been completed: Check the electrical supply voltage being supplied. Be sure This furnace is equipped with an intermittent pilot and that it is the same as listed on the unit nameplate. automatic re-ignition system. -

Page 51: Checking Gas Heat Input

275864-YIM-F-0213 Shut Down Manifold Gas Pressure Adjustment Set the thermostat to the lowest temperature setting. Small adjustments to the high-fire gas flow may be made by turning the pressure regulator adjusting screw on the automatic Turn “OFF” all electric power to unit. gas valve. -

Page 52: Typical Flame

275864-YIM-F-0213 Pilot Checkout Heat Tube Adjustable Shutter Exchanger Burner The pilot flame should envelope the end of the flame sensor. To adjust pilot flame, (1) remove pilot adjustment cover screw, (2) increase or decrease the clearance for air to the desired level, (3) be sure to replace cover screw after adjustment to prevent Burner Flame possible gas leakage. -

Page 53: Charging The Unit

275864-YIM-F-0213 Charging The Unit 15 Ton Charging Chart Outdoor Temp (ºF) 115º 105º 95º 85º 75º Suction Pressure (psi) 1. Make sure that four condenser fans are running when charging. Two fans may switch off at a lower temperatures (about 65 degrees). 2. -

Page 54: Troubleshooting

275864-YIM-F-0213 25 Ton Charging Chart Outdoor Temp (ºF) 115º 105º 95º 85º 75º 100 105 110 115 120 125 130 135 140 145 150 155 160 Suction Pressure (psi) 1. Make sure that four condenser fans are running when charging. Two fans may switch off at a lower temperatures (about 65 degrees). - Page 55 275864-YIM-F-0213 action as needed. If the motor still does not operate, 24 volts is not present from the room thermostat, check for replace the motor. the following: a. 24 volts at the thermostat Y1 terminal If 24 volts is not present at M3, check that 24 volts is b.

- Page 56 275864-YIM-F-0213 To test, disconnect the Mate-N-Locks and jumper between b. Proper wiring between the room thermostat and the the WHITE and YELLOW wires of the UCB’s Mate-N-Lock UCB, i.e. Y1 to Y1, Y2 to Y2, and plug. If compressor #1 energizes, there is a fault in the c.

- Page 57 275864-YIM-F-0213 Check for line voltage at the compressor contactor, M1, 12. For units without economizers: If 24 volts is present at the and that the contactor is pulled in. Check for loose wiring Y1 “OUT” terminal, check for 24 volts at the Y1 “ECON” between the contactor and the compressor.

- Page 58 275864-YIM-F-0213 Place the thermostat fan switch in the “ON” position. If the On calls for heating, the supply air blower operates but the draft supply air blower motor energizes, go to Step 9. motor does not (the room thermostat fan switch is in the “AUTO”...

-

Page 59: Unit Control Board Flash Codes

275864-YIM-F-0213 making good electrical connection. Check to make sure terminals “MV” and “COMMON” terminals. If no voltage that the ceramic insulator on the pilot ignitors or sensors is detected, replace ignitor control. If voltage is present, not broken or cracked, if all are intact, replace the ignition replace gas valve. -

Page 60: Unit Control Board

275864-YIM-F-0213 Table 26: Unit Control Board Flash Codes GREEN FLASH CODE DESCRIPTION On Steady This is a Control Failure 1 Flash Not Applicable 2 Flashes Flashing Control waiting ASCD 3 Flashes HPS1 Compressor Lockout 4 Flashes HPS2 Compressor Lockout 5 Flashes LPS1 Compressor Lockout 6 Flashes LPS2 Compressor Lockout... -

Page 61: Unit Control Board Option Setup

15 Flashes Dirty Filter Switch No Power or Control Failure Subject to change without notice. Printed in U.S.A. 275864-YIM-F-0213 Copyright © 2013 by Johnson Controls, Inc. All rights reserved. Supersedes: 275864-YIM-E-0112 Johnson Controls Unitary Products 5005 York Drive Norman, OK 73069...

Need help?

Do you have a question about the ZR Series and is the answer not in the manual?

Questions and answers