Table of Contents

Advertisement

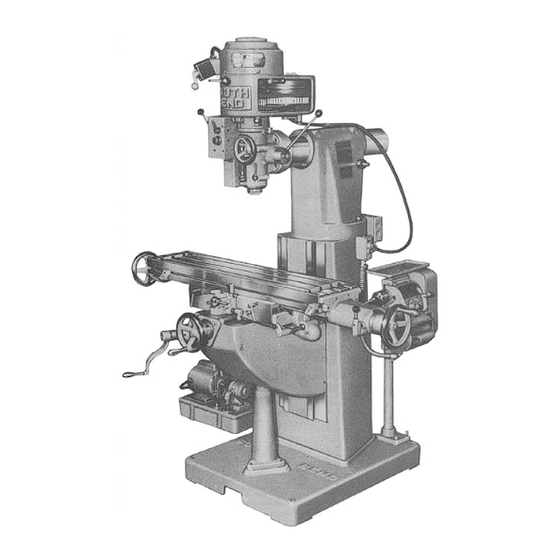

9" X 42" MILLING MACHINE

w/POWER FEED

MODEL SB1024 - VARIABLE SPEED, 220V, SINGLE-PHASE

MODEL SB1025 - 220V, 3-PHASE

MODEL SB1026 - 220V, SINGLE-PHASE

MODEL

SB1025

MODEL

SB1024

OWNER'S MANUAL

Q

Hundreds of Thousands of Lathes Sold With a Tradition of

uality Since 1906!

Copyright © March, 2010. Revised April, 2011 (BL)

For Machines Mfg. Since 8/09

Advertisement

Table of Contents

Summary of Contents for South bend SOUTH BEND LATHE CO.. SB1024

- Page 1 9" X 42" MILLING MACHINE w/POWER FEED MODEL SB1024 - VARIABLE SPEED, 220V, SINGLE-PHASE MODEL SB1025 - 220V, 3-PHASE MODEL SB1026 - 220V, SINGLE-PHASE MODEL SB1025 MODEL SB1024 OWNER'S MANUAL Hundreds of Thousands of Lathes Sold With a Tradition of uality Since 1906! Copyright ©...

-

Page 2: Scope Of Manual

Scope of Manual This manual helps the reader understand the machine, how to prepare it for operation, how to control it during operation, and how to keep it in good working condition. We assume the reader has a basic understanding of how to operate this type of machine, but that the reader is not familiar with the controls and adjustments of this specific model. -

Page 3: Table Of Contents

INTRODUCTION About These Machines... 3 ... 3 Foreword ... 3 Capabilities ... 3 Features Front View Identification ... 4 Model SB1024 Belt Housing & Headstock Identification... 5 Model SB1025/SB1026 Belt Housing & Headstock Identification... 6 SB1024 Machine Specifications ... 7 SB1025 Machine Specifications ... - Page 4 ... 54 Ram Ways Head & Ram Rack & Pinion Gear Table Elevation Leadscrew ... 54 Power Feed Gears Cleaning Coolant Reservoir... 56 ... 56 Hazards ... 56 Cleaning Machine Storage ... 57 SERVICE Adjusting Gibs... 58 Adjusting Leadscrew Backlash ... 59 Longitudinal Leadscrew Backlash ...

-

Page 5: Introduction

For Machines Mfg. Since 8/09 About These Machines Foreword "Most boys should learn a trade in order that they may become skilled workmen. The trained workman is always in demand...When a boy has learned a trade, becomes a skilled mechanic, he has excellent equipment with which to begin life's battle, but he need not stop there. -

Page 6: Front View Identification

SB1024/SB1025/SB1026 Front View Identification Spindle Brake Halogen Work Light Left X-Axis Ball Handle Power Feed Limit Switch Knee Crank One-Shot Oiler Mounting Points (1 of 4) Figure 1. Identification—front view (Model SB1024 shown). I N T R O D U C T I O N Motor Knee Y-Axis Ball Handle... -

Page 7: Model Sb1024 Belt Housing & Headstock Identification

For Machines Mfg. Since 8/09 Model SB1024 Belt Housing & Headstock Identification Low Range Variable Speed Indicator Spindle Brake Auto-Downfeed Rate Selector Auto-Downfeed Direction Pin Fine Downfeed Handwheel Downfeed Clutch Lever Adjustable Downfeed Stop Figure 2. Model SB1024 belt housing and headstock identification. Serious personal injury could occur if you connect the machine to power before completing the setup process. -

Page 8: Model Sb1025/Sb1026 Belt Housing & Headstock Identification

SB1024/SB1025/SB1026 Model SB1025/SB1026 Belt Housing & Headstock Identification Motor Assembly High/Low Range Lever Spindle Brake Auto-Downfeed Rate Selector Auto-Downfeed Direction Pin Fine Downfeed Handwheel Downfeed Clutch Lever Adjustable Downfeed Stop Quill Spindle Figure 3. Model SB1025/SB1026 belt housing and headstock identification (Model SB1025 shown). SB1025-26 belt housing &... -

Page 9: Sb1024 Machine Specifications

For Machines Mfg. Since 8/09 Machine Specifications P.O. Box 2027, Bellingham, WA 98227 U.S.A. 9" x 42" Variable Speed Milling Machine Product Dimensions: Weight ...2000 lbs. Length/Width/Height ... 63" x 58" x 87" Foot Print (Length/Width) ...36" x 24" Shipping Dimensions: Type ... - Page 10 SB1024/SB1025/SB1026 Distance Range Spindle to Column ...6"–19 " Distance Range Spindle to Table ... 0"–18" Drilling Capacity for Cast Iron ... 1" Drilling Capacity for Steel ... Number of Spindle Speeds ... Variable Low Range of Spindle Speeds ... 60–500 RPM High Range of Spindle Speeds ...

-

Page 11: Sb1025 Machine Specifications

For Machines Mfg. Since 8/09 Machine Specifications P.O. Box 2027, Bellingham, WA 98227 U.S.A. 9" x 42" Milling Machine Product Dimensions: Weight ...1920 lbs. Length/Width/Height ... 63" x 58" x 81" Foot Print (Length/Width) ...36" x 24" Shipping Dimensions: Type ... Wood Crate Content ... - Page 12 SB1024/SB1025/SB1026 Operation Information (continued) Distance Range Spindle to Column ...6"–19 " Distance Range Spindle to Table ...0"–18 " Drilling Capacity for Cast Iron ... 1" Drilling Capacity for Steel ... Number of Spindle Speeds ...16 Low Range of Spindle Speeds w/Motor @ 1725 RPM ... 80, 140, 220, 325 RPM Low Range of Spindle Speeds w/Motor @ 3450 RPM ...

-

Page 13: Sb1026 Machine Specifications

For Machines Mfg. Since 8/09 Machine Specifications P.O. Box 2027, Bellingham, WA 98227 U.S.A. 9" x 42" Milling Machine Product Dimensions: Weight ...1940 lbs. Length/Width/Height ... 63" x 58" x 86" Foot Print (Length/Width) ...36" x 24" Shipping Dimensions: Type ... Wood Crate Content ... - Page 14 SB1024/SB1025/SB1026 Operation Information (continued) Distance Range Spindle to Column ...6"–19 " Distance Range Spindle to Table ...0"–18 " Drilling Capacity for Cast Iron ... 1" Drilling Capacity for Steel ... Number of Spindle Speeds ...8 Low Range of Spindle Speeds ... 80, 140, 220, 325 RPM High Range of Spindle Speeds ...

-

Page 15: Safety

For Machines Mfg. Since 8/09 Understanding Risks of Machinery Operating all machinery and machining equipment can be dangerous or relatively safe depending on how it is installed and maintained, and the operator's experience, common sense, risk awareness, working conditions, and use of personal protective equipment (safety glasses, respirators, etc.). The owner of this machinery or equipment is ultimately responsible for its safe use. - Page 16 SB1024/SB1025/SB1026 Entanglement: Loose clothing, gloves, neckties, jewelry or long hair may get caught in moving parts, causing entanglement, amputation, crushing, or strangulation. Reduce this risk by removing/securing these items so they cannot contact moving parts. Mental Alertness: Operating this item with reduced mental alertness increases the risk of accidental injury.

-

Page 17: Additional Milling Machine Safety

For Machines Mfg. Since 8/09 Additional Milling Machine Safety Understanding Controls: The mill is a complex machine that presents severe cutting or amputation hazards if used incorrectly. Make sure you understand the use and operation of all controls before you begin milling. -

Page 18: Preparation

SB1024/SB1025/SB1026 Preparation Overview Things You'll Need The purpose of the preparation section is to help you prepare your machine for operation. The typical preparation process is as follows: Unpack the machine and inventory the contents of the box/crate. Clean the machine and its components. Identify an acceptable location for the machine and move it to that location. -

Page 19: Unpacking

For Machines Mfg. Since 8/09 Unpacking This item was carefully packaged to prevent damage during transport. If you discover any damage, please immediately call Customer Service at (360) 734-1540 for advice. You may need to file a freight claim, so save the containers and all packing materials for possible inspection by the carrier or its agent. -

Page 20: Cleaning & Protecting

SB1024/SB1025/SB1026 Cleaning & Protecting The unpainted surfaces are coated at the factory with a heavy-duty rust preventative that prevents corrosion during shipment and storage. The benefit of this rust preventative is that it works very well. The downside is that it can be time-consuming to thoroughly remove. -

Page 21: Location

For Machines Mfg. Since 8/09 Location Physical Environment The physical environment where your machine is operated is important for safe operation and longevity of parts. For best results, operate this machine in a dry environment that is free from excessive moisture, hazardous or flammable chemicals, airborne abrasives, or extreme conditions. -

Page 22: Lifting & Moving

SB1024/SB1025/SB1026 Lifting & Moving This machine and its parts are heavy! Serious personal injury may occur if safe moving methods are not used. To reduce the risk of a lifting or dropping injury, ask others for help and use power equipment. The method of lifting and moving the mill described below requires at least two other people for assistance and a forklift with two... -

Page 23: Leveling & Mounting

For Machines Mfg. Since 8/09 Leveling & Mounting Generally, you can either bolt your machine to the floor or mount it on machine mounts. Although not required, we recommend that you secure the machine to the floor and level it while doing so. -

Page 24: Assembly

SB1024/SB1025/SB1026 Assembly Ball Handles The ball handles for either end of the X-axis leadscrew have spring-loaded, keyed center bushings, as shown in Figure 9. This allows them to disengage from the leadscrew when using the power feed, avoiding an entanglement hazard. -

Page 25: Way Covers

For Machines Mfg. Since 8/09 Way Covers Remove the five button-head cap screws shown in Figure 11 from the front of the saddle and knee, position the pleated way cover in place, then secure it with the removed cap screws. Cap Screws Figure 11. -

Page 26: Power Connection

SB1024/SB1025/SB1026 Power Connection Electrocution or fire may occur if machine is ungrounded, incorrectly connected to power, or connected to an undersized circuit. Use a qualified electrician to ensure a safe power connection. Once the machine is set up and assembled as previously described in this manual, it is ready to be connected to the power source. -

Page 27: Initial Lubrication

For Machines Mfg. Since 8/09 Initial Lubrication The machine was fully lubricated at the factory, but we strongly recommend that before performing the Test Run you inspect all lubrication points yourself and provide additional lubrication if necessary. Refer to the Lubrication section on Page 51 for specific details. - Page 28 SB1024/SB1025/SB1026 Listen for abnormal noises and watch for unexpected actions from the mill. The machine should run smoothly and without excessive vibration or rubbing noises. — Strange or unusual noises or actions must be investigated immediately. Press the emergency STOP button to turn the machine OFF and disconnect it from the power source before investigating or correcting potential problems.

-

Page 29: Spindle Break-In

For Machines Mfg. Since 8/09 Spindle Break-In Complete the spindle bearing break-in procedure to avoid rapid deterioration of spindle components when the mill is placed into operation. The high-quality bearings and gears used in the mill are manufactured to very close tolerances. However, this does not guarantee perfect dimensional mating of the bearing components or exact meshing of gear teeth. -

Page 30: Operation

SB1024/SB1025/SB1026 Operation Overview The purpose of this overview is to give an example of a typical milling operation. Read through the steps below to better understand the controls and functions described later in this manual, so that you will know how they are used to successfully operate the mill. -

Page 31: Table Movement

For Machines Mfg. Since 8/09 Control Panel Use Figures 15–16 and the following descriptions to understand the functions of the mill control panel. ON Button Spindle Direction Switch OFF Button Figure 15. Model SB1025 control panel. ON Button Spindle Direction Switch Emergency STOP OFF Button... -

Page 32: Table Locks

SB1024/SB1025/SB1026 Graduated Index Rings The table ball handles and elevation crank have graduated index rings attached (see Figure 18) that are used to accurately determine table movement in increments, as listed in the table below: Axis Individual Increment 0.001" 0.001" 0.001"... -

Page 33: X-Axis Power Feed

For Machines Mfg. Since 8/09 X-Axis Power Feed The mill is equipped with a power feed unit for X-axis table movement. Refer to the illustration in Figure 20 and the descriptions below to understand the functions of the various components of the power feed system. Figure 20. -

Page 34: Head Movement

SB1024/SB1025/SB1026 Head Movement The head tilts 45° back and forth, and rotates 90° left and right, as shown in Figures 21–22. 45° Figure 21. Head tilts 45° back-and-forth. 90° Figure 22. Head tilts 90° left-and-right. -32- O P E R A T I O N Always lock the head firmly in place after tilting or rotating it. -

Page 35: Rotating Head

For Machines Mfg. Since 8/09 Rotating Head DISCONNECT MILL FROM POWER! Loosen the four rotation lock bolts on the face of the head shown in Figure 24. Rotation Bolt Lock Bolts Figure 24. Head rotating controls. Use one hand to apply pressure to the head in the direction of tilt, then slowly turn the rotation bolt. - Page 36 SB1024/SB1025/SB1026 Tools Needed Dial Test Indicator (with at least 0.0005" resolution) ... 1 Indicator Holder (mounted on the quill/spindle) ... 1 Precision Parallel Block (at least 9" in length) ... 1 Note: A precision-ground plate can be substituted for the parallel blocks. Keep in mind that the farther the indicator point can be placed from the spindle axis, the more accurate the alignment measurements will be.

- Page 37 For Machines Mfg. Since 8/09 Note: Generally, the goal in the next steps is to get the difference of the indicator readings between the end of the parallel bar down to 0.0005". However, the acceptable variance will depend on the requirements for your operation.

-

Page 38: Ram Movement

SB1024/SB1025/SB1026 Ram Movement The ram travels back and forth 13" and rotates 360° in either direction around the turret. Tool Needed Wrench 19mm ... 1 Moving Ram Back-and-Forth DISCONNECT MILL FROM POWER! Loosen the two lock levers shown in Figure 29 on the right side of the ram. Lock Levers Figure 29. -

Page 39: Setting Spindle Speed

For Machines Mfg. Since 8/09 Setting Spindle Speed Using the correct spindle speed is important for safe and satisfactory results, as well as maximizing tool life. To set the spindle speed for your operation, you will need to: (1) Determine the best spindle speed for the cutting task, and (2) configure the mill controls to produce the required spindle speed. - Page 40 SB1024/SB1025/SB1026 When the spindle speed range is changed, the direction of spindle rotation will reverse. ALWAYS know which way the spindle is rotating before beginning the cutting operation. Setting SB1024 Spindle Speed Range Make sure that the spindle rotation is turned OFF and the spindle is at a complete stop.

- Page 41 For Machines Mfg. Since 8/09 Properly setting the spindle speed range for the Model SB1025/SB1026 involves correctly positioning the high/low range lever AND the spindle speed range selector. ALWAYS make sure these two devices are properly set before beginning the spindle rotation to avoid damaging the machine and voiding the warranty.

- Page 42 SB1024/SB1025/SB1026 Move the high/low range lever back to the right side of the head (see Figure 33. Note: Make sure that the range lever is as far back as it will go before starting the spindle rotation. Tip: When the spindle speed range selector and high/low range lever are correctly set, they will be in the opposite direction from each other.

-

Page 43: Setting Spindle Speed

For Machines Mfg. Since 8/09 Setting Spindle Speed The Model SB1024 uses a variable pulley system to set infinite speeds within the speed range selected. The Model SB1025/SB1026 requires re-positioning the V-belt on the pulleys to change spindle speed. Use the appropriate section below for the mill to select the correct spindle speed. - Page 44 SB1024/SB1025/SB1026 Setting SB1025/SB1026 Spindle Speed DISCONNECT MILL FROM POWER! Remove the belt housing side covers on both sides of the head to expose the V-belt and pulleys, as shown in Figure 35. Adjustment Lever V-Belt & Pulley Access Figure 35. V-belt and pulleys exposed (Model SB1026 shown).

-

Page 45: Downfeed Controls

For Machines Mfg. Since 8/09 SB1026 Low Spindle Speed Range SB1026 High Spindle Speed Range 1170 1860 2800 Figure 37. Model SB1026 V-belt positions and speeds. To re-tension the V-belt, push the adjustment lever back with moderate force, then re-tighten the two lock levers to secure the motor in place. - Page 46 SB1024/SB1025/SB1026 Manual (Disengaged) Position Auto-Downfeed (Engaged) Position Figure 39. Downfeed selector positions. -44- O P E R A T I O N Make sure the pin of the coarse downfeed handle hub is engaged with one of the detents on the downfeed sleeve (see Figure 40).

-

Page 47: Fine Downfeed Controls

For Machines Mfg. Since 8/09 Fine Downfeed Controls There are a number of devices on the head that are used with the fine downfeed handwheel or the auto-downfeed system. Refer to Figure 41 and the descriptions below to become familiar with these controls. -

Page 48: Using The Auto-Downfeed System

SB1024/SB1025/SB1026 Using the Auto-Downfeed System When using the auto-downfeed system, the spindle will move in the direction you choose with the auto-downfeed direction pin. When the quill dog reaches the top or meets the downfeed stop, the downfeed clutch lever will release. Then, if the spindle was traveling upward, the movement will simply stop. -

Page 49: Spindle Brake

For Machines Mfg. Since 8/09 To avoid the risk of gear damage, always start spindle rotation before using the auto- downfeed rate selector. Select one of the three downfeed rates by pulling the knob of the auto-downfeed rate selector out, position the selector over the appropriate detent, then release the knob. -

Page 50: Loading/Unloading Tooling

SB1024/SB1025/SB1026 Loading/Unloading Tooling The mill is equipped with an R8 spindle taper and a ⁄ "-20 x 18 ⁄ " spindle drawbar that includes one spacer for tool attachment flexibility (see Figure 46). Figure 46. Spindle drawbar and spacer. Tool Needed Wrench 21mm ...1 Loading Tooling DISCONNECT MILL FROM POWER! -

Page 51: Maintenance

For Machines Mfg. Since 8/09 Maintenance Schedule Always disconnect machine from power before performing maintenance or serious personal injury may result. Each operator of this machine is responsible for ensuring proper care of the equipment. We strongly recommend that all operators make a habit of following the daily maintenance procedures. -

Page 52: Monthly Maintenance Chart

SB1024/SB1025/SB1026 M A I N T E N A N C E For Machines Mfg. Since 8/09 -50-... -

Page 53: Cleaning

For Machines Mfg. Since 8/09 Cleaning Regular cleaning is one of the most important steps in taking good care of this lathe. Each operator is responsible for cleaning the machine immediately after using it or at the end of the day. -

Page 54: Table Ways (One-Shot Oiler)

SB1024/SB1025/SB1026 Failure to follow reasonable lubrication practices as instructed in this manual for the mill could lead to premature failure of the mill and will void the warranty. Quill Oil Type ... Mobil Vactra 2 or ISO 68 Equivalent Oil Amount ... Fill Oil Cup Check/Add Frequency ...4 hrs. -

Page 55: Speed Range Bearing Sleeve (Sb1024 Only)

For Machines Mfg. Since 8/09 Speed Range Bearing Sleeve (SB1024 Only) Oil Type ... Mobil Vactra 2 or ISO 68 Equivalent Oil Amount ... Fill Oil Cup Check/Add Frequency ...40 hrs. of Operation Lift the oil cup cap shown in Figure 51 to add 5 drops of lubricant. -

Page 56: Table Elevation Leadscrew

SB1024/SB1025/SB1026 Ram Ways Oil Type ... Mobil Vactra 2 or ISO 68 Equivalent Oil Amount ... Thin Coat Check/Add Frequency ...40 hrs. of Operation Move the ram back and forth as necessary to access the full length of the ways (see Figure 54), then use a clean shop rag to apply a thin coat of lubricant. - Page 57 For Machines Mfg. Since 8/09 Remove the hex nut and ball handle from the power unit end of the longitudinal leadscrew (see Figure 57). Graduated Dial Ring Retaining Ring Figure 57. Power feed ball handle removed. Unthread and remove the knurled retaining ring and graduated dial ring from the end of the leadscrew.

-

Page 58: Cleaning Coolant Reservoir

SB1024/SB1025/SB1026 Cleaning Coolant Reservoir BIOLOGICAL & POISON HAZARD! Use the correct personal protection equipment when handling cutting fluid. Follow Federal, State, and the coolant manufacturer's requirement to safely dispose of the used coolant. The cavity in the base of the mill can be used as a coolant reservoir if you choose to install a recirculating coolant pump accessory. -

Page 59: Machine Storage

For Machines Mfg. Since 8/09 Machine Storage To avoid rust problems or corrosion damage, use the following information to protect your investment when storing the mill for any length of time. Lubrication section beginning on Page 51. of the mill as directed in the Cleaning Coolant Reservoir section on Page 56. -

Page 60: Service

SB1024/SB1025/SB1026 Adjusting Gibs Gibs are tapered lengths of metal that are sandwiched between two moving surfaces. Gibs control the gap between these surfaces and how they slide past one another. Correctly adjusting the gibs is critical to producing good milling results. -

Page 61: Adjusting Leadscrew Backlash

For Machines Mfg. Since 8/09 Adjusting Leadscrew Backlash Leadscrew backlash is the amount of motion the leadscrew rotates before the attached device begins to move. Although the mill is equipped with double- bronzed longitudinal and cross leadscrew nuts to minimize backlash, leadscrews will always have a certain amount of backlash that will increase with normal wear. -

Page 62: Cross Leadscrew Backlash

SB1024/SB1025/SB1026 Cross Leadscrew Backlash DISCONNECT MILL FROM POWER! Remove the hex nut and ball handle from the cross leadscrew. Note: In the next step, take care not to misplace the leadscrew key as you remove the parts. Unthread and remove the knurled retaining ring, graduated dial ring, and the leadscrew key, as shown in Figure 65. -

Page 63: Troubleshooting

For Machines Mfg. Since 8/09 If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free to call us at (360) 734-1540. Symptom Possible Cause Machine does not 1. Emergency stop button is pushed in start or a breaker or is at fault. - Page 64 SB1024/SB1025/SB1026 Symptom Possible Cause Tool slips in collect. 1. Collet is not fully drawn into spindle taper. 2. Wrong size collet. 3. Debris on mating surfaces of collet and spindle. 4. Excessive depth of cut. Tool breakage. 1. Spindle speed too slow/feed rate too fast.

-

Page 65: Electrical

For Machines Mfg. Since 8/09 Electrical Safety Instructions These pages are accurate at the time of printing. In the constant effort to improve, however, we may make changes to the electrical systems of future machines. Study this section carefully. If you see differences between your machine and what is shown in this section, call Technical Support at (360) 734-1540 for assistance BEFORE making any changes to the wiring on the machine. -

Page 66: Wiring Overview

SB1024/SB1025/SB1026 Wiring Overview Motor Junction Box SB1024/SB1026: See Page 66 and Figure 70 SB1025: See Page 69 and Figure 74 Work Lamp SB1024/SB1026: See Page 66 and Figure 69 SB1025: See Page 69 and Figure 73 Control Panel SB1024/SB1026: See Page 66 and Figure 71 SB1025: See Page 69 and... -

Page 67: Sb1024/Sb1026 Electrical Box

For Machines Mfg. Since 8/09 SB1024/SB1026 Electrical Box 230V 380V 415V 460V TRANSFORMER Yung-Jeng A009-0383 110V CONTACTOR Allen Bradley C16 01 21 21 Ground E L E C T R I C A L Fuse Fuse CONTACTOR CONTACTOR Allen Bradley Allen Bradley C16 01 C09 400... -

Page 68: Sb1024/Sb1026 Electrical Components

SB1024/SB1025/SB1026 SB1024/SB1026 Electrical Components Motor See Figure 70 Ground Ground (As Recommended) Power Indicator Emergency Stop -66- E L E C T R I C A L 6-20 Plug Control Panel (Viewed From Behind) See Figure 71 T1 T1 Spindle Stop For Machines Mfg. -

Page 69: Sb1024/Sb1026 Electrical Component Pictures

E L E C T R I C A L For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 SB1024/SB1026 Electrical Component Pictures Figure 70. Motor junction box. Figure 68. Electrical box. Figure 71. Control panel. Figure 69. Work lamp. -67-... -

Page 70: Sb1025 Electrical Box

SB1024/SB1025/SB1026 SB1025 Electrical Box 230V 380V 415V 460V TRANSFORMER Yung-Jeng A009-0383 110V CONTACTOR Allen Bradley C09 400 Ground -68- E L E C T R I C A L Fuse Fuse Fuse T1 T1 CONTACTOR Allen Bradley C09 400 22 22 For Machines Mfg. -

Page 71: Sb1025 Electrical Components

For Machines Mfg. Since 8/09 SB1025 Electrical Components Motor See Figure 74 Ground (As Recommended) Power Indicator Emergency Stop E L E C T R I C A L Ground 6-20 Plug Control Panel (Viewed From Behind) See Figure 75 Spindle Direction/Speed Switch (Both Sides Shown) Spindle... -

Page 72: Sb1025 Electrical Component Pictures

SB1024/SB1025/SB1026 E L E C T R I C A L For Machines Mfg. Since 8/09 SB1025 Electrical Component Pictures Figure 74. SB1025 Motor junction box. Figure 72. SB1025 Electrical box. Figure 75. SB1025 Control panel. Figure 73. SB1025 Work lamp. -70-... -

Page 73: Parts

P A R T S For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 Headstock -71-... -

Page 74: Headstock Parts List

SB1024/SB1025/SB1026 Headstock Parts List P RT # DESCRIPTION PSB10240449 ROUND KNOB 3/8-16 PSB10240002 PINION SH FT LEVER PSB10240003 PINION SH FT HUB PSTB004 STEEL B LL 3/16 PSB1024000 COMPRESSION SPRING PSS0 SET SCREW /16-18 X 1/4 PSB1024000 HUB RET INER PSB10240008 PINION SH FT HUB SLEEVE PC P33M... - Page 75 For Machines Mfg. Since 8/09 Headstock Parts List P RT # DESCRIPTION PSB1024009 KNURLED KNOB SCREW M6-1 X 1 PSB10240098 SCRIBING LEVER PSB10240099 REVERSE TRIP B LL LEVER SCREW PSB10240100 FEED REVERSE TRIP PLUNGER PSB10240101 REVERSE TRIP B LL LEVER PSB10240102 QUILL STOP KNOB PSB1024010...

-

Page 76: Quill

SB1024/SB1025/SB1026 Quill P RT # DESCRIPTION PSB10240201 SPINDLE R8 PSS03M SET SCREW M6-1 X 8 PSB10240203 QUILL END C P PSB10240204 QUILL SE L PSB1024020 NGUL R CONT CT BE RING 20 P4 PSB10240206 BE RING SP CER SSEMBLY PSB10240206 BE RING SP CER PSB10240206 BE RING SP CER... -

Page 77: Sb1024 Gearbox

For Machines Mfg. Since 8/09 SB1024 Gearbox 303A For Reference Only P A R T S 307A SB1024/SB1025/SB1026 -75-... - Page 78 SB1024/SB1025/SB1026 SB1024 Gearbox Parts List P RT # DESCRIPTION PSB10240301 GE RBOX PL TE PK 0M KEY 8 X 8 X 12 PSB10240303 SPINDLE GE R HUB SSEMBLY PSB10240303 SPINDLE GE R HUB PSB10240304 SPINDLE BULL GE R PSB1024030 BE RING SLE VE P6908VV-N DEEP GROOVE B LL BE RING 6908VV NSK PSB1024030...

-

Page 79: Sb1025/Sb1026 Gearbox

For Machines Mfg. Since 8/09 SB1025/SB1026 Gearbox For Reference Only P A R T S SB1024/SB1025/SB1026 For Reference Only -77-... - Page 80 SB1024/SB1025/SB1026 SB1025/SB1026 Gearbox Parts List P RT # DESCRIPTION PN04 HEX NUT /8-11 PFH0 M FL T HD SCR M -.8 X 10 PSB102 0303 PULLEY FL NGE PSB102 0304 TIMING BELT PULLEY PC P33M C P SCREW M -.8 X 12 PSB102 0306 GE RBOX COVER PSB1024030...

-

Page 81: Sb1024 Belt Housing

For Machines Mfg. Since 8/09 SB1024 Belt Housing P A R T S SB1024/SB1025/SB1026 For Reference Only 403A 403-1 403-2 403-3 403-4 403-5 -79-... - Page 82 SB1024/SB1025/SB1026 SB1024 Belt Housing Parts List P RT # DESCRIPTION PC P14 C P SCREW 3/8-16 X 1 PLW06M LOCK W SHER 10MM PSB10240403 MOTOR SSEMBLY PSB10240403 MOTOR 2HP 220V 1PH 403-1 PSB10240403 MOTOR F N COVER 403-2 PSB10240403 MOTOR F N 403-3 PSB10240403 C P CITOR COVER 403-4 PSB10240403...

-

Page 83: Sb1025/Sb1026 Belt Housing

P A R T S For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 SB1025/SB1026 Belt Housing -81-... - Page 84 SB1024/SB1025/SB1026 SB1025/SB1026 Belt Housing Parts List P RT # DESCRIPTION PSB102 0401 MOTOR 2HP 220V 3PH (SB102 ) PSB10260401 MOTOR 2HP 220V 1PH (SB1026) 401-1 PSB102 0401-1 MOTOR F N COVER (SB102 ) 401-1 PSB10260401-1 MOTOR F N COVER (SB1026) 401-2 PSB102 0401-2 MOTOR F N (SB102 ) 401-2 PSB10260401-2 MOTOR F N (SB1026)

-

Page 85: Ram

P A R T S For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 -83-... - Page 86 SB1024/SB1025/SB1026 Ram Parts List P RT # DESCRIPTION PC P31M C P SCREW M8-1.2 X 2 PRP90M ROLL PIN 8 X 30 PSB10240 03 GE R 33T PRIV001M FLUTED RIVET 2 X MM STEEL PSB10240 0 HE D ROT TION SC LE PSB10240 06 R M D PTER PSB10240 0...

-

Page 87: Column, Knee, & Saddle

P A R T S For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 Column, Knee, & Saddle -85-... - Page 88 SB1024/SB1025/SB1026 Column, Knee, & Saddle Parts List P RT # DESCRIPTION PSB10240601 COLUMN PRIV001M FLUTED RIVET 2 X MM STEEL PSB10240603 INDIC TOR PL TE PSB10240604 RE R COLUMN COVER PS09M PHLP HD SCR M -.8 X 10 PSB10240606 PIPE PLUG 1/2 PT PS40M PHLP HD SCR M -.8 X 16 PW02M...

-

Page 89: Table

P A R T S For Machines Mfg. Since 8/09 SB1024/SB1025/SB1026 Table -87-... - Page 90 SB1024/SB1025/SB1026 Table Parts List P RT # DESCRIPTION PN01 HEX NUT 1/2-20 PSB10240 02 H NDLE PSB10240 03 CROSS FEED B LL H NDLE PSB10240 04 DI L HOLDER SSEMBLY PSB10240 04 OUTER DI L HOLDER PSB10240 0 T BLE DI L INCH PSB10240 04 INNER DI L HOLDER PC P01M...

-

Page 91: One-Shot Oiler

For Machines Mfg. Since 8/09 One-Shot Oiler P RT # DESCRIPTION PSB10240801 ELBOW JOINT M4 X 1/8 PT PSB10240802 T-JOINT PSB10240803 ONE SHOT OILER SSEMBLY PC P02M C P SCREW M6-1 X 20 P A R T S P RT # PC P01M PSB10240806 PC P38M... -

Page 92: Sb1024/Sb1026 Electrical Box

SB1024/SB1025/SB1026 SB1024/SB1026 Electrical Box & Control Panel Electrical Box P RT # DESCRIPTION PSB10240901 TR NSFORMER 24-440V YJ 009-0383 PSB10240902 FUSE HOLDER 30 PSB10240903 FUSE 30 PSB10240904 FUSE HOLDER 2- PSB1024090 FUSE PSB10240906 FUSE 2 PSB1024090 CONT CTOR B C09-400 220V PSB10240908 TERMIN L B R 6-POST PSB10240910... -

Page 93: Sb1025 Electrical Box & Control Panel

For Machines Mfg. Since 8/09 SB1025 Electrical Box & Control Panel Electrical Box P RT # DESCRIPTION PSB10240901 TR NSFORMER 24-440V YJ 009-0383 PSB10240902 FUSE HOLDER 30 PSB10240903 FUSE 30 PSB10240904 FUSE HOLDER 2- PSB1024090 FUSE PSB10240906 FUSE 2 PSB1024090 CONT CTOR B C09-400 220V PSB10240908 TERMIN L B R 6-POST... -

Page 94: Accessories

SB1024/SB1025/SB1026 Accessories 1001 1007 1006 P RT # DESCRIPTION 1001 PWR1921C CLOSED END WRENCH 19/21MM 1002 PWR1214 WRENCH 12/14MM 1003 P W1 10M HEX WRENCH SET 10PC 1. -10 MM 1004 PSB10241004 TOOL BOX -92- P A R T S 1002 1003 1005... -

Page 95: Sb1024 Head Machine Labels

For Machines Mfg. Since 8/09 SB1024 Head Machine Labels 1102 1106 1105 P RT # DESCRIPTION 1101 PSB10241101 M CHINE ID L BEL 1102 PSBL BEL0 VL EYE INJURY H Z RD L BEL 1103 PSBL BEL01VL RE D M NU L L BEL The safety labels provided with your machine are used to make the operator aware of the machine hazards and ways to prevent injury. -

Page 96: Sb1024 Main Machine Labels

SB1024/SB1025/SB1026 SB1024 Main Machine Labels 1108 1107 1123 1122 P RT # DESCRIPTION PSBL BEL08VL ENT NGLEMENT H Z RD L BEL 1108 SB1319 SOUTH BEND N MEPL TE 90MM 1109 PSB10241109 SPINDLE SPEED DISPL Y L BEL 1110 PSB10241110 HE D LUBRIC TION L BEL 1111 PSB10241111... -

Page 97: Sb1025/Sb1026 Machine Labels

For Machines Mfg. Since 8/09 SB1025/SB1026 Machine Labels 1108 1107 1102 1123 1122 P RT # DESCRIPTION 1101 PSB102 1101 M CHINE ID L BEL (SB102 ) 1101 PSB10261101 M CHINE ID L BEL (SB1026) 1102 PSBL BEL0 VL EYE INJURY H Z RD L BEL 1103 PSBL BEL01VL RE D M NU L L BEL... -

Page 99: Warranty & Returns

W A R R A N T Y This quality product is warranted by South Bend Lathe Company to the original buyer for one year from the date of purchase. This warranty does not apply to consumable parts, or defects due to any kind of misuse, abuse, negligence, accidents, repairs, alterations or lack of maintenance. - Page 100 South Bend Lathe Co. P.O. Box 2027 Bellingham, WA 98227 PHONE: (360) 734-1540 (Administrative Offi ces) FAX: (360) 676-1075 (International) FAX: (360) 734-1639 (USA only) southbendlathe.com Printed In Taiwan #JBTS12116...

Need help?

Do you have a question about the SOUTH BEND LATHE CO.. SB1024 and is the answer not in the manual?

Questions and answers