Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Aslan Machine CMS-504 Series

- Page 1 USER'S MANUAL AUTOMATIC UPCUT MITER SAW CMS-504 series...

- Page 2 ● ● ...

-

Page 3: Table Of Contents

CONTENTS 1. General Information 1.1. Introduction 1.2. Distributor 2. Machine’s Description and Purpose of Use 2.1. Machine’s description 2.2. Technical features 2.3. Cutting diagram 2.4. Overall dimensions 2.5. Part lists and technical drawings for cutting mechanism 2.6. Electric and pneumatic control panel 3. -

Page 4: General Information

The technical drawings and details contained in this manual are a guide for the operator. 1.2. DISTRIBUTOR Aslan Machine, Inc. 20423 Waters Point Lane, Germantown, MD 20874 Phone: +1-301-528-1696 Fax: +1-301-542-0185 Website: www.aslanmachine.com E-mail: info@aslanmachine.com... -

Page 5: Machine's Description And Purpose Of Use

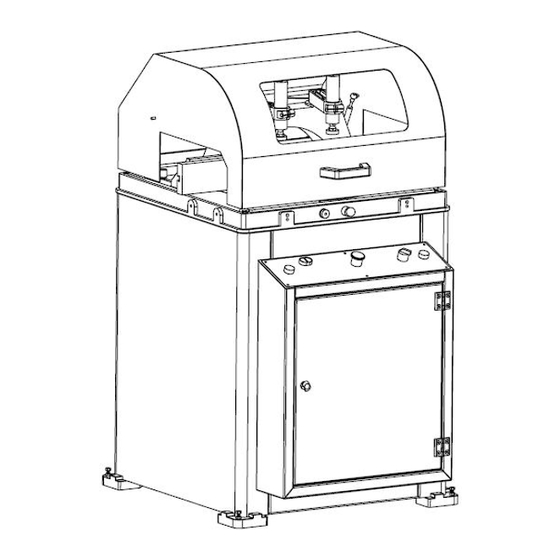

2. MACHINE’S DESCRIPTION AND PURPOSE OF USE 2.1. MACHINE’S DESCRIPTION This is an automatic upcut saw with a circular saw blade for cutting PVC, aluminum and wood profiles at straight and miter angles. The operator can adjust the cutting speed of the saw blade via a knob for the material type and the size. - Page 6 Figure – 1 General front view of the machine and its components. Note: for safety reasons, the motor does not start moving up until the top safety cover and front door are closed.

-

Page 7: Technical Features

2.2. TECHNICAL FEATURES Technical Features (Metric) 2.2kW CMS-504- D=450 mm 95x95x149 400V 50Hz 3000 rpm 210 kg d=32 mm l/min 3-Phase Technical Features (American) 3 HP CMS-504- 3-Phase D=17 1/2" 3000 rpm 37”x37”x59” 450 lb 220V/4610V d=32 mm 60Hz Table 1 – The technical features of this machine. -

Page 8: Cutting Diagram

2.3. CUTTING DIAGRAM Figure - 2 Cutting Diagram. -

Page 9: Overall Dimensions

2.4. OVERALL DIMENSIONS Figure – 3 Overall Dimensions (in terms of millimeters and inch) - Page 10 2.5. PARTS LIST AND TECHNICAL DRAWINGS FOR CUTTING MECHANISM...

- Page 11 PART NO STOCK CODE QUANTITY 150.002.0080 150.001.0094 150.02.0056 150.02.0068 150.02.0084 150.001.0047 150.001.0085 150.02.0093 150.02.0094 150.02.0109 150.02.0607 150.02.0583 150.02.0186 150.02.0001 150.02.0006 150.02.0021 150.006.0005 150.001.0048 150.02.0102 150.02.0119 150.02.0274 150.02.0118 150.011.0073 150.006.0051 150.001.0086 150.02.0120 150.02.0617 150.02.0401 150.02.0540 150.013.0059 150.001.083 150.02.0121 150.02.0122 150.014.0015 150.005.0014 150.006.0114 150.02.0672 150.001.0090...

- Page 12 150.010.0058 150.02.0720 Figure -4 Parts list (see the rest of the manual for all other components)

- Page 13 Table mid angle fixing handle Angle adjustment handle Motor sart/stop Cutting start Clamp button Emergency stop Cutting start Figure – 5 Machine control panel...

- Page 14 Conveyor (optional item) PART NAME Conveyor Foot Conveyor Profile M8 x 20 Bolt Profile Support M10 Handle Figure – 6 A Typical conveyor attachments (This is an optional feature and the conveyor supplied to you might be also different than this, please check with us about how to connect your conveyor to the machine.)

-

Page 15: Electric And Pneumatic Control Panel

2.6. ELECTRIC AND PNEUMATIC CONTROL PANEL The electric and pneumatic control panel enables you to make adjustments regarding the air pressure. The cover of the panel has to be kept closed/locked during cutting. Before servicing the machine: TURN OFF THE ELECTRIC AND PNEUMATIC SUPPLY CONNECTIONS. -

Page 16: Safety

3. SAFETY 3.1. SAFETY INFORMATION The symbols shown hereunder must be read with a special attention. Not reading or observing them may cause damage to the equipment or personal injury. IMPORTANT The IMPORTANT symbol above shows that it is necessary to pay special attention at the specified operation. -

Page 17: Accident Prevention

3.2. ACCIDENT PREVENTION 3.2.1. Our machines are manufactured in accordance with EN 60204-1 and EN 292-2 CE safety directives, which international safety directives. 3.2.2. It is the responsibility of the employer to warn his staff against accident risks, to train them on prevention of accidents, to provide the necessary safety equipment and devices for the operator’s safety. -

Page 18: General Safety Information

3.3. GENERAL SAFETY INFORMATION 3.3.1. The power cable should be placed in a way that nobody can step on it or nothing can be placed on it. Special care must be taken regarding the inlet and outlet sockets. 3.3.2. If the power cable is damaged during operation, don't touch it and do not unplug it. - Page 19 3.3.11. Use safe working position, always keep your balance. 3.3.12. Keep your machine always clean for safe operation. Follow the instructions at maintenance and replacement of accessories. Check the plug and cable regularly. If damaged, have it replaced by a qualified electrician. Keep handles free from any oil and grease.

-

Page 20: Safely Transporting The Machine

4. SAFELY TRANSPORTING THE MACHINE IMPORTANT The transporting must be done by qualified personnel only. The machine should be transported by lifting with proper equipment (The machine should not be touching the ground during the transport). Don’t lift the machine before making sure that lifting devices or other equipment is placed properly under the machine. - Page 21 Figure – 8 Typical safe distances around the machine (when installed without the optional conveyor) Please add also the conveyor distance if you ordered it.

-

Page 22: Electric Connection

5.2. ELECTRIC CONNECTION 5.2.1. The three-phase power cable socket must be installed by your electrician. 5.2.2. Check the power supply before powering the machine. 5.2.3. Make the electric socket connections when the MAIN POWER SWITCH on the machine is set to 0. (i.e. cut the power going to the machine.) CAUTION ! *The power connection must be made by a qualified electrician. - Page 23 To correct the rotation direction of the saw blade, connect the machine to an electric power plug for 3-phase, and follow these instructions: 1. Press the Motor Start Button to operate the saw blade. 2. Monitor the rotation direction of the saw blade through the blade slot. 3.

- Page 25 Figure – 10 Hydrolic-pneumatic system of the machine.

-

Page 26: Machine Safety Information

6. MACHINE SAFETY INFORMATION 6.8.1. It is not allowed to operate the machine with its safety cover and other safety components removed. 6.8.2. Your machine operates with 220 V or 400V (440V) ~ 3 Phase 50Hz (60Hz). Use a qualified electrician only for the installation. 6.8.3. -

Page 27: Operation

7. OPERATION The automatic up-cut saw model CMS-504 cuts non-ferrous aluminum, PVC profiles and PVC materials. The operator adjusts (manually via knob) the cutting speed according to the material type. Inner and outer sharp edges of a carbide tipped circular saw blade ensures high quality clean cutting results. - Page 28 Figure 11 The clamping cylinders must be at a correct position to prevent damage to the cylinders themselves.

-

Page 29: Adjusting The Air Pressure

7.1.8. if you purchased our optional conveyor, adjust the cutting length of the material by using the measuring system with length stop units on the conveyor (See Figure – 6). After adjusting the cutting length, fix the profile support fence by tightening the stopper on the conveyor. - Page 30 Pressure Setting Oil Set Manometer Air Exit Air In Oil Pan Accumulating Water Disposal Figure – 12 Air conditioning Unit.

- Page 31 Figure – 13 Movable Back Fence (Bridge) System.

-

Page 32: Checking Angle Adjustment Of Saw Blade And Bridge

7.3. CHECKING ANGLE ADJUSTMENT OF SAW BLADE AND BRIDGE If you run into any problem during cutting operation (i.e. miter cutting) 7.3.1. Perform a visual control on the saw blade, if possible with the help of a dial gauge. 7.3.2. Make sure that the alignment of the movable bridge is correct with the Back fence (Figure - 4, number 33). -

Page 33: Safe Installation Of The Saw Blade

8. SAFE INSTALLATION OF THE SAW BLADE 8.1 Follow the instructions below to remove the circular saw blade from the blade shaft. 8.1.1. Switch the MAIN POWER SWITCH on the machine to “0” to cut the power coming to the machine. Open the front cover of the main frame with its key. 8.1.2. - Page 34 Figure – 14 Saw Blade Changing Steps.

- Page 35 See Figure 14. Figure – 15 Saw Blade and Nuts assembly.

-

Page 36: Maintenance

9. MAINTENANCE 9.1. ROUTINE CONTROLS and MAINTENANCE 9.1.1 BEGINNING THE WORK 9.1.1. Make sure that the table and all parts are clean and dry. Degrease and dry the table. Especially make sure that the holding grips are clean and dry. 9.1.2. -

Page 37: Maintenance At The End Of The Working Day

9.2. MAINTENANCE AT THE END OF THE WORKING DAY 9.2.1. Disconnect electric power and air power. (Main Power Switch must be on “0” position) 9.2.2. Remove all burr, chip and foreign materials from the machine surfaces. If it is necessary to clean the inside of the blade guard, remove the front cover, use gloves to protect your hands from the sharp edges of the blade. -

Page 38: Troubleshooting Guide

10. TROUBLESHOOTING GUIDE Here are some recommendations for solving urgent problems. If the trouble cannot be solved, or if you have a problem other than those described hereunder, please contact our technical service or your nearest dealer. TROUBLE CAUSES REMEDY ... -

Page 40: Wiring Diagrams

12. WIRING DIAGRAMS... -

Page 47: Pictorial Guide To Use When Ordering Parts For This Machine

13. PICTORIAL GUIDE TO USE WHEN ORDERING PARTS FOR THIS MACHINE We are providing this pictorial guide to help you out when ordering spare parts for this machine. This pictorial guide does not include all parts. For the parts that do not exist here, please refer to the component list provided in the previous pages or call us. - Page 48 Magnetic relay Main Power Switch Vertical piston...

- Page 49 Y1 valve and its connector components Left fence Right Fence Shaft assembly. Spray mist lubrication head...

- Page 50 Emergency Stop Switch Cutting Start Button...

- Page 51 Motor Start-stop button Motor (220V-3P 60 Hz. 1EL070001-0001 440V-3P 60 Hz)

Need help?

Do you have a question about the CMS-504 Series and is the answer not in the manual?

Questions and answers