Table of Contents

Advertisement

Quick Links

®

How To Use This Manual

This manual provides detailed instructions on maintenance,

lubrication, installation, and parts identification. Use the table

of contents below to locate required information.

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Lube Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Limited End Float. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 1-2

Installation & Alignment Instructions . . . . . . . . . . . . . Pages 2-4

Annual Maintenance, Relube & Disassembly . . . . . . . . . Page 4

Installation & Alignment Data . . . . . . . . . . . . . . . . . . . . Page 5

Parts Identification & Parts Interchangeability . . . . . . . . . Page 6

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE

FREE SERVICE.

INTRODUCTION

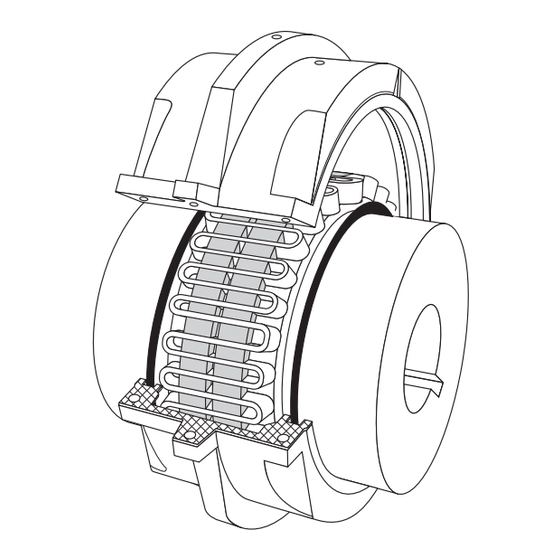

This manual applies to Sizes 1150T thru 1260T and 150T thru

260T Falk SteelfIex Tapered Grid Couplings. Unless otherwise

stated, information for Sizes 1020T thru 1140T applies to Sizes

150T thru 260T respectively, e.g. 1150T = 150T, 1260T =

260T, etc. These couplings are designed to operate in either

the horizontal or vertical position without modification.

The performance and life of the couplings depend largely upon

how you install and service them. Carefully follow the

instructions in this manual for optimum performance and

trouble free service.

CAUTION: Consult applicable local and national safety codes

for proper guarding of rotating members. Observe all safety

rules when installing or servicing couplings.

WARNING: Lockout starting switch of prime mover and remove

all external loads from drive before installing or servicing

couplings.

LUBE FITTINGS

3

Cover halves have

/

NPT Iube holes. Use a standard grease

8

gun and Iube fitting as instructed on

LIMITED END FLOAT

When electric motors, generators, engines, compressors and

other machines are fitted with sleeve or straight roller bearings,

limited axial end float kits are recommended for protecting the

bearings. Falk Steelflex couplings are easily modified to limit

end float; refer to

Manual 428-820

LUBRICATION

Adequate lubrication is essential for satisfactory operation.

Page 2

provides a list of typical lubricants and specifications

for general purpose and long term greases. Because of its

superior lubricating characteristics and low centrifuge

properties, Falk Long Term Grease (LTG) is highly

recommended.

The use of general purpose grease requires re-lubrication of

the coupling at least annually.

The Falk Corporation, P .O. Box 492, Zip 53201-0492

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

Steelflex

Type T10

Page 4.

for instructions.

®

Couplings

•

•

Sizes 1150–1260 & 150–260

TYPE T10 STEELFLEX COUPLING

Long Term Grease (LTG)

The high centrifugal forces encountered in couplings separate

the base oil and thickener of general purpose greases. Heavy

thickener, which has no lubrication qualities, accumulates

in the grid-groove area of Steelflex couplings resulting in

premature hub or grid failure unless periodic lubrication cycles

are maintained.

Falk Long Term Grease (LTG) was developed specifically for

couplings. It resists separation of the oil and thickener. The

consistency of Falk LTG changes with operating conditions. As

manufactured it is an NLGI #1/2 grade. Working of the

lubricant under actual service conditions causes it to become

semifluid while the grease near the seals will set to a heavier

grade, helping to prevent leakage.

LTG is highly resistant to separation, easily out performing all

other lubricants tested. The resistance to separation allows the

lubricant to be used for relatively long periods of time.

Steelflex couplings initially lubricated with LTG will not require

re-lubrication until the connected equipment is stopped for

servicing. If a coupling leaks grease, is exposed to extreme

temperatures, excessive moisture, or experiences frequent

reversals, more frequent lubrication may be required.

Although LTG grease is compatible with most other coupling

greases, the mixing of greases may dilute the benefits of LTG.

USDA Approval

LTG has the United States Department of Agriculture Food Safety

& Inspection Service approval for applications where there is no

possibility of contact with edible products. (H-2 ratings).

CAUTION: Do not use LTG in bearings.

(Page 1 of 6)

428-112

May 2000

Supersedes 12-98

Advertisement

Table of Contents

Summary of Contents for FALK Steelflex T10

- Page 1 260T, etc. These couplings are designed to operate in either are maintained. the horizontal or vertical position without modification. Falk Long Term Grease (LTG) was developed specifically for The performance and life of the couplings depend largely upon couplings. It resists separation of the oil and thickener. The how you install and service them.

- Page 2 Grease application or re-lubrication should be done at temperatures above Annual Lubrication — The following specifications and 20°F (–7°C). If grease must be applied below 20°F (–7°C), consult The Falk Corporation. lubricants for general purpose grease apply to Falk Steelflex †...

- Page 3 ANGULAR INSTALLATION limits specified in Table 2. 428-112 The Falk Corporation, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 May 2000 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com...

- Page 4 The use of lubricant as possible and wipe off excess flush with top of grid. Falk Long Term Grease (LTG) will allow relube intervals to be Position seals on hubs to line up with grooves in cover. Move extended to beyond five years.

- Page 5 1.02 .183 4.64 1.01 25.7 5350 604.5 148.1 67.2 428-112 The Falk Corporation, P .O. Box 492, Zip 53201-0492 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 May 2000 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com Supersedes 12-98...

- Page 6 Keyway: 2.00 x .75 3. Contact your Falk Distributor or Falk for price and availability. 428-112 The Falk Corporation, P.O. Box 492, Zip 53201-0492 May 2000 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131 Supersedes 12-98 Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com...

Need help?

Do you have a question about the Steelflex T10 and is the answer not in the manual?

Questions and answers