Summary of Contents for CPC MultiFlex PAK

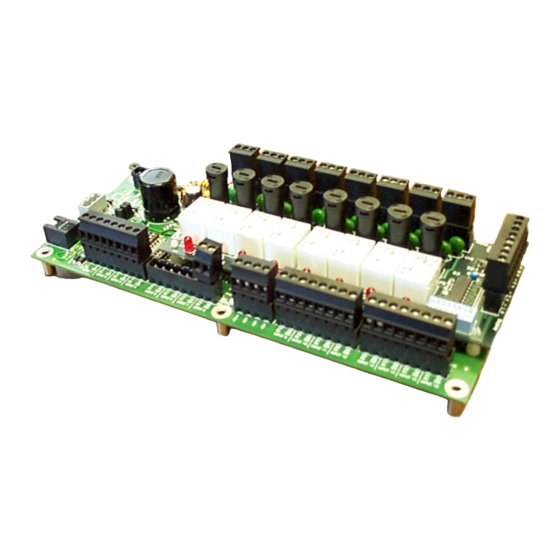

- Page 1 026-1712 Rev 3 03-JAN-2008 MultiFlex PAK Compressor/ Condenser Control Board User’s Guide...

- Page 3 READ ALL INSTRUCTIONS CAREFULLY If the equipment is not used in the manner specified by the manufacturer, the protection provided by the equipment may be impaired. SAVE THIS INSTRUCTION MANUAL This instruction manual contains important operating instructions for the MultiFlex PAK boards.

-

Page 5: Table Of Contents

4 I/O BOARD INPUT AND OUTPUT SETUP......................9 4.1. T ................................... 9 NPUTS 4.1.1. Input Types Supported by the MultiFlex PAK ...................... 9 4.1.2. The PAK Default Input Assignments........................10 4.1.3. Connecting Sensors to Input Boards........................10 4.1.3.1. Wiring ....................................10 4.1.3.2. - Page 6 7.4.6. Screen 6: Outputs ..............................30 7.4.7. Screen 7: PAK Outputs ............................30 7.4.8. Screen 8: Fixed Steps ............................30 7.4.9. Screen 9: Safety..............................31 7.4.10. Screen B: Alarms............................... 31 8 MULTIFLEX PAK HAND-HELD TERMINAL INTERFACE ................32 8.1. T HHT I ..............................32 NTERFACE vi •...

- Page 7 8.1.1. Navigation................................32 8.2. PAK S ..............................33 TART CREENS 8.3. PAK S ............................... 33 TATUS CREENS 8.3.1. Status Screen 1 ..............................33 8.3.2. Status Screen 2 ..............................33 8.3.3. Status Screen 3 ..............................33 8.3.4. Status Screen 4 ..............................34 8.3.5.

-

Page 9: Overview Of The Multiflex Product Line

The communication interface is RS485 I/O using the Standard Extended Address Form for CPC Distributed Controllers. Currently, the PAK is designed to interface with the CPC E2 RX controller, and the previous generation refrigera- tion controller, the Einstein RX. MultiFlex PAK... -

Page 10: Mounting And Powering

Mounting and Power- 2.1. Snap-Track Installation MultiFlex boards not supplied in a custom panel or other enclosure are supplied with a The MultiFlex boards are usually installed snap-track for easy installation. The insulation by the refrigeration or building equipment man- sheet and I/O board must be removed from the ufacturer. -

Page 11: The Plug-In Output Board

2.3. Powering the MultiFlex All models of MultiFlex require a 24VAC Class 2 input power source. The MultiFlex PAK requires the power source to be center-tapped. CPC supplies a wide variety of 24VAC trans- formers with varying sizes and either with or without center taps. -

Page 12: Choosing Transformer Sizes

2.3.2. MultiFlex Combination Input/ (Top Left Corner) Output Board Power Wiring The MultiFlex PAK boards do not use a cen- Figure 2-4 - New-Style vs. Old-Style MultiFlex Board ter tap. Instead, the 0V terminal on the board If there is a power LED next to the connec- should be connected to a separate Earth ground. -

Page 13: Old-Style Multiflex Combination I/O Boards (No Isolated Power Supply)

A center-tapped transformer may power You may also tie one side of the secondary both center-tapped and non-center-tapped boards (but not BOTH sides) or the center tap to an at the same time, as long as none of the non- earth ground, provided none of the boards pow- center-tapped MultiFlex boards are old-style ered by the same transformer are old-style Mul-... -

Page 14: Wire Types And Maximum Distances

8RO, 4AO, 8DO, a Gateway board, or any pre- or the boards will malfunction. vious generation CPC board that uses center- Use these formulas to determine if the wire tapped power. Doing so will destroy the Multi- gauge you are using fits within specification: Flex board. -

Page 15: The I/O Network

E2 must be Belden 8641 (24AWG, 300V, CPC P/N 135-8641); Belden 3.2.1. Network ID Numbers 8761 (22 AWG, 300V not stocked by CPC); or a Each device on an RS485 segment has a net- 600V-shielded 22AWG equivalent stocked by work dip switch that must be used to assign the CPC (P/N 135-0600). -

Page 16: Setting The Baud Rate

3.2.3. Setting the Terminating Re- NOTE: The MultiFlex PAK may only be numbered up to 16, since E2 will only speak to sistance Jumpers a maximum of 16 PAK boards. A PAK num- All MultiFlex boards and other RS485 bered above 16 will be ignored. -

Page 17: O Board Input And Output Setup

Connected to the fault output from the VS Fan inverter - noti- fies the PAK of an inverter fail- Liq Level Dry-contact liquid level sensor Table 4-1 - MultiFlex PAK Input Types The Inputs I/O Board Input and Output Setup • 9... -

Page 18: The Pak Default Input Assignments

All Analog Temperature Sensors and Air Flow Sen- DischTemp 8 sors Table 4-2 - MultiFlex PAK Default Inputs Temperature and air flow sensors are to be wired with shielded, 2 conductor, at least 22 GA 4.1.3. Connecting Sensors to Input wire (Belden # 8761 or equivalent). -

Page 19: Power Connection

24VAC signal isolated from its DC output RIGHT (ON) position. signal (such as CPC’s Dew Point Probe). If the The exception to this rule is for CPC’s output signal is not isolated from the 24VAC 5VDC pressure transducers -- though they input, you must use a separate transformer. -

Page 20: The Relay Outputs

When a controller calls for a MultiFlex relay ating the variable-speed fan(s) output to be ON, it sends a command to the Mul- Table 4-3 - MultiFlex PAK Output Types tiFlex to turn the output to the ON state (signi- 4.2.2. The PAK Default fied by the output LED being ON). -

Page 21: Relay Output Ratings And Fuse Protection

State of Normally Closed (N.C.) Contacts on MultiFlex Relay Points Loss of Fail-safe Light Light Loss of Communi Switch is ON is OFF Power cation Up (ON) Closed Open Closed Closed Down (OFF) Open Closed Closed Closed Table 4-5 - Output Board Fail-Safe and Switch Settings when Contact is Wired Normally Closed (N.C.) State of Normally Open (N.O.) Contacts on MultiFlex Relay Points Loss of... -

Page 22: The Analog And Digital Outputs

Fan speed input for an inverter operating the variable-speed fan(s) Fan Seq Variable-voltage output driving a fan sequencer Table 4-7 - MultiFlex PAK Output Types 4.3.2. The PAK Default Analog/Dig- Figure 4-4 - MultiFlex Digital Points ital Output Assignments Analog/Digital Definition... -

Page 23: Board Status Leds

5.3. Code A and Code B LEDs 5.2. Tx and Rx LEDs The MultiFlex PAK has two LEDs labeled Code A and Code B. These LEDs indicate fail- The Tx and Rx LEDs indicate when the Mul- ure conditions. -

Page 24: Relay Output Leds

commissioned in the E2 or REFLECS Network Configuration screen. Code B Failure Conditions • Blinking 2 times/second - This indicates the board has lost its configuration. If Code B blinks at this rate on an operational board, it means the board must be reprogrammed. -

Page 25: Pak Software Overview

PAK Software Over- Suction Setpoint. The suction pressure you wish to maintain. view Suction Deadband. A small range of values equally above and below the Suction Setpoint, within which the suction pressure will be consid- 6.1. Compressor Groups ered to be acceptably near the Suction Setpoint and no stage activation or deactivation will 6.1.1. -

Page 26: Compressor Control Strategies

13 equally sized compres- 6.1.4. Compressor Control Strate- sors. The compressors are split into five groups gies (one for each relay on the MultiFlex PAK). 6.1.4.1. Cyclic Then, for each of the 14 total steps in the strat- egy, each step is configured to bring on a differ- "Cyclic"... -

Page 27: Suction Float

Note that this is not necessarily a rec- ommendation for setting up all packs using a MultiFlex PAK controller; choose a fixed step strategy that is appropriate for each installation. Group # Com- Step Group ON Group OFF # of Compressors... -

Page 28: Suction Float Input Sources

temperature in line with the float setpoint. A Each case temperature input value used in graph showing an example of suction pressure the combination is determined by taking the setpoint adjustment versus float temperature is average value of the input over a time window provided in Figure 6-1. -

Page 29: Suction Float During Loss Of Communication

FanStage4 and ending Because suction float requires a large num- with FanStage1. ber of inputs and the MultiFlex PAK board has The PAK observes fan ON and OFF inter- only sixteen, the PAK cannot use suction float in stage delays as it activates and deactivates fan stand-alone mode. -

Page 30: Minimum Pressure Set Point

6.2.2. Minimum Pressure Set Point analog output, called "Fan Sequencer," which then can be used as an input to a third-party To prevent overcooling, the MultiFlex PAK device that translates this voltage to a series of features a minimum pressure set point. If the relay activations. -

Page 31: Quiet Mode

OPEN or SHORT Prs Max setpoint (the PAK will allow the fan • If the Multiflex PAK controller has a digital speed to increase up to 100% until the pres- output as an Alarm Output, then the relay... -

Page 32: Multiflex Pak E2 Interface

Controller Setup screen. To access this screen: terface 1. Log in to the E2. The MultiFlex PAK is capable of communi- cating with an E2 RX refrigeration controller 2. Press to access the System Configuration version 2.10 and above, or an Einstein RX Menu. -

Page 33: Deleting A Pak

PAK board as “Online.” If not, it will 1. Press (Configured Applications). be shown as "Offline." 2. Select item "187. MultiFlex PAK". If multi- ple PAKs are associated with this E2, a list Setting the "Connected" and "Read Setpoints" Attributes MultiFlex PAK E2 Interface • 25... -

Page 34: Viewing The Pak Status Screen

2. Select item "187. MultiFlex PAK" ture. The value shown in smaller type to the right of the TD field (enclosed by brackets [ ]) is the... -

Page 35: Compressor Groups

The Compressor Group Mode field explains 7.3.4. Condenser Fans the current state of the fixed step control algo- rithm in the MultiFlex PAK. There are seven The right side of the PAK Status Screen messages that may appear here: shows the current status of the condenser fans. -

Page 36: Connected And Pak State

No. 7.4.2. Screen 2: Comp Setpts The "PAK State" field shows whether the MultiFlex PAK is currently reading as Online or Offline. Note that a status of "Connected" in the Con- nected field does not necessarily mean the PAK is communicating with the E2 - if the PAK State reads "Offline,"... -

Page 37: Screen 3: Cond Setpts

Suction Float feature are configured. This screen is not visible unless the Enable SP Float parameter on Screen 1 is set to "Yes." Programming the PAK using E2 MultiFlex PAK E2 Interface • 29... -

Page 38: Screen 6: Outputs

Figure 7-9 - PAK Screen 7: PAK Outputs The PAK Outputs screen is where you must assign the functions of each of the eight relay outputs and four analog/digital outputs on the MultiFlex PAK. 30 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008... -

Page 39: Screen 9: Safety

E2’s PAK application to generate when failures occur. You may choose advisory types, setpoints, priorities, and delays for most alarm types generated by the PAK. Programming the PAK using E2 MultiFlex PAK E2 Interface • 31... -

Page 40: Multiflex Pak Hand-Held Terminal Interface

Hand-Held Terminal will display the message “CPC Handheld Terminal” and then the first • View failure messages that relate to the MultiFlex screen of the MultiFlex interface. -

Page 41: Pak Start Screens

When the HHT is plugged into the MultiFlex board, the HHT display will show the model Discharge. The current value of the discharge type of the MultiFlex (PAK), the CPC part num- pressure input. ber, and the firmware revision. Amb 1 Temp. The current value of ambient DIP Settings: temperature sensor #1. -

Page 42: Status Screen 4

Cond Temp. The Cond Temp is the condenser DB / SP. The number to the left of the slash is discharge temperature, calculated by converting the programmed deadband value around the con- the discharge pressure input value to a tempera- denser TD setpoint. -

Page 43: Status Screen 7

ON rithm in the MultiFlex PAK. There are seven whenever an alarm is active on the PAK, and messages that may appear here: OFF when no alarms are active. -

Page 44: Pak Configuration Screens

OutDB Delay - Due to the Suction Outer Some (but not all) of the configuration of the Deadband feature, the PAK has skipped a MultiFlex PAK may be changed using the HHT. compressor stage change because it deter- HHT users may change setpoints, redefine input... -

Page 45: The Pak Configuration Menu

TempUnits. Choose the engineering unit you times the flash memory has been rewritten. wish to use for all displayed temperature values on the HHT in the TempUnits field (Deg F or Deg C). PAK Configuration Screens MultiFlex PAK Hand-Held Terminal Interface • 37... -

Page 46: Comp Sp

RefrType. Choose the refrigerant type used in returning to within the Suction Deadband. See the refrigeration system in this field. Section 6.1.3., Compressor Group Stage Acti- vation and Deactivation for a complete descrip- SpecialCode. This field is used by ECT person- tion of this feature. - Page 47 OFF (00000000). #4 (left to right), and line four contains the fields for #5 through #8 (left to right). For each compressor, specify a compressor group assignment from 1-8. PAK Configuration Screens MultiFlex PAK Hand-Held Terminal Interface • 39...

-

Page 48: Outs

To cancel an override, set the Ovrd field to when inactive and 0VDC when active. "NO." This override is also cancelled when the HHT is unplugged from the MultiFlex PAK. 40 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008... -

Page 49: Condsp

The Fan OFF Delay will be the Rtn2Nrml setpoint and remains there longer observed as each stage is deactivated. than the Rtn2Nrml Time. PAK Configuration Screens MultiFlex PAK Hand-Held Terminal Interface • 41... - Page 50 Amb Spray Lkout. The Ambient Spray Lock- Screen 8 out setpoint is the ambient air temperature below VSD Fault Input which the condenser spray output will be locked ActiveLevel: OFF OFF. VSD Max Output QuietMode: 100 Rtn2Nrml and Off Delay. The Return To Nor- VSD Fault Active Level.

-

Page 51: Input

Level Min and Liq Level Max fields. Suct XDucr. Specify the size of the suction pressure transducer being used in this field. You may choose 100 lb or 200 lb. PAK Configuration Screens MultiFlex PAK Hand-Held Terminal Interface • 43... -

Page 52: Safety

The sixteen Input Setup screens are where shutdown after a discharge trip has occurred. the input types for MultiFlex PAK inputs #1 After the Reset Delay has elapsed, if the dis- through #16 must be defined. The input types are charge pressure lowers to below the Discharge listed and described in Table 4-1 on page 9.

Need help?

Do you have a question about the MultiFlex PAK and is the answer not in the manual?

Questions and answers