Table of Contents

Advertisement

Quick Links

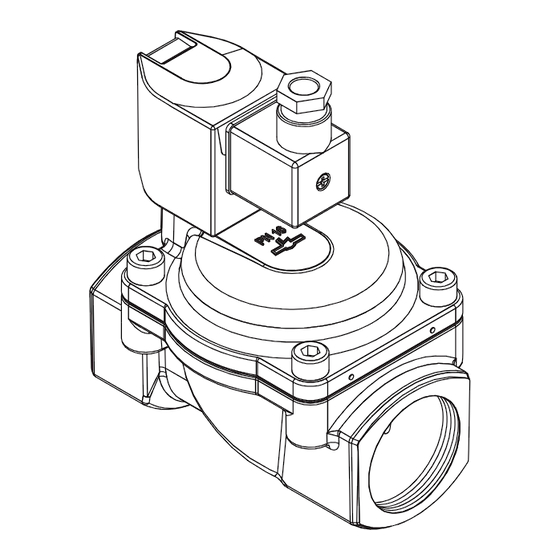

Operation manual -

pre-controlled diaphragm valves

Revision 8

Keep documentation for future use!

Series

82400

82410

G

N

82730

82740

G

N

83030

G

G-Thread

F

NPT-Thread

N

Flange

F

11/2018

Contents

1.1 Documentation validity

1.2 Structure of safety instructions

10

10

10

10

10

10

10

11

11

11

11

Translation of the original operating manual

Status as of November 2018

1

1

1

About this documentation

1

These mounting instructions guides you to

1

mount, operate and maintain pre-controlled

2

diaphragm valves safely.

2

2

This operation manual is intended for:

2

plant operators, installers, maintenance and

2

service technicians.

2

2

1.1

Documentation validity

3

This operation manual applis to pre-controlled

3

diaphragm valves of the following series

3

4

•82400, 82730 (G-Thread)

4

•82410, 82740 (NPT-Thread)

4

•83030 (Flange)

4

•for special products that are based on the

4

series mentioned above

5

in combination with these c-solenoids:

5

5

9136 x

Series

9101

9151

5

5

82400

•

•

•

G

6

82410

•

•

•

N

7

7

82730

G

•

•

•

7

82740

N

•

•

•

7

83030

F

•

•

•

8

8

8

Order No. Connection

Connection

8

8

8

xxxx0xx

G 1/4

1/4 NPT

9

xxxx1xx

G 3/8

3/8 NPT

9

xxxx2xx

G 1/2

1/2 NPT

9

9

xxxx3xx

G 3/4

3/4 NPT

G 1

1 NPT

xxxx5xx

G 1 1/4

1 1/4 NPT

xxxx6xx

G 1 1/2

1 1/2 NPT

G 2

2 NPT

Series

82400

82410

82730

82740

1.2

Structure of safety instructions

Safety instructions warns against dangerous

situations and must be observed in particular.

Safety instructions are structured as follows:

SIGNAL WORD

Type of hazard

Consequences of non-observance

→ Precautions necessary to avoid the hazard

1.3

Hazard classes (ANSI Z535.6)

!

DANGER

Safety information indicates a hazardous situation

with high risk which, if not avoided, will certainly

result in death or (serious) injury.

!

WARNING

Safety information indicates a hazardous situation

with moderate risk which, if not avoided, can cause

death or severe injury.

6106 x

•

!

CAUTION

•

Safety information indicates a hazardous situati-

•

on which, if not avoided, could result in minor or

moderate injury.

•

•

NOTICE

Information indicates a hazardous situation which, if

Nominal

not avoided, could result damage to property.

size

-

-

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50

83030

1377005.0000.10011

1

Advertisement

Table of Contents

Summary of Contents for IMI BUSCHJOST 82400G Series

-

Page 1: Table Of Contents

Contents Translation of the original operating manual Structure of safety instructions Status as of November 2018 1 About this documentation Safety instructions warns against dangerous situations and must be observed in particular. 1.1 Documentation validity About this documentation Operation manual – 1.2 Structure of safety instructions Safety instructions are structured as follows: These mounting instructions guides you to... -

Page 2: Styles And Symbols

deformation – were detected but the valve Markings at the operating site Personal protection equipment remains in operation. → Ensure adequate warning of the risks linked → Wear appropriate protection equipment. •Malfunctions were detected but the valve to the valve. Use in the area of the installed Observe the personal protection equip- remains in operation. -

Page 3: Avoid Damage To Property

Identifying the valve Transport and storage Hazardous fluids The rating plate is situated on the solenoid Phases: assembly, operation, NOTICE body. maintenance, disposal Damage of the valve Risk: skin contact, eye contact, DANGER Valve may be damaged if foreign particles breathing vapors Made in Germany Hazardous electrical voltage... -

Page 4: Function

Normal position: closed Mounting Main valve seat Due to the effect of the compression spring 6 Control bore in the diaphragm (pressure build-up) NOTICE inside the core the pilot seat is closed. 5 Chamber Damage of the valve Compression spring 4 ... -

Page 5: Dimensions

Mounting accessories Conditions of installation Mounting bracket Compliance with operating limits With an optional mounting bracket, you can Ensure to comply with the operating limits pri- Dimensions connect the valve to an load-bearing structure or to mounting the valve. Observe the valve’s at the installation site, thus protecting against data sheet. -

Page 6: Connect Solenoid Electrically

4. Attach the pipelines to the valve. NOTICE Valve with flange connection Connect solenoid electrically Make sure not to distort the valve body. 1. Take out the protective collars from valve → Connect solenoid in accordance with the 5. Attach pipelines threads to the valve’s 2 ... -

Page 7: Operating Conditions

2. Attach the protective conductor at first Permitted media solenoid 9136 (insulation: yellow/green) to the terminal Baureihe 82400, 82410, 83030 marked with the grounding symbol y. 6106 for neutral, gases and liquid fluids Baureihe 82730, 82740 Solenoid 9136 for slightly aggressive, gases and liquid fluids Configuration of the →... -

Page 8: Document No. 1377005.0000.10011 Revision

12.2 12.3 12.4 Checking for tightness and strength Preparing maintenance of internal Component overview parts A NOTICE NC-valve (normally closed) The valve body may remain in the pipework Risk of damaging the valve Operation during maintenance. Invalid test conditions may lead to damage NOTICE of the valve. -

Page 9: Unmounting Solenoid

12.5 12.7 Unmounting solenoid Checking valve parts Valve body → A Slightly bend back fixing clamp 706. 1. Check disassembled valve parts for dama- Valve cover B Pull solenoid with a twist upwards to take ges and wear. Diaphragm ✗ B ... -

Page 10: Replacing Spare Parts

12.11 12.12 Re-commissioning Mounting valve parts Mounting solenoid 1. Place the diaphragm 103 correctly positi- 1. Push the O-ring 707 onto core tube 701 1. Check valve’s switching function without oned on the valve body 101. The tab must until is flush to the screw piece 703 . fluid (refer to 10.1 12.9... -

Page 11: Trouble Shooting

Trouble shooting Disposal → Observe safety information and instructions 1. Disassemble the valve as described in chap- in chapter “Maintenance”. “Decommissioning”. 12 14 2. Disassemble the valve parts to enable reu- sable materials to be recycled. Error table 3. Dispose of the valve parts as appropriate for not function their materials: possible cause: the solenoid coil defective...

Need help?

Do you have a question about the 82400G Series and is the answer not in the manual?

Questions and answers