Summary of Contents for Assum DZ Series

- Page 1 USER MANUAL...

- Page 2 INDEX I. Product description and usage II. Techincal parameters III. Machine Overview IV. Working Princple V. Circuit Diagram VI. Operation VII. Programming VIII. Cautions IX. Assembly diagrams X. Trouble-shooting XI. Maintenance XII. List of accessories...

- Page 3 I. Product description and usage DZ series vacuum packing machine is used for removing air from the package and sealing the mouth of bag. Vacuum packing reduces atmospheric oxygen, limiting growth aerobic bacteria or fungi, and preventing the evaporation of volatile components.

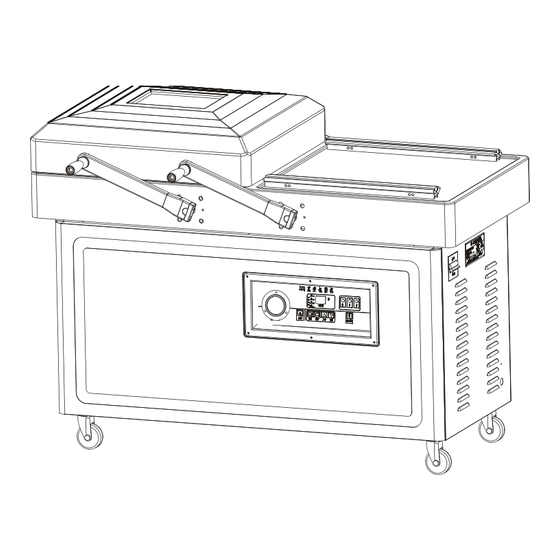

- Page 4 III. Machine Overview Fig. 1 1.Lid 2. parallel arms 3. sealing bar 4. vacuum chamber 5. interrupter 6. controlling panel 7. Housing...

- Page 5 IV. Working Principle Air bag Sealing bar Solenoid valve for pumping solenoid valve for sealing Vacuum meter Vacuum pump Fig. 2 Step 1 vacuum. There is an air bag between sealing bar and lid. When the pump is working, the air in the air bags and vacuum chamber is vacuumed simultaneously, so that the sealing bars and silicon bars not close up.

- Page 6 Fig.3 Single pump 1-phase power supply...

- Page 7 Fig.4 simple pump 3-phase power supply...

- Page 8 Fig.5 double pump 1-phase power supply...

- Page 9 VI. Operation 1. Vacuum meter 2. Time and status indicator. " " indicates the machine is in start-up mode, in which power is connected and machine is not working yet. indicates devacuum, and number indicates the current value of the active function during the program cycle or the set value of the selected function when the machine is inactive.

- Page 10 VII. Programming 1. Vacuum time range: 0 to 99 s.. (Normally 20 s., and for liquid, 25 s is recommended.) 2. Sealing time range: 0 to 3.5 s.. (normally 1.5 s., and for thick film or with aluminum layer, 3 s..) 3.

- Page 11 b. Vacuuming: this program beings at the same time, the timer counts down from the set value, then comes to the next program. c. Sealing: this program beings, and the timer counts down from the set value, then comes to the next program. d.

- Page 12 IX. Assembly diagrams Fig.1 sealing parts Container for air bag Bolt M6 Container for sealing bar Heating element resistance Tube for spring Copper bolt Supporter for spring Teflon cloth Spring Sealing bar...

- Page 13 Fig.2 sealing parts Lid of vacuum chamber Stick for holding bag Container of air bag Gasket Air bag Rubber tube Container of sealing bar Bolt for fix silicone bar Sealing bar Plat of vacuum chamber Copper bolt Insulate tube Silicone bar...

- Page 14 X. Trouble-shooting Form 1 vacuum system Trouble Cause Method Pump do not work See From 3 Adjust bolts on the Lid is not tightly closed parallel arms Not vacuum Solenoid value is broken or short Check or change the circuited solenoid value Check or change the Circuit board is broken...

- Page 15 From 3 pump Trouble Cause Method Vacuum oil deteriorated Check or change oil Insufficient vacuum oil Add oil Not sufficient vacuum Pipe leaks air Check or change pipe Filter get stuck Clean or change the filter Check and connect the right Wrong voltage power Pump can not start...

- Page 16 XI. Maintenance Regular maintenance is required for a long lifespan of the machine, to avoid problem and to achieve an optimal packaging result. If the machine is used intensively, please maintain more regularly. If there are doubts about the maintenance activities or if the machine fails to work correctly always contact the supplier.

Need help?

Do you have a question about the DZ Series and is the answer not in the manual?

Questions and answers