Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Argus MBF

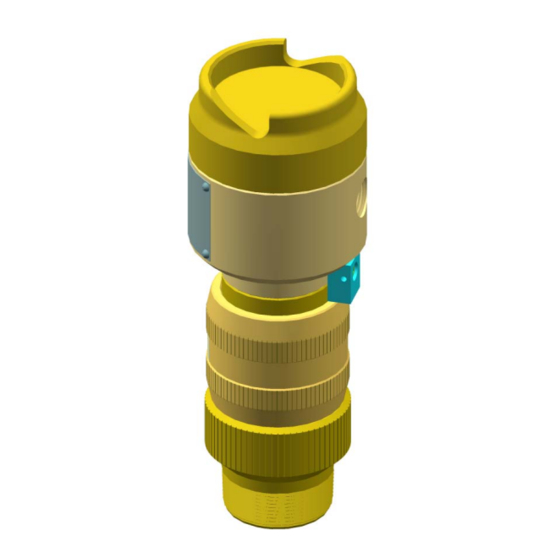

- Page 1 PRESSURE SWITCH (DUAL SEAL) MODEL AEF – MBF Installation, Operation, and Maintenance Manual Argus Machine Co. Ltd. 5820 – 97 Street, Edmonton, Alberta T6E 3J1 Phone: (780) 434-9451 Fax: (780) 434-9909 www.argusmachine.com MN-PS-002 July 2015 Printed in Canada...

-

Page 2: Table Of Contents

10.0 CONTACT INFORMATION ......................7 ATTACHMENTS: INSTALLATION AND OPERATION INSTRUCTIONS (TB-PS-001, Page 1) IMPORTANT NOTICE, CAPACITOR DISCHARGE IGNITION (TB-PS-001, Page 2) WIRING INSTRUCTIONS (ARGUS WIRING HARNESS) (TB-PS-002) MN-PS-002 PRESSURE SWITCH (DUAL SEAL) July 2015 INSTALLATION, OPERATION, AND MAINTENANCE Page 1... -

Page 3: Scope

(September 2007). 2.0 GENERAL The Argus Pressure Switch (automatic or manual reset) is designed to make or break an electrical circuit (an electric motor, a gas engine, etc.) upon sensing either ‘high’ or ‘low’ flow line pressure. Installation, operation, and maintenance of Argus Pressure Switches shall comply with procedures as described in this manual. -

Page 4: Applicable Standards

United States for Class I, Group D, Hazardous Locations (Division 1 and 2), Dual Seal 5) NEMA 4 and 7 enclosure 3.0 APPLICABLE STANDARDS Argus Type 'F' Pressure Switches are designed to meet the following standards: 1) ABSA: CRN No. OF2161.2134 2) ASME: B31.3... -

Page 5: Installation

(Refer to Argus Pressure Switch brochure for more information). On request, Argus technicians can attach the Argus Wiring Harness assembly to the Pressure Switch in the factory. This eliminates the need to remove the Cap when installing an Argus Pressure Switch in the field. -

Page 6: Operation

Switch Housing. It is not necessary to wrench tighten the Cap to ensure a seal. CAUTION: Do not over-tighten the Cap, as damage may occur. 15) Once installation is complete, the Argus Pressure Switch should be operated two (2) or three (3) times to verify the factory settings. 7.0 OPERATION 7.1 OPERATING INSTRUCTIONS 1) Once installation is complete, the Argus Pressure Switch will trip automatically. -

Page 7: Microswitch Replacement

Switch trips off at the appropriate set point. If the set point is incorrect, the operator should adjust it to the original setting. (See 7.2 Pressure Setting). c) The Pressure Switch may also be taken off the line and sent to an Argus Service Center for testing and adjustment. -

Page 8: Troubleshooting

Switch may then be sent to an Argus Service Center for assessment and/or repair. 6) Argus recommends that due to the sensitivity of the Microswitch the customer should consider carrying one (1) spare Microswitch sub-assembly in inventory for every ten (10) Pressure Switches in the field.

Need help?

Do you have a question about the MBF and is the answer not in the manual?

Questions and answers