Summary of Contents for Huge Pump HP 05

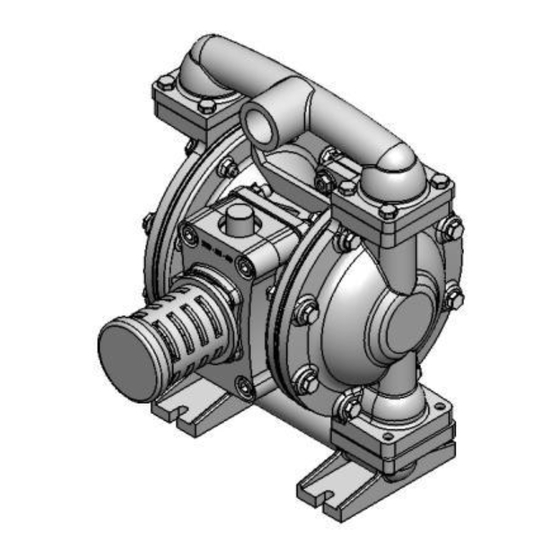

- Page 1 HP 05 PUMP USER’S MANUAL USER MANUAL HP 05 PLASTIC/ METAL PUMPS MODEL HP 05 PUMP Page 1...

- Page 2 HP 05 PUMP USER’S MANUAL HP 05 PUMPS DEVIDED INTO TWO CATEGORIES WHICH ARE: METALLIC PUMPS PLASTIC PUMPS MODEL HP 05 PUMP Page 2...

-

Page 3: Table Of Contents

HP 05 PUMP USER’S MANUAL COMPRESSED AIR DOUBLE DIAPHRAGM TRANSFER PUMPS TABLE OF CONTENT METALLIC PUMP’S PERFORMANCE CURVES METALLIC PUMP’S DIMENSIONS AIR LINE MOISTURE METALLIC PUMP’S PACKAGING AIR INLET AND PRIMING METALLIC PUMP’S SPARE PARTS DRAWINGS FREQUENCY OF USE METALLIC PUMP’S SPARE PARTS LIST TROUBLESHOOTING PLASTIC PUMP’S PERFORMANCE CURVES... -

Page 4: Metallic Pump's Performance Curves

HP 05 PUMP USER’S MANUAL PERFORMANCE CURVES 10 m3/h (hava giriş debisi) ( bar) 16 m3/h 20 m3/h 35 m3/h 40 m3/h 50 m3/h 67 m3/h Dakikadaki Litre Kapasitesi ( lt/dk) Volumetric Capacity - LPM HP 05 (3/4”) METALLIC PUMP Suction / Discharge 3/4"... -

Page 5: Metallic Pump's Dimensions

HP 05 PUMP USER’S MANUAL METRIC DIMENSIONS [ mm ] Dimensional tolerances ± 3 mm 264,6 169 215 294 155,5 138,5 267 94 109 209 200 Page 5... -

Page 6: Metallic Pump's Packaging

HP 05 PUMP USER’S MANUAL PACKING DIMENSIONS[ mm ] 325 270 381 Page 6... -

Page 7: Metallic Pump's Spare Parts Drawings

HP 05 PUMP USER’S MANUAL COMPOSİTE PARTS DRAWING OF HP 05 (3/4”) METALLIC PUMP Page 7... -

Page 8: Metallic Pump's Spare Parts List

HP 05 PUMP USER’S MANUAL METALLIC PUMP COMPOSITE PARTS LIST H080547 Gasket, Air Valve S010530 Suction Line H090547 Gasket, Pilot Valve, Front S020530 Discharge Line H100547 Gasket, Pilot Valve, Rear H010533 Main Body H120547 O-ring, Pin S030530 Outer Chamber H130590... - Page 9 HP 05 PUMP USER’S MANUAL MATERIAL CODES ALUMINUM NEOPRENE CAST IRON SANTOPRENE STAINLESS STEEL BUNA-N POLYPROPYLENE EPDM DELRIN TEFLON VİTON PVDF POLYETHYLENE DIA SPECIAL MATERIAL BRONZE STEEL Page9...

-

Page 10: Plastic Pump's Performance Curves

HP 05 PUMP USER’S MANUAL HP 05 PLASTIC PUMP PERFORMANCE CURVES ( bar) 10 m3/h (hava giriş debisi) 16 m3/h 20 m3/h 35 m3/h 40 m3/h 50 m3/h 67 m3/h HP 05 (3/4”) PLASTIC PUMP Dakikadaki Litre Kapasitesi ( lt/dk) Volumetric Capacity - LPM Suction / Discharge 3/4"... -

Page 11: Plastic Pump's Dimensions

HP 05 PUMP USER’S MANUAL METRIC DIMENSIONS [ mm ] Dimensional tolerances ± 3 mm 261.5 151,5 178 225,5 78,5 93,5 208,5 143 PACKING DIMENSIONS [ mm ] Page11... -

Page 12: Plastic Pump's Packaging

HP 05 PUMP USER’S MANUAL 325 270 380 COMPOSİTE PARTS DRAWING OF HP 05 (3/4”) PLASTIC PUMP Page12... -

Page 13: Plastic Pump's Spare Parts Drawings

HP 05 PUMP USER’S MANUAL Page13... -

Page 14: Plastic Pump's Spare Parts List

HP 05 PUMP USER’S MANUAL PLASTIC PUMP COMPOSITE PARTS LIST H030533 Air Valve Repair Kit S010533 Suction Line H040533 Pilot Valve Repair Kit S010535 Suction Line H050547 Bumper S260533 Suction Line Elbow H060546 Pin Bushing S260535 Suction Line Elbow H070533... - Page 15 HP 05 PUMP USER’S MANUAL SM8-P Ring Nut, M8 Ring Nut, M8 PM8-P Washer, M8 Washer, M8 KSM8-P Ring Nut, Square KSM8 Ring Nut, Square MATERIAL CODES ALUMINUM NEOPRENE CAST IRON SANTOPRENE STAINLESS STEEL BUNA-N POLYPROPYLENE EPDM DELRIN TEFLON VİTON...

-

Page 16: Diaphragm Materials

HP 05 PUMP USER’S MANUAL DIAPHRAGM MATERIALS AND OPERATION TEMPERATURES Material Maximum Minimum Neoprene It is resistant to the vegetable oils. Its abrasion resistant is very 90 ˚C 22 ˚C good. The fluids like acids, esters, ketones can cause damages to the material of construction and therefore they are not recommended. -

Page 17: Principle Of Pump Operation

HP 05 PUMP USER’S MANUAL PRINCIPLE OF PUMP OPERATION The diaphragm pump is consisted of two diaphragm chambers and reciprocal motions pump the liquid during entering to andexitingfrom two diaphragms.The diaphragms are connected to each other with a the chambers.The flow of the fluid from one chamber to another is diaphragm rod andmove in a reciprocating action.As one diaphragm... - Page 18 HP 05 PUMP USER’S MANUAL The interconnections of the diaphragm pump are straightforward.The Special precautions should be observed in the operation of fluid is taken from the bottom manifold and discharged at the upper diaphragm pump.These precautions will provide the maximum manifold.Diaphragm pumps are characterized by turbulence flow.To...

-

Page 19: Areas Of Application

HP 05 PUMP USER’S MANUAL AREAS OF APPLICATION Diaphragm pumps can also be used as submerged pump. It is necessary to maintain the exhaust port of the pump above the liquid surface with pipe or hose. Diaphragm pumps can be used to transfer the fluid in the tank readily by connecting them to the bottom of the tank. -

Page 20: Air Connection

HP 05 PUMP USER’S MANUAL Diaphragm pumps can also be used as barrel pumps. They have effective suctions ability and able to transfer allthe fluid in the barrel. The diaphragm pumps are able to transfer fluids at 6 meter of deepness. -

Page 21: Air Valve Lubrication

HP 05 PUMP USER’S MANUAL The air pressure should not be in excess 7 bars.The pump should be operate withproperly lubricated compressed airsupply. Proper provided with the air supply at such pressure and flow to achieve lubrication requires theuse of an airline lubricator system to deliver desired performance.When the airsupply line is solid piping, use a... -

Page 22: Troubleshooting

HP 05 PUMP USER’S MANUAL suspended particles that settle and harden in the course of time when * The pump suction and discharge port sizes are not proper.In such it is kept stand still.(Otherwise, product remaining in thepump case, the air flow for the pump operation will be insufficient. -

Page 23: Warnings

HP 05 PUMP USER’S MANUAL Read these safety warnings and instructions in thismanual completely, beforeinstallation and start-up of the pump.It is the user’s responsibility to retain this manual.Any operation performed that is not in according to the information provided under the manual may render the pump’s warranty invalid. - Page 24 HP 05 PUMP USER’S MANUAL WARNING: The fittings should be installed to WARNING: Please be careful at the pump transfer. eliminate any possible leakage of the transferred liquid. WARNING: In order to prevent the knock at the WARNING: The pump should be installed onto the discharge, the pump should be complete with the rubber mountings.

-

Page 25: Pumping Hazardous Liquids

HP 05 PUMP USER’S MANUAL WARNING: If the diaphragm is split then, the transferred fluid may pass to the air side of the pump and diffuse to the atmosphere.If pumping a product which is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe disposition. -

Page 26: Air Valve Assembly

HP 05 PUMP USER’S MANUAL AIR VALVE ASSEMBLY( H030533 ) 8 PART LIST OF AIR VALVE REPAIR KIT Item No. Part No. Name of Part H550533B Air Valve Body H560570 Sleeve and Spool Set H570547 O-ring H580536 H500532 Snap ring... -

Page 27: Air Valve Maintenance

HP 05 PUMP USER’S MANUAL To begin with the servicing of the air valve first shut off thecompressed air, bleed pressure from thepump, and disconnect the * Third: reassembly of the air valve. air supply line from the pump. To do this, install one bumper together with its O-ring on the one side of the air valve assembly. -

Page 28: Pilot Valve Assembly

HP 05 PUMP USER’S MANUAL PILOT VALVE ASSEMBLY( H040533 ) 9 PART LIST OF PILOT VALVE REPAIR KIT Item No. Part No. Name of Part H450533B Pilot Valve Body H460590 Sleeve H470547 O-ring, sleeve H480590 Spool H490547 O-ring, spool S124090... -

Page 29: Pilot Valve Maintenance

HP 05 PUMP USER’S MANUAL PILOT VALVE MAINTENANCE To begin with the servicing of the air valve first shut off the compressed air, bleed pressure from the pump, and disconnect the Third Installing the pilot valve air supply line from the pump. -

Page 30: Diaphragm Maintenance

HP 05 PUMP USER’S MANUAL DIAPHRAGM MAINTENANCE Item No. Part No. Name of Part H010533 Main Body H160547 Oil Seal H150590 Diaphragm Rod H050547 Bumper H130590 Inner Diaphragm Holder S060547 Diaphragm S070533 OuterDiaphragm Holder Double diaphragms are used for the pump with Teflondiaphragm.The... - Page 31 HP 05 PUMP USER’S MANUAL For maintenance of diaphragms, first remove the suction line of the *Second: Installing diaphragms pump and than block the pump discharge line.Cut off the compressed air supplybleed thepressure from the pump and disconnectthe air supply line from the pump. Drainany remaining liquid from the Insert M16 capscrews onto the outer diaphragm holder and push the pump.Inspect the pump assembly drawings and maintenance...

-

Page 32: Intermediate Assembly Maintenance

HP 05 PUMP USER’S MANUAL THRUST PIN MAINTENANCE Item No. Part No. Name of Part H010533 Main Body H140590 Actuator Pin H120547 O-ring, pin H060536 Pin Bushing In order to prevent damages at the high pressure operation replace the actuator pin with new one. If this situation continues use bigger size of actuator pin. -

Page 33: Metallic Check Valve Maintenance

HP 05 PUMP USER’S MANUAL CHECK VALVE (BALL & SEAT) MAINTENANCE METALLIC Shut off the suction line and discharge line of the pump before starting the maintenance work.Then shut the compressed air supply, The damaged or worn out discharge the pressure in the pipe and remove the compressed air parts should be replaced as connection.Discharge the fluid in the pump.Now the pump can be... -

Page 34: Plastic Check Valve Maintenance

HP 05 PUMP USER’S MANUAL CHECK VALVE (BALL & SEAT) MAINTENANCE PLASTIC Shut off the suction line and discharge line of the pump before check balls must seat flush to the starting the maintenance work. Then shut the compressed air supply,... -

Page 35: Adress

HP 05 PUMP USER’S MANUAL ADRESS GÜNALSAN POMPA ve MAK. SAN. TİC. LTD. ŞTİ. Adress:Maltepe Mah. Çifte Havuzlar Cd. Ayvalıdere Sok. No:6 Davutpaşa - Zeytinburnu / İstanbul Tel: +90 212 613 41 42 Fax : +90 212 613 41 49 e-mail:satis@gunalsanpompa.com...

Need help?

Do you have a question about the HP 05 and is the answer not in the manual?

Questions and answers