Summary of Contents for GRIGGIO GF 21

- Page 1 BORING MACHINE Mod. GF 21G GF 27G GF 35G INSTRUCTIONS SPARE PARTS Via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY GRIGGIO S.p.A. Tel. 049/9200920 Fax 049/9201433 WOODWORKING MACHINERY http://www.griggio.com E-Mail:info@griggio.com...

- Page 3 GRIGGIO S.p.A. WOODWORKING MACHINERY MODEL BORING MACHINES GF21 spindles GF27 spindles GF35 spindles MACHINE N° YEAR OF MANUFACTURE GRIGGIO S.p.A. WOODWORKING MACHINERY Via Ca’ Brion, 40 - Reschigliano (PD) ITALY Tel. 049. .9200920 Fax 049. .9201433 C.A.P. 35011 http://www.griggio.com E-Mail:info@griggio.com...

- Page 5 GRIGGIO S.p.A. WOODWORKING MACHINERY WE WOULD LIKE TO THANK YOU FOR HAVING CHOSEN ONE OF OUR PRODUCTS This manual contains all information, advice and warnings that our technicians deemed essential to operate the machine properly. It also contains routine maintenance rules, so that your machine will always be kept in perfect working order.

-

Page 6: Table Of Contents

GRIGGIO S.p.A. WOODWORKING MACHINERY INDICE 1. CONFORMITY CERTIFICATE ..................4 2. SAFETY AND GENERAL SAFETY INFORMATION ............4 USAGE AND MAINTENANCE ADVICE ..............4 MACHINE IDENTIFICATION ................. 4 3. OPERATIVE NOTES ....................... 5 4. DESCRIPTION OF THE MACHINE ................. 5 APPLICABLE TOOLS .................... - Page 7 GRIGGIO S.p.A. WOODWORKING MACHINERY 16.8 HOW TO USE REFERENCE PIN TO BORE SERIES OF HOLES ON LARGE PIECES (OPTIONAL)…………………………………………………………………...17 16.9 HOW TO USE TRIANGULAR FENCE FOR 45° BORING AND SPLINE (OPTIONAL)………………………………………………………………...………18 16.10 WOODWORKING EXAMPLES…………………………………………………….,….19 17. HOW TO START THE MACHINE .................. 21 17.1 WORKING CYCLE ....................

-

Page 8: Conformity Certificate

WOODWORKING MACHINERY 1. CONFORMITY STATEMENT Griggio S.p.A. declares that this Boring machine has been manufactured accurately, by using the best techniques available to manufacture a quality product. We also declare that our boring machine com- plies with EEC 89/392 Machines Guideline, as well as with the following standards:... -

Page 9: Operative Notes

GRIGGIO S.p.A. WOODWORKING MACHINERY 3. OPERATIVE NOTES WOODWORKING MACHINES CAN BE DANGEROUS To operate the machine safely and correctly, follow the indications contained in this manual care fully and scrupulously. The machine will have to be operated only by personnel who is both qualified and over 18. People responsible for safety should make sure that the machine operator has read and fully understood all the information contained in this manual. -

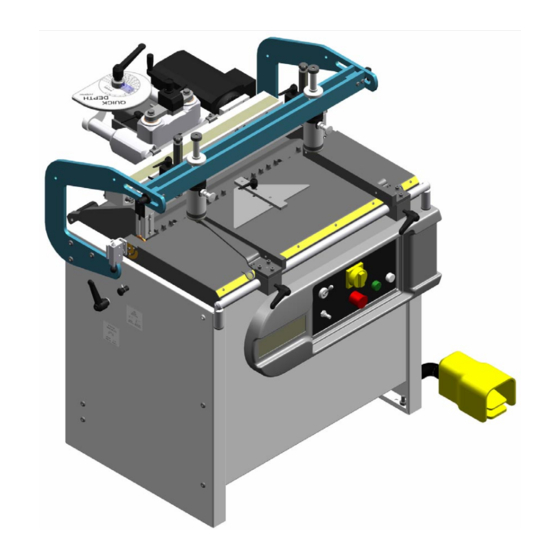

Page 10: Machine Parts

GRIGGIO S.p.A. WOODWORKING MACHINERY 13) Clamping handle for limiters rails 4.2 MACHINE PARTS 14) Limiters exclusion device 1) Electric power line light 15) Electric control board 2) Switch to make the engine operational 16) Rack rotation clamping handle 3) Emergency pushbutton... -

Page 11: Safety Devices

GRIGGIO S.p.A. WOODWORKING MACHINERY 6. SAFETY PROTECTION The main risk is due to the revolving drills. To reduce this risk to the minimum, our machines have been equipped with the following safety devices: 1) Emergency Pushbutton It is located on the control board in the front part of the machine. When it is pressed, all machine move- ments are halted immediately. -

Page 12: Individual Safety Devices

For further information and advice, please read chapter 3 “OPERATIVE NOTES” 8. TECHNICAL SPECIFICATION 8.1 WEIGHT NET WEIGHT Version. GF 21 320 Kg Version. GF 27 360 Kg Version. GF 35 444 Kg 8.2 OVERALL SIZE Version. -

Page 13: Interaxial Distance Between Spindles

GRIGGIO S.p.A. WOODWORKING MACHINERY 8.5 TABLE SIZE Version GF 21 900 X 380 mm Version GF 27 1050 X 380 mm Version GF 35 1360 X 410 mm 8.6 INTERAXIAL DISTANCE BETWEEN SPINDLES The interaxial distance between spindles is 32 mm. -

Page 14: Shipment

GRIGGIO S.p.A. WOODWORKING MACHINERY 10. SHIPMENT This boring machine is packed in a wooden box and/or in a cardboard and nylon box. Machine handling is possible with: fork-lift trucks bridge cranes pallet trucks Weight is indicated in paragraph 8.1 and hoisting points can be seen in the picture below. When the ma- chine is handled it is necessary to make sure that the surrounding area is free from obstacles. -

Page 15: Installation

GRIGGIO S.p.A. WOODWORKING MACHINERY 12. INSTALLATION The machine must be installed on a surface strong enough to sustain its weight so as to prevent harmful vibrations from impairing the good performance of the machine. To guarantee maximum machine efficiency and safety, the surface where the machine is located must be made of well-levelled concrete. -

Page 16: Assembly And Preliminary Steps To Operate The Machine For The First Time

GRIGGIO S.p.A. WOODWORKING MACHINERY 14. ASSEMBLY AND PRELIMINARY STEPS TO OPERATE THE MACHINE FOR THE FIRST TIME When the machine is delivered, it is partially assembled. It is therefore necessary to assemble those pieces that are delivered disassembled for packaging reasons. -

Page 17: Control Panel

GRIGGIO S.p.A. WOODWORKING MACHINERY A regulator that adjusts compressed air working pressure by keeping this value within the above- mentioned limits. A lubricator that puts a determined amount of oil into the system to lubricate cylinders, valves, gas- kets and moving parts. -

Page 18: Checks And Adjustments

GRIGGIO S.p.A. WOODWORKING MACHINERY 16. CHECKS AND ADJUSTMENTS WE ADVISE YOU TO DISCONNECT THE MACHINE FROM POWER SUPPLY AND FROM THE PNEUMATIC SYSTEM WHENEVER YOU NEED TO SERVICE THE MACHINE ITSELF OR TO RE- PLACE DAMAGED OR WORN PARTS. IF THIS IS THE CASE, FOLLOW THE PROCEDURES INDI- CATED BELOW AND PAY ATTENTION TO THE ADVICE GIVEN IN CHAPTER 6 OF THIS MANUAL. -

Page 19: How To Adjust Head Parallelism

GRIGGIO S.p.A. WOODWORKING MACHINERY 16.4 HOW TO ADJUST HEAD PARALLELISM To adjust head parallelism according to the working table: partially unscrew the screws (3) and operate alternatively on the screws (1) and screw nuts (2) position the drills parallel to the table tighten the screws very well (3) 16.5 HOW TO POSITION SPINDLEHEAD VERTICALLY AND HORIZONTALLY... -

Page 20: How To Use Reference Stops For Standard 0°-90°Woodworking

GRIGGIO S.p.A. WOODWORKING MACHINERY 16.6 HOW TO USE REFERENCE STOPS FOR STANDARD 0°-90°WOODWORKING Side rails and back stops are used to position the piece to be worked in a standard working cycle. With spindlehead at 90° and spindle unit locked into position: Set side rails at the right distance from drills that will be used and fasten them. -

Page 21: How To Use Reference Pin To Bore Series Of Holes On Large Pieces (Optional)

GRIGGIO S.p.A. WOODWORKING MACHINERY LONGITUDINAL POSITION OF EXTENSION FENCE: Unfasten the appropriate handles and turn side limiters over to bring them out of the table, making sure they are under the working table. Once the working table has been cleared, position the extension fence against the back stops and fasten it with the apposite screws. -

Page 22: How To Use Triangular Fence For 45° Boring And Spline (Optional)

GRIGGIO S.p.A. WOODWORKING MACHINERY 16.8 HOW TO USE REFERENCE PIN FOR LINE BORING ON LARGE PIECES (optional) As it can be complicated to use the extension fence to bore large pieces, our machines comes with a reference pin. This reference pin can be used for line boring on a large wood piece with higher axial dis- tance between first and last drill than the one obtainable with this type of boring machine. -

Page 23: Woodworking Examples

GRIGGIO S.p.A. WOODWORKING MACHINERY 16.10 WOODWORKING EXAMPLES... - Page 24 GRIGGIO S.p.A. WOODWORKING MACHINERY...

-

Page 25: How To Start The Machine

GRIGGIO S.p.A. WOODWORKING MACHINERY 17 HOW TO START THE MACHINE The operator’s site and the control board are located in front of the electrical control panel of the ma- chine. 17.1 WORKING CYCLE After having programmed the machine, follow the instructions given in the following paragraph to start the working cycle: 1) Turn the main switch (4), set it to position 1 and press MOTOR button (2). -

Page 26: Extraordinary Maintenance

GRIGGIO S.p.A. WOODWORKING MACHINERY 18.4 EXTRAORDINARY MAINTENANCE Make sure electrical system is safe. Check clamping of mechanical components. Check lubricating oil level in air-filtering unit and refill if necessary. Make sure the machine is lubricated regularly. Check air pressure. Line feed must be at 6 bar. -

Page 27: Failures That Might Occur During Machine Working Cycle

20.4 HOLD DOWN CLAMPS CANNOT CLAMP WOOD PIECE If hold down clamps cannot clamp pieces, check air pressure and connection tubes. To solve these problems, we suggest that you contact GRIGGIO S.p.A. Post-sale Assistance Service or your local dealer. 21. A. NOISE LEVEL Assuming the machine is functioning properly and that tool balancing and sharpness are correct, noise emissions can vary according to the material being worked, to drills diameter and to boring depth. -

Page 28: Pneumatic Scheme

GRIGGIO S.p.A. WOODWORKING MACHINERY 22. PNEUMATIC SCHEME 1) ¼” Male quick-change 2) G ¼” lubrication-filter- regulator unit 3) ¼” Wye 4) Wire muffler 5) Overturning lever Ø 30 6) G ¼”Flux Reg. 7) Overturning cylinder 8) 5/2 Pedal G ¼”... -

Page 29: Electrical Scheme For Gf35 (With Two Engines)

GRIGGIO S.p.A. WOODWORKING MACHINERY 23B. ELECTRICAL SCHEME FOR GF35 (WITH TWO ENGINES) I.G.: main switch; RT ½: temperature relay; C1/2: engine contactor; PR: air pressure; M1/2: driving shaft rotation; F: main fuse. -

Page 30: Machine Is Put Out Of Commission

GRIGGIO S.p.A. WOODWORKING MACHINERY 24. MACHINE IS PUT OUT OF COMMISSION If the machine has to be put out of commission, you will have to follow the following instructions strictly so as to guarantee people’s safety and to protect the environment around the machine. -

Page 31: Guarantee Certificate

GRIGGIO S.p.A. guarantees that the machine is in good working order and that it is a quality product ac- cording to law requirements, for a 12-month period. The guarantee is not valid in case of improper usage and servicing that do not comply with the regulations contained in this handbook and in case of adjustments and modifications that have not been approved by the manufacturer. - Page 32 GRIGGIO S.p.A. WOODWORKING MACHINERY Sale and Technical Service GRIGGIO S.p.A via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY Tel. 049/9200920 Fax 049/9201433 http://www.griggio.com E-Mail:info@griggio.com...

-

Page 33: Spare Parts Catalogue

GRIGGIO S.p.A. WOODWORKING MACHINERY 26. SPARE PARTS CATALOGUE... - Page 34 GRIGGIO S.p.A. TABLE 1 FRAME WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Frame Left Side 36200084 36200084 Clamping Block 36222147 36222147 D-En M 12 00000117 00000117 V-Te M 10 X 25 00018402 00018402 Electrical Box G Version...

- Page 35 GRIGGIO S.p.A. TABLE 1 FRAME WOODWORKING MACHINERY...

- Page 36 GRIGGIO S.p.A. TABLE 2 MACHINE TABLE WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Table 36222017 36722017 Millimetrical scale 36222019 36722019 Release lever 563-65 M8 L16 0003924 0003924 Central spline 36000021 36000021 45° plate 36000022 36000022 Rotation pin...

- Page 37 GRIGGIO S.p.A. TABLE 2 MACHINE TABLE WOODWORKING MACHINERY...

- Page 38 GRIGGIO S.p.A. TABLE 3 RACK WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Rack 36200005 36700005 V-tbei M 8X18 00018608 00018608 Boteco Sleeve 775-38 M12 00003940 00003940 V-tcei 8X16 00018307 00018307 90° Pawl 36222148 36222148 Hexagon stop 36222129 36222129 90°...

- Page 39 GRIGGIO S.p.A. TABLE 3 RACK WOODWORKING MACHINERY...

- Page 40 GRIGGIO S.p.A. TABLE 4 LIMITERS WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Limiter Unit 36222139 36222139 Right limiter 36222134 36722134 Slide rail 36222136 36222136 Vertical Slide rail 36222135 36222135 r-cild M 8 00018521 00018521 DEB M 4...

- Page 41 GRIGGIO S.p.A. TABLE 4 LIMITERS WOODWORKING MACHINERY...

- Page 42 GRIGGIO S.p.A. TABLE 5 SPINDLES UNIT WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Spiral stop support 36000047 36000047 VCCE-5931 M16X40 00018314 00018314 Spiral washer 36000043 36000043 r-cild M16 00018524 00018524 Spiral spigot 36000042 36000042 Lens support 36000045...

- Page 43 GRIGGIO S.p.A. TABLE 5 SPINDLES UNIT WOODWORKING MACHINERY...

- Page 44 GRIGGIO S.p.A. TABLE 6 HOLD DOWN CLAMPS FRAME WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Right and left hold down clamps support 36200101 36200101 Cross beams 36200041 36700041 Spacing block 36000091 36000091 V-tbei M 10x30 00018602 00018602...

- Page 45 GRIGGIO S.p.A. TABLE 6 HOLD DOWN CLAMPS FRAME WOODWORKING MACHINERY...

- Page 46 GRIGGIO S.p.A. TABLE 7 BACK STOP WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Back stop rail 36222070 36722070 Extruded thickness 36222130 36222130 Boteco 732-30 M8 L200 00003111 00003111 Release lever M8 L50 00004025 00004025 Back stop Shaft...

- Page 47 GRIGGIO S.p.A. TABLE 7 BACK STOP WOODWORKING MACHINERY...

- Page 48 GRIGGIO S.p.A. TABLE 8 HOLD DOWN CLAMPS WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Boteco 119-32 M6 00003120 00003120 Wedge-shaped piston 49970047 49970047 Threaded cylinder 49970048 49970048 Nut M14-basso-5589 00000118 00000118 Piston spring 49970146 49970146 Clamping ring nut...

- Page 49 GRIGGIO S.p.A. TABLE 8 HOLD DOWN CLAMPS WOODWORKING MACHINERY...

- Page 50 GRIGGIO S.p.A. TABLE 9 SPINDLEHEAD WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity Spindles plate 36222095 36722095 Head unit 36200054 36700054 Quick-change bush 36000061 36000061 V-tcei M 6x90 00018305 00018305 Bearing 6001 2RS1 00003424 00003424 V-tcei M 8x85...

- Page 51 GRIGGIO S.p.A. TABLE 9 SPINDLEHEAD WOODWORKING MACHINERY...

- Page 52 GRIGGIO S.p.A. TABLE 10 EXTENSION FENCE WOODWORKING MACHINERY Pos. Code 21G Code 27G Part name Quantity 3-meter extension fence with stops 36222143 36222143 Crescent stop 36222145 36222145 Release lever KRP 63 M8 L60 00004030 00004030 Shimming washer 00000037 00000037 VP-RL M 12x35...

- Page 53 GRIGGIO S.p.A. TABLE 10 EXTENSION FENCE WOODWORKING MACHINERY...

- Page 54 GRIGGIO S.p.A. WOODWORKING MACHINERY 35. SPARE PARTS ORDER FORM EVERY PART OF THIS FORM MUST BE FILLED IN. Customer Date ……………………………………………………. ………………………………………………………….. Telephone Address ………………………………………………………….. ………………………………………………………….. ………………………………………………………….. ………………………………………………………….. Date of Machine type Serial number Table Rev. Quantity delivery NOTES ……………………………………………………………………………………………………………………...

- Page 56 GRIGGIO S.p.A. WOODWORKING MACHINERY Via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY Tel. 049/9200920 Fax 049/9201433 http://www.griggio.com E-Mail:info@griggio.com...

Need help?

Do you have a question about the GF 21 and is the answer not in the manual?

Questions and answers