Summary of Contents for IMPERIA & MONFERRINA S.p.A. P6

- Page 1 TRANSLATION OF “ISTRUZIONIORIGINALI” IMPERIA & MONFERRINA S.p.A. AUTOMATIC FRESH PASTA MACHINE User and maintenance manual Construction year: 2013 Revision: 01 Edition: 05/2013...

- Page 3 IMPERIA & MONFERRINA S.p.A. REVISIONS REVISIONS MODEL LANGUAGE DATA VERSION NOTE English 05/13 FIRST RELEASE The information contained in this handbook is the property of IMPERIA & MONFERRINA S.P.A. Drawings and other documents that accompany the machining centre are property of IMPERIA & MONFERRINA S.P.A.

- Page 4 IMPERIA & MONFERRINA S.p.A. HANDBOOK STRUCTURE The manual is divided into 8 chapters. CHAPTER 1 – GENERAL INFORMATION This chapter contains general descriptions regarding the handbook structure. CHAPTER 2 – SAFETY This chapter contains a description regarding the standards, working environment conditions, ergonomics, accident prevention devices used, residual risks, warning plates applied to the machining centre.

-

Page 5: Table Of Contents

IMPERIA & MONFERRINA S.p.A. TABLE OF CONTENTS GENERAL INFORMATION ......................1-1 INTRODUCTION........................1-1 GLOSSARY .......................... 1-2 SYMBOLS ..........................1-4 ADDRESS OF MANUFACTURER ..................1-5 SAFETY STANDARDS ......................1-5 RESPONSIBILITIES OF THE MANUFACTURER ............... 1-6 MACHINE MANAGEMENT ....................1-6 WARRANTY .......................... 1-7 SUGGESTIONS FOR PASTA PRODUCTION .............. - Page 6 IMPERIA & MONFERRINA S.p.A. 6.1.1 General Hazard Notes ....................6-2 6.1.2 General Warnings ....................... 6-3 QUALIFICATION OF MAINTENANCE TECHNICIANS ............6-4 6.2.1 General Tasks ......................6-4 6.2.2 Tasks of Qualified Operators ..................6-5 SAFETY CONTROL PLAN ....................6-6 6.3.1 Checks and Functional Tests on Safety Devices ............6-6 STOP PROCEDURE FOR MAINTENANCE ................

- Page 7 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 8 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 9: General Information

This document is the instructions handbook for the: AUTOMATIC FRESH PASTA MACHINE “P6” and has been drawn up in compliance with Directive 2006/42/EC. The Use and Maintenance Handbook is to be considered an integral part of the system, and is to be kept until final dismantling. -

Page 10: Glossary

IMPERIA & MONFERRINA S.p.A. GLOSSARY Control circuit (of a machine): circuit used to control the machine operation and to protect the power circuits. Component: part of the electrical equipment, usually specified by its function, but used in various applications. Machines Directive: DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND COUNCIL concerning the harmonising of the laws of Member States related to machinery. - Page 11 IMPERIA & MONFERRINA S.p.A. Transport: operations involved to transfer the machine from the manufacturer’s assembly site to the final workplace of the Customer. Incorrect use: machine use out of the limits specified in the technical documentation. User: those who use the machine and associated electrical equipment. ...

-

Page 12: Symbols

IMPERIA & MONFERRINA S.p.A. SYMBOLS Some symbols are used in the handbook to call the attention of the reader and to highlight certain aspects which are especially important. SYMBOL MEANING NOTES Indicates a hazard with accident risk, even death, for the user. -

Page 13: Address Of Manufacturer

IMPERIA & MONFERRINA S.p.A. ADDRESS OF MANUFACTURER For any type of information or clarification regarding the use, maintenance, installation etc, the Manufacturer Technical Office is always available for requests from the Customer. Please state your requests in clear terms, with reference to this handbook, and always indicating the data of the system identification plate. -

Page 14: Responsibilities Of The Manufacturer

IMPERIA & MONFERRINA S.p.A. RESPONSIBILITIES OF THE MANUFACTURER The Manufacturer shall not be held in any way liable for incidents caused by incorrect or improper use of the machining centre, or for any damage cause by the use of spare parts that are not those specified, by maintenance operations not carried out correctly and/or by tampering on system circuits, components and software. -

Page 15: Warranty

IMPERIA & MONFERRINA S.p.A. WARRANTY The manufacturer guarantees, for a period of 12 months from the date of purchase, all parts excluding those subject to normal wear. The warranty shall no longer be valid if the machine has been repaired by unauthorised third parties or if fixtures, accessories are used that have not been supplied by the manufacturer or have not been recommended or approved by the same, or if the serial number is altered or removed during the warranty period. -

Page 16: Suggestions For Pasta Production

IMPERIA & MONFERRINA S.p.A. SUGGESTIONS FOR PASTA PRODUCTION Any type of flour or durum flour or flour/durum flour mixture can be used for the dough. The dough must be kneaded with eggs alone or an eggs/water mix. The water can be replaced in part by finely-chopped spinach or vegetables to obtain green pastas or tomato puree to obtain red pastas or other ingredients: in these cases it is advisable to use hard grain durum flour. -

Page 17: General Description

IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM... - Page 18 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 19: Safety

IMPERIA & MONFERRINA S.p.A. SAFETY GENERAL INFORMATION The Customer shall instruct the personnel regarding accident risks, safety devices installed on the machining centre and the general rules concerning accident prevention specified by the EU Directives and the laws of the country where the machining centre is installed. The operators are to know the position and functioning of all the system controls and the relevant characteristics. -

Page 20: Machining Centre Certification

IMPERIA & MONFERRINA S.p.A. 2.2.2 Machining centre Certification The system is supplied with the EC Declaration of Conformity to the essential safety requirements as per Machines Directive 2006/42/EC (annex II A), the Low Voltage Directive 2006/95/EC and the Electromagnetic Compatibility Directive 2004/108/EC. ... -

Page 21: Environmental Working Conditions

IMPERIA & MONFERRINA S.p.A. ENVIRONMENTAL WORKING CONDITIONS To permit the best possible environment conditions, it is necessary that the Customer organizes the machining centre and related systems in the workshop in a manner that provides good ventilation. The machining centre is to be installed in an environment equipped with all the safety precautions required by the laws in force in the user country. -

Page 22: Noise

IMPERIA & MONFERRINA S.p.A. 2.3.4 Noise The noise has been measured in accordance with the requirements of acoustic standard EN ISO 11200 and related standards. The typical phonometrical data is kept by the Manufacturer. The machining centre operating characteristics are such that, in a dry run, overall noise generated is less that 75 dB (A), measured in the operator workstations. -

Page 23: Safety Devices Applied On The System

IMPERIA & MONFERRINA S.p.A. SAFETY DEVICES APPLIED ON THE SYSTEM The machining centre is equipped with safety devices/solutions: Type of device/solution Function Main switch To cut-out machine electric power Fixed and mobile Enclosure of machine hazardous zones protections Emergency stop of entire system, or part of Emergency stop the same. -

Page 24: Energy Cut-Out

IMPERIA & MONFERRINA S.p.A. 2.4.1 Energy Cut-out Function: To cut-out power supplies of the machining centre. Characteristics and Before starting any type of maintenance job on the system, or part of the same, method: cut-out the power supplies and discharge any accumulated energy. Cut-out the machine electrical supply acting on the main switch. -

Page 25: Fixed And Mobile Protections

IMPERIA & MONFERRINA S.p.A. Fixed and Mobile Protections 2.4.2 Function: To segregate hazardous zone of the machining centre Characteristics and Protections are fixed and mobile. method: Fixed protections: The purpose of the fixed protections is to prevent access to machine component movements during the operating cycle. -

Page 26: Emergency Stop

IMPERIA & MONFERRINA S.p.A. Emergency Stop 2.4.3 Function: Emergency stop by pressing the red head emergency push-button on the machining centre, following a hazard risk for the safety of the operators and/or the system. Characteristics and All motion of the system is stopped. method: Pressing this push-button deactivates all movements, due to cut-out of power of all the machine actuators. -

Page 27: Personal Protection Devices

IMPERIA & MONFERRINA S.p.A. Personal protection Devices 2.4.4 Function: To protect the operator when working. Characteristics and The persons operating on the machine are to use personal protection devices to method: cut the possibility of risks to a minimum. DANGER Clothing of those who operate or carry out maintenance on the system, is to conform to the essential safety requirements and the laws in force in the country where the machine is installed. -

Page 28: Residual Risks

IMPERIA & MONFERRINA S.p.A. RESIDUAL RISKS 2.5.1 General information During the design, all the zones or parts with risks have been assessed, and as a consequence all the necessary precautions have been taken to avoid risks to persons and damage to system components. In order to assure the health and safety of exposed persons, at a general level the system is fitted with fixed and mobile protections, casings to cover moving parts. -

Page 29: Plates Installed On Machine

IMPERIA & MONFERRINA S.p.A. 2.5.3 Plates Installed on Machine The Manufacturer has installed several hazard warning and obligatory plates on the machining centre, in accordance with standards regarding the graphic symbols to be used on systems (Directive 92/58/EC). Maintenance shall immediately replace any plates that, due to wear, become illegible. These plates are located in positions well in sight. - Page 30 IMPERIA & MONFERRINA S.p.A. BLANK PAGE 2-12 / 86...

-

Page 31: Wiring Diagram

IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM... - Page 32 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 33: General Description

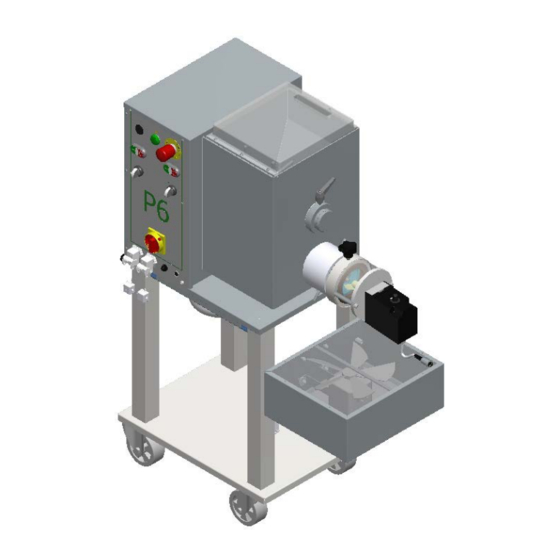

IMPERIA & MONFERRINA S.p.A. GENERAL DESCRIPTION MACHINE MAIN COMPONENTS Legend: Stainless-steel shaft Safety cover Mixer shaft clamp/release lever Dough-cutter motor clamp/release knob Plate support ring nut Dough-cutter motor Cooler blower Stainless-steel feeder Wheel block Truck Electric motor Plugs for electrical link with the cooler blower and optional units Tank Control panel 3-1 / 86... -

Page 34: Technical Specifications

IMPERIA & MONFERRINA S.p.A. TECHNICAL SPECIFICATIONS The following table contains the machine technical data. General Mixing tank capacity 6 Kg Dough production 15 ÷18 Kg/h Three-phase or single-phase motor 1,5Hp Weight 107 Kg 820 mm 440mm 3-2 / 86... -

Page 35: Accessories Supplied

IMPERIA & MONFERRINA S.p.A. ACCESSORIES SUPPLIED N4 dough plates (the type of plate is chosen by the customer when the order is placed). N1 plate ring nut support tightening spanner. N° 1 dough-cutter motor N° 2 knives for standard dough cutter motor (one with one blade and one with two blades). -

Page 36: Optional Accessories

IMPERIA & MONFERRINA S.p.A. OPTIONAL ACCESSORIES N° 1 knife for 4-blade pastry cutter motor Ravioli unit. Gnocchi unit Attachment point, for optional units, at the rear side of the machine. 3-4 / 86... - Page 37 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 38 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 39: General

IMPERIA & MONFERRINA S.p.A. GENERAL Before installation of the system: • Remove the protective packaging; • Remove any fastening restrictions used for transport. INSTALLATION 4.1.1 Positioning WARNING Before starting the positioning, carefully visually inspect the machine to identify any damage caused during transport. If one or more components are found to be damaged, do not proceed with the installation and notify the manufacturing company of the fault found, agreeing with same on the action to be taken. -

Page 40: Installation

IMPERIA & MONFERRINA S.p.A. 4.1.2 Installation WARNING All the operations described below are with the tank without the flour. Position the machine on perfectly level ground and lock the wheels with the wheel locks provided. Unscrew the plate support ring nut. Insert the plate required into the ring nut and screw the ring nut with plate into the machine again. - Page 41 IMPERIA & MONFERRINA S.p.A. If you wish to produce short pasta, choose the suitable dough-cutting blade from the two supplied. Insert the spring supplied into the blade and fit it onto the pin on the dough-cutter motor. CAUTION Handle the dough-cutting blades carefully. Fit the dough-cutter motor onto the machine by fixing it with the knob shown in the figure.

-

Page 42: 380 V Electrical Connection

IMPERIA & MONFERRINA S.p.A. 380 V ELECTRICAL CONNECTION Check that the main switch knob is in the "0" and connect the power plug of the unit to the wall outlet. CAUTION! Before starting the machine, make sure the voltage specified on the ID plate corresponds to the mains voltage. - Page 43 IMPERIA & MONFERRINA S.p.A. CAUTION! If the mixer shaft is turning in the opposite direction, press the EMERGENCY button 3 immediately to stop the machine. Remove the power supply plug from the socket and swap the position of the brown and black wires as shown in the figure.

-

Page 44: V Electrical Connection

IMPERIA & MONFERRINA S.p.A. 220 V ELECTRICAL CONNECTION Check that the main switch knob is in the "0" and connect the power plug of the unit to the wall outlet. CAUTION! Before starting the machine, make sure the voltage specified on the ID plate corresponds to the mains voltage. -

Page 45: Removal And Disposal Of Packaging

IMPERIA & MONFERRINA S.p.A. REMOVAL AND DISPOSAL OF PACKAGING The machine packing consists of: • Wooden box: usually deal-poplar, recyclable material. • Protective sack: sack in recyclable aluminium. • Expanding film: expanding polyethylene film. recyclable (LLDPE). • "Bubble" film: polyethylene film or recyclable material. •... - Page 46 IMPERIA & MONFERRINA S.p.A. BLANKE PAGE 4-8 / 86...

- Page 47 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 48 IMPERIA & MONFERRINA S.p.A. BLANKE PAGE...

-

Page 49: Use

IMPERIA & MONFERRINA S.p.A. DESCRIPTION OF THE CONTROLS Legend: Main switch Cooler blower on / off selector KNEAD on / off button Machine on signalling lamp Emergency stop button EXTRUDE on / off button Dough-cutter on / off selector Dough-cutter motor speed adjusting knob 5-1 / 86... -

Page 50: Work Cycle

IMPERIA & MONFERRINA S.p.A. WORK CYCLE Before the cycle • Check the selector switches on the control panel are all at “0”. • Make sure to have respected all precautions described in the Safety section Work cycle • Open the cover and fill the mixing tank with the basic ingredients (flour and/or hard-grain durum flour), water and/or eggs. - Page 51 IMPERIA & MONFERRINA S.p.A. WARNING Under no circumstances let the machine run with the button green “EXTRUDE” before kneading the flour. This could cause serious mechanical damage • The friable dough broken up into granules will be ready to be extruded after around 15 minutes. ...

- Page 52 IMPERIA & MONFERRINA S.p.A. If the machine stops during the working cycle: • The thermal protection inside the machine could have tripped as the result of the motor overheating or excessive voltage fluctuation. • After a few minutes, the thermal protection will be reset automatically and the machine will be ready to continue the working cycle.

-

Page 53: Changing The Plate

IMPERIA & MONFERRINA S.p.A. CHANGING THE PLATE To change the pasta type it is necessary to change the plate in the following way: • Press the red button • Bring the “COOLING BLOWER” and “DOUGH- CUTTER” back to zero “0”. •... - Page 54 IMPERIA & MONFERRINA S.p.A. Unscrew and remove the ring nut. • Remove the plate and replace it with another. WARNING After use, the plates must always be immersed in a container full of water to prevent the dough from drying ...

- Page 55 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 56 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 57: Maintenance

IMPERIA & MONFERRINA S.p.A. MAINTENANCE GENERAL SAFETY PRECAUTIONS Operations concerning maintenance, troubleshooting and repairs are only to be carried out by the authorised persons. The persons who run and carry out maintenance on the system are to be well trained and have in-depth knowledge of accident-prevention rules;... -

Page 58: General Hazard Notes

IMPERIA & MONFERRINA S.p.A. 6.1.1 General Hazard Notes • High voltages can cause death upon contact. Always work with maximum caution and in accordance with the accident prevention rules in force in the country. • When the system is running there are moving parts that can cause serious damage to persons. For this reason cleaning and special maintenance operations that require removal or replacement of components on the machining centre or control units, are to be carried out with the system off and with no pressure in the systems:... -

Page 59: General Warnings

IMPERIA & MONFERRINA S.p.A. 6.1.2 General Warnings • System maximum reliability and minimum maintenance costs are the result of a maintenance and inspection schedule planned and scrupulously followed during the entire system life. Scrupulously observe the maintenance time scales set and time operations according to specific requirements related to the machining centre production cycle. -

Page 60: Qualification Of Maintenance Technicians

IMPERIA & MONFERRINA S.p.A. QUALIFICATION OF MAINTENANCE TECHNICIANS WARNING The safety warden shall make sure that all the persons operating on the machining centre have received all the instructions that concern them, contained in this handbook, including the initial installation and start-up operations. -

Page 61: Tasks Of Qualified Operators

IMPERIA & MONFERRINA S.p.A. 6.2.2 Tasks of Qualified Operators The composition and qualifications of the teams indicated in the maintenance plan are those recommended by the Manufacturer The operations, if necessary can also be carried out by persons with the same or higher qualifications, who have attended the relevant training courses. -

Page 62: Safety Control Plan

IMPERIA & MONFERRINA S.p.A. SAFETY CONTROL PLAN WARNING It is strictly forbidden to electrically or mechanically jumper safety switches of guards, light barriers, safety circuits or tamper with them in any way. 6.3.1 Checks and Functional Tests on Safety Devices Maintenance technicians have the obligation to periodically check functioning of safety devices. -

Page 63: Stop Procedure For Maintenance

IMPERIA & MONFERRINA S.p.A. STOP PROCEDURE FOR MAINTENANCE Before carrying out the maintenance procedures the operator has to stop the machining centre and set it in maintenance mode, using this procedure: • Cut out machining centre power supplies if this is required by the maintenance operations. Otherwise it is not necessary. -

Page 64: Cleaning And Maintenance

IMPERIA & MONFERRINA S.p.A. CLEANING AND MAINTENANCE CAUTION Before starting any type of maintenance work, cut out and lock all energy sources and block the machine safeties. Place a warning signboard near the main switch. "MACHINE BEING SERVICED DO NOT POWER ON". Before putting back into service, recheck the entire system according to the start-up procedures. - Page 65 IMPERIA & MONFERRINA S.p.A. • Unscrew the ring nut and remove it. Remove the feeder and clean it with a damp sponge. • Remove the plate from the ring nut and plunge it into a container full of water. The dough inside the plate holes must never be allowed to dry.

- Page 66 IMPERIA & MONFERRINA S.p.A. BLANK PAGE 6-10 / 86...

- Page 67 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 68 IMPERIA & MONFERRINA S.p.A. BLANKL PAGE...

-

Page 69: Spare Parts

IMPERIA & MONFERRINA S.p.A. SPARE PARTS COMPONENTS SUBJECT TO WEAR AND MECHANICAL FATIGUE CAUTION The components subject to wear caused by the relevant functioning are to be checked at regular intervals and replaced as soon as they show significant signs of wear. The manufacturer has designed and built the machine for a rational life, taking into account the normal use conditions of the Customer;... - Page 70 IMPERIA & MONFERRINA S.p.A. BLANK PAGE 7-2 / 86...

-

Page 71: Table 1 Truck

IMPERIA & MONFERRINA S.p.A. 7.2.1 Table 1 Truck 7-3 / 14... - Page 72 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-463/1 Pivot wheel with brake LM-462 Fixed wheel LM-13857 Front legs LM-13856 Rear legs LM-13858 Sheet covering wheels LM-455F Ventilator LM-13859 Ventilator connection ring 7-4 / 86...

-

Page 73: Table 2 Pastry Cutter Motor

IMPERIA & MONFERRINA S.p.A. 7.2.2 Table 2 Pastry cutter motor 7-5 / 14... - Page 74 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-484 Motor bearing ring LM-478/A Pastry cutter knife 1 blade LM-478/B Pastry cutter knife 2 blade LM-481/A Spring pastry cutter knife LM-485 Hand-wheel LM-479 Pillar pastry cutter motor LM-469 Pastry cutter protective screen LM-476 Pastry cutter crosspiece LM-474...

-

Page 75: Table 3 Control Panel

IMPERIA & MONFERRINA S.p.A. 7.2.3 Table 3 Control Panel 7-7 / 14... - Page 76 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-13890 Control Panel LM-68415 Selector M22S WKV LM-68566 Fastening adapter M22 LM-62272 Contact NA M22-CK10 LM-68012 Emergency button M22 LM-62276 Emergency plate M22-XBK1 LM-68008 Luminous button M22S-DDLF LM-65302 Led M22 White LM-65303 Luminous indicator green LM-2852 3-pole panel socket LM-63787...

-

Page 77: Table 4 Switchboard

IMPERIA & MONFERRINA S.p.A. 7.2.4 Table 4 Switchboard 7-9 / 14... - Page 78 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-13860 Electronic installation case LM-930 Cable Gland PG7 LM-1608 Microswitch type OMRON Z15GQ LM-61654 0,3 mt Omega Bar 35x7,5 LM-853/1 Cable gland PG13,5 LM-859 Fuse carrier LM-74306 Transformer 250VA V=400/24 LM-73110 Thermal cut-out 1,3/3,1 A LM-73100 U-turn meter VB6-30-10-24CA LM-65830...

-

Page 79: Table 5 Press Tank

IMPERIA & MONFERRINA S.p.A. 7.2.5 Table 5 Press tank 7-11 / 14... - Page 80 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-13853 Press tank LM-13870 Crosspiece tank lid LM-401 Tank lid LM-2885 Rapid closing inox bent LM-1695 Pickup handle M8x20 zinced LM-406 Lip retaining ring LM-13878 Pastry shaft LM-408 Bushing LM-409F Konb LM-13868 Archimedean screw LM-832 Cooling jacket draw-plate LM-871...

-

Page 81: Table 6 Motorization

IMPERIA & MONFERRINA S.p.A. 7.2.6 Table 6 Motorization 7-13 / 14... - Page 82 IMPERIA & MONFERRINA S.p.A. Item Code Description LM-436 Guard LM-494 LM-493 LM-448 Cams LM-1612 Radial ball bearing SKF 6005 25/47/12 LM-13879 Output shaft male clutch LM-13880 Reducing shaft male clutch LM-1500 Chain tensioner spring LM-491 Chain tensioner arm LM-498 Roller LM-431F Pinion LM-439...

- Page 83 IMPERIA & MONFERRINA S.p.A. GENERAL INFORMATION SAFETY GENERAL DESCRIPTION INSTALLATION MAINTENANCE SPARE PARTS WIRING DIAGRAM...

- Page 84 IMPERIA & MONFERRINA S.p.A. BLANK PAGE...

-

Page 85: Wiring Diagrams

IMPERIA & MONFERRINA S.p.A. WIRING DIAGRAMS WIRING DIAGRAM 380 V 50 Hz 8-1 / 86... -

Page 86: Wiring Diagram - 220 V 50 Hz

IMPERIA & MONFERRINA S.p.A. WIRING DIAGRAM - 220 V 50 Hz 8-2 /86...

Need help?

Do you have a question about the P6 and is the answer not in the manual?

Questions and answers