Summary of Contents for WeighTech MicroWeigh

- Page 1 MicroWeigh Standard Bagger/Bulker WeighTech, Inc. Staff Waldron, Arkansas 1-800-457-3720 November 12, 2012...

-

Page 2: Table Of Contents

1 Introduction 1.1 MicroWeigh Features ......1.2 MicroWeigh Applications ...... - Page 3 12.2 Machines ....... . 12.3 Before calling WeighTech......

-

Page 4: Introduction

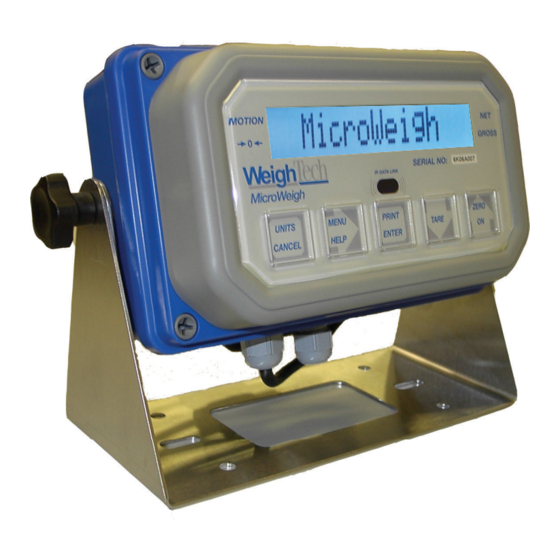

Batch weighing 2 Keypad Operation The WeighTech MicroWeigh keypad is a watertight sealed touch sensitive sensor. The keys are actually sensitive to contact area, not force. Press lightly with the ball of your fingertip as though you were giving fingerprints. Best results come from using the ball of your finger, not the very tip. -

Page 5: Main Menu Items

To unlock the keypad, you must play follow the leader. One key will be lit. Press it. Another key will then light up. Press it. Continue until the indicator displays “Exit washdown”. The indicator will require that you press five keys in a row correctly before it will unlock the keypad. -

Page 6: Tare

3.8 “Tare” Keypad entered tare: Touch the Enter key to set a new pushbutton tare by scrolling through digits one place at a time. Keypad tare values are entered in the current units, and are limited to be greater than gross zero weight and less than the indicator capacity. Entering a tare of zero will clear any existing tare from indicator. -

Page 7: How To Select From A List

5 General Scale Operations 5.1 Scale On Procedure Touch the “Zero / On” key. Indicator will come on and display will read “MicroWeigh by WeighTech” and then continue to the weigh mode. At this point the scale is ready for product or operator input. -

Page 8: Zero Procedure

After the machine has been wired and plumbed, turn on the air supply and turn off the Microweigh control indicator. The buffer hopper (top hopper) and weigh hopper (bottom hopper) should both be open, the infeed belt (if controlled by the system) should be running, and all knockoff gates should be retracted. - Page 9 should run (the system is trying to fill the weigh hopper). If the weigh and buffer hopper gates are swapped check the wiring—the weigh hopper valve is probably wired to the buffer hopper output module. After powering up the indicator, you may see “Setup Required” on the display. If so, go into the “Parameters”...

-

Page 10: Machine Operation

7 Machine Operation 7.1 Startup Ensure that all hoppers are empty and that all moving parts are in good working condition. Power up the machine and indicator. No air cylinders should move when the indicator is powered on. Touch the “Menu” key, scroll until “Production” is visible, and touch the “Enter” key. -

Page 11: Dump Cycle

tolerance settings and the target weight. For example, if the target weight is 10 pounds, the tolerance low setting is 0.5 pounds, and the tolerance high setting is 1.0 pounds, the acceptable weight range will be from 9.5 (target-low) pounds to 11 (target+high) pounds. -

Page 12: Keying In Cal Weight

8.2 Keying in cal weight The display will show “Cal weight ” and the cursor will be blinking. Using the up, down, and right keys to enter the size of your calibration weight in pounds (i.e. 1, 2, 5, or 10). Press “Enter” to accept the cal weight, or “Cancel” if you make a mistake. 8.3 Calibration Example (Entering a 25.00 lb cal weight value.) The blinking cursor is the clue that you can enter an arbitrary number using the up and down keys. -

Page 13: Capacity

calibration weights will be entered in this unit. The units parameter is both sealed and audited. 9.2 “Capacity” Capacity sets the maximum capacity of the indicator, in setup units. This parameter is both sealed and audited. Factory default is 0, which must be changed before the indicator will weigh. -

Page 14: Iz Set

9.10 “IZ set” When this parameter is on, the indicator will attempt to establish a new initial zero every time the indicator powers on. HB44 limits the amount of weight that can be initially zeroed to 20% of scale capacity. (This initial zero does not reduce the indicator capacity.) This parameter is both sealed and audited. -

Page 15: Calibration Warnings

“Excite Shorted!” The measured load cell excitation voltage has been below 1V for more than one second. To prevent any damage to the indicator or load cell, the excitation supply has been disabled. Double check the load cell cable and connections to the interface board, especially at the terminals marked “EX+”... -

Page 16: Menus

“Check sig+ wire” The positive load cell signal was measured at either less than 1.5 volts or more than 4 volts. Check wiring at terminal marked “S1+”, check that the load cell signal and excite pairs are correct, and finally consider that the load cell may be damaged. -

Page 17: Setup Menu

11.4 Setup menu Parameters Scale settings Dump settings Settings that control the automatic dump cycle operation I/O test Test input and output modules Info menu Troubleshooting features Set time/date Clock Control display intensity Contrast 11.5 Parameters Setup units Setup units: used for entering capacity and resolution (defaults to pounds) Capacity Scale capacity, in setup units... -

Page 18: Dump Settings

11.6 Dump settings Target Target weight for complete batch, in pounds Dump lmt Target weight for each dump, in pounds (hopper capacity) Zero thrs Dump cycle zero threshold, in pounds (default is 5 pounds) Autozero Dump cycle autozero settings (on/off) How long (in seconds) to wait for a stable dump weight Weigh TO How long (in seconds) to wait for an autozero to happen... -

Page 19: Info Menu

On/Off: Turn this parameter on for more extensive messages during boot and dump cycle Bootload WeighTech use only 12 Troubleshooting 12.1 Load cells Go to the “Info menu” and verify that the “Excite” voltage is about 4.5V. A reading of less than 1V probably indicates a short from excite to ground. -

Page 20: Machines

(available for purchase from WeighTech), or a known good load cell. Calibrate the scale with a convenient test weight and check to see if the weight reading is stable. If so, the noisy load cell has probably been damaged or water-soaked. -

Page 21: Replacement Parts

13 Replacement Parts Part Number Description EF0009 Strain Relief, Load Cell HW0018 Housing Screw, MicroWeigh (Pack of 4) HW0019 Screw, 6-19 x 0.375, Trilobe PPH Steel (Pack of 10) WE0028 Main Gasket, MicroWeigh WE0029 Power Cord, MicroWeigh WE0043 Interface Board, MicroWeigh machine control... -

Page 22: Wiring Diagram

JOB: BAGGER / BULKER PLANT: Tech LOCATION: Weigh PAGE: 1 OF 1 DRAWN BY: NEWELL DATE: 02-11-2010 FIRMWARE: BAGGER_1 SLOT TYPE FUNCTION DARK BLACK OAC-5 LINE STOP STOP FEED BLACK OAC-5 BUFFER HOPPER SHUT OPEN BLACK OAC-5 WEIGH HOPPER SHUT OPEN BLACK OAC-5 BAG OPENER... -

Page 23: Load Cell Color Codes

15 Load Cell Color Codes Manufacturer Models Signal + Signal - Excite + Excite - Shield Sense + Sense - Advanced Transducers Green White Black Bare wire Allegany Technology White Green Black Bare wire Artech Green White Black Beowulf White Green Black C2P1 C3P1 T2P1 T3P1... - Page 24 WeighTech, Inc. 1649 Country Elite Drive Waldron, AR 72958 Toll free: (800)-457-3720 Phone: (479)-637-4182 Fax: (479)-637-4183 Email: info@weightechinc.com Web: www.weightechinc.com $Id: bagger_1.tex,v 1.1.2.19 2010/02/11 16:16:14 newell Exp $...

Need help?

Do you have a question about the MicroWeigh and is the answer not in the manual?

Questions and answers