Table of Contents

Advertisement

Quick Links

!WARNING!

Failure to follow these instructions or to properly install and

maintain this equipment could result in an explosion and/or

fire causing property damage and personal injury or death.

MEC equipment must be installed, operated, and maintained

in accordance with federal, state, and local codes and

manufacturer's instructions. The installation in most states

must also comply with NFPA No. 58, and ANSI/CGA G-2.1.

For installation in the European Union, the equipment must

also comply with PED/TPED and EN ISO standards. Periodic

inspections, intermediate inspections and exceptional checks

of transportable pressure equipment should be carried out

in accordance with the Annexes of Directive 2008/68/EC and

with 2010/35/EU Directive (TPED) to ensure continued

compliance with their safety requirements.

Only personnel trained in the proper procedures, codes,

standards, and regulations of the LP-Gas industry should

install and service this equipment.

The internal valve must be closed except during product

transfer. A line break downstream of a pump may not

actuate the excess flow valve. If any break occurs in the

system or if the excess flow valve closes, the system should

be shut down immediately.

WARNING: These products contain a

chemical known to the state of California to

cause cancer and birth defects or reproductive

harm

Scope of the Manual

This manual covers instructions for the ME990-4F

"Excelerator" Series 4" Flanged internal valves.

Also included in this manual are the instructions for the

pulley cable assembly for connection from the valve's

operating lever to a cable control.

Introduction

The ME990-4F internal valve is typically used on the inlets

and outlets of transport truck tanks and large stationary

storage tanks. They can also be installed in-line. Designed

for propane or NH

(Anhydrous Ammonia) at ambient

3

temperatures, the valves can be used on other

compressed gases, but the user should check with the

factory to make sure the valve is suitable for the particular

service and application. Actuation of the valve can be

achieved manually, by cable, or with a pneumatic actuator.

Marshall Excelsior Company

1506 George Brown Drive Marshall, MI 49068

Phone (269) 789-6700 Fax (269) 781-8340

www.marshallexcelsior.com

The contents of this publication are for informational purposes only. While every effort has been made to ensure accuracy, these contents

are not to be construed as warranties or guarantees, expressed or implied, regarding the products or services described herein or for their use

or applicability. Marshall Excelsior Co. reserves the right to modify or improve the designs or specifications of such products at any time

without notice. The MEC™ logo is the trademark of Marshall Excelsior Co.

FORM #919 ME990-4F IOM

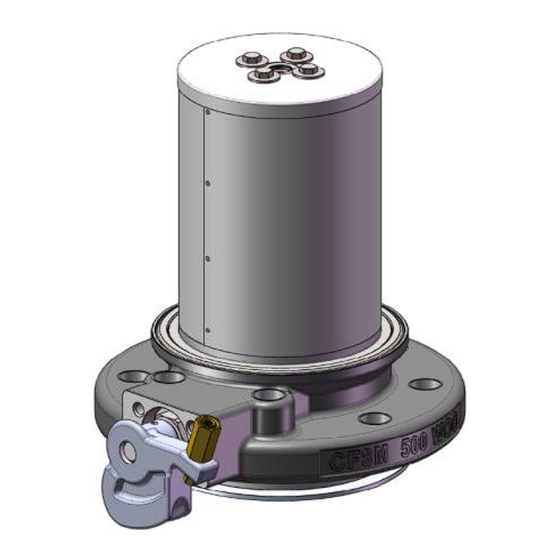

ME990-4F

4" FLANGED INTERNAL VALVE

INSTALLATION AND

OPERATING MANUAL

Specifications

Body Size and End Connection Styles:

Maximum Allowable Inlet Pressure:

Excess Flow Springs:

Temperature Capabilities: -20° to 150°F / -29° to 66°C

Approximate weight: 50 pounds / 23 kg

Body Material: Stainless Steel

DOT Internal Self-Closing Stop Valve Requirement--

U.S. Department of Transportation (DOT) regulations

49CFR§178.337-8(a)(4) require each liquid or vapor

discharge outlet on cargo tanks (except for cargo tanks

used to transport chlorine, carbon dioxide, refrigerated

liquid, and certain cargo tanks certified prior to January 1,

1995) to be fitted with an internal self-closing stop valve.

The ME990 series internal valves comply with the internal

self-closing stop valve requirement under the DOT

regulations.

Specifications

Inlet: NPS 4 / DN 100, CL300 ASME RF Modified

Flange (5.875"bore)

Outlet: NPS 4 / DN 100, CL300 ASME Flange

500 psig / 34.5 bar WOG

GPM (vertical down): 375, 500, 650, 850, 1250, AND

1500

l/min: 1419, 1893, 2460, 3217, 4731, and 5678

Marshall Excelsior Europe LTD

90 Brynteg Road

Gorseinon, Swansea, SA4 4FR - UK

01382-714308

Rev F 5/8/19

Advertisement

Table of Contents

Summary of Contents for Marshall Excelsior ME990-4F

-

Page 1: Specifications

Marshall Excelsior Co. reserves the right to modify or improve the designs or specifications of such products at any time without notice. - Page 2 ME990-4F FORM #919 ME990-4F IOM Rev F 5/8/19...

- Page 3 Pulley Cable Assembly: On ME990-4F valves, insert the cable through the hole in the operating lever until the fuse Keep piping from the valve outlet to the pump full size and link portion fits tightly in the hole, see Figure 3.

- Page 4 20 seconds of an unintentional release caused by complete separation of a delivery hose. The FORM #919 ME990-4F IOM Rev F 5/8/19...

-

Page 5: Troubleshooting

ME990-4F Operation Troubleshooting Since the ME990-4F internal valve is most often used on Internal Valve Will Not Open: This could be due to leakage transport trucks, the following procedure applies to that downstream, engaging the pump too soon or from type of application. - Page 6 A simple preventative maintenance program for the valve and its controls will eliminate a lot of potential problems. FORM #919 ME990-4F IOM Rev F 5/8/19...

- Page 7 ME990-4F Parts List for ME990-4F ME990-4F- Ref. # Description Qty. Body Stem Cage Bushing Valve Holder Excess Flow Spring, Cyan, 375 GPM Excess Flow Spring, Black, 500 GPM Excess Flow Spring, Green, 650 GPM Excess Flow Spring, Yellow, 850 GPM...

- Page 8 ME990-4F FORM #919 ME990-4F IOM Rev F 5/8/19...

Need help?

Do you have a question about the ME990-4F and is the answer not in the manual?

Questions and answers