Advertisement

Quick Links

DESCRIPTION

The PROFIBUS-DP option enables the

KS 94 to be connected to PROFIBUS-DP

networks. This allows de-centralized and

independent industrial and process con-

trollers to be integrated into PLC or PC

systems. The PLC/IPC transfers

set-points and control information to the

KS 94, and polls process values cycli-

cally.

All control functions and the associated

scaling and monitoring tasks are exe-

cuted independently. This ensures high

process safety together with short times

for engineering and commissioning.

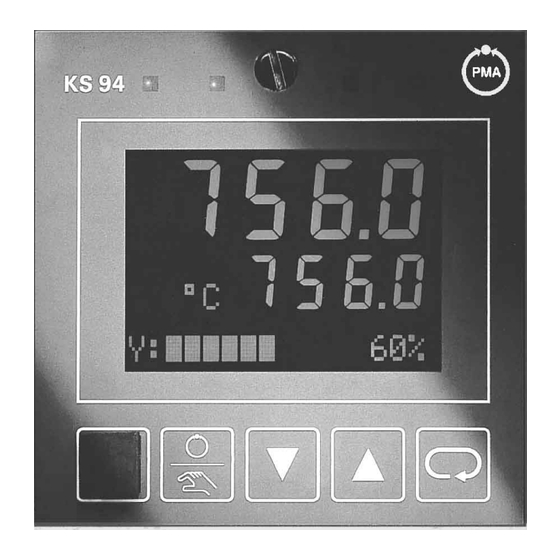

DISPLAY AND OPERATION

Via its "day & night" display, the KS 94

shows all process data locally and easily

readable. If required, one line of the dis-

play can be used to show a

freely-definable message.

Furthermore, the controller can be

switched to local operation, e.g. for com-

missioning the control loop without any

previous programming of the PLC or the

supervisory system. In addition, the En-

gineering Tool ET/KS 94 is available as a

useful device. It is connected via a

front-panel socket of the KS 94, and

serves for configuration, parameter set-

ting, and operation of the controller.

The standard graphical trend display al-

lows a qualitative evaluation of the

control results.

DE-CENTRALIZED I/O

Apart from the control function of the

KS 94, it is possible to access all inputs

and outputs directly. In this way, all the

controller's I/O are also available to the

PLC/IPC.

756. 0

756. 0

qm/h

y:óóóóó

The basic functions of the KS 94 / DP,

such as inputs/outputs, control

functions, etc. are described in the data

sheet (9498 737 28213) for the KS 94.

KS 94 / DP

PROFIBUS-DP option for KS 94

Cyclic transmission of up to

16 input and 16 output values

Free definition of data content

Transmission of process and parameter data

Inputs and outputs as decentral IO

Technical data

According to EN 50170 Vol. 2

Reading and writing of all process data,

parameters and configuration data.

DATA FORMAT

Real values such as set-points and pro-

cess data are transmitted in the IEEE

format (REAL) or in the 16-bit fiexed

point format (FIX) with one digit behind

55

the decimal point (configurable).

PARAMETER CHANNEL

Process data and selected parameter

data are written and read cyclically. All

process-, parameter- and configuration

can be transmitted via parameter chan-

nel. These data are transmitted over

several cycles on request.

PROFIBUS-DP Slave

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for PMA KS 94 PROFIBUS-DP

- Page 1 KS 94 / DP PROFIBUS-DP option for KS 94 PROFIBUS-DP Slave Cyclic transmission of up to 16 input and 16 output values Free definition of data content Transmission of process and parameter data Inputs and outputs as decentral IO Technical data DESCRIPTION DE-CENTRALIZED I/O Apart from the control function of the...

- Page 2 Writing of inputs/outputs can be acti- CONFIGURABLE PROCESS DATA Back-up controller mode During “normal” operation, the control vated individually for each input and MODULES output. output is computed by the master. The Module a (I/O): KS 94 is used to measure the process DATA CONTENTS (MODULES values, to generate the control output process data...

- Page 3 DIAGNOSIS/BEHAVIOR ON ERROR Fig. 1 Connection diagram KS 94/DP: If the master fails or the bus connection galvanic isolation is interupted (communication error) the last setpoint remains active and the 90...250V 24 V KS 94 works independently. If the mas- 24 V UC di 1 ( ) ter PLC is switched in stop-mode the...

- Page 4 Your local distributor Prozeß- und Maschinen-Automation GmbH Miramstraße 87, D-34123 Kassel Tel.: +49 561 505 - 1403 Fax: +49 561 505 - 1661 E-mail: export@pma-online.de Internet: http://www.pma-online.de Printed in Germany - Edition 0306 Data subject to alteration without notice 9498-737-37213...

Need help?

Do you have a question about the KS 94 PROFIBUS-DP and is the answer not in the manual?

Questions and answers