Table of Contents

Summary of Contents for Smart Lift SL 380 MIDI

- Page 1 US SL 380 MIDI 03-2016 User Manual © 2006 Copyright. www.smartlift.dk Model/type: SL 380 MIDI – 0.95 hp N.A. Christensensvej 39, DK-7900 Nykøbing Mors Tlf.: +45 97 72 29 11 Fax: +45 97 72 39 11 smart@smartlift.dk E-mail: ; www.smartlift.dk...

-

Page 2: Table Of Contents

US SL 380 MIDI 03-2016 Table of Contents: Table of Contents Introduction EU Declaration of Conformity General Description Transport/Handling/Putting into Operation/Storage Technical Data, Safety Rules Overview/ - General Description Operation for Vacuum function Control for arm and yoke Important Operation (vacuum & electric functions) Electric Functions Charger &... -

Page 3: Introduction

Read these safety rules on the following pages before putting your Smart LIFT into operation, and imagine how you may, in your daily use of the machine, ensure that warnings and safety rules will be adhered to. -

Page 4: Eu Declaration Of Conformity

N.A. Christensensvej 39 DK - 7900 Nykøbing Mors Hereby declares that: The machine/system: Lift Model/type: SL 380 MIDI – 0.95 hp Serial No.: Year/Month: 2016 has been made in conformity with Council directive Machine directive 2006/42EC Low voltage directive 2006/95/EC + 2014/35/EU... -

Page 5: General Description

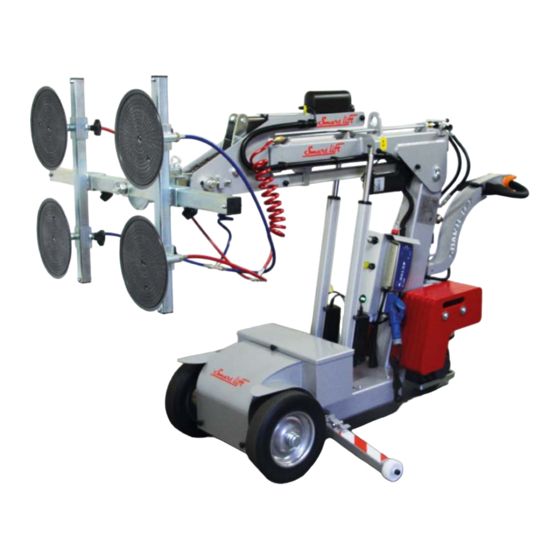

US SL 380 MIDI 03-2016 General Description/List of Spare Parts Pos.no. Product Number Vacuum Pump 007 Suction Cup diam. 11.8 " Check Valve ½", vacuum Replacement rubber t/suction cup Slide Valve w/lock, vacuum Vacuummeter diam.63 ¼", stainless Hose Set Hose Coupling... -

Page 6: Transport/Handling/Putting Into Operation/Storage

Smart Lift to be fastened securely in truck/trailer for transport and protected against rain and snow. Lifting by crane or similar: Always lift Smart Lift in lift eye intended for this purpose (pos. 41). NEVER lift under Smart LIFT by forks (truck and similar) For transport on the transport frame, Smart Lift must always be fastened in the lock fitting (pos. -

Page 7: Technical Data, Safety Rules

Safety Rules ( Pages 9, 11, 14) Daily Use Your Smart LIFT may only be used by persons who have been given qualified training in the operation of this machine and its safety functions. Before use, user should check that there are no loose objects on the machine since this would entail breakdown and danger risks. -

Page 8: Overview/ - General Description

US SL 380 MIDI 03-2016 WARNING! Explosion Danger! This machine may NOT be used in ATEX area. (Explosion danger environment). DANGER! Staying under the lifted work is strictly prohibited. PROHIBITED! May NOT be used for person lifting. Overview/ - General Description (pages 8, 9, 11, 14) 21 –... - Page 9 US SL 380 MIDI 03-2016 5- Slide Valve w/lock, Vacuum 32 – Control Panel in holder 2-circuit vacuum safety system 6 – Two vacuummeters. One for each vacuum circuit 31- Overload safety breaker Switch for high and low speed (turtle/rabbit)

-

Page 10: Operation For Vacuum Function

Users should make a point of reading the function description below, so as to become familiar with the functioning of the machine. Smart LIFT is operated manually. This machine generally has four functions which may be operated individually. UP/DOWN function: This function will make the arm move either up or down. -

Page 11: Important Operation (Vacuum & Electric Functions)

US SL 380 MIDI 03-2016 MAIN SWITCH: (Pos. 38) Placed on the battery case inside. Turn handle to switch off all electric functions. DRIVE MOTOR, (pos. 47): The drive motor is activated by an on/off switch (pos. 47a). Then turn the regulating lever (pos. 48). -

Page 12: Charger & Battery Case

US SL 380 MIDI 03-2016 Charger Victron Energy Blue Power Charger IP65 ( pos. 26) – Battery Charger for lead acid batteries. The blue Power charger is a three state charger (bulk-absorption float). The absorption stage ends 2 hours after the charger current has reduced to 10% of the nominal current, with a maximum charge time of 18 hours. -

Page 13: View Of Vacuum System (Top And Bottom Of Machine)

US SL 380 MIDI 03-2016 View of Vacuum System (top of machine) Pipe connection 2 – Suction Cups, standard diam. 11.8 in 5 – Slide Valve w/lock. Aktivating vacuum Load Diagram Double Vacuum © 2006 Copyright. www.smartlift.dk 10 – Hose Set 2-circuit... -

Page 14: Control Box

US SL 380 MIDI 03-2016 33 – Emergency stop 35 – Controller telescopic arm 35 – Controller tilt of yoke 16 – Acoustic alarm - vacuum 15 – Alarm light - vacuum 34 – Controller lifting arm 36 – Controller side shift 39 - Fuse 30 Ampere ©... -

Page 15: Control Panel For Arm And Yoke

US SL 380 MIDI 03-2016 Control Panel for arm and yoke (pos. 32) Lift arm up Lift Arm Down Tilt back Tilt forward Telescopic Arm in Telescopic arm out Side shift right Side shift left © 2006 Copyright. www.smartlift.dk... -

Page 16: Load Diagram

US SL 380 MIDI 03-2016 LOAD DIAGRAM © 2006 Copyright. www.smartlift.dk... -

Page 17: Stop-Down Troubleshooting Of Smartlift

US SL 380 MIDI 03-2016 Stop-Down Troubleshooting For any fault on Smartlift, first look into the options below: Has anything visible been broken, or is anything unusual, about the machine? Is there any • murmuring or noise? Have the batteries been charged, and the main switch switched on? (the On/Off button on the •... - Page 18 US SL 380 MIDI 03-2016 1. Stop-Down at Vacuum System Slide Valve w/safety lock for activation and deactivation of vacuum suction. Vacuum suction on both pressure gauges to be 0.62 (between 0.6 – 0.7) © 2006 Copyright. www.smartlift.dk © 2006 Copyright. www.smartlift.dk If –...

- Page 19 US SL 380 MIDI 03-2016 If – the vacuum pump starts and runs constantly, possibly with dropping pressure, when the slide valve is opened, in connection with suction of work. Check that all suction cups bear correctly on the work, i.e. that the particular suction cup is parallel with the work, and that no parts of the suction cups protrude from the work (IMPORTANT !!!).

- Page 20 US SL 380 MIDI 03-2016 2. Stop-Down at ”movements” controlled via control panel If – no response to pushing control panel, all functions Has emergency stop been released? Reconnect emergency stop by turning the release pressure. Check whether main switch is on (placed on battery case between lift actuators) – to be turned clockwise to switch on.

- Page 21 US SL 380 MIDI 03-2016 If –no response when pushing control panel , individual functions Has the safety switch been activated? If activated, try one of the possibilities above. There may be a fault on actuators for movements, or when controlling these.

- Page 22 US SL 380 MIDI 03-2016 Fault on lift actuator If the lift actuators, or one of these, stop due to “unbalanced” load, one of the safety switches under the actuators will have switched off the power supply. The following may be done to re-establish normal function: Pushing the operation panel button repeatedly to function ”down”...

- Page 23 US SL 380 MIDI 03-2016 Control box with controllers for all actuators Faults on movement of actuators can be diagnosed by measuring systematically as described in the following two pages. Controller for tilting Controller for telecoping actuator actuator Controller for sideshift...

- Page 24 US SL 380 MIDI 03-2016 Synchronous controller (controller for lifting actuators) Controller for lifting actuators (2 pcs.) Voltage between clamps 1 and 2 must be approx. 24 Volt Safety switch below the lifting actuators can be switched off. Clamp 1 and 16...

- Page 25 US SL 380 MIDI 03-2016 Controller for single actuator (sideshift, tilt of yoke, telescopic arm) (The illustration is from sideshift controller. The procedure is the same for tilt and telescoping) No reaction on actuator for sideshift, tilt of yoke or telescopic arm.

- Page 26 US SL 380 MIDI 03-2016 3. Stop-Down at Drive Section If - no response at activation on regulating lever (no click sound) Check whether the main switch is on – to be turned clockwise to switch on. Has the red On/Off switch on...

-

Page 27: Information And Manual Charger

US SL 380 MIDI 03-2016 Battery Charger Victron Energy - Blue Power Charger IP65 For complete manual refer to: https://www.victronenergy.com/upload/documents/Datasheet-Blue-Power-Battery-Charger-IP65- 90-135VAC-EN.pdf LED indication Description Yellow LED on: battery being charged. Yellow LED on and green LED on: absorption charge. Green LED on:... -

Page 28: Wiring Diagrams

US SL 380 MIDI 03-2016 WIRING DIAGRAMS © 2006 Copyright. www.smartlift.dk... - Page 29 US SL 380 MIDI 03-2016 © 2006 Copyright. www.smartlift.dk...

- Page 30 US SL 380 MIDI 03-2016 © 2006 Copyright. www.smartlift.dk...

Need help?

Do you have a question about the SL 380 MIDI and is the answer not in the manual?

Questions and answers