Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for LumaSense technologies MCS640

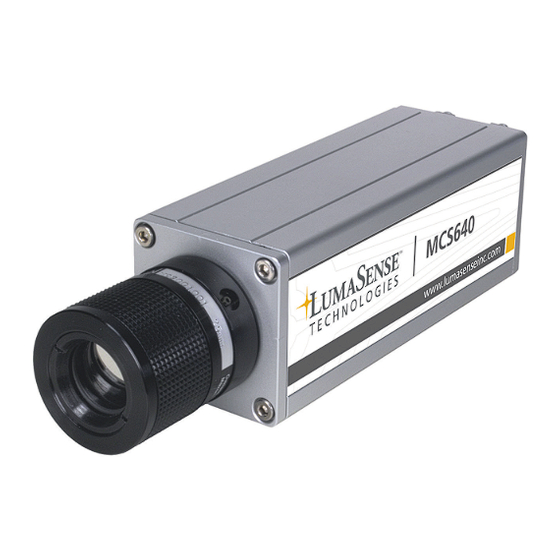

- Page 1 MCS640 Thermal Imager...

- Page 2 LumaSense Technologies prohibits the duplication of any portion of this manual or the use thereof for any purpose other than the operation or maintenance of the equipment described in this manual, without the express written permission of LumaSense Technologies.

-

Page 3: Table Of Contents

Configure the Windows Operating System................25 3.2.4 Acquire Images ........................27 Principle of Thermal Imaging ......................... 29 Infrared Radiation ........................29 Emissivity ............................. 29 Blackbody Radiation ........................30 Blackbody Type Source and Emissivity ..................32 Contents • iii MCS640 Thermal Imager Manual... - Page 4 Determining Emissivity ......................... 33 Background Noise ........................34 Practical Measurement ........................ 34 Emissivity of Various Materials ....................36 Index................................41 Contents • iv MCS640 Thermal Imager Manual...

-

Page 5: General

Chapter 4 of this manual. Qualified personnel should provide education and training in these subjects. Caution: The MCS640 instrument is a sealed unit. Do not attempt to open the instrument housing as this will void the LumaSense warranty. -

Page 6: Limit Of Liability And Warranty

LumaSense Technologies is not liable for any damages that arise from the use of any examples or processes mentioned in this manual or in case the content of this document should be incomplete or incorrect. -

Page 7: Service Request, Repair, Or Support

Email: eusupport@lumasenseinc.com Shipments to LumaSense for repair All RMA shipments of LumaSense Technologies instruments are to be prepaid and insured by way of United Parcel Service (UPS) or preferred choice. For overseas customers, ship units air-freight, priority one. The instrument must be shipped in the original packing container or its equivalent. LumaSense Technologies is not responsible for freight damage to instruments that are improperly packed. -

Page 8: Disposal / Decommissioning

Disposal / decommissioning Inoperable thermal imagers must be disposed of in compliance with local regulations for electro or electronic material. General • 8 MCS640 Thermal Imager Manual... -

Page 9: Introduction

Gigabit Ethernet and provides an option for remote monitoring through a Local Area Network. As such, the MCS640 thermal imaging system can be used as a machine vision system, operator- based temperature monitoring system, fully automatic temperature control system, or stand-alone smart sensor for alarm temperature control. -

Page 10: System Configuration

2 m Ethernet cable, 2 m power supply cable, power supply unit (100 to 240 VAC, 47 to 63 Hz), mounting adapter, lens cap, carrying case, quick start guide, and LumaSpec R/T Viewer software. Introduction • 10 MCS640 Thermal Imager Manual... -

Page 11: Technical Data

2.19 in x 2.46 in x 6.5 in (55.6 mm x 62.5 mm x 165.1 mm) CE-label According to EU directives about electromagnetic immunity Interface Analog: None Digital: Gigabit Ethernet (1000 MBit/s) Optics: Manual focus Connections: 12 pin power connector; RJ45 Ethernet connector Introduction • 11 MCS640 Thermal Imager Manual... -

Page 12: Dimensions

Optics A wide range of alternative lenses are available for the MCS640, making the thermal imager suitable for most applications. The table and picture below show the correlation between the measurement distance, different optics, and the size of the measurement fields. -

Page 13: Camera Interface

Note: The size of the measured object must be at least 3 x 3 pixels to guarantee precise temperature determination. This ensures that at least one pixel of the detector is completely covered. Camera Interface The rear panel of the MCS640 supports connectors for the Gigabit Ethernet and DC Power input. Gigabit Ethernet Connector DC Power Entry... -

Page 14: Lenses

Lenses The MCS640 is a process camera that has a full array of optional lenses available to meet the needs of most applications. However, because of the extreme and application-specific nature of the camera system, it is necessary that the appropriate lens be fitted and calibrated at the LumaSense Factory according to the application requirements. -

Page 15: Getting Started

In addition, the MCS640 camera is a Gigabit Ethernet camera. In order to ensure all frames are transferred and reconstructed successfully, the following hardware needs to be used at minimum: •... -

Page 16: Connecting The Camera To A Dedicated Computer

1. Connect one end of the RJ45 (Ethernet) Cross-over cable to the Ethernet port on the camera and the other end to the computer. The MCS640 requires a Gigabit Ethernet network adapter (see the software manual for a list of supported adapters). All cabling should be Cat5e or Cat 6. -

Page 17: Installing The Software

4. Turn on the computer. 5. Consult Section 3.2 Installing the Software. Note: The MCS640 requires a Gigabit Ethernet network adapter. The appropriate PCI/Gigabit Ethernet card (Express Card, PCI, or PCI Express Card) is selected at the time of ordering and supplied with the camera. -

Page 18: Optimize The Network Interface Card

Note: Your instructions may vary slightly based upon which version of Windows you are using. These instructions were written using Windows 7. To optimize the network interface card: 1. Access the network interface card by clicking Start, right clicking on Computer, and then select Properties. Getting Started • 18 MCS640 Thermal Imager Manual... - Page 19 3. Click the arrow next to Network adapters to expand the list and access the network interface card. Note: Some computers may list more than one network interface card. Mark sure you select the network interface card on which the camera is connected. Getting Started • 19 MCS640 Thermal Imager Manual...

- Page 20 5. In the Link Speed tab, use the drop down box under Speed and Duplex to select 1.0 Gbps/full duplex. If the camera is already connected and powered up, the Link Status LED will be green, as shown below. Getting Started • 20 MCS640 Thermal Imager Manual...

- Page 21 Note: Not all network adapters have this feature. 8. Click OK to save these settings. Note: Since there are different types of Ethernet controllers, the tabs on the Ethernet controller properties window may be different. Another example follows. Getting Started • 21 MCS640 Thermal Imager Manual...

- Page 22 2. Click the Advanced tab and select Speed & Duplex from the Property box on the left. Select 1.0 Gbps Full Duplex (preferred) or Auto-Negotiation. 3. Select Jumbo Packets from the Property box on the left. Select 9014 Bytes. 4. Click OK to save these settings. Getting Started • 22 MCS640 Thermal Imager Manual...

-

Page 23: Set The Ip Address

Windows 7. 1. Access Network and Internet Settings by clicking Start, selecting Control Panel, and selecting Network and Internet. 2. Click on Network and Sharing Center. 3. Click Change adapter settings. Getting Started • 23 MCS640 Thermal Imager Manual... - Page 24 5. Click Internet Protocol Version 4 (TCP/IP) and click Properties. Next, select Use the following IP address radio button and enter an IP address. The IP address could be any number in the form of 192.168.1.127 and subnet mask 255.255.255.0. Click OK. Getting Started • 24 MCS640 Thermal Imager Manual...

-

Page 25: Configure The Windows Operating System

1. Click Start > Control Panel > Systems and Security > Windows Firewall. 2. Click Allow a program or feature through Windows Firewall. 3. If LumaSpec R/T is not in the list, click Allow another program… Getting Started • 25 MCS640 Thermal Imager Manual... - Page 26 C: \ Program Files (x86) \ LumaSense \ LumaSpec RT \ Mikron \ LumaSpec RT Select the file and click Open. 5. LumaSpec RT software should now appear in Allowed Programs and Features. Ensure the relevant networks are checked. Getting Started • 26 MCS640 Thermal Imager Manual...

-

Page 27: Acquire Images

3. Click OK. 4. The software will initialize and display the streaming camera video. Refer to the software manual for additional controls or to learn more about the LumaSpec R/T software. Getting Started • 27 MCS640 Thermal Imager Manual... - Page 28 To ensure consistent document formatting, this page was intentionally left blank. Getting Started • 28 MCS640 Thermal Imager Manual...

-

Page 29: Principle Of Thermal Imaging

When the temperature of the material equals that of its surroundings, the amount of thermal radiation absorbed by the object equals the amount emitted by the object. Principle of Thermal Imaging • 29 MCS640 Thermal Imager Manual... -

Page 30: Blackbody Radiation

It does not reflect or transmit any IR energy. Perfect blackbody surfaces do not exist in nature. Where, = total radiant energy emitted by a body at a given temperature T. = total radiant energy emitted by a blackbody at the same temperature T. Principle of Thermal Imaging • 30 MCS640 Thermal Imager Manual... - Page 31 In radiation of a normal object, as the emissivity is (<1) times of the blackbody, multiply above equation by the emissivity. The following figures show the spectral radiant emittance of a blackbody. (a) is shown by logarithmic scale and (b) is shown by linear scale. Principle of Thermal Imaging • 31 MCS640 Thermal Imager Manual...

-

Page 32: Blackbody Type Source And Emissivity

L, if L/r is equal or more than 6, it is used as a blackbody-type source for practical use. The following figure shows an example of a blackbody-type source based on blackbody conditions. Principle of Thermal Imaging • 32 MCS640 Thermal Imager Manual... -

Page 33: Determining Emissivity

An object, resembling a blackbody, is attached to a heat source to make the temperature of the blackbody part and the measuring object the same. The ratio of infrared radiation energies are then determined as in #2 above. Principle of Thermal Imaging • 33 MCS640 Thermal Imager Manual... -

Page 34: Background Noise

There are a number of methods for correcting emissivity in order to obtain the true temperature. The correction procedure with each method will be explained next. Note: If you already know the emissivity, you can make thermal imaging measurements immediately. Principle of Thermal Imaging • 34 MCS640 Thermal Imager Manual... - Page 35 But one must be careful about the number of reflections and/or the measuring angle. A small change in angle will reduce the emissivity enhancement. Measuring by Wedge effect Principle of Thermal Imaging • 35 MCS640 Thermal Imager Manual...

-

Page 36: Emissivity Of Various Materials

Emissivity of Various Materials From “Infrared Radiation, a Handbook for Applications” by Mikael A. Bramson Principle of Thermal Imaging • 36 MCS640 Thermal Imager Manual... - Page 37 Principle of Thermal Imaging • 37 MCS640 Thermal Imager Manual...

- Page 38 Principle of Thermal Imaging • 38 MCS640 Thermal Imager Manual...

- Page 39 Principle of Thermal Imaging • 39 MCS640 Thermal Imager Manual...

- Page 40 To ensure consistent document formatting, this page was intentionally left blank. Principle of Thermal Imaging • 40 MCS640 Thermal Imager Manual...

-

Page 41: Index

Environmental Conditions 14 Software 17 Ethernet Cable 15 Storage 7 Support 7 System Overview 9 Infrared Radiation 29 Interface 13 Transport, packaging, storage 7 Legend 5 Lenses 14 Unpacking 6 Network Device 16 Warranty 6 Index • 41 MCS640 Thermal Imager Manual...

Need help?

Do you have a question about the MCS640 and is the answer not in the manual?

Questions and answers