Summary of Contents for Buderus Logano GB125

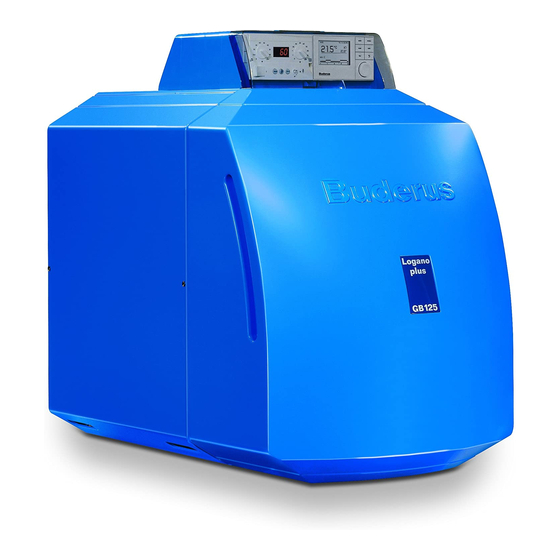

- Page 1 Installation and Oil condensing boilers maintenance instructions Logano GB125 with For contractors Logatop BE burner Read carefully prior to installation and maintenance.

-

Page 2: Table Of Contents

........23 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 3 ........48 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 4 ........... . 64 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 5: Safety

USER INFORMATION User tips for the optimum utilisation and adjustment of the appliance plus other useful information. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 6: Installation Tips

RISK TO LIFE through toxic flue gases. B Only operate these boilers with a chim- ney or flue system that provides the re- quired draught during operation. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 7: Product Description

The insulation prevents energy Oil burner losses. Burner cover Heat exchanger system Fig. 2 Back view Logano GB125 (shown excluding thermal insulation) Heat exchanger system Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 8: Specification

Example: Safety limit (STB) = 100 °C, maximum possible flow temperature = 100 – 18 = 82 °C The safety limit must meet the relevant national regulations. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 9 Carry out maintenance and cleaning procedures annually. For this, check the entire system is functioning per- fectly. Immediately rectify any faults discovered. Tab. 5 Country-specific fuels and comments Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 10: Declaration Of Conformity

Tab. 6 General operating conditions A control unit for heating circuits with mixers improves control characteristics and is particularly recommended for systems with multiple heating circuits. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 11: Installation Room And Environmental Conditions

50 kW no more than 2 vents) Tab. 8 Observe country-specific requirements for open flue operation. For balanced flue operation Chapter 3.8, page 15 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 12: Fuel Conditions

Only use drinking water to fill and top up the boiler. We recommend a pH value of 8.2 – 9.5 (observe VDI 2035). Tab. 11 Hydraulics and water quality Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 13: Balanced Flue Operation

Tab. 13 Design details for OC For the technical details regarding the sizing of the ba- lanced flue system for OC , see the adjacent Tab. 13. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 14: Open Flue Operation

Badly designed terminal openings can lead to unsafe combustion and burner faults. Fig. 6 Samples of terminal designs (dim. in mm) Flue gas Ventilation air Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 15: Installation Options

Tab. 16, page 17. tical via roof. Terminals close beside each other in the same pressure area. Tab. 15 Installation options Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 16 – Flue gas connecting piece according to Chapter 3.9. – Ventilation air pipe according to Chapter 3.10, page 18. Tab. 15 Installation options Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 17: Flue Gas Systems

Should different details apply to your chosen system, provide a function verification for your balanced flue sys- tem in accordance with the country-specific standards and directives. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 18: Ventilation Air Systems

If the ventilation air is drawn in via the roof, the silencer may be dispensed with. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 19: Standard Delivery

Component Packaging Concentric flue outlet 1 x foil packaging Tab. 20 Additional parts of the standard delivery Buderus supplies the boiler support as an accessory. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 20: Transporting The Boiler

B Remove mains plug, communication and sensor ca- ble from SAFe. In balanced flue operation, detach combustion air hose as well ( burner documentati- on). Fig. 7 Removing the burner cover Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 21: Lifting And Handling The Boiler

Fig. 10 Transporting the boiler with a boiler trolley Chapter 6.3, page 24). You can order the boiler trolley from one of our sales offices. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 22: Positioning The Boiler

DHW cylinder, pipe con- nections, flue gas silencer or other components on the flue side. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 23: Reversing The Burner Door

6304 3726-04.1K Fig. 13 Reversing the burner door (on the door side) Hinge lobe hexagon bolts Hinge lobes Burner door Hinge pins Hot gas baffle plates Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 24: Fitting Adjustable Feet Or A Boiler Plinth

B Turn the adjustable feet 5 - 10 mm into the second elements of the boiler support. Fig. 15 Fitting adjustable feet to plinth (height 140 mm) Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 25: Positioning And Levelling The Boiler

B Move the boiler into its final location. Level the boiler horizontally by turning the adjustable feet using a spirit level. Fig. 17 Levelling the boiler horizontally Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 26: Installing The Boiler

B Make the flue connection in accordance with the re- quirements applicable in your country. Please refer Chapter 3.4, page 13 for balanced flue operati- Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 27: Fit The Concentric Balanced Flue Outlet For Balanced Flue Operation (Accessory)

3˚ 7 747 011 453-18.1RS Fig. 19 Flue gas pipe Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 28: Making The Ventilation Air Connection For Balanced Flue Operation

Fig. 20 Ventilation air and flue system (example for installation type OC Wall bezel Plastic plug-in system DN60 Silencers Air hose Santo SL DN 63 Test port Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 29: Condensate Drain

In accordance with the ATV Code of Practice A251, neutralising is not required Siphon for low-sulphur fuel oil EL (sulphur content < 50 ppm) up to 200 kW boiler output. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 30: Fitting The Condensate Drain Set

Fig. 23 Fitting the return connector Flat gasket Locking cap RK/RS: Return connection G 1¼ RK: Boiler return G 1¼ RS: DHW cylinder return G 1 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 31: Connecting The Heating Flow And Return

B Never connect a summer line, DHW cy- linder or another heating circuit to the VSL. Fig. 26 Connecting the air vent valve to the safety flow (dimensions in mm) Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 32: Connecting The Air Vent Valve Set To The Heat Exchanger

B Seal in air vent valve set (3) in place of the original air vent valve. Fig. 27 Connecting the air vent valve set Heat exchanger connection Air vent valve Air vent valve set Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 33: Connecting The Dhw Cylinder

BDF valve with reducer (optional accessory); alternative BDF valve ½ B Fit the boiler drain & fill valve together with gasket to O-ring connection EL. Reducer 1x½ Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 34: Filling The Heating System And Checking For Leaks

B Open the mixing and shut-off valves on the heating water side. B Slowly fill the heating system via the on-site fill valve. During filling, observe the pressure gauge. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 35 B Reopen the cap valve. Fig. 31 Venting the heat exchanger Air vent valve (5 mm quadrant) on the heat exchanger (condensing heat exchanger) Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 36: Making The Electrical Connection

B Push cable clamp down (step 2). B Push against the clamp (step 3). B Flip the toggle up (step 4). Fig. 33 Securing cables with cable clamps Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 37 B Fasten rear boiler cover with two screws. B Place end cover on rear boiler cover and fasten with two screws. Fig. 34 Fitting covers Controller cover End cover Rear boiler cover Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 38: Commissioning The Heating System

B Top up the heating water or drain via the boiler drain & fill valve until the required operating pressure has Green band been reached. B Vent the heating system while filling. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 39: Checking The Location Of The Hot Gas Baffle Plates

B Turn on the fuel supply at the main shut-off valve. B Switch on the heating system emergency stop switch (if installed) and/or insert/set the corresponding do- mestic fuse/circuit breaker. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 40: Switching On The Heating System

For this, read the relevant chapters in the installation and service instructions of the RC30 or RC35 carefully. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 41: Starting The Burner

B Set both rotary selectors on the control unit to "AUT" (automatic mode). The programming unit takes con- trol of the panel in this setting. Fig. 40 Setting the control unit Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 42: Commissioning Report

Confirm professional commissioning Company stamp/signature/date USER INFORMATION B Inform your customer of the correct fuel and enter it in the table ( boiler ope- rating instructions). Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 43: Operating The Logamatic Bc10 Base Controller

10 "Status display" key Rotary selector for maximum boiler water temperature in heating mode 11 "Flue gas test" key "DHW demand" LED 12 "Reset" key Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 44: Switching On And Off

The LED underneath the rotary selector illuminates if the heating system has been switched on and there is a heat demand. Central heating is switched off in summer mode (LED off). Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 45: Set Dhw Temperature

In case of faults, the status display immediately indicates the relevant fault or a warning. Locking faults cause the status display to flash. Press the "status display" key to change between the various status displays. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 46 B Check the communications cable. Tab. 24 Possible status displays Standard display for this operating state. This display is shown after 5 minutes if no keys are pressed. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 47: Resetting The Service Interval

Press the "Reset" button to reset faults. The display shows "rE" whilst the reset is being implemented. The reset is only possible, if there is no active fault. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 48: Burner On" Led

B After switching on, reactivate manual mode so that the heating system remains operational (especially if there is a risk of frost). Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 49: Adjusting Parameters

"C". At setting 0, even frost protection is deactivated. Input range DHW C 0 (no DHW) 1 (DHW) Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 50: Shutting Down The Heating System

B Turn off the fuel supply at the main shut-off valve. B Isolate the heating system from the power supply via the heating system emergency stop switch or the ap- propriate domestic fuse/MCB. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 51: Heating System Inspection And Maintenance

If the burner door is modified to l.h. closing, you must remove the communication and sensor cable as well as the mains supply plug from the SAFe. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 52: Cleaning The Boiler

B Reposition the hot gas baffle plates in their original location. Fig. 45 Brushing out the combustion chamber Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 53: 2Wet Cleaning (Chemical Cleaning)

B Heat up the boiler to a boiler water temperature of at least 70 °C. B Shut down the heating system. B Allow boiler to cool; open burner door. B Brush out the hot gas flues. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 54: Cleaning The Heat Exchanger

B Remove the cleaning cover and gasket from the heat exchanger system. Fig. 47 Sweeping the heat exchanger system Quick-acting closures Cleaning cover Thermal insulation Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 55 Prevent damage to the flue gas sensor du- ring cleaning. Additional wet cleaning is possible. Proceed in the same order as described for cleaning with the brush. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 56: Cleaning The Neutralising System And Siphon

B Undo the condensate hoses on the siphon. B Remove deposits from the siphon and refill with wa- ter. B Refit the condensate hoses. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 57: Checking The Heating System Operating Pressure

11.8 Ventilation air system B If CO or CO values are excessively high, check the ventilation air system for blockages. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 58: Inspection And Maintenance Reports

11. Final check of inspection work including recording readings taken and test results Confirm professional inspection Company Company Company stamp/ stamp/ stamp/ signature signature signature Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 59 Date:______ Date:______ Date:______ Date:______ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ signature signature signature signature signature signature signature Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 60 8. Final check of the maintenance work 9. Check the function and operational safety Confirm professional maintenance Company Company Company stamp/ stamp/ stamp/ signature signature signature Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 61 Date:______ Date:______ Date:______ Date:______ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ Company stamp/ signature signature signature signature signature signature signature Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

-

Page 62: Troubleshooting

B If this is not possible, protect your hea- ting system against freezing by drai- ning the central heating and DHW pipework at the lowest possible point. B Drain the heat exchanger. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 63: Sensor Curves

Resistance (kΩ) Temperature (°C) USER INFORMATION Two similar, so-called double sensors, are used as boiler flow sensors. These are in- stalled in a sensor well. Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. -

Page 64: Index

Operating Conditions ....10 Operating pressure, permissible ..9 Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice. - Page 65 Notes Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 66 Notes Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 67 Notes Logano GB125 oil condensing boiler - Technical specifications are subject to change without prior notice.

- Page 68 Middle East and Caucasian Area Bosch Termoteknik Dýþ Ticaret A.Þ. Ýstanbul Deri ve Endüstri Serbest Bölgesi T-10 Parsel 34975 Tuzla Ýstanbul / Turkey Tel.: +90 216 581 03 00 Products manufactured by Bosch Thermotechnik GmbH Sophienstrasse 30-32 D-35576 Wetzlar www.buderus.com...

Need help?

Do you have a question about the Logano GB125 and is the answer not in the manual?

Questions and answers