Subscribe to Our Youtube Channel

Summary of Contents for IMP PUMPS NMT Max C

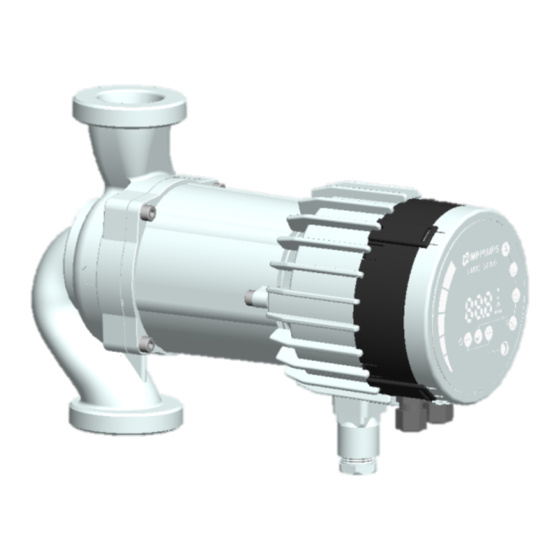

- Page 1 NMTC module Installation and operating manual for • NMT Smart C, • NMT Max C, • NMT Lan C. 7340055, v22...

-

Page 2: Table Of Contents

CONTENTS Symbols and conventions used in this Ethernet ............24 document .............. 4 6.1. Bus topology .......... 25 1.1. Abbreviations and conventions ....4 6.2. Connecting to pump ad-hoc ....25 Introduction ..........4 6.3. Connecting to pump via router ..... 25 2.1. -

Page 3: Symbols And Conventions Used In This Document

2. INTRODUCTION This manual describes the NMTC module for NMT range of pumps that is either integrated (NMT LAN C) or separately (NMT Smart C and NMT MAX C) available. This module is used for various remote control applications, including: •... -

Page 4: System Diagram

2.1. SYSTEM DIAGRAM There are several possible connection configurations. Not all functions can be used simultaneously. on/off + 0..10 V + relay output Modbus RTU + Relay output Ethernet + on/off + 0..10 V Modbus RTU + Ethernet … Ethernet + on/off + relay output 2.2. - Page 5 Modbus specifications Data protocol Modbus RTU Modbus connector Screwless terminals 2+1 pins. See section 7.3 “Connection to Modbus”. Modbus connection RS-485 type Modbus wire Two-wire + common Conductors: A, B and COM (Common). configuration See section 7.3 “Connection to Modbus”. Communication Integrated, 1/8 of Connect either via passive taps or daisy chain.

-

Page 6: Module Layout

Analog signals (SET1, SET2, SET3) Input voltage range -1..32 VDC When used as input. Output voltage range 0..12 V When used as output. 5 mA max. Load allowed per output. Input resistance ~100 kΩ 0.5 mA load is added for most configurations. Output current sink 0..33 mA (4-20 mA) Current sink to COM if configured as output. -

Page 7: Connection Considerations

3.1. CONNECTION CONSIDERATIONS All cables connected must be heat-resistant to at least +85 °C. • All cables connected must be installed in accordance with EN 60204-1. • • All wires to the communications module must be connected to the terminals or cut. No loose wiring permitted. -

Page 8: Module Installation

3.2. MODULE INSTALLATION Only for NMT Smart and NMT MAX pump models. Installing the module WARNING! Before performing any work on the module, make sure that the pump and module electricity supply has been switched off and that it cannot be accidently switched on. - Page 9 Make sure that the position tab and position slot are aligned. Push the NMTC module back to the heat sink...

-

Page 10: Connecting The Module Wiring

3.3. CONNECTING THE MODULE WIRING Opening the cover WARNING! Before performing any work on the module, make sure that the pump and module electricity supply has been switched off and that it cannot be accidently switched on. Press two top hooks on the display panel (Use flat tip screwdriver if needed) and simultaneously pull display panel away from the pump. - Page 11 Closing the cover WARNING! Before performing any work on the module, make sure that the pump and module electricity supply has been switched off and that it cannot be accidently switched Reconnect display panel cable. Make sure that the position tab and position slot are aligned.

-

Page 12: Connection Examples

3.4. CONNECTION EXAMPLES Default (factory) configuration ETHERNET MODE LED2 LED1 LED1 / LINK ETHERNET LED2 / ACT B/D - A/D + RELAY ANALOG SET1 / RUN MODE COM / 0V RS 485 SET2 / MAX SET3/ FB Relay and Modbus connection ETHERNET LED2 LED1 RELAY... - Page 13 Relay and Ethernet connection ETHERNET LED2 LED1 MODE LED1 / LINK ETHERNET RELAY ANALOG LED2 / ACT MODE B/D - RS 485 A/D + SET1 / RUN COM / 0V SET2 / MAX SET3/ FB NOTE: To maintain pump IP protection, the network cable should be pulled through the gland inlet and then crimped to a connector.

-

Page 14: Control Modes And Priorities

4. CONTROL MODES AND PRIORITIES 4.1. PRIORITY OF SETTINGS Several signals will influence the pump operation. For this reason, settings have priorities as shown in the table below. If two or more functions are active at the same time, the one with highest priority will take precedence. Pump control panel &... -

Page 15: Module Mode Selection

4.3. MODULE MODE SELECTION WARNING! Before performing any work on the module, make sure that the pump and module electricity supply has been switched off and that it cannot be accidently switched on. There is a mode selection rotary switch in the terminal box. It can be rotated by gently inserting a screwdriver into the arrow mark on top and rotating the switch to desired value. -

Page 16: Mode 1

4.4. MODE 1 Mode 1 is most often used mode of operation. It has 2 pre-prepared inputs that can be used for either digital control or with analog control voltages. Additional 10.5V output provides voltage feedback for analog or digital control. - Page 17 Contact position Function Description Stop the pump The pump is stopped The pump will run with internal set point Start the pump The pump will run with minimal speed for selected regulation mode Minimum curve The pump will run with maximum speed form selected regulation mode Maximum curve...

-

Page 18: Analog Control

ANALOG CONTROL Mode 1 connection configurations (analog) MODE MODE LED1 / LINK LED1 / LINK ETHERNET ETHERNET 0…10 V LED2 / ACT LED2 / ACT B/D - B/D - A/D + A/D + SET1 / RUN SET1 / RUN COM / 0V COM / 0V SET2 / MAX SET2 / MAX... - Page 19 ETHERNET ETHERNET LED2 LED1 LED2 LED1 RELAY RELAY MODE MODE RS 485 RS 485 0…10 V ETHERNET ETHERNET LED2 LED1 LED2 LED1 RELAY RELAY MODE MODE RS 485 RS 485 0…10 V...

- Page 20 Function voltage voltage < 2 V < 1 V Pump stopped > 3 V < 1 V Internal regulation < 2 V 2..10 V Minimum curve > 3 V 2..10 V H [m] / n[RPM] H/ n = 15% H = 25% n U[V] Figure 1: External 2..10 V transfer curve for Mode 1...

-

Page 21: Mode 2

4.5. MODE 2 Mode 2 is used for external 0..10 V voltage control. Terminal Signal function designation SET1 / RUN RUN input. Signal load 0.5 mA. COM / 0V Common ground for voltage input. SET2 / MAX SPEED input. Signal load 0.5 mA SET3 / FB 10.5 V feedback voltage for SET1 and SET2. -

Page 22: Relay Output

Function voltage voltage < 2 V 0..10 V Pump stopped. > 3 V 0..10 V H [m] / n[RPM] = 15% H = 25% n U[V] Figure 3: External 0..10 V transfer curve for Mode 2 5. RELAY OUTPUT Terminal Terminal description designation MODE... -

Page 23: Ethernet

Relay Output Relay LED status Description configuration status position LED 1 LED 2 Error Only active when the pump is powered up [default] and detects a problem with operation. Ready The relay signal is active when the pump is ready for operation. Operation The relay signal is active as long as the pump is operating. -

Page 24: Bus Topology

6.1. BUS TOPOLOGY Ethernet connection topologies Figure 5: connecting to a network via router Figure 4: connecting to a computer with a cross-over cable 6.2. CONNECTING TO PUMP AD-HOC When connecting directly with the computer, a cross-cable must be used to connect with the pump. The pump can then be accessed by typing IP address “192.168.0.245”... - Page 25 2. Pump settings (web page PUMP) is meant to provide regulation and control (input and output) settings. It has control over: Operation mode • • Head limit(depending on pump mode) • RPM limit (depending on pump mode), Ratio between head and flow HQ (depending on pump mode) •...

-

Page 26: Modbus

7. MODBUS 7.1. MODBUS RELATED INTERFACE Designation Description MODE Can be used to reset network configuration LED2 / ACT Indicates Ethernet activity or Modbus reception. B/D- RS-485 negative data signal for Modbus. A/D+ RS-485 positive data signal for Modbus. COM/0V RS-485 common and analog input common (ground). -

Page 27: Register Block Overview

For short wiring and/or low baud rate, interface can operate without termination. However it is recommended that termination (~150 ohm resistor) is added on both ends of bus wiring. There are wiring length limits regarding to speed and termination: Maximum speed [baud] Maximum cable length [m] 38400 1200, terminated cable... -

Page 28: Nmtc Status Register Block

Address Register name Range Resolution Description SlaveDelay 0..10000 1 ms Delay in milliseconds for slave reply. This delay will be added to every Modbus reply [default = 0]. RESERVED ModbusAddress 1..247 Modbus address [default = 245]. BitRate 0..5 Modbus transmission speed enumeration. 0 = 1200 baud 1 = 2400 baud 2 = 4800 baud... -

Page 29: Pump Control Register Block

7.9. PUMP CONTROL REGISTER BLOCK Registers in this block are read with either function codes 0x03 or 0x04. They can be written as holding registers with function codes 0x06 and 0x10. Address Register name Range Description ControlReg Control bit that sets local or remote control. RemoteAccess Setting this bit will enable pump control over Modbus. -

Page 30: Pump Status Register Block

7.10. PUMP STATUS REGISTER BLOCK Registers in this block can be read by means of function codes 0x03 and/or 0x04. They are read-only. Address Register name Description StatusReg b0..b5: RESERVED b6: Rotation Indicates if the pump is rotating (running) or not. 0 = No rotation 1 = Rotation. -

Page 31: Pump Data Register Block

ErrorCode2 Second error code. Non-zero when there is more than one error. See section “8.1 Error codes” for code details. ErrorCode3 Third error code. Non-zero when there is more than two errors. See section “8.1 Error codes” for code details. ControlMode Indicates the actual control mode. -

Page 32: Fault Finding

8. FAULT FINDING 8.1. ERROR CODES The following codes will show up on display panel and on the appropriate Modbus registers to help you diagnose the cause of improper operation. Error code Description Probable cause Load errors E10 (drY) Low motor load Low load detected.

Need help?

Do you have a question about the NMT Max C and is the answer not in the manual?

Questions and answers