Table of Contents

Advertisement

Questo manuale è da conservare per futuri riferimenti e dovrà sempre seguire la macchina

This manual is to be kept for future reference and must always accompany the machine.

Ce manuel doit être conservé pour de futures références et devra toujours suivre la machine.

Das Handbuch ist für künftigen Gebrauch aufzubewahren und muß stets die Maschine begleiten.

Este manual tiene que conservarse para futuras referencias y tiene que estar junto con la máquina.

0000571057C 1-1

OPERATION AND MAINTENANCE

FONCTIONNEMENT ET ENTRETIEN

BETRIEBS- UND WARTUNGSANLEITUNG

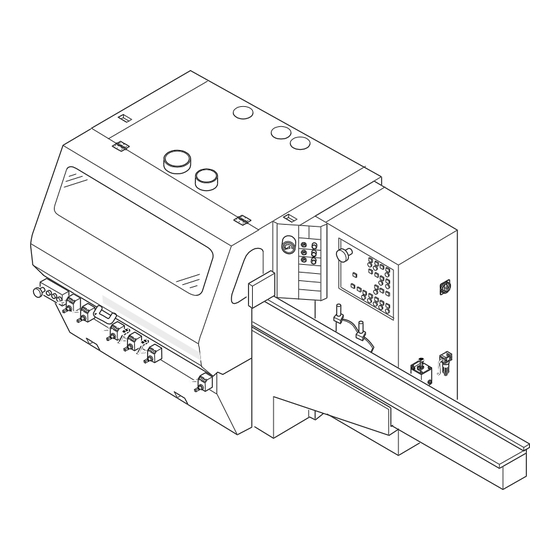

SUPERSET XL

AUTOMATIC PLANING AND MOLDING MACHINE

USO E MANUTENZIONE

USO Y MANTENIMIENTO

SCORNICIATRICE A

SCORNICIA

SCORNICIA

SCORNICIA

SCORNICIA

TRICE A

TRICE A

TRICE A

TRICE AUT

MOULURIERE A

MOULURIERE AUT

MOULURIERE A

MOULURIERE A

MOULURIERE A

PR

PROFILFRÄSA

PR

OFILFRÄSA

OFILFRÄSAUT

OFILFRÄSA

PR

PR

OFILFRÄSA

MOLDURERA A

MOLDURERA A

MOLDURERA A

MOLDURERA A

MOLDURERA AUT

(USA)

(USA)

(USA)

(USA)

(USA)

UTOMA

UT

UT

UT

OMA

OMA

OMA

OMATICA

TICA

TICA

TICA

TICA

UTOMA

UT

UT

OMA

OMATIQ

OMA

TIQ

TIQUE

TIQ

UE

UE

UE

UT

OMA

TIQ

UE

UTOMA

UT

UT

OMA

OMA

OMAT T T T T

UT

OMA

UT

UT

OMA

OMA

TICA

TICA

UT

UTOMA

OMA

OMATICA

TICA

TICA

Advertisement

Chapters

Table of Contents

Summary of Contents for SCMI SUPERSET XL

- Page 1 Este manual tiene que conservarse para futuras referencias y tiene que estar junto con la máquina. USO E MANUTENZIONE OPERATION AND MAINTENANCE FONCTIONNEMENT ET ENTRETIEN BETRIEBS- UND WARTUNGSANLEITUNG USO Y MANTENIMIENTO (USA) (USA) (USA) (USA) (USA) SUPERSET XL SCORNICIA SCORNICIA SCORNICIA SCORNICIA SCORNICIATRICE A TRICE A TRICE A TRICE A TRICE AUT UTOMA...

-

Page 2: General Information

GENERAL INFORMATION SCMI cannot be held responsible for damages resulting from use not described in this manual or from improper maintenance. Contact your local dealer for any requirements or advice on use. MACHINE OPERATORS Personnel who will be working on the machine must, apart from being professionally trained for the job, read the manuals paying particular attention to the safety regulations and the paragraphs relative to his area of competence. -

Page 3: Table Of Contents

RIGHT VERTICAL SPINDLE ................4.8 4.2.3 LEFT VERTICAL SPINDLE ................. 4.10 4.2.5 TOP HORIZONTAL SPINDLE ................4.12 4.2.6 SECOND BOTTOM HORIZONTAL SPINDLE ........... 4.14 TOP MOBILE UNIT..................4.16 INLET GUIDE AND TABLE ................4.18 UNIVERSAL SPINDLE UNIT................4.20 CNusa1 SUPERSET XL... - Page 4 OPERATING UNIT BELT REPLACEMENT ..........20.8 20-9 VARIATOR TIMING BELT REPLACEMENT .......... 20.10 20-10 INSPECTION OF SAFETY DEVICES ............20.10 20-11 REMOVAL - STORAGE - DEMOLITION ..........20.11 20-12 EMERGENCY CONDITIONS ..............20.11 20-13 TROUBLESHOOTING ................20.12 CNusa1 SUPERSET XL...

-

Page 5: Correspondence

GENERAL INFORMATION 1-1 CORRESPONDENCE When writing or phoning the dealer or SCMI for any reason concerning the machine, always supply the following information: 1) Machine model 2) Serial number 3) Voltage and frquency 4) Date of purchase 5) Name of dealer where the machine was purchased... -

Page 6: Machine Identification

90% Temperature: min. +1°C max. +40°C Altitude: max. 1,000 m above sea level (over this level consult the manufacturer) The machine may only be operated in closed environments. The machine may not be operated in explosive environments. CNusa1 SUPERSET XL... -

Page 7: Concepts Of Use Related To The Operator

The door of the electric box is closed with one or more locks. The key to open the box is provided with the machine. In normal operating and maintenance conditions the door must always be closed. The expert operator is responsible for and custodian of all the keys. CNusa1 SUPERSET XL... -

Page 8: Safety Warnings

The operator must be informed concerning the noise levels which may be generated during normal use of the machine and the factors which affect the exposure to noise. The factors include: correct tool selection; correct speed selection; CNusa1 SUPERSET XL... - Page 9 Before mounting any tool, ensure that the mortising surfaces are well-cleaned and without dents. SAFETY DURING MAINTENANCE Use only original SCMI spare parts. When maintenance operations need to be carried out, stop the machine, set the main electrical and pneumatic switches to zero and padlock them.

-

Page 10: Technical Characteristics

Quick adjustment for inlet guide and table ................. 10 mm Net weight composition 1 ............... 2200 kg Net weight composition 5 ............... 2350 kg Net weight composition 2 ............... 2900 kg Net weight composition 6 ............... 3050 kg CNusa1 SUPERSET XL... - Page 11 - Pump for work table lubrication with manual drive. - Pump for work table lubrication with automatic drive. - Manual centralised lubrication. - Hour counter for hours of service. - Metre counter with reset. - Lighting inside the horizontally-pivoted protection. - Auto-braking motor 1.10 CNusa1 SUPERSET XL...

- Page 12 GENERAL INFORMATION COMPOSITIONS Legend: Bottom horizontal (planer) Top horizontal Right vertical Left vertical Universal unit Composition 1 Composition 2 Composition 5 Composition 6 1.11 CNusa1 SUPERSET XL...

-

Page 13: Noise Level

GENERAL INFORMATION 1-8 NOISE LEVEL Planing and profiling machine model: SUPERSET XL As per test report: CSR No. 99033 Operating conditions: Planing Reference norm: ISO 3746/79 Other reference regulations: ISO 7960/95 Annex H UNI EN ISO 11201-97 In idle without suction... -

Page 14: Overall Dimensions

GENERAL INFORMATION 1-9 OVERALL DIMENSIONS COMPOSITIONS 1 AND 5 (*) + 500 mm with optional 2500 mm inlet table COMPOSITIONS 2 AND 6 (*) + 500 mm with optional 2500 mm inlet table 1.13 CNusa1 SUPERSET XL... -

Page 15: 1-10Work Areas And Stationing

NOTE: The distance * must be 800 mm longer than the longest piece to be machined CAUTION: Failing to respect the minimum free spaces may create dangerous conditions for the operator and the personnel around the machine. Do not deposit goods of any kind within the zone limits. 1.14 CNusa1 SUPERSET XL... - Page 16 INSTALLATION SECTION 2 INSTALLATION MACHINE UNLOADING ....................... 2.2 POSITIONING ..........................2.2 LEVELLING ............................. 2.2 ELECTRICAL CONNECTION AND EARTHING ................2.4 CONNECTION TO SUCTION SYSTEM ..................2.6 PNEUMATIC CONNECTION ......................2.8 SAFETY DEVICES USED ......................2.10 cnusa2 SUPERSET XL...

-

Page 17: Machine Unloading

For transversal levelling place the level near the first spindle and move it by successive sections of 300 mm. The inlet table must be perfectly aligned with the fixed table of the machine. Misalignment in both directions between the two tables must not exceed 0.1 mm. cnusa2 SUPERSET XL... - Page 18 INSTALLATION cnusa2 SUPERSET XL...

-

Page 19: Electrical Connection And Earthing

It may only be opened by a specialised electrician using the special key provided with the machine and kept by the expert operator. The complete wiring diagrams and certificates may be found in the accessory bag. cnusa2 SUPERSET XL... - Page 20 INSTALLATION L2 L3 Ref. cnusa2 SUPERSET XL...

-

Page 21: Connection To Suction System

Efficient suction considerably reduces danger deriving from exposure to dust. Other factors which reduce the emission of dust are: Maintenance of the tools, the machine and the suction system Right relation between cutting speed and feed speed Proper adjustment of the hoods / screens / switches Proper use of dust protectors cnusa2 SUPERSET XL... - Page 22 INSTALLATION cnusa2 SUPERSET XL...

-

Page 23: Pneumatic Connection

(B Fig.2.4b) which in closed position allows releasing the air from the system. 2) Connect one of the two devices mentioned above to the tube coming from the main system and then connect the tube coming from one of the devices to the herringbone coupling (E Fig.2.4). cnusa2 SUPERSET XL... - Page 24 INSTALLATION 2.4a cnusa2 SUPERSET XL...

-

Page 25: Safety Devices Used

12) The safety devices used on the control panel are described in Chapter 3. Periodic checking of the functioning of the above mentioned devices is the task of the production and expert operator. Any faults must timely be reported to the person in charge. 2.10 cnusa2 SUPERSET XL... - Page 26 INSTALLATION CAUTION CAUTION CAUTION 2.11 cnusa2 SUPERSET XL...

- Page 27 Tool diameter of bottom horizontal unit Tool diameter of right vertical unit Tool diameter of left vertical unit Axial translation of right vertical unit Axial translation of left vertical unit Axial translation of bottom horizontal unit 2.12 cnusa2 SUPERSET XL...

- Page 28 (C)- Rotation direction and max. and min. diameter of tool mountable on left vertical spindle and bottom horizontal spindle and number of spindle revolutions. (D)- Rotation direction and max. and min. diameter of tool mountable on universal unit spindle and number of spindle revolutions. 2.13 cnusa2 SUPERSET XL...

- Page 29 INSTALLATION 2.14 cnusa2 SUPERSET XL...

- Page 30 USE - ADJUSTMENTS SECTION 3 USE - ADJUSTMENTS CONTROL PANEL .......................... 3.2 STARTING THE MACHINE ......................3.11 STOPPING THE MACHINE ......................3.11 EMERGENCY STOP ........................3.11 AUTO-BRAKING MOTOR ......................3.12 cnusa3 SUPERSET XL...

-

Page 31: Control Panel

WHITE LUMINOUS BUTTON Turns on the 110 VAC auxiliary Press to turn on voltage on the electric panel. Light on – voltage present When the EMERGENCY is activated, the light goes off. cnusa3 SUPERSET XL... - Page 32 Light on - unit started WHITE LUMINOUS BUTTON Starts the left vertical unit Press to start Light on - unit started WHITE LUMINOUS BUTTON Press to start Starts the top horizontal unit Light on - unit started cnusa3 SUPERSET XL...

- Page 33 WHITE LUMINOUS BUTTON Press to start Starts the universal unit in left vertical Light on - unit started or bottom horizontal position. BLACK BUTTON Press to stop Simultaneously stops the motors of all the operating units and the traction. cnusa3 SUPERSET XL...

- Page 34 BLACK BUTTON Press to stop Stops the piece traction unit Pulse-press to start WHITE BUTTON Starts reverse pulse feed of the piece traction unit WHITE BUTTON Starts reverse pulse feed of the piece Pulse-press to start traction unit cnusa3 SUPERSET XL...

- Page 35 KEY SELECTOR Selected: enabled to start Enables and selects the rotation universal unit as bottom horizontal direction of the universal unit or left vertical. Selected: enabled to start universal unit as top horizontal or right vertical. cnusa3 SUPERSET XL...

- Page 36 Light off: lubrication inactive Consult the attached user manual ELECTRONIC PROGRAMMER Positions the units: top horizontal and left vertical at the programmed operating values. cnusa3 SUPERSET XL...

- Page 37 With the special key unlock the 2 locks. Open the cover. Inside the electric box the following components may be found: Main switch Magnetothermal switches Starters Transformer for auxiliary circuit (110 V AC) Autotransformer for motor brake (220 V AC) cnusa3 SUPERSET XL...

- Page 38 P9, P10) Turn the knob until the P9) Adjusts the output flow of the desired flow is obtained. wood-sliding fluid onto the table (first slot). P10) Adjusts the output flow of the wood-sliding fluid onto the table (second slot). cnusa3 SUPERSET XL...

- Page 39 – When passing from automatic to manual with units on, these stop with the intervention of the motor brakes (if present) and feeding stops. IMPORTANT!!!: The mode selector may exclusively be used by the expert operator (also see paragraph 1-5). 3.10 cnusa3 SUPERSET XL...

-

Page 40: Starting The Machine

To stop the machine in imminent dangerous conditions, press one of the mushroom emergency buttons on the machine (the mushroom emergency buttons are always active). The units switch off, the motor brakes (if present) are activated and the traction stops. 3.11 cnusa3 SUPERSET XL... -

Page 41: Auto-Braking Motor

The motor can only be started if the selector (16) is turned to the left NOTE: The material used in the auto-braking motors to obtain rapid stopping of the tool does not contain carcinogenic substances. 3.12 cnusa3 SUPERSET XL... -

Page 42: Operating Units

RIGHT VERTICAL SPINDLE ..........................4.8 4.2.3 LEFT VERTICAL SPINDLE ..........................4.10 4.2.5 TOP HORIZONTAL SPINDLE ........................4.12 4.2.6 SECOND BOTTOM HORIZONTAL SPINDLE ....................4.14 TOP MOBILE UNIT ........................4.16 INLET GUIDE AND TABLE ......................4.18 UNIVERSAL SPINDLE UNIT ....................... 4.20 cnci4 SUPERSET XL... -

Page 43: Tool Adjustment And Locking On Spindles

NOTE: With machines equipped with a shaver, take care that the planer knives intersect perfectly with the shaver knives. To set up the tools follow the instructions of the manufacture. For the traditional-type tools marked SCMI consult paragraph 10.1. The support surfaces of the tools must be perfectly clean. Locking and unlocking the fastening screws of the tool on the spindle is easily done with the wrench (A) supplied (see Fig. - Page 44 OPERATING UNITS ØMAX ØMAX Ø m i n Ø m i n Ø P Ø P cnci4 SUPERSET XL...

- Page 45 (1) of the graph; any combination which falls in zone (3) is not usable. 6000 RPM – 40 mm ø spindle 6000 RPM – 50 mm ø spindle 6000 RPM – 1'13/16 mm ø spindle cnci4 SUPERSET XL...

- Page 46 OPERATING UNITS 8300 RPM – 40 mm ø spindle 8300 RPM – 50 mm ø spindle 8300 RPM – 1'13/16 mm ø spindle cnci4 SUPERSET XL...

-

Page 47: Operating Units

Relock the screw (B Fig. 4.4). d) Remount the protection (C fig. 4.3). Set the padlockable main switch to “1”, or if present, set the selector (16) to the brake lock position cnci4 SUPERSET XL... - Page 48 OPERATING UNITS cnci4 SUPERSET XL...

-

Page 49: Right Vertical Spindle

With tools with a diameter of more than 140 mm and up to 200 mm the section (S) is not used. e) Remount the protection (C fig. 4.6). Set the padlockable main switch to “1”, or if present, set the selector (16) to the brake lock position cnci4 SUPERSET XL... - Page 50 OPERATING UNITS 4.6b 4.6a cnci4 SUPERSET XL...

-

Page 51: Left Vertical Spindle

This operating unit can be equipped with the following optional: Automatic adjustment device for left spindle to machine pieces of different width in succession. Use and adjustment of this optional is described in Section 10 of this manual. 4.10 cnci4 SUPERSET XL... - Page 52 OPERATING UNITS 4.11 ø max 140 4.11a max 10mm max 50mm 4.11b max 40mm 4.10 4.13a 4.12 4.13 4.11 cnci4 SUPERSET XL...

-

Page 53: Top Horizontal Spindle

(J) to lift the traction wheel, then loosen the screws (W), remove the pad (T) and turn it by 180°, re-insert it and tighten the screws (W). e) Remount the protection (Q). Set the padlockable main switch to “1”, or if present, set the selector (16) to the brake lock position 4.12 cnci4 SUPERSET XL... - Page 54 OPERATING UNITS 4.14 4.15 4.16 4.13 cnci4 SUPERSET XL...

-

Page 55: Second Bottom Horizontal Spindle

Position the tables, sliding them according to requirements and avoiding collision with the tool tighten screws (Q) e) Remount the protection (M). Set the padlockable main switch to “1”, or if present, set the selector (16) to the brake lock position 4.14 cnci4 SUPERSET XL... - Page 56 OPERATING UNITS 4.17 4.18 4.15 cnci4 SUPERSET XL...

-

Page 57: Top Mobile Unit

This unit may be equipped with the following optionals: Tandem feed unit in front of right vertical unit. The use and adjustment of these optionals is described in Section 10 of this manual. 4.16 cnci4 SUPERSET XL... - Page 58 OPERATING UNITS 4.19 4.19a 4.19b 4.19c 4.17 cnci4 SUPERSET XL...

-

Page 59: Inlet Guide And Table

Each notch on the plate corresponds to a movement of about 1 mm. The inlet guide and table function through a parallelogram system, which is perfectly adjusted at the factory during the test phase. Nevertheless, if lack of precision of the device is noted, contact our Technical Service. 4.18 cnci4 SUPERSET XL... - Page 60 OPERATING UNITS 4.20 4.19 cnci4 SUPERSET XL...

-

Page 61: Universal Spindle Unit

Remove the protection (X). Insert the tool and lock the nut with the special wrench supplied (also see paragraph 4.1). Remount the protection (X). Set the selector (19) to the brake lock position 4.20 cncgb4_1 SUPERSET XL... - Page 62 OPERATING UNITS B C1 4.21 cncgb4_1 SUPERSET XL...

- Page 63 Apart from the normal traction rollers, the piece must be held firm near the tool by means of special vertical pressers (V). Adjust the left lateral guide (G1) according to the piece width. 4.22 cncgb4_1 SUPERSET XL...

- Page 64 OPERATING UNITS 4.23 cncgb4_1 SUPERSET XL...

- Page 65 Move the right guides (K1) and (K2) into position in such a way that they are as close as possible to the tool. Once positioned, relock the screws (J). Mount and adjust the vertical pressers (V). Mount and adjust the left lateral guide (G2) according to the piece width. 4.24 cncgb4_1 SUPERSET XL...

- Page 66 OPERATING UNITS 4.25 cncgb4_1 SUPERSET XL...

- Page 67 Move the right guides (K1) and (K2) as close together as possible in such a way as to create a continuous guide. Once positioned, relock the screws (J). Mount and adjust the vertical pressers (V). Remount and adjust the left lateral guide (G2) according to the piece width. 4.26 cncgb4_1 SUPERSET XL...

- Page 68 OPERATING UNITS 4.27 cncgb4_1 SUPERSET XL...

- Page 69 With the unit set up as top horizontal, but with spindle inclined from 10° and greater, the pressers (V) can be mounted, this time not on the usual support, but taken off and mounted on the supports (V1) placed before and after the unit. 4.28 cncgb4_1 SUPERSET XL...

- Page 70 OPERATING UNITS 4.29 cncgb4_1 SUPERSET XL...

- Page 71 Possible positions Possible positions starting Ø 125 starting from the top from the right vertical horizontal Ø 125 Possible positions starting from the left Possible positions starting vertical from bottom horizontal 4.30 cncgb4_1 SUPERSET XL...

- Page 72 OPERATING UNITS 15˚ 20˚ Ø 125 Possible inclination positions starting from the left vertical 4.31 cncgb4_1 SUPERSET XL...

- Page 73 OPERATING UNITS 4.32 cncgb4_1 SUPERSET XL...

-

Page 74: Adjustment And Use Of Optional Units

METRE COUNTER ........................10.8 10-8 HOUR COUNTER ......................... 10.8 10-9 TW0-SECTOR PRESSURE SHOE POSITIONED AFTER THE UNIT ........10.10 Note: In this chapter those optional units requiring specific controls and adjustments for their use are described. 10.1 Cnusa10 SUPERSET XL... -

Page 75: Knife Adjustment Device

– Release the handle (G) and press on the fulcrum point (X) in the direction of the arrow until the unit assumes the position as represented by the dotted lines. – Tighten the handle (G) when the operation has been completed. 10.2 Cnusa10 SUPERSET XL... - Page 76 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.1 10.1a 10.2 10.3 Cnusa10 SUPERSET XL...

-

Page 77: Vertical Presser

The optional consists of 2 toothed wheels with 10 mm width. These wheels replace the standard toothed wheels : it is so possible to set the mobile left vertical unit up to a min. working width of 15 mm. 10.4 Cnusa10 SUPERSET XL... - Page 78 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.3 10.5 Cnusa10 SUPERSET XL...

-

Page 79: Manually Operated Table Lubrication Pump

NOTE: Insert exclusively “SCORRILEGNO WURTH” fluid through the cap (T), obtainable on the market or from our spare parts service with the code 0002402040E. Lack of fluid in the tank is signalled by the luminous button flashing. In this condition the pump is no longer active. 10.6 Cnusa10 SUPERSET XL... - Page 80 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.5 10.6 10.7 Cnusa10 SUPERSET XL...

-

Page 81: Metre Counter

When the adjustment has been completed, lock the screw (T). 10-8 HOUR COUNTER (FIG. 10.8) The service hour counter is located inside the electric box. It starts functioning each time the piece traction is active. The hour counter cannot be reset. 10.8 Cnusa10 SUPERSET XL... - Page 82 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.7 10.8 10.9 Cnusa10 SUPERSET XL...

- Page 83 E0036 if this alarm appears, switch the machine off then on again. If the problem persists, contact the support ... team. E0037 if this alarm appears, press the backup power pushbutton (3) and the system continues normal operation. E0038 if this alarm appears, switch the machine off and contact the support team. 10.10 Cnusa10 SUPERSET XL...

- Page 84 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.9 ERL 100 m/min 10.10 10.11 Cnusa10 SUPERSET XL...

- Page 85 Valve (A) controls the supply of air from the nozzles closest to the right-hand guide. The other valves control the other rows of nozzles (see figure). Only use the rows of nozzles required according to the width of the wood to be machined. 10.12 Cnusa10 SUPERSET XL...

- Page 86 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.11 10.12 10.13 Cnusa10 SUPERSET XL...

- Page 87 E0036 if this alarm appears, switch the machine off then on again. If the problem persists, contact the support ... team. E0037 if this alarm appears, press the backup power pushbutton (3) and the system continues normal operation. E0038 if this alarm appears, switch the machine off and contact the support team. 10.14 Cnusa10 SUPERSET XL...

- Page 88 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.13 ERL 100 m/min 10.14 10.15 Cnusa10 SUPERSET XL...

- Page 89 To reach the minimum cutting width of 10 mm, the dividing knives must be staggered, also using the rear part (L) of the guide to mount the knife-holder block. When machining is carried out where the fitting is not required, it can be excluded by dismantling the guide (H) with the dividing knives mounted on it. 10.16 Cnusa10 SUPERSET XL...

- Page 90 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.15 10.16 10.17 Cnusa10 SUPERSET XL...

- Page 91 To execute the “RESET” cycle, the tool spindle motor must be switched off. Position the selector (T) to and act on the selector (D) to make the unit execute a complete opening and closing stroke until the yellow light (S) comes on and the blue light (B) goes off. 10.18 Cnusa10 SUPERSET XL...

- Page 92 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.19 Cnusa10 SUPERSET XL...

- Page 93 To execute the “RESET” cycle, the tool spindle motor must be switched off. Position the selector (T) to and act on the selector (D) to make the unit execute a complete opening and closing stroke until the yellow light (S) comes on and the blue light (B) goes off. 10.20 Cnusa10 SUPERSET XL...

- Page 94 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.21 Cnusa10 SUPERSET XL...

- Page 95 N.B.: The rebound strap (J) operates when automatic positioning is ON. It is designed to regulate the feed of short workpieces with high feed speeds. If the workpieces to be machined are long or machining is carried out at a low feed speed, the rebound strap (J) may be excluded using handle (J1). 10.22 Cnusa10 SUPERSET XL...

- Page 96 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.23 Cnusa10 SUPERSET XL...

- Page 97 Dirt under the pressure regulating valve Disassemble, clean and, if necessary, replace the valve No pressure release in line Release valve functions irregularly Disassemble the valve, inspect it and, if necessary, replace it. 10.24 Cnusa10 SUPERSET XL...

- Page 98 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.25 Cnusa10 SUPERSET XL...

- Page 99 ADJUSTMENT AND USE OF OPTIONAL UNITS 10.26 Cnusa10 SUPERSET XL...

- Page 100 AUTO-BRAKING MOTOR SECTION 19 AUTO-BRAKING MOTOR (OPTIONAL) 19-1 AUTO-BRAKING MOTOR ......................19.2 19-2 “ELETTRO ADDA” AUTO-BRAKING MOTOR ..............19.4 19-3 “LAFERT” AUTO-BRAKING MOTOR ..................19.6 19.1 Cnusa19 SUPERSET XL...

- Page 101 Progressively turn the screw until compacting the mobile elements and eliminating the distance (air gap). Unscrew the idling screw by 1/4 turn, maximum 1/3 turn (corresponding to about 0.4 mm air gap). Start and stop the motor several times to check proper functioning. 19.2 Cnusa19 SUPERSET XL...

- Page 102 AUTO-BRAKING MOTOR 19.3 Cnusa19 SUPERSET XL...

- Page 103 Unscrew the nut (D) by half a turn (corresponding to about 0.4 mm) Install the protection cover (P) Start and stop the motor several times to check proper functioning. NOTE: By turning the nut (D) backward by more than 1 mm, mechanical locking of the brake is obtained. 19.4 Cnusa19 SUPERSET XL...

- Page 104 AUTO-BRAKING MOTOR 19.5 Cnusa19 SUPERSET XL...

- Page 105 (part 38) from falling out. N.B. For electrical repairs it is recommended to contact an authorised LAFERT dealer or the machine manufacturer The electrical connections of the motor and the brake must be carried out according to the diagrams supplied. 19.6 Cnusa19 SUPERSET XL...

- Page 106 AUTO-BRAKING MOTOR parts 11 DRIVE SHAFT 13 REAR BEARING 14 COVER 17 FAN COVER 36 FAN WITH FRICTION DISK 43 ELECTROMAGNET BODY 55 SNAP RING 56 SPRING 57 SAFETY WASHER 58 RING NUT 19.7 Cnusa19 SUPERSET XL...

- Page 107 AUTO-BRAKING MOTOR 19.8 Cnusa19 SUPERSET XL...

- Page 108 OPERATING UNIT BELT REPLACEMENT ................. 20.8 20-9 VARIATOR TIMING BELT REPLACEMENT ................20.10 20-10 INSPECTION OF SAFETY DEVICES ..................20.10 20-11 REMOVAL - STORAGE - DEMOLITION .................. 20.11 20-12 EMERGENCY CONDITIONS ....................20.11 20-13 TROUBLESHOOTING ........................ 20.12 20.1 Cnnci20 SUPERSET XL...

-

Page 109: Maintenance

- the dovetails for vertical movement - the gibs for vertical movement The machine part: right vertical unit(s) - the lead nuts for horizontal movement - the lead nuts for vertical movement - the dovetails for horizontal movement 20.2 Cnnci20 SUPERSET XL... - Page 110 MAINTENANCE 20.1 20.3 Cnnci20 SUPERSET XL...

-

Page 111: Pneumatic System

If necessary, fill up through the cap (R), checking the level through the cap (L). Use AGIP BLASIA 320 oil or equivalent. 20-3 PNEUMATIC SYSTEM Discharge the condensate water from the tank (V Fig. 20.3) unscrewing the cap (T) when the level reaches 1/ 3 of total capacity. 20.4 Cnnci20 SUPERSET XL... - Page 112 MAINTENANCE 20.2 20.2a 20.3 20.5 Cnnci20 SUPERSET XL...

-

Page 113: Bottom Horizontal Operating Unit Belt Tensioning

The tension is correct when, pressing on the belt with a force (K) of 8 kg, a camber (F) of 5 mm is obtained. When adjustment has been completed, relock the counternut (N). Subsequently, check every 1000 hours of operation or at the first sign of slippage. 20.6 Cnnci20 SUPERSET XL... - Page 114 MAINTENANCE 20.5 20.4 20.6a 20.6 20.7 Cnnci20 SUPERSET XL...

-

Page 115: Left Vertical Operating Unit Belt Tensioning

Subsequently, check every 1000 hours of operation or at the first sign of slippage. 20-8 OPERATING UNIT BELT REPLACEMENT – Slacken the belt tension. – Remove the worn belt, insert a new one and tension it correctly. 20.8 Cnnci20 SUPERSET XL... - Page 116 MAINTENANCE 20.7 20.7a 20.7b 20.9 Cnnci20 SUPERSET XL...

-

Page 117: Variator Timing Belt Replacement

The operating and traction units should stop. c) with the machine in normal operating conditions, press the emergency button on the push-button panel on the machine. The operating and traction units should stop. 20.10 Cnnci20 SUPERSET XL... -

Page 118: Removal - Storage - Demolition

A free space without obstructions must be provided around the machine, as already described in Chapter 1.10 to allow fast escape in case of danger. This machine must not be operated in explosive environments. 20.11 Cnnci20 SUPERSET XL... -

Page 119: Troubleshooting

The knives should remain at the edge of the table. The knives shall be flush with the table. 20.12 Cnnci20 SUPERSET XL... - Page 120 4.2.4 Ensure that the knives on the planers are perfectly adjusted with the special knife adjustment, since to obtain good machining, it is indispensable that the knives protrude from the planer body by 1 mm. 20.13 Cnnci20 SUPERSET XL...

- Page 121 4.3 Piece to be machined too small with See paragraph 1.4 “Dimensions of the piece to be respect to the machining capacity machined” and ensure that there are no pieces smaller than these dimensions. 20.14 Cnnci20 SUPERSET XL...

Need help?

Do you have a question about the SUPERSET XL and is the answer not in the manual?

Questions and answers

besoin réparation-technicien for Candiac pour une moulurière Superset xl