Summary of Contents for R&M CMX 007

- Page 1 English Original Instruction INSTALLATION INSTRUCTION TMU Upgrade Kit 020131en / Revision C 2013-03-20...

-

Page 2: Table Of Contents

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 TABLE OF CONTENTS INTRODUCTION........................... About this manual......................... About the upgrade kit usage......................Waste treatment and recycling of removed material..............SAFETY..............................Before starting to work at the site....................Main switch and emergency stop buttons.................. -

Page 3: Introduction

Note that this manual is not intended as a substitute for proper training. About the upgrade kit usage This upgrade kit is designed only for CMX 007 frequency converter which is mounted in a TROLLEY MOTOR UNIT (TMU) in chain hoist crane. It is not designed for wire rope hoist application. -

Page 4: Safety

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 SAFETY Before starting to work at the site Before starting any work on the crane: • Familiarize yourself with the equipment and its user instructions. •... -

Page 5: Description Of The Upgrade Kit

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 DESCRIPTION OF THE UPGRADE KIT Parts included in the kit Part Name Qty. Image Part 1 Frequency converter 1 pcs Part 2 Mounting rack 1 pcs Part 3 Installation accessory... -

Page 6: Required Tools

Wire cutters Socket wrench, 8 mm Crimping tool for wire end ferrules Wire strippers Terminal connections The following table describes the differences between the terminals of CMX 007 and ControlMaster®NXT 003 . Description of terminal ControlMaster®NXT 007 Terminal X1 003 Power terminals... -

Page 7: Dip Switches

P.: (937) 328-5100 FAX: (937) 325-5319 DIP switches CMX 007 has 4 groups of DIP switches (S1-S4), whereas ControlMaster®NXT has 10 groups of DIP switches (S1-S10). The correct DIP switch settings for ControlMaster®NXT 003 can be found in Chapter 5: “Commissioning”. -

Page 8: Emc Filter

EMC filter CMX 007 has an external EMC filter package (KC310 / KC330), whereas ControlMaster®NXT 003 has an internal EMC filter in the power supply. By default, the EMC level of the frequency converter is set to N by the manufacturer. -

Page 9: Installation

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 INSTALLATION Before installation. After installation. Old frequency converter removal If the trolley is operable (not broken), record the trolley driving directions. Push the main power off from the pendant or radio controller. High voltage inside the Frequency converter. - Page 10 (page 17) you can find an empty table where to write the settings. Remove the wire terminal by pulling. Remove the CMX 007 . Remove wires from the terminal one at the time. 10/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

- Page 11 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Cut the wire. Make sure you leave as much length for the wire as you can. Strip the wire end from the length of 10 mm. Connect the end ferrule to the wire end.

-

Page 12: Control Voltage Front Resistors

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Mark the wire with markers. Use installation mandrel for easy installation. Do steps 5-9 to the rest of the wires. Control voltage front resistors The TMU should not have front resistors. - Page 13 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Remove the input wire terminal from the ControlMaster®NXT 003 frequency converter. Remove the grounding wire connector. See image. Leave the other in place. The inverter doesn't fit into the motor connection box otherwise.

- Page 14 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Push the new frequency converter into the c-rail. Leave the input lid open. Install the ground wire. Install the control wires (1,2,3 and 7) into the input terminal. 14/28 R&M Materials Handling, Inc.

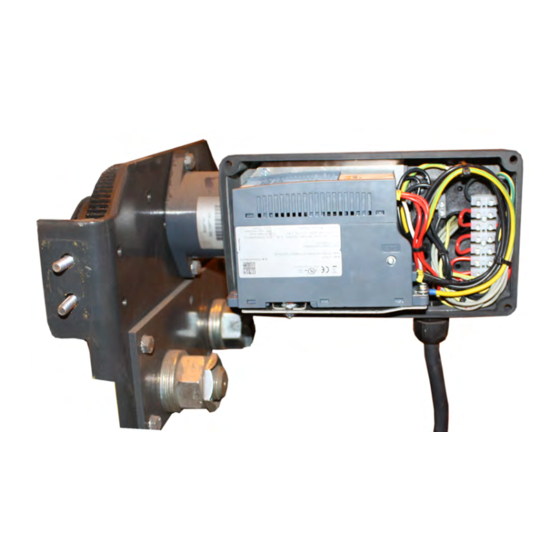

- Page 15 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Push the input terminal into ControlMaster®NXT 003 . And close the lid. Fold the wires inside the box. Secure the wires with cable ties. The image on the right shows how the final assembly should look alike.

- Page 16 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Install the motor connection box lid. Install the festoon electric connection box (if installed). Release the main power button up from the pendant or radio controller. Make sure that the trolley move's into correct directions by operating the trolley.

-

Page 17: Commissioning

P.: (937) 328-5100 FAX: (937) 325-5319 COMMISSIONING Compare the DIP switch settings of the CMX 007 with the following tables and find the correct settings for the ControlMaster®NXT 003 DIP switches. Old inverter parameter settings Write in the table below the old frequency converter DIP switch settings. -

Page 18: S1 Maximum Driving Frequency

S1 Maximum driving frequency Set the maximum driving frequency according to the following tables Table 3. Motor nominal frequency = 100/120 Hz CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1 Table 4. Motor nominal frequency = 80 Hz CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1... - Page 19 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1 Table 5. Motor nominal frequency = 35 Hz CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1 19/28 R&M Materials Handling, Inc.

-

Page 20: S2 Minimum Driving Frequency

4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 CMX 007 Switch 1 ControlMaster®NXT 003 Switch 1 S2 Minimum driving frequency Set the minimum driving frequency according to the following tables: Table 6. Motor nominal frequency = 100/120 Hz CMX 007 Switch S2 ControlMaster®NXT 003 Switch S2... - Page 21 Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Table 7. Motor nominal frequency = 80 Hz CMX 007 Switch S2 ControlMaster®NXT 003 Switch S2 Table 8. Motor nominal frequency = 35 Hz CMX 007 Switch S2 ControlMaster®NXT 003 Switch S2 21/28 R&M Materials Handling, Inc.

- Page 22 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 CMX 007 Switch S2 ControlMaster®NXT 003 Switch S2 22/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

-

Page 23: S3 Acceleration And Deceleration Ramp Time

Do not set the ramp time to be shorter than the original; this would shorten the lifetime of the frequency converter. Increasing of the ramp time is allowed if the customer accepts it. Table 9. Acceleration and deceleration ramp time Ramp CMX 007 Switch S3 ControlMaster®NXT 003 Switch Ramp time (s) -

Page 24: S4 Control Mode And Slowdown Mode

S4 Control mode and slowdown mode Set the control mode (EP or MS control) and slowdown mode according to the following table: Table 10. Control mode CMX 007 Switch S4 ControlMaster®NXT 003 Switch S4 24/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice. -

Page 25: S5-S10 Motor Parameters

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 S5–S10 Motor parameters Set the motor parameters according to the following table: 25/28 R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice. -

Page 26: Testing The Trolley Functions

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Testing the trolley functions If any problems or malfunctions occur during the commissioning, refer to Chapter “Troubleshooting” to find out the reason. The source of any problems with the product must be solved before continuing with the commissioning procedure. -

Page 27: Troubleshooting

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 TROUBLESHOOTING Purpose of troubleshooting The purpose of troubleshooting is primarily to determine whether problems are caused by the frequency converter or external devices. It is also possible that a faulty external device has caused damage to the frequency converter. -

Page 28: Electrical Drawing

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 ELECTRICAL DRAWING Frequency controllerControlMaster®NXT L1 L2 L3 2.5 mm² L1 L2 L3 L1 L2 L3 TRAVELLING INVERTER TMK003E0100WMM DIRECTION 1 SUUNTA 1 DIRECTION 2 SUUNTA 2 DI3-6 DIGITAL INPUT... - Page 29 English Original instructions OWNER'S MANUAL FOR TRAVEL FREQUENCY CONTROL SYSTEM CMNXT PS11648 29.2.2012...

- Page 30 R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Table of contents GENERAL INTRODUCTION ......................3 Foreword: About This Manual ........................3 Symbols Used In This Manual ........................3 Safety Alert Symbols and Signal Words ....................... 3 Questions And Comments ..........................

-

Page 31: General Introduction

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 GENERAL INTRODUCTION Foreword: About This Manual This manual offers guidance to enable safe and efficient operation of the crane. As a crane operator, taking the time to read this manual will help you to prevent damage to the crane and load, and, most importantly, personnel situated close to the crane. -

Page 32: Questions And Comments

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Addresses situations not related to personal injury, such as likely or possible damage NOTICE to equipment. Shall Indicates that a rule is mandatory and must be followed. Should Indicates that a rule is a recommendation, the advisability of which depends on the facts in each situation. -

Page 33: Terminology

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Terminology The following terms and definitions may have been used in this manual: ANSI American National Standards Institute Authorized personnel Persons who are authorized by the owner and who have the necessary training to carry out operation or service actions. -

Page 34: Directives And Standards

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Directives and standards 1.8.1 CE/CSA/UL/CCC This product complies with one or more of the following requirements and directives described in this section. For more detailed information about which requirements the product meets, see the main sticker attached to the device. -

Page 35: Identification

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 IDENTIFICATION Product identification data This manual covers the installation and use of the switch based frequency converter model. Converter can be used on traveling movement application and chain hoist lifting application. Application type is selected with switch S10-2. -

Page 36: 2.1.1 Main Sticker

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 2.1.1 Main sticker The main sticker shows, for example, the model and serial number of the frequency converter, as well as the rated voltage. Indicates the exact model of the product. -

Page 37: Safety Related Instructions

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 SAFETY RELATED INSTRUCTIONS Intended use of the frequency converter Travelling movements These frequency converters are designed for industrial crane usage for controlling the speed of travelling motors. Hoisting movements These frequency converters are designed for industrial crane usage for controlling lifting speed in chain hoist applications. -

Page 38: Operating Instructions

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 OPERATING INSTRUCTIONS Normal function 4.1.1 Control methods Two speed joystick control The motor moves at one of two preset speeds corresponding to the force applied to the direction control. The motor moves at its slowest speed when the control is partially pushed and at its maximum speed when the control is fully pushed. -

Page 39: 4.1.2 Slowdown-Limit

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 1 Pushbutton released: the motor does not turn 2 Pushbutton half-pressed: the motor accelerates until it reaches the preset slow speed 3 Pushbutton fully pressed: the motor accelerates towards maximum speed 4 Pushbutton half-pressed: the current speed is held 5 Pushbutton fully pressed: the motor accelerates until it reaches maximum speed 6 Pushbutton half-pressed: the current (maximum) speed is held... -

Page 40: Taking Product Out Of Operation

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 TAKING PRODUCT OUT OF OPERATION Disposal of waste materials Waste material from installation, maintenance or dismantling shall be disposed of according to local regulations. If the product is taken out of use, the metal and electrical parts should be recycled.

Need help?

Do you have a question about the CMX 007 and is the answer not in the manual?

Questions and answers