ADIMLab Gantry User Manual

Hide thumbs

Also See for Gantry:

- Pre-installation instructions (6 pages) ,

- Assembly specifications (23 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for ADIMLab Gantry

- Page 1 User Guide ADIMLab-gantry 3D printer Version V1.3.2...

-

Page 2: Table Of Contents

四、Prepare printing ................... 9 4.1 ADIMLab-gantry printer architecture ..........10 4.2Assembly and wiring ................ 11 4.3 First time test the ADIMLab ............11 4.4 First time prepare printing ..............13 五、Slice software installation and configuration ........17 5.1 Software copy .................. 17 5.2 Install software ................ - Page 3 6.4 Select printing way ................34 6.5 Printing finish ................. 39 7、Printer operating .................. 39 7.1 Replace filament ................41 7.2Replace filament during printing ............41 7.3Pause and resume printing ..............43 7.4 Stop printing ..................45 7.5Filament detector ................45 7.6 Adjust printing temperature ............

-

Page 4: 一、Overview

一、Overview Thank you for your support of our company's products,the guidelines only apply to ADIMLab-gantry 3D printer. This guide is based on Win7 operating system. Chapter 1: Introduction of architecture, settings, and other preparatory work Chapter 2: Introduction of software and printing step... - Page 5 * Place the printer on a flat solid platform...

-

Page 6: 二、Thanks And Commitment

二、Thanks and Commitment Thanks Thanks for your purchase and support for ADIMLab-gantry 3D printer . You may also purchased our other 3D products or well understand 3D printing technology. But we still want you to read this guide, it contains a lot of important information about the use of the product so that customers get a better 3D experience. -

Page 7: 三、What Is 3D Printer

The most common 3D printing technology is called FDM (Fused Deposition Modeling), namely melting precipitation manufacturing technology, ADIMLab-gantry belong to this one. The way it works is melted on the printing platform supplies plastic called high temperature. -

Page 8: Slice Output 3D Model

ADIMLab-gantry by dividing into a 3D model of a plurality of layers in the form of g-code file output format of thisfile can be read by ADIMLab-gantry. Files can be in the form of a USB cable, SD card, then transferred to ADIMLab-gantry for printing operation. -

Page 9: 四、Prepare Printing

Once the input file begins to run in ADIMLab-gantry, and it begins to pile up layer by layer so as to print the 3D model into an actual entity. 4.1ADIMLab-gantryArchitecture:... -

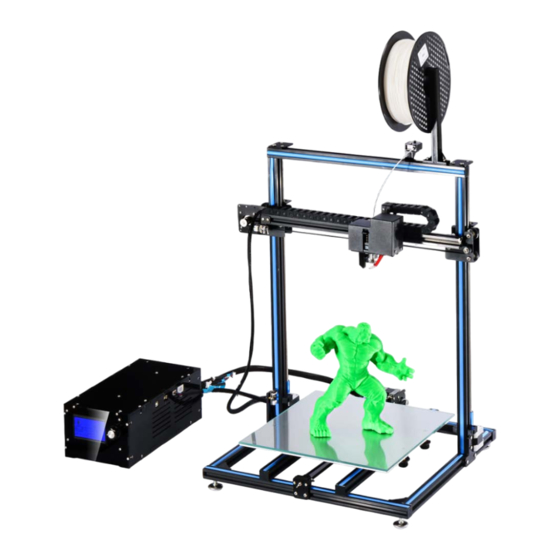

Page 10: Adimlab-Gantry Printer Architecture

1.Frame 2.Towline 3. Extruder 4.Slideron the right side of the axis 5.Nozzle 6.The print platform 7.Z-motor2 8.Foot pad9.Slideron the left side of the Z axis 10.X-endstop 11.Cooling fan12.Y axis the wheel stand 13.Z-endstop 14. Z-motor1 15.Y axis pulley 16.X-motor 17.Z-endstop mounting plate 18.Z -screw rod 19.Z axis screw 20.Coupling 21.Y-motor... -

Page 11: Assembly And Wiring

4.2Assembly and wiring (Please reference SD card file contents“2.Assembly and debugging tutorial”“HCmaker7Assembly instruction”1~2) 4.3 First time test the maker7 (Please reference SD card file contents“2.Assembly and debugging” “HCmaker7Assembly instruction”3) 4.3.1 Home test: (1) “Info screen” Press the knob,Rotate select“Prepare”, Click OK: (2) Select“Auto home”in Submenu,Click OK:... - Page 12 4.3.2Heating test: (1)“Info screen” Press the knob, Rotate select “ Prepare” ,Click OK: (2) Select“Preheat PLA”in Submenu,Click OK: (3) Select“Preheat PLA”in Submenu,Click OK: (4) If Extruder and hotbed temperature rises, It mean heating working:...

-

Page 13: First Time Prepare Printing

4.4First time prepare printing: (Please reference SD card file contents“2.Assembly and debugging” “HCmaker7Assembly instruction”4) 4.4.1XaxisHeight calibration: (1) “Info screen” Press the knob, Rotate select “Prepare” ,Click OK: (2) Select“X Height adjustment”in Submenu,Click OK: (3) Z axis Automatic rise30mm,use solid glue or print model... - Page 14 test shaft guide distance between the two ends and the base, Make the metal parts at both ends of the X-axis guide just touch the glue stick or print model. 4.4.2Leveling Heating Platform: (1) “Info screen” Press the knob,Rotate select“Prepare”,Click OK:...

- Page 15 (4) Adjust the hand nut under the platform in turn so that the nozzle just touches the hot bed. Click after leveling“Back”。 4.4.3 First time test the maker7: (Please reference SD card file contents“2.Assembly and debugging” “HCmaker7Assembly instruction”5) (1)“Info screen” Press the knob,Rotate select“Print from SD”,Click OK:...

- Page 16 (2) Select“505020.gcode”in Submenu,Click OK: (3) Printer Preheating,Pls wait patiently: (4) Finish preheating,star printing:...

-

Page 17: 五、Slice Software Installation And Configuration

五、Slice software installation and configuration 5.1 Software copy Insert the SD card into the computer, SD card file "4. control software, Repetier-Host installation and introduction", there are various systems Repetier-Host control software installation package, You can copy the required installation to your computer. (Take Win7 operating system as an 5.2 Install control software example)... - Page 18 (2) Using the desktop icons or start menu’s shortcuts to start the software . 5.3 Setting software: Users can use Repetier-Host software to control ADIMLab-gantry printer to print, you should set up control software, open Repetier-Host. 5.3.1 Printer parameter set :...

- Page 19 (2) Choose language:...

- Page 20 (3) Select Printer Settings: Choose their own corresponding serial port, such as: COM3, COM4 and so on (in the serial drop-down menu selection), in the drop-down menu set baud rate of 250000.,Cache size127,Click apply...

- Page 21 Set nozzle number “1”and extruder diameter “0.4”, Click apply” :...

- Page 22 Set printer shape,click“Apply”,“OK”:then close. 5.3.2 Slicer setting: (1) Click “Slicer” , in “Slicer” choose “ Slic3r” , click “Configuration:...

-

Page 23: Setting Software

(2)“Slic3r”Slicing software setting: (3)Select file to load configuration (slice settings on SD card 6. slice settings) - Page 25 (4) Save configuration (three items need to be saved) Click”Print Settings”,click“Save”button: Click“Filament Setting”,click“Save”button:...

- Page 26 Click”Printer Settings”,Click“Save”button: Saved,Close the settings window,Slice setting finish!...

- Page 27 5.4Slic3r setting Slicing software basic configuration, here briefly introduces several important configuration (details please refer to SD card 7.slice resolution tutorial)Click slice configuration (2) Print Setting:...

- Page 28 (3) FilamentSetting: (4) Printer Settings:...

-

Page 29: 六、Start Printing

六、Start printing... -

Page 30: Model Slice

6.1Get print model (common ways to download online and their own modeling, file formats, such as STL, AMF, etc.) 6.2 Model slice: (1) Open the software , click “ Load” , selection model, click “ Open” , The model appears in the 3D window:... -

Page 31: Select Printing Model

(2) Setting ADIMLab-gantry slice parameter: click“Slicing software“button,select“Slic3r” Print setting:select“HCmaker7”; Printer setting:select“HCmaker7”; Filament setting:select“HCmaker7”;... - Page 32 (3) Click“Slice with Slic3r”button:...

-

Page 33: Install Filament

(4) Slicing completed: 6.3Install filament: One hand presses the lever first, the other hand advances the material. Note: consumables head can not be larger than the wire diameter, front end straightened, easier to insert supplies, supplies need to push to the bottom. -

Page 34: Select Printing Way

6.4Choose print method: online print or SD card offline print (recommended offline printing) 6.4.1Online printing:(not recommended, easily affected by the computer) (1) Use USB connect pritner and computer, click “Printer Settings”, select“Connection”,In“Port”select(COM3),“Device Manager” click“Apply”。... - Page 35 (2) Click “ Connect” , become green, It mean succed, click “ Start Print” , star printing:...

- Page 36 6.4.2 Offline printing: (1)Save file (Note: file names need to be saved as English letters or numbers) (Recommended to save the file to the computer first then copy it to the SD card.)...

- Page 37 (2) Slice file copy to SD card,Plug in the printer:...

- Page 38 (3)“Info screen” click button,select“Print from SD”,click ok: (4) Select Slice file in Submenu,click ok: (5) Printer need preheating ,pls waite be patient:...

-

Page 39: Printing Finish

(6) Preheating ok,star printing: 6.5Printing finish,take the model: After finish printing,waiting platform cooling,take the model(Lateral output makes it easier to remove the model)Observe, measure 七、 : Printer operating : Replace filament Please refer to the following steps to standardize the operation Note: need to be heated to the melting temperature of the printer supplies replacement supplies (such as PLA need to be heated to 200 DEG C), and then press the lever supplies downward after a period of... - Page 40 (1)“Info screen” Press the button, rotate the button, and select the ready (2) Press the button, rotate the button, and select the ready (3) Rotate the button, drop the menu, and select preheat PLA:...

-

Page 41: Replace Filament

(4) Preheat to a specified temperature (e.g., 195℃), Follow the steps below to replace filament. : Replace filament during printing (1)“Info screen”,select“Change filament”,click ok:... - Page 42 (2) Print paused,Nozzle move to the left-back position: (3) Press the lever to push the filament down one step and pull it out, reinsert the new consumables, click: (4) Extruder automatically extrude a piece of filament.

-

Page 43: Pause And Resume Printing

(5) click“Continue”: (6) Extruder back the printing position,continue printing: : Pause and resume printing 7.3.1Pause printing: (1)“Info screen”click button,select“Pause print”,click: (2) Pause printing, Extruder moves to the left-back position。... - Page 44 7.3.2Resume printing: (1)“Info screen” click,select“Resume print”,click ok: (2) Extruder automatically extrudes a piece of filament: (3) click“Continue”:...

-

Page 45: Stop Printing

(4) Extruder back the position and continues printing: 7.4 Stop printing: (1)“Info screen” click,select“Stop print”,click ok: (2)“Info screen” show“Print aborted” : Filament detector (1)The filament detector module detect filament discontinued or filament run out,printing pause waiting,The extruder moves to the left-back position:... - Page 46 (2) Press the lever to push the filament down one step and pull it out, reinsert the new filament, and click (3)Extruder automatically extrudes a piece of filament: (4)Click“Continue”menu:...

-

Page 47: Adjust Printing Temperature

(5)Extruder back the printing position and continues printing: : Adjust printing temperature (1)“Info screen”click,select“tune”,click ok: (2) Select“Nozzle”or“Bed”in Submenu, click ok... -

Page 48: 8、Problem Solutions

(3)Setting nozzle or hotbed temperature,click ok : Adjust printing speed (1)“Info screen” rotate the knob,adjust speed: 8,Problem Solutions : Analysis common problem (Please reference SD card file“9.Analysis common problem FAQ” “Common problem solutions”) : Protect heating (Please reference SD card file“9.Analysis common “Protect problem”... -

Page 49: 9、Support And Service

Our all the staff will by your side all the time and we are happy to solve any problems you encountered in the use of ADIMLab-gantry process. If you can't find the answer from the user’s guide or technical card, you can enter into our official website to search for the solution, by the way, you can contact us by phone or facebook group.

Need help?

Do you have a question about the Gantry and is the answer not in the manual?

Questions and answers