Summary of Contents for Jeio tech OF-02G

- Page 1 Operation manual [FORCED CONVECTION OVEN] Model : OF-02G / 12G / 22G Manual No : 00HAA0001159 ( Version : 5.0 ) Page 1...

- Page 2 Page 2...

- Page 3 “Caution” means that the user may have not so serious damage and unit may have physical damage by wrong handling on this unit. Copyright 2003 Jeio tech Co,. LTD. ALL RIGHT RESERVED. Page 3...

-

Page 4: Table Of Contents

Contents 1. Purpose and peculiar of this unit........2. Installation ..............3. Matters that require attention ..........4. Name of each parts ............5. Controller ................. 6. Maintenance of the unit ............. 7. Action for malfunction ............8. Warranty criterion .............. 9. -

Page 5: Purpose And Peculiar Of This Unit

1. Purpose and specificity of this unit 1) Purpose (1) Forced convection oven is used for rapid dry for glass ware test of thermal hardness and thermal variation. (2) Forced convection oven is used for preheating before heating test and test of dry for architecture component and electric component and thermal durability. -

Page 6: Installation

2. Installation (1) Scope of delivery. Main body(1set), Operation manual (1EA), Glass fuse (2EA), Shelf(2EA), Shelf guide(4EA), Communication CD(1EA), RS-232 Communication cable(1EA) (2) This unit will work correctly on proper power supply. Please check power supply and ID Plate information are the same. User must use power supply connected earth and power cord must be connected to wall outlet supplying ground point. -

Page 7: Matters That Require Attention

It is dangerous and causing fire and electric shock. (7) Circuit and electric component used in this unit are developed by Jeio tech. Please don’t try to repair by yourself. Wrong combination of electric part may cause fire. You must ask to official Jeio tech dealer or distributor in your region. -

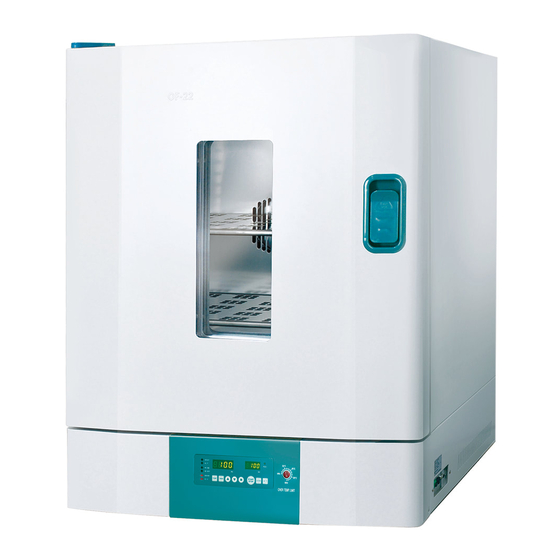

Page 8: Name Of Each Parts

4. Name of each parts (1) Main body Made by iron plate and painted. (2) Ventilation hole It changes air volume of ventilation. It’s very hot, please wear safety glove when you need to adjust it. The safety gloves must be dry. Wearing wet gloves causes burning and electric shock. - Page 9 (5) Door There are air barrier between door surface and insulation of the door. Therefore the surface of the door is cool. (6) Window (option) Observing glass is made by triple glass therefore it’s easy to observe. (7) Door Handle It is Door handle for door opening.

-

Page 10: Controller

(14) Communication port User can monitor and control the unit via RS-232C protocol interface through COM1 or COM2 port to computer device. The control values can be stored and printed out. (15) Door limit switch It’s installed inside of the unit. The Logic IC of this switch put off the main switch. This cut off all 2 phase currency in the instrument therefore heater and blower stops for safety of user. - Page 11 2) Name and operation (1) HEATER LED It shows Heating function is “ON” (2) Auto Tune LED Flickering begins on Auto-tuning. (3) Wait On Timer LED This is the LED indicating operation start time. The LED is blinking when the timer works and the LED off when the timer is in waiting condition.

- Page 12 (7) Temp. button. This button is for temperature setting. (8) Timer button. This button is for timer setting. (9) Up button. This button is for increasing set value. (10) Down button. This button is for decreasing set value. (11) Enter button. This button is for saving value after varying set value.

- Page 13 3) Temperature setting way (1) Press button. Set temperature value (SV) is blinking. This means you can vary set value. (2) Press button to vary digit number and press button when you save the value. (3) It goes back to previous state without saving if you don’t touch any button for 10 seconds. (4) Press button again when it is in SV set state then following additional functions are activated.

- Page 14 (2) This is a function vary the unit of temperature value. Initial display is ℃ and it can be varied ℃ and ℉ by pressing buttons. (3) Next mode is shown by pressing 6 times. This compensates the temp. value errors. Requested values are put on PV display.

- Page 15 (4) W/OFF LED turns on with Beep sound after finishing wait on timer set. (5) The function of Timer is as follows. T e m p e ra tu re T im e W a it o n T im e r W a it o ff T im e r ①...

- Page 16 6) Additional function of button. Press button once again on wait On/Off Timer function then following additional f unction displayed. (1) This is selection of unit state after power failure. If you set yes the unit will run or else the unit will not run after power failure situation finished.

-

Page 17: Maintenance Of The Unit

6. Maintenance of this unit (1) Turn off the main power switch and pull out a power plug from wall outlet. (2) Remove all liquid in the bath. (3) Wash with soft cloth containing neutral detergent. (4) Wash with soft cloth containing distilled water. (5) Dry with dry cloth. -

Page 18: Action For Malfunction

7. Action for malfunction 1) Check points when the unit doesn’t work. (1) Check out power supply. (2) Check out fuse if off. (4) Check out Run LED on display is off. Please press Start / Stop button if it is off. (5) Please check the power is out. -

Page 19: Warranty Criterion

It covers for 1 year since you purchase the unit and then after the duration you need to pay for service parts. Please contact your authorized Jeio tech dealer when you need warranty service. You have a right to repair, replacement and payback within the warranty service duration. -

Page 20: Specifications

9. Specifications Model OF-02G OF-12G OF-22G Chamber volume 102L 151L Temperature 5℃ to 40℃ Permissible Maximum relative humidity 80% environmental condition Altitude up to 2,000m Range Amb.+10℃ ~ 250℃ Uniformity ±1℃ at 100℃ Accuracy ±1℃ at 100℃ Temperature Controller Digital PID auto tuning... -

Page 21: Install Lab Tracer

10. Install Lab Tracer (1) Insert Installation CD and the software starts installation automatically. (In case of no automatic running, run “SETUP.exe” file in CD.) (2) Click “Next” button to choose destination of installation. (Default folder recommended) (3) Click “Install” to start installation. (4) Lab Tracer icon will be created on desktop after installation successfully. -

Page 22: How To Use Lab Tracer

11. How to use Lab Tracer. (1) Connection for communication Click Comm → Connect and your PC and equipment start connection of communication. (In case of no connection, click Comm → Port and try to other ports.) “On Line” displays on the bottom of the software, once communication is connected successfully. - Page 23 ② If you click View → Status, additional separate window appears below showing actual temperature and set point window. Operating, Auto Tune, Program, Over Temp., Level, and etc display on this window. The following picture is a monitoring window after choosing Status and Parameter in View menu.

- Page 24 ③ Parameter interface has following values; ☞ PV is actual temperature. ☞ SV is temperature set point. ☞ Heat is output value of heating element. ☞ Run Time says operating time after you press button. ☞ Wait On Timer, Wait Off Timer displays remained time from setting time. ☞...

- Page 25 ⓝ ⓞ ⓟ ⓠ ⓡ ⓢ ⓣ ⓤ ⓥ ⓦ ⓧ ⓨ ⓝ To display Status interface. (Ctrl + T) ⓞ To display Parameter interface. (Ctrl + R) ⓟ Panel View When you click Panel View, the same appearance of display panel of unit pops up and you can control the unit by the pop-up window.

- Page 26 ① Print range - All : Print a total page. - Print the screen : Print the current screen. (In case Graph, Status, Parameter Frame on the window, they are printed. If not, they are not printed. - Current page : Print a page of the currently main screen. - Selected pages : Print selected page(s).

- Page 27 when you see preview and printing. If user wants to check a certain point, move curser to the point and click. Green line with PV and SV will be printed on the copies. (see above) ① Last Point Delete - Delete last set point. ②...

- Page 28 Pic 2. Pattern Program In case you move mouse and click a certain point like pic 3., temperature set point and time, step number display on left side of window. Pic 3. SV Pattern after clicking a certain point of window. If you want to edit the selected point, Drag &...

- Page 29 ↓ : Decrease temperature by 1 degree. ← : Decrease time by 1 minute. → : Increase time by 1 minute. Alt + ↑ : Move an edit point to the right (the following step) Alt + ↓ : Move an edit point to the left (a previous step) Alt + ←...

- Page 30 - If you put and set number of pattern repetition, the main body will work as programmed. - If you tick “Deleting the previous data” and press start icon, previous data will be erased. Please, be cautious. ※ Caution - Maximum operating time is up 99 hours. - If you program total working time over 99 hours, the unit does not perform in Program Mode.

- Page 31 Page 31...

Need help?

Do you have a question about the OF-02G and is the answer not in the manual?

Questions and answers