Subscribe to Our Youtube Channel

Summary of Contents for WABCO System Saver 318

- Page 1 SYSTEM SAVER 318 AIR COMPRESSOR FOR MACK E-TECH™ AND ASET™ ENGINES MAINTENANCE MANUAL NON-THROUGH DRIVE THROUGH DRIVE...

- Page 2 Information contained in this publication was in effect at the time the publication was approved for printing and is subject to change without notice or liability. WABCO reserves the right to revise the information presented or to discontinue the production of parts described at any time.

-

Page 3: Table Of Contents

Contents Section 1: Introduction pg. 1 Application Description Operation Maintenance Intervals Cylinder Head Visual Inspection Section 2: Troubleshooting Section 3: Compressor Replacement Compressor Replacement Information Removal Installation Cylinder Head Removal Installation Testing Air System Leakage Test... - Page 4 Notes...

-

Page 5: Section 1: Introduction

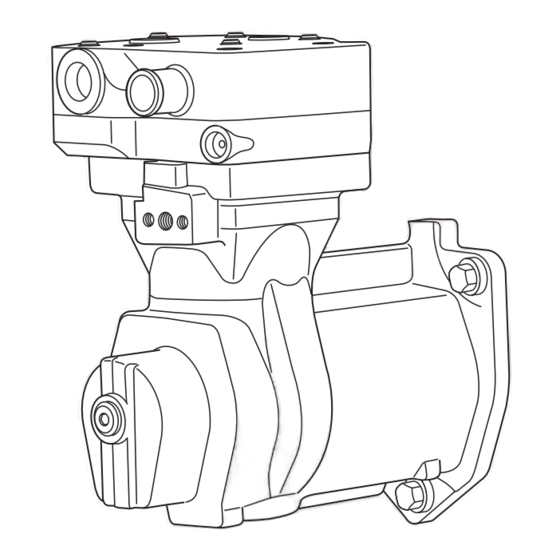

Description 1 Introduction System Saver 318 non-through drive version air compressor The WABCO System Saver 318 air compressor provides and used on Mack engines. Figure 1.1. maintains air under pressure to operate devices in the air brake and auxiliary air systems of a vehicle. It consists of two major System Saver 318 through-drive version air compressor used on subassemblies: Cylinder head and crankcase/cylinder block. -

Page 6: Operation

1003375b Figure 1.4 GOVERNOR PORT Maintenance Intervals The WABCO System Saver 318 air compressor receives inlet air, oil 1003374b and coolant from the engine, so it is important to follow the engine manufacturer’s recommendations and maintenance schedules Figure 1.3 regarding fluid levels, air filter and recommended change intervals. -

Page 7: Visual Inspection

Check water ports for leakage. Check under plate or at power steering pump for leakage. Check Check flanges flanges for cracks for cracks or breaks. or breaks. NON-THROUGH DRIVE THROUGH DRIVE 1003376b Figure 1.5 WABCO Maintenance Manual 31 (Revised 08-18) -

Page 8: Section 2: Troubleshooting

To prevent serious eye injury, always wear safe eye protection when you perform vehicle maintenance or service. Use Table A to troubleshoot the WABCO System Saver 318 air compressor. NOTE: If you have any questions or need additional information, please contact WABCO North America Customer Care at 855-228-3203. Table A: Compressor Troubleshooting Guide... - Page 9 Check oil pressure. Verify oil passage is free of obstructions. Make crankshaft bearing necessary repairs. Failed power steering pump Verify power steering pump is in correct operating order. Refer to the (through-drive version only) component manufacturer’s service instructions. All of the above Replace compressor. WABCO Maintenance Manual 31 (Revised 08-18)

- Page 10 Inspect gasket. Replace if necessary. Verify all bolts are correctly machining defect on cylinder head or torqued. If problem persists, replace cylinder head. block, defective cylinder head gasket None of the above, but condition Replace compressor cylinder head assembly. persists WABCO Maintenance Manual 31 (Revised 08-18)

-

Page 11: Section 3: Compressor Replacement

Refer to the vehicle manufacturer’s manual for Figure 3.2 additional information. The front of the WABCO System Saver 318 air compressor is mounted to the engine. Before you remove the compressor, make sure you have a replacement gasket to install with the new compressor, Mack part number 590GB2159. -

Page 12: Installation

Connect all air and water and lines leading to the compressor. Tighten per Mack specifications. Through-drive version air compressor only: If necessary, reinstall the power steering pump. Refer to the manufacturer’s maintenance manual to verify that the installation is to the correct specifications. WABCO Maintenance Manual 31 (Revised 08-18) -

Page 13: Installation

Install the sliding leaf. The two holes in the sliding leaf must be installed over the two pins on the base of the cylinder head. Figure 3.6. Figure 3.6 SLIDING LEAF VALVE CYLINDER CYLINDER HEAD HEAD ALIGNMENT ALIGNMENT SLEEVE SLEEVE 1003379a Figure 3.8 1003386a Figure 3.6 WABCO Maintenance Manual 31 (Revised 08-18) -

Page 14: Testing

Listen for air leaks. Soapy water or high frequency acoustic 90˚ +15˚/–5˚ detectors may be used to detect air leaks. Make the necessary Apply repairs. 90˚+15˚/–5˚ rotation. 1003381a Figure 3.10 WABCO Maintenance Manual 31 (Revised 08-18) - Page 15 Partnering with the transportation industry as it maps a route toward autonomous driving, WABCO also uniquely © 2018 WABCO North America – All rights reserved – MM31 / 08.2018...

Need help?

Do you have a question about the System Saver 318 and is the answer not in the manual?

Questions and answers