Table of Contents

Advertisement

Quick Links

Published 01/11

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

RHINO

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

OPERATOR'S MANUAL

© 2011 Alamo Group Inc.

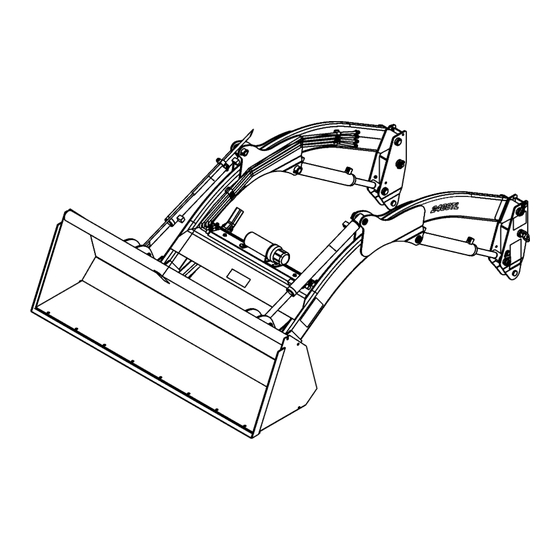

2409TL

LOADER

Part No.

F-4203C

$0.00

Advertisement

Table of Contents

Summary of Contents for RHINO 2409TL

- Page 1 READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment. C01- Cover ® RHINO 1020 S. Sangamon Ave. Gibson City, IL 60936 800-446-5158 Email: parts@servis-rhino.com © 2011 Alamo Group Inc. LOADER F-4203C Part No. $0.00...

-

Page 2: Warranty Information

To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents. -

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ... 1-1 General Safety Instructions and Practices ... 1-2 Operator Safety Instructions and Practices ... 1-4 Equipment Operation Safety Instructions and Practices ... 1-6 Connecting or Disconnecting Implement Safety Instructions and Practices ... 1-12 Transporting Safety Instructions and Practices ... 1-13 Maintenance and Service Safety Instructions and Practices ... - Page 4 Troubleshooting Guide ... 4-43 MAINTENANCE SECTION ... 5-1 Lubrication Schedule ... 5-4 Adjusting Bucket Level Indicator ... 5-4 Daily Maintenance ... 5-5 Cylinder Service ... 5-6 Lift and Bucket Cylinder Disassembly ... 5-6 Lift and Bucket Cylinder Reassembly ... 5-7 Storage ...

-

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 6: General Safety Instructions And Practices

(ROPS). Always wear seat belts. Serious injury or even death could result from falling off the tractor--particularly during a turnover when the operator could be pinned under the ROPS. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SG-3) - Page 7 Push and pull the control levers in and out several times to remove pressure. Do not work under raised Boom or Bucket unless components are securely blocked up to prevent inadvertent dropping. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY...

-

Page 8: Operator Safety Instructions And Practices

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Never allow inexperienced or untrained personnel to... - Page 9 In those conditions, personal protective equipment including an appropriate respirator must be used. If excessive dust is generated, a dust collection or suppression system should also be used during operation. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SG-32)

-

Page 10: Equipment Operation Safety Instructions And Practices

Operate the Tractor and/or Implement controls only while properly seated in the Tractor seat with the seat belt securely fastened around you. Implement may cause serious injury or death. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (S3PT-12) - Page 11 Do not raise the loader into an overhead structure or allow a raised attachment to contact overhead structures. Sudden or unexpected contact with an overhead structure could result in serious injury. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SL-05)

- Page 12 Do not work from the loader or attachments. Do now allow any riders on the loader, tractor or attachments. Falling off the loader could result in serious injury and/or tractor run over. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY...

- Page 13 Use extreme care when piling material above 6 feet high. Material could shift and fall onto the operator or bystanders. The material could crush or suffocate the operator or bystander resulting in serious injury or death. (SL-17) 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SL-15) (SL-16)

- Page 14 Turn curves or go up slopes only at low speed and using a gradual turning angle. Go up slopes with the Implement located uphill. Slow down on rough or uneven surfaces. (SPU-2) 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY...

- Page 15 Sudden or unexpected movement or dropping of the loader and attachment could result in serious injury. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY...

-

Page 16: Connecting Or Disconnecting Implement Safety Instructions And Practices

For added safety when lifting loads above the height of the operator, install a certified Falling Object Protective Structure. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY... -

Page 17: Transporting Safety Instructions And Practices

Tractor wheel contact with any wash out, drop off or the ground obstruction with a raised loader could result in the tractor tipping over and causing serious bodily injury. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Determine the maximum... -

Page 18: Maintenance And Service Safety Instructions And Practices

When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. Do not modify or alter this Implement. Implement, any of its components or any Implement function. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SL-39) (SNPO-37) - Page 19 Be alert to worn component surfaces which have sharp edges. Sharp surfaces can inflict severe laceration injuries if proper hand protection is not worn. (SG-37) 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY (SG-15) (SG-20)

-

Page 20: Storage And Parking Safety Instructions And Practices

Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY... -

Page 21: Decal Location

Rhino cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). Contact your Rhino dealer to order replacement decals. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY... - Page 22 D471 D470 00776031 03200347 55580 * Supplied by Tractor Manufacturer. Replace if missing from tractor. NOTE: Order D438 Safety Decal Sheet which includes all safety decals. 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY LEVEL DESCRIPTION LOGO Rhino, Left LOGO...

-

Page 23: Decal Description

Decal Description Rhino, Left P/N 49696 Rhino, Right P/N 51448 MODEL NAME: 2409TL P/N 54173 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Safety Section 1-19... - Page 24 A doctor familiar with this type of injury must surgically remove immediately. P/N 52740 WARNING! Lock valve when in transport or storage. P/N 52203 Loader Positions. P/N 52204 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY HYDRAULIC injected fluid Safety Section 1-20...

- Page 25 -Do not allow riders on tractor or loader. -Do not allow children or untrained persons to operate loader. D469 Crushing Hazard, Electrocution Hazard, Falling Hazard. D468 Crushing Hazard D471 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Safety Section 1-21...

- Page 26 If the manual is missing order one from your dealer. P/N 00776031 Slow Moving Vehicle Decal. Keep SMV reflector clean and visible. DO NOT transport or operate without the SMV. P/N 03200347 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Safety Section 1-22...

- Page 27 Do not use attachment if it disengages. -NEVER walk or work underneath raised loader or attachment (Located on the Quick Attach Device Only) P/N D516 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY Safety Section 1-23...

-

Page 28: Federal Laws And Regulations

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) 2409TL 01/11 © 2011 Alamo Group Inc. SAFETY... -

Page 29: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 30 This 2409TL Loader is designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize and instruct. The Assembly Section instructs the owner/operator in the correct assembly of the Front End Loader using standard and optional equipment.

- Page 31 (ROPS). Always wear seat belts. Serious injury or even death could result from falling off the tractor--particularly during a turnover when the operator could be pinned under the ROPS. 2409TL 01/11 © 2011 Alamo Group Inc. INTRODUCTION (SG-30)

- Page 32 INTRODUCTION The RHINO 2409TL Loader is designed for two or four-wheel drive tractors. They are intended to lift only loose materials that will fit in the bucket. All cylinders are double-acting. Parking stands support loader so tractor can be “driven in” for quick attaching.

-

Page 33: Attention Owner/Operator

Alamo Group within thirty days of delivery of the implement. 3. Record the Loader Model and Serial Numbers on the Warranty page. Keep this as part of the permanent maintenance file for the implement. 2409TL 01/11 Introduction Section 2-5 © 2011 Alamo Group Inc. -

Page 35: Assembly And Connecting The Loader Section

ASSEMBLY AND CONNECTING THE LOADER SECTION Assembly Section 3-1... -

Page 36: Assembly Instructions

Make sure the loader is properly attached to the tractor and the retaining pins securely lock the loader into position. Improper mounting of the loader onto the tractor can result in the loader falling causing serious injury. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY... - Page 37 Sudden or unexpected movement or dropping of the loader and attachment could result in serious injury. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY...

-

Page 38: Proper Ballasting And Wheel Spacing

Spread front wheels to maximum distance. Spread rear wheels to maximum distance. Add rear wheel weight, rear ballast box or implement. Make sure there is 20% of total weight on rear axle. 2409TL 01/11 Assembly Section 3-4 © 2011 Alamo Group Inc. -

Page 39: Dismounting And Mounting Mid-Mount Loader

(tires can be off ground). 5. Stop engine. Allow tractor front end to lower by relaxing ONLY lift cylinders with control lever. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY saddle... - Page 40 Note: If front wheel spacings were changed while loader was off tractor, tire clearances must be checked and possibly adjusted to insure proper clearances. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY Assembly Section 3-6...

-

Page 41: Attaching Pin On Bucket

5. Set parking brake. Rotate parking stands from storage position by removing linch pins and clevis pins. Reinstall clevis pins and linch pins when parking stands are in operation position (See Figure Asm-L-0001). 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY (SL-26) (SL-27) - Page 42 Relax lift cylinders and bucket cylinder by moving each control lever in both directions. Disconnect hydraulic hoses from tractor. 11. Start tractor engine and release brakes. Slowly back tractor out of loader. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY Assembly Section 3-8...

-

Page 43: Assembling Quick Attach Device

1. Quick attach device is pre-assembled at the factory. 2. Unband the quick attach device and wood blocks. (Figure Asm-L-0012) 2409TL 01/11 Assembly Section 3-9 © 2011 Alamo Group Inc. -

Page 44: Installing Quick Attach Device

2. Attach bucket leveling rod indicator (supplied with loader), to outside of right ear on quick attach as shown. Figure Asm-L-0014_A. Secure bucket leveling rod indicator with the ear at the lower end of the rod bucket cylinder and inside ear on right side of bucket. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY... -

Page 45: Connecting Attachment

If there is a gap of more than 1/8” or if the pins are not firmly seated do not use the attachment. Contact your dealer before using the attachment. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY Assembly Section 3-11... - Page 46 Do not use an attachment that is not securely attachment that is not securely attached to the quick hitch. The attachment could fall resulting in severe crushing injuries or death to the operator or bystanders. 2409TL 01/11 © 2011 Alamo Group Inc. ASSEMBLY...

-

Page 47: Operation Section

OPERATION SECTION Operation Section 4-1... - Page 48 Pictures contained in this section are intended to be used as a visual aid to assist in explaining the operation of a 2409TL loader and are not necessarily of a 2409TL loader or exact tractor. Some pictures may show shields removed for purposes of clarity.

-

Page 49: Standard Equipment And Specifications

Reach with Attachment on Ground Attachment Rollback Angle Digging Depth Overall Height in Carry Position (at Boom Arm Top) (Manufacturers estimated specifications and design subject to change without notice.) 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION 3890 lbs. 2880 lbs. -

Page 50: Operator Requirements

NOTE: Hearing loss from loud noise [from tractors, chain saws, radios, and other such sources close to the ear] is cumulative over a lifetime without hope of natural recovery. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... - Page 51 If you are using a tractor equipped with a cab, make sure the cab is rated for appropriate environmental exposure. Be safe and always wear proper protection. Short or long term exposure to certain chemicals and materials can result in serious injury or death. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-22)

-

Page 52: Personal Protective Equipment (Ppe)

Protective Eye Glasses, Goggles, or Face Shield • Hard Hat • Steel Toe Safety Footwear • Gloves • Hearing Protection • Close Fitting Clothing • Respirator Filter Mask operating conditions) OPS-L- 0021 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-41) (depends Operation Section 4-6... -

Page 53: Tractor Requirements

Most tractor’s have different settings for operating and transporting lighting. Refer to the tractor operator’s manual for using the tractor’s light switch and operating the turn signals. OPS-B- 0017 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-7) bucket load on rear tires... -

Page 54: Tractor Ballast

Before getting onto the tractor, the operator must read and completely understand the implement and tractor operator manuals. If any part of either manual is not completely understood, consult an authorized dealer for a complete explanation. OPS-L- 0022 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... -

Page 55: Boarding The Tractor

Use hand rails and steps when exiting the tractor. Be careful of your step and use extra caution when mud, ice, snow or other matter has accumulated on the steps or hand rails. Use all handrails and steps for support and never rush or jump off the tractor. OPS-L- 0024 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... -

Page 56: Starting The Tractor

Never bypass the ignition switch by short circuiting the starter solenoid. After the tractor engine is running, avoid accidental contact with the tractor transmission to prevent sudden and unexpected tractor movement. OPS-L-0025 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-23) -

Page 57: Pre-Operation Inspection And Service

Perform repairs and replacement of damaged and missing parts as soon as noticed. By performing a thorough pre-operation inspection and service, valuable down time and repair cost can be avoided. OPS-L-0026 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... -

Page 58: Tractor Pre-Operation Inspection/Service

Relieve hydraulic pressure before performing maintenance or repairs. Use gloves and eye protection when servicing hot components. Contact with a hot surface or fluid can cause serious injury from burns or scalding. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... -

Page 59: Mount Assembly

• Ensure all pins are in place and fastened with screws. • Ensure frame is properly mounted to tractor hardware properly tightened. OPS-L-0004_A 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION installed Operation Section 4-13 (SG-15) Mount Frame Assembly... - Page 60 • Inspect the condition of the bucket lug weldments. • Inspect condition of bushings. OPS-L-0007_A 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION along hoses, Operation Section 4-14 Hydraulic Hoses Bucket Pins...

- Page 61 The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature: DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Condition at Start of Shift...

- Page 62 The Control Valve Lock functions correctly The Pivot Pins are properly lubricated The Loader Storage Stands are in good condition Operator’s Signature: DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Condition at Start of Shift...

-

Page 63: Driving The Tractor And Loader

Failure to maintain adequate vision of the public roadway and traffic can result in serious injury or even death. (STI-10) 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Determine the maximum... -

Page 64: Driving The Tractor And Loader

Use extreme caution when operating on steep slopes. Keep the tractor in a low gear when going downhill. DO NOT coast or free-wheel downhill. OPS-L-0030 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION... -

Page 65: Operating The Tractor And Loader

Tractor control failure occur while operating, immediately shut down the Tractor and perform repairs before resuming operation. Serious injury and possible death could occur from not maintaining this Implement and Tractor in good operating condition. (SG-36) 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SL-21) - Page 66 Do not work from the loader or attachments. Do now allow any riders on the loader, tractor or attachments. Falling off the loader could result in serious injury and/or tractor run over. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION...

- Page 67 Use extreme care when piling material above 6 feet high. Material could shift and fall onto the operator or bystanders. The material could crush or suffocate the operator or bystander resulting in serious injury or death. (SL-17) 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SL-15) (SL-16)

- Page 68 If you are unable to clearly see these types of items discontinue operating. Contact with unseen vehicles, bystanders, obstructions, or drop-offs can cause serious injury. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION...

- Page 69 Always have a heavy attachment, such as a bucket mounted on loader when it is removed from tractor. It is important not to put excessive weight on parking stands with lift cylinder retraction. Damage may result. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SPU-3)

-

Page 70: Operating The Loader

Loaders with 1-lever control, ease lever back toward you to lift and roll back bucket. With series valve, prevent loader stall by not lifting and rolling back at the same time. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Operation Section 4-24... - Page 71 Time is lost if two or more attempts are made to fill the bucket on each pass. 2409TL 01/11 Operation Section 4-25 © 2011 Alamo Group Inc.

-

Page 72: Lifting The Load

Tilt bucket forward while raising to maintain bucket angle. CARRYING THE LOAD Position bucket just below tractor hood for maximum stability and visibility, whether bucket is loaded or empty. 2409TL 01/11 Operation Section 4-26 © 2011 Alamo Group Inc. - Page 73 When transporting the load, keep bucket as low as possible, to avoid tipping, in case a wheel drops in a rut. 2409TL 01/11 Operation Section 4-27 © 2011 Alamo Group Inc.

-

Page 74: Dumping The Bucket

Move tractor in as close as possible to side of vehicle, then dump bucket. LOWERING THE BUCKET After bucket is dumped, back away from vehicle while lowering and rolling back bucket. 2409TL 01/11 Operation Section 4-28 © 2011 Alamo Group Inc. -

Page 75: Operating With Float Control

Float will also prevent mixing of surface material with stockpile material. Float position will reduce the chance of surface gouging when removing snow or other material. 2409TL 01/11 Operation Section 4-29 © 2011 Alamo Group Inc. -

Page 76: Loading From A Bank

If the pile sides are too high and liable to cause cave-in, use loader to break down the sides until a slot can be cut over the top. 2409TL 01/11 Operation Section 4-30 © 2011 Alamo Group Inc. - Page 77 Another method for large dirt piles is to build a ramp approach to the pile. It is important to keep the bucket level when approaching a bank or pile. This will help prevent gouging the work area. 2409TL 01/11 Operation Section 4-31 © 2011 Alamo Group Inc.

-

Page 78: Peeling And Scraping

Make additional passes until desired depth is reached. During each pass, use only bucket control while working depth. This will allow you to concentrate on controlling bucket angle to maintain a precise cut. 2409TL 01/11 Operation Section 4-32 © 2011 Alamo Group Inc. -

Page 79: Loading Low Trucks Or Spreaders From A Pile

Do not roll bucket over and attempt to backgrade. This type of use can cause severe overloading of bucket cylinders when fully extended, possibly causing bucket cylinder rods to become bent. 2409TL 01/11 Operation Section 4-33 © 2011 Alamo Group Inc. - Page 80 Do not use bucket in dumped position for bulldozing. This method, shown above, will impose severe shock loadings on dump linkage, bucket cylinder and tractor. 2409TL 01/11 Operation Section 4-34 © 2011 Alamo Group Inc.

- Page 81 OPERATION Leave dirt in bucket. Dumping on each pass wastes time. Operate tractor at right angles to ditch. Take as big a bite as tractor can handle without lugging down. 2409TL 01/11 Operation Section 4-35 © 2011 Alamo Group Inc.

-

Page 82: Handling Large Heavy Objects

Never lifting large objects with equipment that does not have an anti-rollback device. • Moving slowly and carefully, avoiding rough terrain. • Tilt bucket forward while lifting to maintain bucket angle. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Operation Section 4-36... -

Page 83: Operating Bale Spear (Optional Attachment)

Load bale spear by approaching from round end to prevent cutting strings or puncturing plastic or net wrap.Tilt bale spear upward to prevent bale from falling off of spear, 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Operation Section 4-37... -

Page 84: Loader Storage

Store the loader in a clean, dry place resting securely on parking stands at ground level. • Use spray touch-up enamel where necessary to prevent rust and maintain the appearance of the loader. OPS-L-0010_A 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION pins Perform Operation Section 4-38... -

Page 85: Transporting The Tractor And Implement

Serious injury could result. (SL-04) 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-10) Determine the maximum... - Page 86 Use extreme caution and avoid hard applications of the tractor brakes when towing heavy loads at road speeds. Never tow the implement at speeds greater than 20 MPH (32 kph). OPS-U- 0018 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Locking the wheels...

-

Page 87: Transporting On Public Roadways

Consult an authorized tractor dealer for lighting kits and modifications available to upgrade the lighting on older tractor models. OPS-U- 0021 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION (SG-6) Remember that roadways are primarily designed for... -

Page 88: Hauling The Tractor And Implement

OPS-U- 0025 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION Operation Section 4-42... -

Page 89: Troubleshooting Guide

TROUBLE Loader slow or will not lift and/or dump Loader chatters or vibrates when raising or lowering. Oil Leaks 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION POSSIBLE CAUSE Hydraulic oil too heavy. Oil filter plugged. Hydraulic pump worn. Oil line restricted or leaking. - Page 90 PROBLEM Insufficient lift capacity Excessive wear on bucket cutting edge Bucket cutting edge not flat on theground. 2409TL 01/11 © 2011 Alamo Group Inc. OPERATION POSSIBLE CAUSE Load is greater than boom lift capacity. Improper hydraulic pump operation. Internal lift cylinder leakage.

-

Page 91: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1... -

Page 92: Maintenance

Do Not fill fuel tank while engine is running. Refuel only after engine has cooled down. If fuel is spilled, move machine away from the area of the spill and avoid creating any source of ignition until the fuel has evaporated. 2409TL 01/11 © 2011 Alamo Group Inc. MAINTENANCE... - Page 93 These parts are made and tested to Rhino specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard. Use genuine Rhino parts for economy and safety. 2409TL 01/11 © 2011 Alamo Group Inc. MAINTENANCE...

-

Page 94: Lubrication Schedule

Loosen u-bolt hex nuts and adjust level guide tube along bucket cylinder until end of guide tube is flush wtih end of rod. Tighten u-bolt hex nuts. 2409TL 01/11 Maintenance Section 5-4 © 2011 Alamo Group Inc. -

Page 95: Daily Maintenance

• Tighten all connections before starting engine or pressurizing lines. NOTE: If any fluid is injected into skin, obtain medical attention immediately or gangrene may result. 2409TL 01/11 © 2011 Alamo Group Inc. MAINTENANCE Maintenance Section 5-5... -

Page 96: Cylinder Service

6. Clean all parts including cylinder tube, in a suitable cleaning solvent, then use air pressure to blow any dirt or excess solvent from all parts. 7. Examine all parts for wear or damage and replace, if necessary. 2409TL 01/11 © 2011 Alamo Group Inc. MAINTENANCE... -

Page 97: Lift And Bucket Cylinder Reassembly

NOTE: When loader hydraulics are disconnected from tractor, the tractor hydraulic circuit must be completed. Failure to do so will result in tractor hydraulic pump damage. 2409TL 01/11 © 2011 Alamo Group Inc. MAINTENANCE... - Page 98 1. Store loader with attachment securely attached. 2. Place dust caps on hydraulic quick couplers. 3. Do not remove attachment from stored loader. 4. Do not allow children to play on or around loader. 2409TL 01/11 Maintenance Section 5-8 © 2011 Alamo Group Inc.

-

Page 99: Proper Torque For Fasteners

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads. 2409TL 01/11 Maintenance Section 5-9 © 2011 Alamo Group Inc. - Page 100 MAINTENANCE 2409TL 01/11 Maintenance Section 5-10 © 2011 Alamo Group Inc.

- Page 101 MAINTENANCE 2409TL 01/11 Maintenance Section 5-11 © 2011 Alamo Group Inc.

-

Page 102: Limited Warranty

ATTENTION: Purchaser should fill in the blanks below for his reference when buying repair parts and/or for proper machine identification when applying for warranty. Rhino Implement Model___________________________ Date Purchased _________________________________ ATTENTION: READ YOUR OPERATOR'S MANUAL RHINO LIMITED WARRANTY Serial Number_________________________ Dealer _______________________________ RHINO ® 1020 S Sangamon Ave. Gibson City, IL 60936 800-446-5158 Email: parts@servis-rhino.com... - Page 103 To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety require- ments of tractor operators: REQUIRED OF THE OWNER:...

- Page 104 2409TL LOADER 2409TL-SOM-01/11 P/N F-4203C Printed U.S.A...

Need help?

Do you have a question about the 2409TL and is the answer not in the manual?

Questions and answers