Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hettich BlueMax Mini Type 3

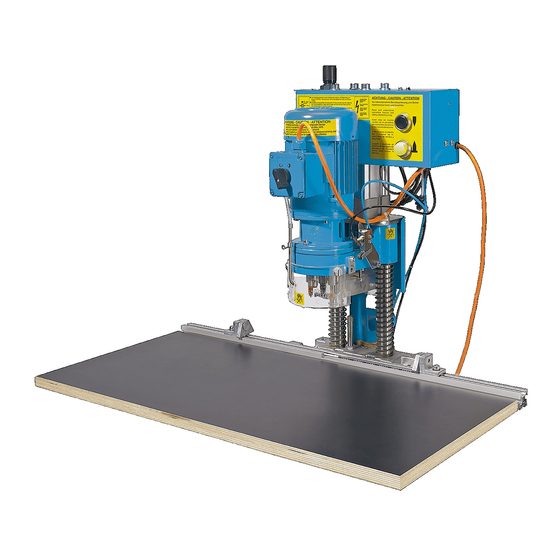

- Page 1 Operating manual BlueMax Mini Type 3...

-

Page 2: Ec Declaration Of Conformity

Automatic Drilling Unit – BlueMax Mini Type 3 , as a machine from Paul Hettich GmbH & Co. KG, Vahrenkampstraße 12 - 16, D-32278 Kirchlengern is a machine within the meaning of the Machinery Directive and that it conforms to the following applicable provisions:... -

Page 3: Foreword

Customer Service Paul Hettich GmbH & Co. KG, Vahrenkampstrasse 12 - 16, D-32278 Kirchlengern Operating manual: Paul Hettich GmbH & Co. KG© 2017 Copyright to the operating instructions The copyright to this operating manual remains with Paul Hettich GmbH & Co. KG. -

Page 4: Table Of Contents

Contents EC Declaration of Conformity 7. Operation Foreword 1. Preparing machine Base frame for BlueMax Mini Type 3 Contents Drilling spindles Drill bits Connecting to extractor system 1. Introduction Connecting to compressed air supply Connecting to the power supply 1. Introduction Add on ”swivel unit with sensor roller“... -

Page 5: Introduction

The machine must only be assembled and installed by persons always ensured when using genuine replacement parts from instructed to do so by Paul Hettich GmbH & Co. KG. This also the applicable replacement parts list. applies in particular to starting it up for the first time. -

Page 6: Verification Of Instruction

Confirmation I hereby confirm that I have read and understood the operating manual for the machine: Designation BlueMax Mini Type 3 Type Automatic drilling and insertion machine Machine no. I furthermore undertake to observe and follow the general... -

Page 8: General

Machine life used for its intended purpose! 4. Liability The BlueMax Mini Type 3 is a semi automatic drilling and insertion machine for panel type workpieces. This machine must only be used for working on flat panels made of wood- based materials, such as chipboard, blockboard panels, MDF, solid wood or similar materials. -

Page 9: Description Of The Machine

The situations above describe some of the residual hazards Space required by the machine which, despite being impermissible, may occur and harm the The space required by the BlueMax Mini Type 3 is largely health of staff. determined by the dimensions of the machine base frame. -

Page 10: Safety

Safety 3. Safety 1. Information on signs, symbols and markings The safety advice in the operating instructions is structured as follows: 1. Information on signs, symbols and markings 2. General DANGER 3. Safety advice for the user company This danger advice draws attention to an immediately 4. -

Page 11: General

Work requiring specialised knowledge (e.g. electrical, pneumatic system) must only be carried out by persons WARNING specifically trained and suitable to do so. Fire risk! Before attempting any work on the machine, turn the main Grinding and welding work must never be performed switch to the ”0“... -

Page 12: Safety Advice For The User Company

Safety Pneumatic energy through the supply connection on the machine frame. Make sure that all machine components are WARNING depressurised and any stored energy is dissipated. As part of the installation process, the owner will provide a mechanical Hearing damage warning! main cock at which the machine can be disconnected from Local conditions may produce elevated sound pressure the compressed air supply. -

Page 13: Work Which May Be Done By The Operating Personnel

• The generally recognised code of occupational health and 9. Safety advice for carrying out maintenance work safety as well as accident prevention regulations must be • Maintenance work must only be performed by observed the manufacturer‘s skilled personnel or under the •... -

Page 14: Description Of The Machine

For your own safety, please instruct a qualified electrician to connect the machine. You will find the applicable connection specifications on the rating plate on the machine. Motor overview - BlueMax Mini Type 3: Volts (V) Phases (Ph) Version Hertz (Hz) -

Page 15: Controls

HINWEIS N N N 3. Setting up NOTE For further Technical Specifications, refer to the WARNING documentation provided by the manufacturers. Setup work may only be performed by qualified staff who, Unauthorised changes and modifications to the system are on the basis of their specialised training, experience and not permitted for safety reasons and rule out any liability on instruction, possess sufficient knowledge of the part of the manufacturer for any resultant damage. -

Page 16: Labelling

Description of the machine 5. Labelling Area: motor / drive Reminder to unplug the mains power plug before changing Area: entire machine tools Warning of the risk of hands getting crushed Fig. 9: Labelling – entire machine Fig. 12: Labelling – motor / drive Area: hold-down clamps Warning of the risk of hands getting crushed Area: entire machine... -

Page 18: Transportation And Installation

Transportation and installation 5. Transportation and installation 1. Transportation The machine must only be transported and installed by companies / persons instructed / authorised to do so by the 1. Transportation manufacturer or under the manufacturer‘s supervision. 2. Internal transportation After moving the machine, every part of it must be checked for transportation damage as possible harm may impair 3. -

Page 19: Checking Delivery For Missing Items

The BlueMax Mini Type 3 comes in secure shipment packaging for safe transportation. A number of components must be installed to make the machine ready for operation. -

Page 20: Start Up

Start up 6. Start up 1. General The instructions described here are to be understood as minimum recommendations. Depending on operating 1. General conditions, they may need to be broadened in order to maintain the machine‘s working quality. 2. Starting up for the first time Servicing and maintenance work in specific disciplines 3. -

Page 21: Starting Up For The First Time

2. Starting up for the first time Establish the cause of any malfunctions with the machine shut down and made safe and have it rectified by a Before starting up the machine for the first time, observe the qualified and skilled person trained to do so or eliminate the following: malfunction yourself if you are in possession of the necessary qualification. -

Page 22: Operation

Operation 7. Operation 1. Preparing machine The BlueMax Mini Type 3 is shipped in cardboard packaging. A number of parts and components must be installed to 1. Preparing machine make the machine ready for operation. Once assembled, the Base frame for BlueMax Mini Type 3 machine must be thoroughly cleaned. -

Page 23: Connecting To Extractor System

Drill bits Connecting to compressed air supply The machine is intended for use with solid carbide drill bits in To connect the machine to the compressed air supply a length of 57 mm and shaft diameter of 10 mm. Insert drill system, push the air supply line onto the air filter using bits all the way, chucking faces turned towards the threaded quick release connector... -

Page 24: Add On "Swivel Unit With Sensor Roller

Operation Add on ”swivel unit with sensor roller“ 3. Performance test! If compressed air is escaping anywhere else, recheck the hose connections to make sure they are pushed in all the way. NOTE Add on ”hold-down clamp“ Before fitting accessories, disconnect machine from compressed-air supply and unplug from mains power! NOTE Position swivel unit against drilling unit block and attach on... -

Page 25: Preparing For Work

2. Preparing for work Pendulum stops The stop profile is factory set to 0 at the centre of the main spindle, making it possible to precision adjust stops to the WARNING left and right on the basis of the millimetre scale. Warning - Hand injuries! After undoing the clamping screw, set stops to the required dimension and retighten. -

Page 26: Die

Operation Hold-down clamp Mount the insertion die onto the swivel unit with two hexa- The hold-down clamps are automatically tensioned gon socket screws. If you wish to use any other die, e.g. for on actuating the manual valve or foot pedal and can be connecting fittings or mounting plates, you must exchange released again by pressing the yellow button the hinge insertion die, including the fixing screws. -

Page 27: Fitting Hettich Hinges

(C dimension) on the scale. Fig. 33: Manually operated Fig. 34: Foot switch valve 2. The Hettich hinge for fast installation on the cup side can now be fitted by hand. Fig. 31: Fence with hexagon socket screw... -

Page 28: Pressing In

Operation Pressing in 3. Initiate the insertion process by pressing manually operated valve 1 and terminate by letting it go again. 1. Clip hinge with premounted sockets into the insertion die Move up the hinge insertion die. Release hold-down clamp for hinges and clip hinge arm in between the retaining using lower momentary switch springs. -

Page 30: Troubleshooting

Troubleshooting / Servicing and maintenance 8. Troubleshooting 8. Troubleshooting Machine malfunctions must only be rectified by qualified 9. Servicing and maintenance staff instructed to do so by the person responsible. In identifying the source of malfunction attention must be Drilling head paid to the entire area surrounding the machine. -

Page 31: Taking Out Of Service

Taking out of service / Disposal Labelling, information signs Scrapping Labelling/information signs must be If the machine is ever taken out of service for good, the laws • cleaned with a cloth, and regulations on disposal in force at that time must be •... -

Page 32: Replacement And Expendable Parts

* These replacement part nos. only apply to the standard 4-spindle 52/5.5 mm drilling unit. A list of parts for configuring of conformity given by Paul Hettich GmbH & Co. KG as manu- other drilling unit is provided at the end of this table. - Page 33 1321 Handle rod 1671 Plug connector NW 7.2 1322 Pan head screw DIN 923 M 8x6 1672 Switchover valve toggle switch 1/8” 1353 Direkta ll 38 mm 1673 AND valve 1/8” 1428 Clamping plate 1676 Cable band T 40 R 1429 Bolt for clamping plate 1680...

- Page 34 Replacement and expendable parts 1800 Bench frame 1570 BoWex coupler assy, drilling unit ø 10, motor ø 19 for 1.3 kW motor 1801 Stop block 1802 Shaft support with ø 20 shaft Drilling pattern, 4-spindle 38/8 mm 1803 Tape measure 1188 Special drilling unit block 1804...

-

Page 35: Exploded Drawings

Fig 38: Exploded drawing 1 1551 1551 1428 1552 1452 1530 1454 1453 1251 1248 1554 1454 1250 1252 1247 1554 1429 1554 1249 1223 1179 1167 1451 1262 1256 1102 1258 1257 1151 1151 1173 1221 1173 1105 1105 1151 1253 1106... - Page 36 Replacement and expendable parts Fig 40: Exploded drawing 3 1654 1638 1125 1682 1690 1689 1665 1659 1671 1688 1656 1687 1663 1661 1660a 1660a 1669 1662 1660 1691 1651 1680 1265 1760 1163 1760 1685 1668 1669 1684 1659 1260 1225 1664...

- Page 37 Fig 42: Exploded drawing 5...

-

Page 38: Pneumatic Circuit Diagrams

Option Connection for Option hold-down clamp Swivel unit Hold-down clamp 1766 Connection for hold-down clamp Fig. 43: BlueMax Mini Type 3 Option Connection for hold-down Hold-down clamp 1766 clamp Option Swivel unit Fig. 44: BlueMax Mini Type 3 with accessories... -

Page 39: Wiring Diagrams

Wiring diagrams optional optional (only with CE electrics) (only with CE electrics) 1 and 2: gr; 3 and 4: br; 5 and 6: sw; 1 and 2: bn; 3 and 4: bl; PE: gr/ye PE: gr/ye UL/CSA: UL/CSA: 1 and 2: rd; 3 and 4: br; 5 and 6: sw; 1, 2, 3 and 4: sw;... - Page 40 Paul Hettich GmbH & Co. KG Vahrenkampstrasse 12 - 16 32278 Kirchlengern, Germany Phone.: +49 52 33 / 77 - 0 www.hettich.com...

Need help?

Do you have a question about the BlueMax Mini Type 3 and is the answer not in the manual?

Questions and answers