Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mithraeum Brewiks 500

- Page 1 Users%manual%for%Brewiks%500%USA% v.!2.0!

-

Page 3: General Safety Instructions

Please! read! these! through! carefully! and! completely! before! you! get! going!on!your!first!brew.!If!you!follow!these!notes!and!instructions!to!the!letter,! your!Brewiks!will!work!to!your!complete!satisfaction!and!give!you!a!long!life!of! service.! The! manufacturer,! Mithraeum! d.o.o.! hereby! declares! that! the! product! named! "Brewiks"! in! these! Instructions! to! which! this! Declaration! refers,! complies! with! the! following! European! Directives:!EMC! 2004/108/EC,! Low! Tension! 2006/95/EC! Details!of!manufacturer:! Mithraeum!d.o.o.! -

Page 4: Special Safety Instructions

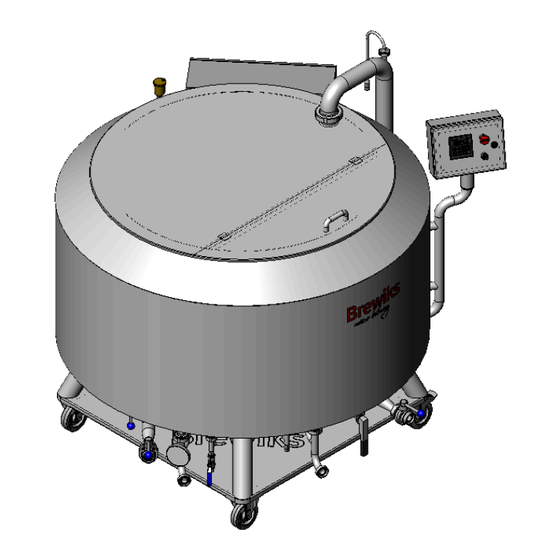

d) Lay!the!mains!cable!so!that!it!cannot!come!into!contact!with!sharp4edged! objects.!The!cable!must!be!complete!uncoiled.!! e) If! you! use! an! extension! lead,! it! should! have! the! same! current! capacity.! This!must!also!be!completely!uncoiled.!Do!not!use!a!multiple!socket!unit! since! our! device! is! too! powerful.! Avoid! overloading! the! electric! fuse! protection.! Because! of! the! Brewiks! heavy! current! requirements,! do! not! switch!on!any!other!large!current4consuming!devices!on!the!same!circuit.! Fire%hazard!! f) The! Brewiks! may! only! be! used! for! the! purpose! intended! and! with! its! safety!devices!in!flawless!condition.!Make!sure!every!time!before!you!use! - Page 5 3. Components,and,scope,of,delivery, For!the!parts!of!the!device!and!scope!of!delivery,!please!see!the!figure!below:! 4. Technical,Data,on,the,Brewiks, Brewiks!500! ! Weight:!! Mash!tun!is!500!kg!and!Lauter!tun!150!kg! Dimensions:!! ! Mash!tun:!180!cm!(L)!x!180!cm!(W)!x!160!cm!(H)! Lauter!tun:!150!cm!(L)!x!150!cm!(W)!x!90!cm!(H)! Heating!coil:!! ! 2x!12.000!W! Pump:!! 1!X!450!watt!–!with!rotation!speed!control! Power!supply!connection!! 240!V,!60!Hz! Minimum!fuse!protection:!! 63!A! Total!power!consumption:!! 24,5!kW! Cooling:! Pipe!heath!exchanger!4optional! Contents:! Brew!volumen:!max!700!l!of!wort! Malt!quantity:!! Maximum!malt!quantity!225!kg! Max.!filling!level:!! 730!l! Min.!filling!level:! 200!l!

- Page 6 5. Setting,up,the,Brewiks,, The! Brewiks! should! be! set! up! before! use! or! before! brewing! commences! on! a! robust,!stable!and!horizontal!base.!Note!that!the!Brewiks!when!filled!can!weigh! up! to! 1.300! kg! and! is! filled! with! boiling! hot! worth.! Circulatory! pumping! of! the! contents! during! the! brewing! process! assumes! that! the! device! is! set! up! horizontally.! Avoid! an! unstable,! uneven! base! surface.! During! brewing,! the! Brewiks! must! not! be! moved.! Keep! children! and! the! infirm! well! away! from! the! device! when! in! use.! Equally! avoid! direct! sunlight,! as! well! as! extreme!

-

Page 7: Before The First Use

8. Before,the,first,use,, Brewiks!500!needs!electricity!and!cold!water!for!full!operation.!! Heating%system% Heating! system! works! with! pressurized! water.! Before! first! use! adequately! trained! personnel! needs! to! fill! water! in! the! system.! This! is! done! with! standard! tap! water.! Under! main! unit! is! inlet! pipe,! which! needs! to! be! connected! to! cold! water.! Water! pressure! needs! to! be! 1! bar;! this! is! seen! on! manometer! installed! near!filling!pipe.!When!water!goes!in!then!air!needs!to!go!out.!Air!release!valve!is! on!topside!of!main!unit.!Air!is!released!through!small!black!plastic!screw,!which! - Page 8 Manometer!and!filling!pipe! Electrical%system% Before! first! use! adequately! trained! personnel! needs! to! connect! Brewiks! to! electricity.! New! Brewiks! unit! is! without! power! cable.! Power! cable! needs! to! provide! adequately! trained! personnel! and! connect! Brewiks! electricity! box! to! power!source.!Adequately!trained!personnel!need!to!provide!appropriate!cable! and!power!plug.!At!the!end!of!main!user!manual!is!electrical!plan!where!is!seen! consumption!of!Brewiks!heaters,!pumps!and!electrical!components.!

-

Page 9: Water Connection

Power!connection!in!electrical!box! 9. Water,connection, Brewiks! 500! needs! electricity! and! cold! water! for! full! operation.! ! Cold! water! is! used!for:! 1. Filling!mash!tun!with!water! 2. Condensing!steam!on!condensing!unit!(optional!equipment)! 3. Heating! water! for! sparging.! Brewiks! have! built! in! heat! exchanger! for! heating!cold!water!for!sparging!with!main!heaters!(optional!equipment)! 4. Cooling! down! the! wort! with! built! in! pipe! heat! exchanger! (optional! equipment)! 5. - Page 10 1. Filling!mash!tun!with!water! Valve!on!lower!part!of!pump!have!1/2”!male!thread!connection.!This!is!suitable! to! use! standard! graden! connection! and! garden! hose.! Same! valve! is! used! to! fill! water!in!side!of!mash!tun!and!also!for!total!cleaning.!At!end!of!brewing!proces! this!valve!stays!open!and!all!water!will!drain!out!of!brewery.!

- Page 11 2. Condensing!steam!on!condensing!unit!(optional!equipment)! Blue! hose! represent! standard! garden! hose! for! cold! water.! Connection! is! 1/2”! male!thread.!Cold!water!is!used!for!condensing!steam!when!boiling!is!in!process.! Hot!water!and!maybe!some!amount!of!steam!go!out!on!bottom!of!conceding!unit.! On!end!of!condensing!unit!is!used!same!connection!as!on!other!valves.!! Warning:% Condensing% unit,% hot% water% and% steam% on% outlet% of% condensing% unit%are%very%hot%during%brewing%process.%Be%aware%of%potencial%burn.%%...

- Page 12 3. Heating!water!for!sparging.!Brewiks!have!built!in!heat!exchanger! for!heating!cold!water!for!sparging!with!main!heaters!(optional! equipment)! Inlet! for! heating! cold! water! for! sparging! uses! 1/2”! male! thread! connection! so! standard!garden!connection!and!hose!can!be!used!to!supply!cold!water.!During! sparing! processes! is! heating! system! in! mash! tun! already! hot! and! main! heaters! are! heating! system! and! cold! water! heats! up! in! real! time! for! sparging.! Outlet! of! heat!exchanger!and!inlet!on!lauter!tun!for!sparging!uses!special!quick!connection! and! special! red! hose,! which! is! provided! with! unit.! Red! hose! seen! on! picture! above!is!provided!with!unit!and!this!hose!is!used!only!during!sparging!process.!!

- Page 13 4. Cooling!down!the!wort!with!built!in!pipe!heat!exchanger!(optional! equipment)! Brewiks! have! built! in! wall! counter! flow! wort! chiller! –! pipe! heat! exchanger! (optional!equipment).!!In!inner!pipe!is!wort!and!on!outer!pipe!is!cooling!liquid.! Cooling! liquid! can! be! cold! water! or! glycol! cooling! system.! When! cold! water! is! used,! then! this! water! can! be! used! for! next! brewing! proces,! because! cold! water! heats!up!while!wort!is!cooling!down.!! Connection!on!inlet!and!outlet!of!heat!exchanger!is!1/2”!male!thread!connection! so!standard!garden!connection!and!hose!can!be!used!to!supply!cold!water.!Hot!

-

Page 14: Servicing And Maintenance

5. Filling!water!in!heating!system! Cold! water! is! filled! in! pipe! installed! under! mash! tun! to! fill! water! in! heating! system.! Connection! on! inlet! pipe! is! ¾! male! thread! connection! so! standard! garden!connection!and!hose!can!be!used!to!supply!cold!water.!(How!to!fill!water! in!heating!system!please!see!chapter!Before!first!use)! Servicing,and,Maintenance, All! component! used! are! standard! components! and! can! be! replace! with! same! component!or!with!substitute!components.!! Waste,disposal, Take! care! of! our! environment;! electrical! components! do! not! belong! in! the! - Page 15 Working,with,the,Brewiks, Notes,on,the,circulation,pump, Circulation! pipe! is! used! for! mixing! when! mash! tun! is! in! use! (heating! water,! mashing!and!boiling)!and!for!pumping.!Pump!is!also!used!to!pump!worth!from! mash! tun! to! lauter! tun! and! back! and! can! also! be! used! as! pump! in! brewery! for! pumping!from!one!tank!to!another.!! Note,on,the,lid,of,mash,tun, During! boiling,! the! lid! helps! to! reach! the! temperatures! quicker.! At! higher! temperatures!water!condenses!on!the!underside!of!the!lid.!When!lifting!the!lid,! care!should!be!taken!that!the!rim!of!the!lid!is!held!over!the!mouth!of!the!kettle!so! that!the!condensation!runs!off!(with!lid!held!slanted)!back!into!the!tun.!!!

- Page 16 8.%Bottom% Valve!“5.%Whirlpool”!is!used!to!pump!wort!and!grains!from!mash!tun!to!lauter! tun!before!lautering.!Same!valve!is!also!used!to!make!whirlpool!effect!in!lauter! tun!when!wort!is!pumped!from!mash!tun!to!lauter!tun.! Valve!“6.%Side”!is!used!for!recirculation!before!lautering.!Before!lautering!starts! wort!can!be!recalculated.!Wort!is!pumped!out!of!“8.%Bottom”!valve!and!pumped! in!through!valve!“6.%Side”.!On!valve!“8.%Bottom”!it!is!advisable!to!put!sight!glass! to!see!how!clear!is!wort.!! Valve!“7.%Side%bottom”!is!used!to!pump!wort!out!after!whirlpool.!! 9.%Hot%wort%inlet% 10.%Cold%wort%outlet% Counter!flow!pipe!heat!exchanger!is!used!to!cool!down!hot!wort!after!whirlpool! is!done.!For!proper!use!of!heat!exchanger!cold!water!or!glycol!cooling!system!is! needed.!Hot!wort!is!pumped!through!valve!“9.%Hot%wort%inlet”.!Valve!“10.%Cold% wort% outlet”! is! connected! to! fermentation! tank.! (Pipe! heat! exchanger! is! optional).!

- Page 17 11.%Water/Cleaning% Valve!“11.%Water/Cleaning”%on!lower!side!of!pump!is!used!to!fill!fresh!water!in! side! of! a! mash! tun! and! for! complete! cleaning! at! the! end! of! brewing.! With! this! total!outlet!all!residual!water!in!the!sistem!is!drained!out.% 12.%Inlet%for%sparging% 13.%Outlet%for%sparging% Valve!“12.%Inlet%for%sparging”!and!valve!“13.%Outlet%for%sparging”!are!used!for! heating! cold! water! when! doing! sparging! with! heat! recuperation! from! heating! system!while!heating!is!on.!(Heating!for!sparge!water!is!optional).% 14.%Sparging%...

- Page 18 Connection!“14.% Sparging!“!is!used!to!connect!to!heated!water!from!valve!“13.% Outlet%for%sparging”.!Brewiks!is!equipped!with!special!hose,!which!is!connected! between!valves!“13.%Outlet%for%sparging”!and!“14.%Sparging!“.!

- Page 19 15.%Condensing%inlet% 16.%Condensing%outlet% Connection!“15.%Condensing%inlet”!is!used!to!connect!cold!water,!which!is!used! to!cool!down!steam,!which!condenses!in!condensing!unit.!On!end!of!condensing! unit!is!connection!“16.%Condensing%outlet”!where!cold!or!hot!water!and!maybe! steam!goes!out!while!brewing!process.!(Conceding!system!is!optional).% 17.%Cold%water%inlet% 18.%Hot%water%outlet%...

- Page 20 Counter!flow!pipe!heat!exchanger!(optional!equipment)!is!used!to!cool!down!hot! wort! after! whirlpool! is! done.! For! proper! use! of! heat! exchanger! cold! water! is! connected!to!valve!“17.% Cold% water% inlet”!and!hot!water!from!“18.% Hot% water% outlet”!valve!is!suggested!for!using!for!next!batch.!% 19.%Water%for%heating%inlet% 20.%Air%outlet% 21.%Safety%outlet% Brewiks!uses!hot!water!under!pressure!as!heating!medium.!So!inside!of!heating! system!must!always!be!water!more!then!1!bar!of!pressure.!Valve!“19.%Water%for% heating%inlet“!is!used!to!fill!water!in!heating!system.!How!to!fill!water!in!heating! system!please!read!more!in!chapter!8.!Before!the!first!use.!Valve!“20.%Air%outlet”! is! used! for! air! to! go! out! of! heating! system.! If! in! any! case! pressure! in! heating! system! exceed! 3! bar! then! valve! “21.% Safety% outlet”! open! and! pressure! is! released.!% 22.%Hot%external%inlet%...

-

Page 21: Notes,On,Hygiene

Brewing! process! can! be! heated! with! external! hot! water! system.! For! this! valve! “22.%Hot%external%inlet”!and!“23.%Hot%external%outlet”!are!used.! Notes,on,hygiene,, Hygiene! is! the! number4one! rule! when! brewing! beer.! Above! all! during! cold! processes,!(when!cooling!down,!when!decanting!and!when!fermenting),!the!beer! or!the!worth!is!exposed!to!the!danger!of!infection!which!can!spoil!the!beer!and! means! all! the! work! was! for! nothing.! So! take! particular! care! that! containers! (fermenting! vessel,! bottles)! and! utensils! (ladle,! valves,! gaskets)! are! absolute! clean.!Sulphurous!acids!or!similar!are!particularly!suitable!for!disinfecting!these! containers!and!utensils.!! -

Page 22: Starting,The,Brewing,Process

Preparations, Getting!hold!of!the!ingredients.!Acquire!the!necessary!ingredients!in!time!(hops,! malt!and!yeast).!Here!it!is!important!that!the!grain!is!freshly!malted.!After!milling! (crushing! open! the! grains! –! not! too! fine)! the! malt! should! be! used! as! soon! as! possible.! The! specifications! on! quantities! vary! somewhat! depending! on! recipe.! The! hops! are! mostly! available! in! compressed! form! (as! pellets).! Dried! yeast! is! recommended!for!fermenting!since!it!is!easy!to!store!and!keeps!for!longer.!These! ingredients! can! be! bought! in! home4brewing! shops! or! through! the! internet.! A! third! possibility! for! getting! hold! of! the! ingredients! are! from! a! brewery! in! your! - Page 23 1.%Inlet!4!OFF! 2.%Outlet!4!OFF! 3.%Mixing%inlet!4!ON! 4.%Mixing%outlet!4!ON! When! valves! are! set,! pump! can! be! turned! on! and! set!on!50!%!speed.!! At!this!stage!all!is!done!in!mash!tun.! Lautering, Lautering!is!the!process!of!separating!the!crushed!malt!from!the!wort.!For!safety! reasons,!it!is!recommended!to!wear!heat4resistant!gloves!at!all!times,!since!some! parts!are!extremely!hot.! Valve%position%when%lautering% First!step!is!to!pump!worth!to!lauter!tun.!Switch!pump!OFF!and!connect!valve!“2.% Outlet”!to!“5.%Whirlpool”!with!flexible!hose.!Valves!must!be:! 1.%Inlet!–!OFF! 2.%Outlet!–!ON! 3.%Mixing%inlet!–!ON! 4.%Mixing%outlet!–!OFF! 5.%Whirlpool!4!ON! Switch!pump!ON!and!increase!speed.!Hose!connection!is!on!next!picture.! After!total!amount!is!pumped!from!mash!tun!to!lauter!tun!then!lautering!begin.! Switch!pump!OFF!and!connect!valve!“8.%Bottom”!to!“1.%Inlet”!with!flexible!hose.! Valves!must!be:! 1.%Inlet!–!ON! 2.%Outlet!–!OFF! 3.%Mixing%inlet!–!OFF!

- Page 24 4.%Mixing%outlet!–!ON! 8.%Bottom!4!ON! Switch!pump!ON!and!decrease!speed!on!40!%!and!slightly!close!valve!“4.%Mixing% outlet”.!Hose!connection!is!on!next!picture.! Sparging, Sparging! is! the! proces! of! washing! the! sugar! from! malt.! With! this! you! increase! you! brewing! efficiency.! ! Amount! of! water! needed! for! sparging! depends! on! the! beer!recipe.!(Heating!water!for!sparging!is!optional)! Valve%position%when%sparging% Connect! cold! water! to! “12.% Inlet% for% sparging”! valve.! Connect! “13.% Outlet% for% sparging”!to!“14.%Sparging”!on!lauter!tun.!When!heating!in!mash!tun!is!ON!and! valve!“12.%Inlet%for%sparging”!is!ON!and!connected!to!cold!water,!then!hot!water! goes! in! lauter! tun! through! built! in! special! nozzle! under! lid! of! lauter! tun.! Hose!

-

Page 25: Boiling,The,Hops

Note:!Heating!only!works!if!mash!tun!was!previously!used!for!heating!the!wort! and! heating! system! is! hot.! Otherwise! heating! doesn’t! work! and! cold! water! doesn’t!get!hot.!! If! Brewiks! doesn’t! have! this! additional! equipment! then! can! be! connected! connection! “14.% Sparging”! to! external! hot! water! system! if! available! in! place! where!Brewiks!is!positioned.!! Boiling,the,hops, Adding!hops!to!the!beer!originally!served!to!keep!the!beer!for!longer.!The!hops! remain!in!the!worth!until!the!end!of!the!boiling!time,!since!their!substances!only! produce! their! effect! after! a! prolonged! boil! time! and! transfer! the! specified! bitterness! to! the! beer.! In! the! process,! resins! and! oils! in! the! hops! will! also! be! - Page 26 5.%Whirlpool!4!ON! Switch! pump! ON! and! decrease! speed! on! 100! %.! Hose! connection! is! on! next! picture.! Cooling,, Cooling!is!done!through!pipe!heat!exchanger!(optional),!which!is!built!in!the!wall! of!Brewiks!!mash!tun.! Valve%position%when%cooling%through%pipe%heat%exchanger% Switch!pump!OFF!and!connect!valve!“7.%Side%bottom”!to!“1.%Inlet”!with!flexible! hose.! ! Connect! valve! “2.% Outlet”! and! “9.% Hot% wort% inlet”! with! second! flexible! hose.! Connect! valve! “10.% Cold% wort% outlet”! and! fermentation! tank! with! third! flexible!hose.! Valves!must!be:! 1.%Inlet!–!ON!

-

Page 27: Cleaning Instructions

Cleaning,instructions, Immediately!after!brewing,!it!is!best!to!place!the!Brewiks!in!the!cleaning!position! and!to!pump!off!all!the!fine!solids!diluted!with!water.!Observe!the!correct!valve! positions.! Now! the! residues! from! brewing! can! be! removed! with! a! brush! and! water!(use!a!hose)!from!the!inside!surfaces!of!the!kettle.!Keep!pumping!off!the! dirty!water!as!you!work.!Also!pump!clean!water!through!the!inlet!to!the!kettle,!to! rinse! out! this! connection! and! the! valve,! too.! Remember! to! clean! the! outlet! and! inlet.! Conditions,of,warranty,and,settling,complaints, Conditions:! a) The!legal!warranty!conditions!apply.!The!warranty!period!for!consumers! is!limited!to!that!stipulated!for!commercial!customers,!insofar!as!they!are! using! a! device! suited! to! commercial! use! –! even! though! it! be! only! to! a! limited!extent.!! b) An!indispensable!pre4condition!for!warranty!claims!against!our!company! or! against! one! of! our! agents! is! to! remit! a! copy! of! the! proof! of! purchase.! - Page 28 Please!send!us!your!complete!address!with!contact!details!to!info@mithraeum.si.! Besides! this,! we! need! the! Type! Identifier! of! the! device! concerned,! a! short! description! of! the! fault! if! possible! with! photos,! the! purchase! date! (copy! of! the! invoice)!and!the!name!of!the!agent!where!you!bought!the!device.!!

- Page 29 Troubleshooting., Brewiks!500!needs!electricity!and!cold!water!for!full!operation.!! 1.!If!computer!is!shut%down:!an!adequately!trained!personnel!needs!to!check:! If!main!switch!is!ON! If!all!fuses!in!electricity!box!are!ON!(upper!position!of!switch)! If!fuses!are!on!in!power!plug!on!wall!where!Brewiks!power!cord!in!plug!in! If!extension!cord!is!between!Brewiks!power!cable!in!power!plug!on!wall,! then!adequate!extension!cord!needs!to!be! 2.! If! computer! screen! is! showing! “flashing% two! red! light! bulb”! and! heating% doesn’t% work.!(see!picture!on!right).!When!this!two!bulb!are!flashing!it!means! that!thermostat!switched!OFF!heaters.!Heaters!can!over!heat!when!there!is!not! enough!water!in!heating!system.!Please!see!chapter!“Before!first!use”!how!to!fill! water! in! heating! system.! Once! water! is! in! the! system! adequately! trained! personnel!need!to!reset!thermostat.!Resetting!the!thermostat!is!done!by!pressing! on!two!red!bottom!located!under!stainless!steel!heater!box.!This!box!is!located! near!electricity!box.!Please!see!picture!below.!! Electrical!heating!box! 3.!If!computer!screen!is!showing!“yellow%and%black%triangle”!and!heating% doesn’t%work.!(see!picture!on!right).!When!triangle!is!shown!on!computer!

- Page 30 Brewiks.process.flow. Step%1:%Fill!water!in!mash!tun! Step%2:%Heat!up!water! Step%3:%Add!malt!in!mash!tun! Step%4:%Heat!up!wort!

- Page 31 Step%5:%Pump!wort!to!lauter!tun! Step%6:%Recirculation! Step%7:%Lautering!

- Page 32 Step%8:%Boil! Step%9:%Add!hops!

- Page 33 Step%10:%Whirlpool! Step%11:%Cooling!the!wort! Step%12:%Add!yeast!to!fermentation!tank!

Need help?

Do you have a question about the Brewiks 500 and is the answer not in the manual?

Questions and answers