Summary of Contents for MHS Boilers Alpha Jetstream MD

-

Page 1: User Guide

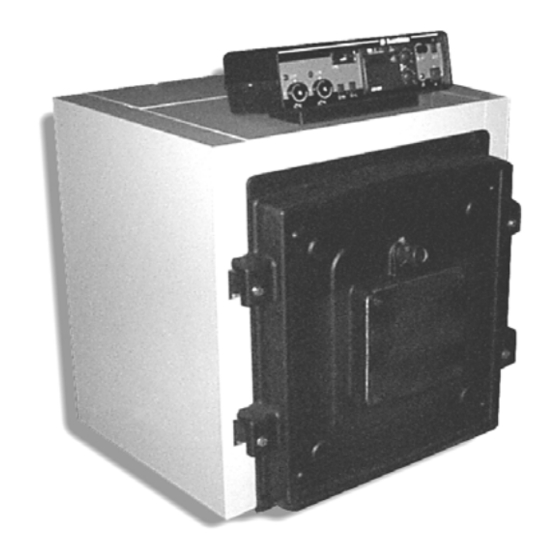

Installation User Guide Alpha Jetstream MD Cast Iron Boiler 105 - 300 kW Assembly, Operating and Maintenance Instructions 35 Nobel Square Basildon Essex SS13 1LT 01268 591010 / 01268 724064 01/07/04... - Page 2 INTRODUCTION The Alpha Jetstream MD is a cast iron sectional boiler for pressure jet oil or forced draught gas firing. The boiler is of the horizontal 3 pass type. The boilers are able to be utilised as low temperature boilers as described in the Boiler...

-

Page 4: Technical Information

TECHNICAL INFORMATION Boiler type MD 4 MD 5 MD 6 MD 7 MD 8 MD 9 Number of sections Product-ID number– Notified body number 86/AT/572 – CE0086 Rated heat output Flue gas resistance mmwg Combustion diameter chamber depth 1105 Length 1012 1146 1280... - Page 5 Also a reverse flow of hot water in the rear section of the boiler protects the section against excessive thermal shocks. The Alpha Jetstream MD will operate without condensation providing the minimum return...

- Page 6 TECHNICAL INFORMATION Fluegas resistance 100% load 75% load 50% load Efficiencies Combustion Overall LOAD Values given according to average boiler water temperature of 70 C Flue gas temperatures LOAD Values given according to average boiler water temperature 70 C, ambient temperature 20 C...

- Page 7 MD boiler must be fired only with a CE APPROVED BURNER which is according to Gas Appliance Directive and tested according to EN 676. MHS Boilers will not be held responsible for any damage or failure due to use of a non approved burner.

- Page 8 TECHNICAL INFORMATION Water side The fully watercooled sections are joined by cast iron conical nipples, and distribution of boiler pipe fitted to the return ensures even the temperature distribution throughout the boiler. The cast iron sections are to BS.1452 Grade 200 with 7 mm wall thickness. Return and flow connections to heating system are provided by stub-pipes at the rear of the boiler.

- Page 9 PREPARATIONS BEFORE ASSEMBLY Boiler room The installation must be arranged in accordance with Mandatory Regulations and Codes arrangement of Practice. The following sketch shows the recommended minimum dimensions of clearance around the bolier for servicing and maintenance Boiler room should not be used for any other applications, floor should always be kept dry and clean.

- Page 10 PREPARATIONS BEFORE ASSEMBLY Water The system design must ensure a flow rate consistant with the output of the boiler at a temperature rise not normally exceeding 20ºC (25ºC Max). Circulation System Due to the Jetstream technology employed in the boiler, the boiler may be operated at continuous low return water temperatures without condensation and without the need for back-end temperature protection measures, providing the minimum temperature limits detailed in the technical data are observed.

- Page 12 PREPARATIONS BEFORE ASSEMBLY Requirements on filling The quality of the filling and any refilling water is important and must be of water sufficient quality to maintain the following requirements: pH 8 - 9.5 Maximum hardness between 8 and 12 grammes of calcium carbonate per 100 litres of water.

-

Page 13: Assembly Instructions

2. Casing/insulation box: This box contains all casings and baseframes (if required) together with the insulation blankets. Retarder sets and control panel are also supplied in this box. Delivery method of Alpha Jetstream MD boilers. - Page 14 ASSEMBLY INSTRUCTIONS Assembly of Numbers in the brackets refer to position numbers in the exploded drawing. Boiler Body 1. Place steel profiles (19) which are used as baseframes of the boiler parallel to each other as shown in the figure at the l/h side. The distance from the baseframes vary 320/450/580/ from 320 mm to 970 mm as the number of...

- Page 15 ASSEMBLY INSTRUCTIONS After assembly of all sections, apply compression tools for the block. Before loosening fit upper and lower staybolts (7,8) using M12 nuts (9) and washers (10). 5. Fit studs M12x45 (20) to return and flow connections of the rear section. Do not use excessive force to tighten the nuts up on the staybolts, from 48 to 54 Nm (35 - 40 lbf/ft) torque is recommended.

- Page 16 ASSEMBLY INSTRUCTIONS 6. Fit distribution pipe (22) with gasket (25) to return connection. Fit flanged stubpipes (21) and their gaskets (25) to flow and return connections. Fit nuts and washers to the 35 mm threaded end of M10x105 studs (145), screw and lock the studs into the corner positions of rear section.

- Page 17 ASSEMBLY INSTRUCTIONS Jacket assembly 1. Fit cast iron hinges(143) used for carrying front door onto front section using 2 M8x30 setscrews (142) for each hinge. Before assembly of front door (131), first decide the side of hinging (for LH or RH opening). Screw hinge pins (141) into threaded holes. Screw a M16 nut (49) onto each hinge pin as shown in figure below left.

- Page 18 ASSEMBLY INSTRUCTIONS 5. Place boiler body insulation (117) squarely on top of boiler block. After placing the insulation, secure both ends of the insulation blanket to lower staybolts by using four retaining springs(156). 6. Fit left and right rear insulation panels(157) to smokehood (11) and secure by pushing onto the M10x105 studs (145).

- Page 19 ASSEMBLY INSTRUCTIONS Electrical 1. Before assembly of control panel on top casing front piece (163), pass the capillary Installation tubes of the panel through the large hole on the top casing. Fix control panel (110) onto the top casing using 4 self tapping screws S 4.8x9.5 2.

- Page 20 ASSEMBLY INSTRUCTIONS...

-

Page 21: Operation

The Alpha Jetstream MD Boiler must only be commissioned and serviced by competant Pre-firing checks persons of approved classes, qualified and certified to undertake the works involved. -

Page 22: Maintenance And Cleaning

MAINTENANCE AND CLEANING Before carrying out any maintenance operations on the boiler, first of all turn off/isolate electricity and oil or gas fuel supply valves. Periodic 1. Cleaning of heat transfer surfaces of the boiler heat exchanger at a frequency determined inspections by the usage patterns of the boiler but not exceeding 6 months for oil and 12 months for gas. - Page 24 END-USER INSTRUCTIONS To shut down Switch off the electrical supply and decrease the control thermostats on boiler control the boiler panel to the minimum set point. If switching off for an extended period e.g. Holidays, turn off the gas or oil supplies at the service and isolating gas or oil valves on the burner. Care of the 1.

-

Page 25: Exploded Drawings

EXPLODED DRAWINGS MD JETSTREAM EXPLODED DRAWING (BOILER GROUP) - Page 26 EXPLODED DRAWINGS ALPHA JETSTREAM MD EXPLODED DRAWING (INSULATION AND OUTER CASINGS)

- Page 27 ……. minutes, and No leakage detected Leakages detected and corrected on following points: OTHER FAULTS OR DEFICIENCIES DETECTED TESTED BY: (Print Name) DATE and SIGNATURE A COPY OF THIS TEST CERTIFICATE MUST BE RETURNED TO MHS BOILERS LTD...

- Page 28 A member of the Modular Heating Group Plc 35 Nobel Square, Burnt Mills Industrial Estate, Basildon, Essex, SS13 1LT. Tel: 01268 591010. Fax: 01268 728202 www.mhsboilers.co.uk...

Need help?

Do you have a question about the Alpha Jetstream MD and is the answer not in the manual?

Questions and answers