Apeks 2000PSI THE DUPLEX Operation Manual

Botanical oil extraction system

Hide thumbs

Also See for 2000PSI THE DUPLEX:

- Operation manual (42 pages) ,

- Installation manual (29 pages)

Table of Contents

Advertisement

Quick Links

2000

THE DUPLEX™

PSI

B

O

E

S

OTANICAL

IL

XTRACTION

YSTEM

O

M

PERATION

ANUAL

WARNING

FAILURE TO FOLLOW THE SETUP AND OPERATION PROCEDURE

PROVIDED IN WITHIN THIS MANUAL MAY VOID THE EXTRACTION

SYSTEM'S WARRANTY

Apeks LLC

150 Commerce Blvd.

Johnstown OH 43031

740-809-1160

www.apekssupercritical.com

Scan this QR code to get the

most recent version of the

operating instructions.

Updated 08/28/2018

©Apeks, LLC 2014

Advertisement

Table of Contents

Summary of Contents for Apeks 2000PSI THE DUPLEX

- Page 1 PROVIDED IN WITHIN THIS MANUAL MAY VOID THE EXTRACTION SYSTEM’S WARRANTY Apeks LLC 150 Commerce Blvd. Johnstown OH 43031 740-809-1160 www.apekssupercritical.com Scan this QR code to get the most recent version of the operating instructions. Updated 08/28/2018 ©Apeks, LLC 2014...

-

Page 2: Table Of Contents

Apeks Supercritical The Duplex™ Operation Manual Table of Contents Content Page# 1. Critical Safety Overview 2. System Overview 2.1. Diaphragm System Overview 2.1.1. Diaphragm Compressor 2.1.2. Extractor Vessel Stand 2.1.3. Separation Vessel/Control Stand 2.1.4. Bottle Connections 2.1.5. Extractor Chiller/Temperature Control Chiller 2.1.6. - Page 3 Apeks Supercritical The Duplex™ Operation Manual 3.2.3. System Response on Startup 3.3. Recommended Operating Parameters 3.3.1. Subcritical 3.3.2. Supercritical 3.4. During the Cycle 3.4.1. Service Separator/Cleaning out Separator that is offline 3.4.2. Cleaning Out Extractor in Continuous Batch Mode 3.4.3. Changing Bottles 3.5.

- Page 4 Apeks Supercritical The Duplex™ Operation Manual 5.2.13. Extractor Not Equalizing Alarm 5.2.14. Extractor Water Flow Lost Alarm 5.2.15. Extractor Ambient Temperature Alarm 5.2.16. Extractor (Vessel A/B, Top/Bottom) PSI High Alarm. 5.2.17. Extractor (A/B) Vessel Temperature Alarm 5.2.18. Filter (1B/2B) PSI Drop Fault/Warning 5.2.19.

-

Page 5: Critical Safety Overview

Apeks Supercritical The Duplex™ Operation Manual 1. Critical Safety Overview Throughout these instructions, this symbol is used to indicate that the instructions are critically important to your safety and the safety of your system. Failure to follow the instructions as written... -

Page 6: System Overview

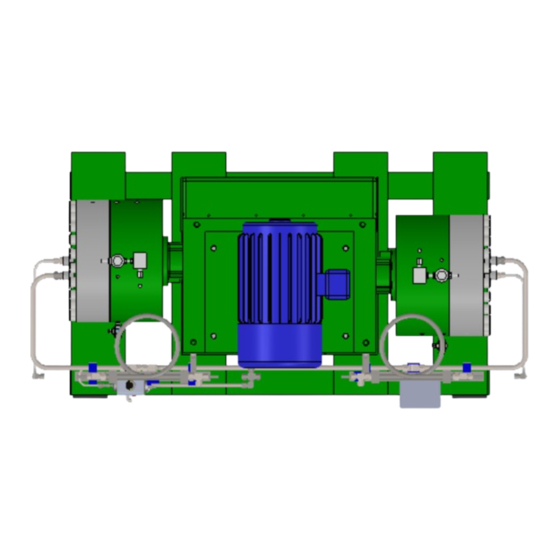

Apeks Supercritical The Duplex™ Operation Manual 2. System Overview The Duplex™ Diaphragm Compressor Separator Chiller Extractor Chiller Extractor Vessel Stand Separator Vessel Stand Main Control Enclosure Fork Pockets Revision Date 8/28/2018... -

Page 7: Diaphragm Compressor

Apeks Supercritical The Duplex™ Operation Manual 2.1. The Duplex™ System Overview 2.1.1. Diaphragm Compressor – The diaphragm compressor for the Apeks 2000psi Duplex™ system is dual head compressor where both heads work in parallel to compress CO to the desired target pressure in the extractors. - Page 8 Apeks Supercritical The Duplex™ Operation Manual a black handle that can be opened in order to bypass the OPV. This is done during priming of the compressor and during head maintenance. (see appendix B) 2.1.1.4. Junction Box – The diaphragm compressor has a single junction box for the pressure switches that has a Harding Connector (electrical quick-connect) and thermocouples that go to the main control enclosure.

-

Page 9: Separation Vessel/Control Stand

Apeks Supercritical The Duplex™ Operation Manual intended to valve off the inlet and outlet of the vessel to protect the user from any release of pressure. WARNING: Failure to use these valves can lead to injury. 2.1.2.3. Temperature Control Heat Exchanger – The temperature control heat exchanger... - Page 10 Apeks Supercritical The Duplex™ Operation Manual right. Each bank contains a main separator with an oil collection cup and a secondary separator with no cup. Users may use either set of separators at any time but only one set at a time. Separator banks that have identical gauges, filters and manual valving.

-

Page 11: Bottle Connections

Apeks Supercritical The Duplex™ Operation Manual Cup Lift Regulator Main Supply and Recovery Bottles Make-Up Supply Bottle 2.1.4. Bottle Connections 2.1.4.1. Main Supply and Recovery Bottles – Three 75lb Gas Supply CO bottles should be used as the main bottles for The Duplex™ system. These bottles are connected to the location shown above. -

Page 12: Automation Overview

2.2. Automation Overview 2.2.1. Logo Screen – This screen contains the software version information for your machine. You will find the version in the lower left-hand corner of the screen. Contact Apeks with current version information. 2.2.2. Home/Main Screen – This screen is the most common area to monitor the system during a cycle. -

Page 13: Cycle Parameter Screen

(Single or Double Extractor or Continuous Batch) cannot be adjusted after the run begins. 2.2.4. Valve Control Screen – This screen is for Apeks use only and is locked from customer use. Valve positioning can be seen on this screen. Current valve position will be highlighted. -

Page 14: Manual Screen

Apeks Supercritical The Duplex™ Operation Manual 2.2.5. Manual Screen – Aside from the Main Screen this screen is the most common screen the operator will interact with. The manual screen is where you will go to reset any alarms, service/ switch separators, change bottle and more. -

Page 15: Message Screen

Apeks Supercritical The Duplex™ Operation Manual 2.2.7. Message Screen – This screen is where the operator will select which messages to receive notifications about. This email messaging will require an initial setup which can be scheduled at http://www.apekssupercritical.com/customer-support/service-request/ . Setup will require a dedicated email address for the system. -

Page 16: I/O Screens

Apeks Supercritical The Duplex™ Operation Manual 2.2.9. I/O Screens – This screen is used for more precise system monitoring. The operator can monitor every input and output of the Program Logic Controller (PLC) from these screens. These screens are mainly used during troubleshooting. - Page 17 Apeks Supercritical The Duplex™ Operation Manual 2.2.9.2. PLC Digital Outputs 2.2.9.3. PLC Analog Inputs Revision Date 8/28/2018...

- Page 18 Apeks Supercritical The Duplex™ Operation Manual 2.2.9.4. PLC Analog Outputs Revision Date 8/28/2018...

-

Page 19: Alarm History Screen

Apeks Supercritical The Duplex™ Operation Manual 2.2.10. Alarm History Screen – This screen holds all the information about past alarms on the system. See the troubleshooting section for information about specific alarms. 2.2.11. Popup Screens – These screens will either appear to prompt the operator to enter additional information or will be called up by the operator to view or change parameters 2.2.11.1. - Page 20 Apeks Supercritical The Duplex™ Operation Manual 2.2.11.3. Elapsed Time Setting – This Screen can be called up from the bottom middle of the main screen and allows the operator to change/monitor time settings. In continuous batch mode the operator will need to go to this screen to verify that extractors are ready to come online.

-

Page 21: Running Modes

Apeks Supercritical The Duplex™ Operation Manual 2.2.11.6. Master Reset Confirm – This window will popup when a master reset is selected to make sure it is not done accidently. 2.3. Running Modes 2.3.1. Single Extractor – In this run mode, the system will run only one extractor (selected by the operator) for the duration of the cycle time and will then recover the CO . -

Page 22: Continuous Batch

Apeks Supercritical The Duplex™ Operation Manual 2.3.3. Continuous Batch – In this run mode, the system will run both extractors bring extractors online and offline automatically based on parameters selected by the operator. The operator will have the option to start with one vessel or both and will control the amount of time each extractor will be ran. -

Page 23: System Operation

Apeks Supercritical The Duplex™ Operation Manual 3. System Operation 3.1. Before the Cycle 3.1.1. Loading and Closing Extractor 3.1.1.1. CAUTION: Extractor flange can weigh up to 50lbs and care should be given to avoid damage and injury. 3.1.1.2. NOTE: Use appropriate tools to open and close vessels. Only use a rubber mallet on the extractor vessel hammer unions. -

Page 24: Prepping And Securing Separators

Apeks Supercritical The Duplex™ Operation Manual 3.1.1.7. Verify that all flexible lines are attached to top and bottom of vessel. 3.1.1.8. Open the Vessel Isolation valves once vessel is secure. 3.1.2. Prepping and Securing Separators 3.1.2.1. Before running a separator, be sure that the separator is clean and the proper orifice for the desired operating parameters is selected. -

Page 25: The Main Screen

Apeks Supercritical The Duplex™ Operation Manual 3.2.1.15. Enter separator switch-over time. 3.2.1.15.1. If no switch-over is desired, make switch-over time longer than total run time. 3.2.1.15.2. Phases are related to which separator is online and separate from the extractors entirely. - Page 26 Apeks Supercritical The Duplex™ Operation Manual 3.4.1.3. Open Valve 10A or B depending on the vessel being serviced to vent separator bank. 3.4.1.4. Close the two Vessel Isolation Valves on both the inlet and outlet lines to protect from an unexpected release of pressure.

- Page 27 Apeks Supercritical The Duplex™ Operation Manual 3.5. After the Cycle 3.5.1. System Response on Shutdown 3.5.1.1. Once the total run time is complete, the system will automatically recover the CO in the system back into the bottles. When all vessels get under 100 psi the system will stop and vent the extractors.

-

Page 28: System Preventive Maintenance

Apeks Supercritical The Duplex™ Operation Manual 4. System Preventive Maintenance For Apeks System Manuals and Other Component Manuals visit http://www.apekssupercritical.com/apeks- supercritical-operation-manuals/ Included with each system is a small squeeze bottle to help with proper maintenance and cleaning of your systems C0 lines. -

Page 29: Chiller Maintenance

Apeks Supercritical The Duplex™ Operation Manual • Replace diaphragms and o-rings in process head • Clean and inspect oil inlet check valve Every 4000 • Clean and inspect oil relief valve Hours • Inspect crankcase assembly • Inspect compressor lower head •... -

Page 30: Troubleshooting

Apeks Supercritical The Duplex™ Operation Manual 5. Troubleshooting 5.1. System Messages 5.1.1. Leak Detect Switch Tripped, when pump stops, check leak detect valve for hydraulic oil. If no oil is present, press OK. If there is oil present, press OIL FOUND – Follow prompt. -

Page 31: Diaphragm Compressor Ambient Temperature Alarm

Vent pressure if still present and check for oil. If oil is present, call Apeks (740-809-1160 ext. 2) about replacing diaphragms. If no oil is present, reset alarm on the manual screen, restart system and monitor the leak detect gauge for pressure. If no pressure appears continue to run. -

Page 32: Pressure Test Fail Alarm

5.2.31. Valve Fault Alarm – The air valve manifold has faulted. Check the manifold for fault code and then try unplugging the yellow cord and plugging it back in. if fault continues contact Apeks (740-809-1160 ext. 2). - Page 33 Apeks Supercritical The Duplex™ Operation Manual 6. References YouTube Instructional Videos https://www.youtube.com/user/ApeksSupercritical Apeks online store (740)-809-1160 ext. 4 http://www.apekssupercritical.com/online-store/ Software Updates and E-mail Alerts (740)-809-1160 ext. 2 http://www.apekssupercritical.com/service/ Revision Date 8/28/2018...

- Page 34 Apeks Supercritical The Duplex™ Operation Manual Appendix A. Belt Tension Testing/Adjustment. a) Remove the belt guard b) Check belt(s) tension with belt tension tester a. Belts should be tensioned to 10lbs b. If you need help using your tension tester tool please view the following video https://www.youtube.com/watch?v=bYEHvfo8t6A...

- Page 35 Apeks Supercritical The Duplex™ Operation Manual Appendix B. Diaphragm Pump Priming. a) Open BOTH of the Oil Bypass Valves (one on each head), see figure below, by turning counterclockwise until it stops Oil Bypass Valve b) Go to the “Manual Screen” on the HMI and hit the “Start Prime Compressor” button.

-

Page 36: Appendix C – Check Valve Cleaning

Dissemble check and clean thoroughly with alcohol or acetone. For heavily soiled valves us an ultrasonic cleaner on metal pieces to help remove soil. Do not clean the poppet (brown donut) in the ultrasonic cleaner. If poppet is beyond cleaning or damaged contact Apeks for a replacement. Revision Date 8/28/2018... - Page 37 Apeks Supercritical The Duplex™ Operation Manual Poppet Springs Suction Check Valve Revision Date 8/28/2018...

- Page 38 Apeks Supercritical The Duplex™ Operation Manual Discharge Check Valve e) Reassemble checks when cleaned and assemble in pump f) Torque the retaining bolts to 15 ft-lbs after reassembly. Revision Date 8/28/2018...

-

Page 39: Appendix D – Electrical Screw Torque Requirement

Apeks Supercritical The Duplex™ Operation Manual Appendix D. Electrical Screw Torque Requirements a) Fuse Holders (1492-H6) = 7.1 lb-in b) Power Supply (1606-XLE120E) – 7 lb-in c) Terminal Blocks (1492-J4) = 9 lb-in d) Ground Blocks (1492-JG4) = 9 lb-in e) Ground Block Middle Screw (1492-JG4) = 7.1 lb-in... - Page 40 Apeks Supercritical The Duplex™ Operation Manual Appendix E. Piping and Instrumentation Diagram Revision Date 8/28/2018...

- Page 41 Apeks Supercritical The Duplex™ Operation Manual Revision Date 8/28/2018...

- Page 42 Apeks Supercritical The Duplex™ Operation Manual Revision Date 8/28/2018...

- Page 43 Apeks Supercritical The Duplex™ Operation Manual Appendix F. CO2 Phase Diagram Revision Date 8/28/2018...

Need help?

Do you have a question about the 2000PSI THE DUPLEX and is the answer not in the manual?

Questions and answers