Subscribe to Our Youtube Channel

Summary of Contents for Pfeiffer TPG 261

- Page 1 A P A S S I O N F O R P E R F E C T I O N VACUUM TPG 261 SingleGauge™, Single-Channel Measurement and Control Unit for Compact Gauges Operating Instructions...

-

Page 2: Product Identification

In all communications with Pfeiffer Vacuum, please Product Identification specify the information on the product nameplate. For convenient reference copy that information into the space provided below. Pfeiffer Vacuum, D-35614 Asslar Typ: F-No: This document applies to products with part number Validity PT G28 030. -

Page 3: Intended Use

The TPG 261 is used together with Pfeiffer Vacuum Intended Use Compact Gauges (in this document referred to as gauges) for total pressure measurement. All products must be operated in accordance with their respective Operating Instructions. The scope of delivery consists of following parts:... -

Page 4: Table Of Contents

3.4 Gauge Connector sensor 3.5 control Connector 3.6 relay Connector 3.7 Interface Connector RS232 4 Operation 4.1 Front Panel 4.2 Turning the TPG 261 On and Off 4.3 Operating Modes 4.4 Measurement Mode 4.5 Parameter Mode 4.5.1 Switching Function Parameters 4.5.2... - Page 5 5 Communication (Serial Interface) 5.1 RS232C Interface 5.1.1 Data Transmission 5.1.2 Communication Protocol 5.2 Mnemonics 5.2.1 Measurement Mode 5.2.2 Parameter Mode 5.2.2.1 Switching Function Parameters 5.2.2.2 Gauge Parameters 5.2.2.3 Gauge Control 5.2.2.4 General Parameters 5.2.2.5 Test Parameters 5.2.3 Example 6 Maintenance 7 Troubleshooting 8 Repair 9 Storage...

-

Page 6: Safety

1 Safety 1.1 Symbols Used Symbols for residual risks DANGER Information on preventing any kind of physical injury. WARNING Information on preventing extensive equipment and environmental damage. Caution Information on correct handling or use. Disregard can lead to malfunctions or minor equipment damage. Further symbols The lamp/display is lit. -

Page 7: Personnel Qualifications

1.2 Personnel Qualifications Skilled personnel All work described in this document may only be carried out by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product. Adhere to the applicable regulations and take the nec- 1.3 General Safety essary precautions for all work you are going to do and Instructions... -

Page 8: Liability And Warranty

Pfeiffer Vacuum assumes no liability and the warranty 1.4 Liability and becomes null and void if the end-user or third parties Warranty • disregard the information in this document • use the product in a non-conforming manner • make any kind of interventions (modifications, altera- tions etc.) on the product... -

Page 9: Technical Data

2 Technical Data Voltage 90 … 250 VAC Mains specifications Frequency 50 … 60 Hz Power consumption 45 W ≤ Overvoltage category Protection class Connection European appliance connec- tor IEC 320 C14 ( → Temperature Ambiance storage –20 … +65 °C operation + 5 …... - Page 10 750 mA Power 18 W Fuse protection 900 mA with PTC element, self-resetting after turning the TPG 261 off or disconnecting the gauge. The supply con- forms to the requirements of a grounded protective extra low voltage (SELV). Front panel...

- Page 11 Number Switching functions Reaction delay ≤20 ms if switching threshold close to measurement value (for larger differences con- sider filter time constant) Adjustment range depending on gauge (→ [1] … [17]) Hysteresis ≥1% F.S. for linear gauges, ≥10% of measurement value for logarithmic gauges Contact type floating changeover contact...

- Page 12 Gauge control Manual via keys activation/deactivation (→ 28, 49, 50) External via control connector signal ≤ +0.8 VDC ON condition signal +2.0 … 5 VDC or input OFF condition open Hotstart when mains power on (→ Self control deactivation when pressure rises OFF threshold adjustable (→...

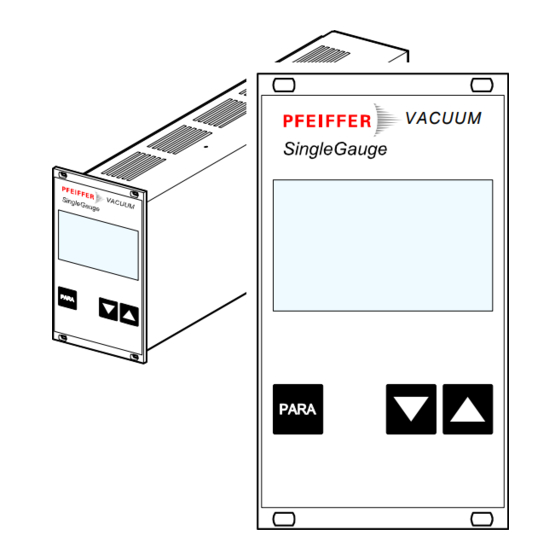

- Page 13 Dimensions [mm] 70.8 ≈310 55.9 228.5 68.1 ø3.5 VACUUM For incorporation into a rack or control panel or as desk- top unit. Weight 1.1 kg BG 5195 BEN / A (2011-05) TPG261.oi...

-

Page 14: Installation

The TPG 261 is suited for incorporation into a 19" rack 3.2 Installation, Setup or a control panel or for use as desk-top unit. - Page 15 Guide rail In order to reduce the mechanical strain on the front panel of the TPG 261, preferably equip the rack chassis adapter with a guide rail. Slide rails For safe and easy installation of heavy rack chassis adapters, preferably equip the rack frame with slide rails.

- Page 16 Rack chassis adapter Height 3 U Slide the TPG 261 into the rack chassis adapter … … and fasten the adapter panel to the rack chas- sis adapter using the screws supplied with the TPG 261.

-

Page 17: Installation In A Control Panel

EN 60204-1 regulations for switching cabi- nets. Take appropriate measures for the control panel to meet the specifications of the pro- tection class. For mounting the TPG 261 into a control panel, the fol- lowing cut-out is required: 55.9 The admissible maxi- mum ambient tem- perature (→... -

Page 18: Use As Desk-Top Unit

Slide the TPG 261 into the cut-out of the control panel … … and secure it with four M3 or equivalent screws. The TPG 261 is also suited for use as desk-top unit. For 3.2.3 Use as Desk-Top this purpose, two self-adhesive rubber feet as well as a Unit slip-on rubber bar are supplied with it. -

Page 19: Mains Power Connector

Select a location where the admissible maxi- mum ambient temperature (→ 9) is not ex- ceeded (e.g. due to sun irradiation). 3.3 Mains Power DANGER Connector DANGER: line voltage Products that are not professionally connected to ground can be extremely hazardous in the event of a fault. -

Page 20: Gauge Connector Sensor

Do not unfasten this screw (internal ground protection) 3.4 Gauge Connector Connect the gauge to the sensor connector via sensor a sensor cable set available from us ( → sales literature) or your own, screened (electromag- netic compatibility) sensor cable. Make sure the gauge you are connecting is compatible (→... -

Page 21: Control Connector

Gauge signal ≤+0.8 VDC signal +2.0 … 5 VDC or input open Not assigned 1, 6 Error or power No error supply turned off A suitable connector is supplied with the TPG 261. BG 5195 BEN / A (2011-05) TPG261.oi... -

Page 22: Relay Connector

This connector allows to use the floating switching con- 3.6 relay Connector tacts for an external control system. Connect the peripheral components to the relay connector on the rear of the unit using your own, screened (electromagnetic compatibility) cable. Pin assignment Contact positions relay Pin assignment of... -

Page 23: Interface Connector Rs232

The RS232C interface allows for operating the TPG 261 3.7 Interface Connector via a HOST or terminal (→ 65). It can also be used for RS232 updating the firmware (→ 97). Connect the serial interface to the RS232 con- nector on the rear of the unit using your own, screened (electromagnetic compatibility) cable. -

Page 24: Operation

4 Operation 4.1 Front Panel Measurement value in floating point or exponential format or status messages Parameter mode activated Measurement VACUUM Warning/error unit (flashing) Operator keys Switching function status Offset value ≠ 0 Correction factor ≠ 1 Degas activated Gauge activated No function BG 5195 BEN / A (2011-05) -

Page 25: Turning The Tpg 261 On And Off

• adapts the parameters if required (if another gauge was previously connected). Turning the TPG 261 Turn the TPG 261 off with the power switch (or centrally, via a switched power distributor, if the unit is incorpo- rated in a rack). -

Page 26: Operating Modes

The TPG 261 works in the following operating modes: 4.3 Operating Modes • Measurement mode for displaying measurement values or statuses (→ • Parameter mode for displaying or editing parameters (→ − Switching function parameter group for entering or displaying thresholds (→... -

Page 27: Measurement Mode

The Measurement mode is the standard operating mode 4.4 Measurement Mode of the TPG 261. Measurement values and statuses as well as the gauge identification are displayed in this mode. Measurement mode Parameter depending mode on history Measurement value Status... - Page 28 Turning the gauge on Certain gauges can be turned on and off manually, if the and off gauge control is set to (→ 50). Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR) FullRange™ CC Gauge (PKR) Process Ion Gauge (IMR)

- Page 29 Measurement range If the TPG 261 is operated with linear gauges (CMR 261 … 375, APR 250 … 267), negative pressures may be indicated. Possible causes: • negative drift • offset correction activated with positive offset. BG 5195 BEN / A (2011-05) TPG261.oi...

- Page 30 Connected gauge cannot be identified (no Identifier) TPR and PCR have identical identifiers. In the TPG 261, there is no distinction made on the display and in data evaluation, since pres- sure ranges of these gauges are approximately the same.

-

Page 31: Parameter Mode

The Parameter mode is used for displaying, editing and 4.5 Parameter Mode entering parameter values as well as for testing the TPG 261. For ease of operation, the parameters are di- vided into groups. Measurement Parameter mode mode Switching function parameters... - Page 32 Selecting a parameter Switching function parame- group ters → Gauge parameters → Gauge control → General parameters → Test parameters → Selecting a parameter in a parameter group Editing a parameter in Modifications of parameters come into effect immedi- a parameters group ately and are stored automatically.

-

Page 33: Switching Function Parameters

The switching function parameter 4.5.1 Switching Function group (setpoint parameters) is Parameters used for displaying, entering and editing threshold values of the two switching functions. Parameter mode depending on history Switching function 1 lower threshold Switching function 1 upper threshold >10 s Switching function 2 lower threshold Swiching function 2 upper threshold... - Page 34 The TPG 261 has two switching functions with two ad- justable thresholds each. The status of the switching function is displayed on the front panel (→ 24, 21) and can be evaluated via the floating contacts at the relay connector.

- Page 35 Gauge dependent ( → table). e.g.: If another gauge type is con- nected, the TPG 261 automati- cally adjusts the switching threshold if required. 5×10 1500 -4 *) 1×10 1×10 1×10...

- Page 36 Gauge dependent ( table). → e.g.: If another gauge type is con- nected, the TPG 261 automati- cally adjusts the threshold if required. +10% lower threshold 1500 +10% lower threshold 1×10 +10% lower threshold 1×10...

-

Page 37: Gauge Parameters

The Gauge parameter group 4.5.2 Gauge Parameters (sensor parameters) is used for displaying, entering and editing parameters of the connected gauge. Parameter mode depending on history Filter time constant Calibration factor Measurement range Offset >10 s Penning Underrange Control Degas Pirani range extension BG 5195 BEN / A (2011-05) - Page 38 Selecting a The name of the parameter, parameter e.g.: Filter time constant is displayed as long as the key is pressed or at least for 1.5 s. Afterwards, the currently valid parameter value is dis- played. Some parameters are not available for all gauges and thus not always displayed.

- Page 39 Pressure p Time t Slow: The TPG 261 does not re- spond to small changes in measured values. As a result, it will respond more slowly to changes in the measured val- ues.

- Page 40 The value is increased/ decreased by the defined in- crements. Calibration factor The calibration factor allows the measured value to be calibrated for other gases than N (→ characteristic curves in [1] … [13]). Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR)

- Page 41 Press key <1 s: The value is increased/ decreased by 1 increment. Press key >1 s: The value is increased/ decreased continuously. Measurement range For linear gauges, the full scale (F.S.) value has to be (F.S.) of linear defined according to the connected gauge type. For gauges logarithmic gauges it is automatically recognized.

- Page 42 Offset correction The offset value is displayed and readjusted according to the actual measurement value (in the range of … +110% of the set full scale value). Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR) FullRange™...

- Page 43 Underrange control Behavior in the event of an underrange with Cold Cath- ode Gauges (Penning underrange control). Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR) FullRange™ CC Gauge (PKR) Process Ion Gauge (IMR) FullRange™ BA Gauge (PBR) Capacitance Gauge (CMR)

- Page 44 Value Underrange state is interpreted as admissible measurement value. is displayed. The switching function remains Underrange state is interpreted as inadmissible measurement value. is displayed. The switching function changes to OFF. Activate/deactivate the underrange control. If chances are that the pressure in the vacuum system drops below the measurement range of the gauge, it is advisable to select is selected, the evaluation of the...

- Page 45 Degas Contamination deposits on the electrode system of hot cathode gauges may cause instabilities of the measure- ment values. The Degas function allows to clean the electrode system. Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR) FullRange™...

- Page 46 Pirani range The display and setpoint adjustment range of the Pirani extension Capacitance Gauge can be extended. Available for: Measurement range Pirani Gauge (TPR) Pirani Capacitance Gauge … (PCR) 5×10 1500 mbar Cold Cathode Gauge (IKR) FullRange™ CC Gauge (PKR) Process Ion Gauge (IMR) FullRange™...

-

Page 47: Gauge Control

The Gauge control group (control 4.5.3 Gauge Control parameters) is used for display- ing, entering and editing parame- ters which define the activation/ deactivation of the connected gauge. If the connected gauge cannot be controlled (→ 49), this group is not available. - Page 48 Selecting a The name of the parameter, parameter e.g.: Gauge activation is displayed as long as the key is pressed or at least for 1.5 s. Afterwards, the currently valid parameter value is dis- played. Some parameters are not available for all gauges and thus not always displayed.

- Page 49 The gauge is activated by an input signal fed via the control connector (→ 21). Hotstart: The gauge is automatically ac- tivated when the TPG 261 is turned on. Measurement is thus automatically resumed after a power failure. Gauge deactivation → Increase/decrease the value by the defined increments.

- Page 50 Gauge deactivation Certain gauges can be deactivated by different means. The following gauges can be controlled: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKR) FullRange™ CC Gauge (PKRx) Process Ion Gauge (IMR) FullRange™ BA Gauge (PBR) Capacitance Gauge (CMRx) Piezo Gauge (APR)

- Page 51 OFF threshold Definition of the OFF threshold for the gauge to be de- activated by itself (self control). Available for: Pirani Gauge (TPR) Pirani Capacitance Gauge (PCR) Cold Cathode Gauge (IKRx) FullRange™ CC Gauge (PKR) Process Ion Gauge (IMR) FullRange™ BA Gauge (PBR) Capacitance Gauge (CMR)

-

Page 52: General Parameters

The General parameter group 4.5.4 General (general parameters) is used for Parameters displaying, entering and editing generally applicable system pa- rameters. Parameter mode depending on history Measurement unit Transmission rate Display resolution >10 s Default settings BG 5195 BEN / A (2011-05) TPG261.oi... - Page 53 Selecting a The name of the parameter parameter e.g.: Measurement unit is displayed as long as the key is pressed or at least for 1.5 s. Afterwards, the currently valid parameter value is dis- played. The parameters are available for all gauge types and thus always displayed.

- Page 54 Measurement unit Unit of measured values, thresholds etc. See Appendix (→ 95) for conversion. Value mbar/bar Torr (only available if Torr lock is not activated i.e. Torr is not suppressed → Pascal Transmission rate Transmission rate of the RS232C interface. Value 9600 baud 19200 baud...

- Page 55 Display resolution Display resolution of measured values. Value Display • rounded to one decimal digit • or two integrals Display • rounded to two decimal digits • or three inte- grals When the PrE (→ 46) is ON and the pressure is in the range p<1.0E-4 mbar the display resolution of the PCR Gauge is reduced by one decimal digit.

-

Page 56: Test Parameters

This group is only avail- able if the key was pressed while the TPG 261 was turned on. Parameter mode depending on history Power Firmware version Watchdog control... - Page 57 Selecting a The name of the parameter parameter e.g.: Firmware version is displayed. The parameters are available for all gauge types and thus always displayed. → 58 The name of the parameter is dis- played as long as the key is pressed or at least for 1.5 s.

- Page 58 │ The last character indicates the modifi- cation index (-, A … Z). Please mention this index when contacting Pfeiffer Vacuum in the event of a prob- lem. Watchdog control Behavior of the system control (watchdog) in the event of an error.

- Page 59 Torr lock The measurement unit can be suppressed in the corresponding parameter setting (→ 54). Setting Measurement unit avail- able. Measurement unit available. Keylock The entry lock function prevents inadvertent entries in the Parameter mode and thus malfunctions. Setting Entry lock function disabled. Entry lock function enabled.

- Page 60 Test finished, error(s) found. lamp flashes. If the error message persists after several test sequences have been run, please contact your local Pfeiffer Vacuum service center. EPROM test Test of the program memory. Test sequence The test runs automatically one...

- Page 61 Test finished, no error found. Test finished, error(s) found. lamp flashes. If the error message persists after several test sequences have been run, please contact your local Pfeiffer Vacuum service center. Display test Test of the display. Test sequence The test runs automati-...

- Page 62 (→ 20)). If the signal input is open, the TPG 261 displays a default value that may easily fluctuate be- cause of the high sensitivity of the open meas- urement circuit.

- Page 63 I/O test Test of the relays of the TPG 261. The program tests their switching function. Caution Caution: The relays switch irrespective of the pressure Starting a test program may cause unwanted effects in connected control systems. Disconnect all sensor and control system lines to ensure that no control commands or messages are triggered by mistake.

- Page 64 Gauge relay No function Error relay RS232C test Test of the RS232C interface. The TPG 261 repeats each sign transmitted by the communicating HOST. The data transferred from/to the TPG 261 can be displayed by the computer only (→ 65).

-

Page 65: Communication (Serial Interface)

No parity bit 1 stop bit No hardware handshake Communication structure and procedures are identi- cal for both controllers TPG 261 and TPG 262. Therefore the term TPG 26x is used in this chapter. BG 5195 BEN / A (2011-05) - Page 66 Definitions The following abbreviations and symbols are used: Symbol Meaning HOST Computer or terminal [...] Optional elements ASCII American Standard Code for Information Interchange Dec. Hex. <ETX> END OF TEXT (CTRL C) Reset the interface <CR> CARRIAGE RETURN Go to beginning of line <LF>...

-

Page 67: Communication Protocol

5.1.2 Communication Protocol Transmission format Messages are transmitted to the TPG 26x as ASCII strings in the form of mnemonic operating codes and parameters. All mnemonics comprise three ASCII char- acters. Spaces are ignored. <ETX> (CTRL C) clears the input buffer in the TPG 26x. - Page 68 Reception protocol HOST TPG 26x Explanation Mnemonics Receives message with "end of mes- [and parameters] ──────────> sage" <CR>[<LF>] ─────────────> <───────── <ACK><CR><LF> Positive acknowledg- ment of a received message <ENQ> ─────────────────> Requests to transmit data <────── Measurement values Transmits data with "end of message"...

-

Page 69: Mnemonics

5.2 Mnemonics → A/D converter test Baud rate (transmission rate) Continuous mode Calibration factor Display control digits (display resolution) Degas Display control (display changeover) Display test EEPROM test EPROM test Error status Filter time constant (measurement value filter) Full scale range (measurement range of linear gauges) I/O test Keylock Offset correction (linear gauges) -

Page 70: Measurement Mode

(concluded) Keyboard test (operator key test) Torr lock Pressure unit Watchdog control 5.2.1 Measurement Mode Measurement data Transmit: <CR>[<LF>] gauge │ 1 or 2 └─ Measurement value x = 1 –> Gauge 1 2 –> Gauge 2 Receive: <ACK><CR><LF> Transmit: <ENQ>... - Page 71 Measurement data Transmit: <CR>[<LF>] gauges 1 and 2 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x,sx.xxxxEsxx,y,sy.yyyyEsyy <CR><LF> │ │ │ │ └ Measurement │ │ │ value gauge 2 │ │ │ [in current │ │ │ pressure unit] │ │ │ │...

- Page 72 Continuous output of Transmit: [,x] <CR>[<LF>] measurement values │ (RS232) └─ Mode x = 0 –> 100 ms 1 –> 1 s (default) 2 –> 1 min. Receive: <ACK><CR><LF> <ACK> is immediately followed by the con- tinuous output of the measurement value in the desired interval.

- Page 73 Turning a gauge Transmit: [,x,x] <CR>[<LF>] on/off │ │ │ └─ Gauge 2, x = 0 –> No status change │ 1 –> Turn gauge off │ 2 –> Turn gauge on │ │ └─ Gauge 1 Receive: <ACK><CR><LF> Transmit: <ENQ>...

- Page 74 Measurement Transmit: [,x] <CR>[<LF>] channel change │ └─ Display channel, x = 0 –> Gauge 1 1 –> Gauge 2 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x <CR><LF> │ └─ Display channel Error status Transmit: <CR>[<LF>] Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: xxxx <CR><LF>...

- Page 75 Reset Transmit: [,x] <CR>[<LF>] │ └─ x = 1 –> Cancels currently active error and returns to measurement mode Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: [x]x,[x]x,... <CR><LF> │ └─ List of all present error messages, xx = 0 –> No error 1 –>...

-

Page 76: Parameter Mode

5.2.2 Parameter Mode 5.2.2.1 Switching Function Parameters Threshold value Transmit: [,y,x.xxxxEsxx,x.xxxxEsxx] <CR>[<LF>] setting, allocation │ │ │ │ └ Upper threshold │ │ │ [in current │ │ │ pressure unit] │ │ │ (default = │ │ │ depending on │... -

Page 77: Gauge Parameters

Switching function Transmit: <CR>[<LF>] status Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x,x,x,x <CR><LF> │ │ │ │ │ │ │ └─ Status switching function 4 │ │ │ │ │ └─ Status switching function 3 │ │ │ └─ Status switching function 2 │... - Page 78 Calibration factor Transmit: [,x.xxx,x.xxx] <CR>[<LF>] ( │ │ └─ Gauge 2 │ log. 0.100 ... 9.990 │ (default = 1.000) │ lin. 0.500 ... 2.000 │ (default = 1.000) │ │ └─ Gauge 1 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x.xxx,x.xxx <CR><LF> │...

- Page 79 Offset correction Transmit: [,x,x] <CR>[<LF>] ( (linear gauges) │ │ │ └─ Gauge 2, x = 0 –> off (default) │ 1 –> on │ 2 –> auto (offset measurement) │ │ └─ Gauge 1 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x,x <CR><LF>...

- Page 80 Underrange control Transmit: [,x,x] <CR>[<LF>] │ │ │ └─ Gauge 2, x = 0 –> off (default) 1 –> on │ │ └─ Gauge 1 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x,x <CR><LF> │ │ │ └─ Gauge 2 │ └─ Gauge 1 Degas Transmit: [,x,x] <CR>[<LF>] (...

- Page 81 Pirani range Transmit: [,x,x] <CR>[<LF>] extension │ │ Gauge 2, x = │ └─ 0 –> off (default) │ 1 –> on │ │ └─ Messröhre 1 Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x,x <CR><LF> │ │ │ └─ Gauge 2 │...

-

Page 82: Gauge Control

5.2.2.3 Gauge Control Gauge control Transmit: [,x,y,x.xxEsxx,y.yyEsyy] <CR>[<LF>] │ │ │ │ │ └─ OFF threshold │ │ │ │ │ │ │ │ └─ ON threshold │ │ │ │ │ │ │ │ └─ Controlling source for gauge deactivation, x = │... -

Page 83: General Parameters

5.2.2.4 General Parameters Pressure unit Transmit: [,x] <CR>[<LF>] │ └─ Pressure unit, x = 0 –> mbar/bar (default) 1 –> Torr 2 –> Pascal Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x <CR><LF> │ └─ Pressure unit Transmission rate Transmit: [,x] <CR>[<LF>] │... -

Page 84: Test Parameters

Save parameters to Transmit: [,x] <CR>[<LF>] EEPROM │ └─ x = 0 –> Save default parameters 1 –> Save user parameters Receive: <ACK><CR><LF> Display changeover Transmit: [,x] <CR>[<LF>] │ └─ Measurement display behavior when a Pirani gauge or a Pirani Capacitance gauge is combined with a linear gauge with 1000 mbar F.S., x =... - Page 85 Watchdog control Transmit: [,x] <CR>[<LF>] │ └─ x = 0 –> Manual error acknowledgement 1 –> Automatic error acknowledgement (default) If the watchdog has responded, the error is automatically acknowledged and cancelled af- ter 2 s. Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: x <CR><LF>...

- Page 86 RAM test Transmit: <CR>[<LF>] Receive: <ACK><CR><LF> Transmit: <ENQ> Starts the test (duration <1 s) Receive: xxxx <CR><LF> │ └─ ERROR word EPROM test Transmit: <CR>[<LF>] Receive: <ACK><CR><LF> Transmit: <ENQ> Starts the test (duration ≈5 s) Receive: xxxx,yyyy <CR><LF> │ │ └─...

- Page 87 ADC test Transmit: <CR>[<LF>] Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: [x]x.xxxx,[x]x.xxxx,x.xxxx,x.xxxx <CR><LF> │ │ │ │ └ ADC channel 4 │ │ │ identification │ │ │ Gauge 2 │ │ │ [0.0000 ... │ │ │ 5.0000 V] │ │ │...

- Page 88 I/O test Caution Caution: The relays switch irrespective of the pressure. Starting a test program may cause unwanted effects in connected control systems. Disconnect all sensor cables and control system lines to ensure that no control com- mands or messages are triggered by mistake. Transmit: [,x,yy] <CR>[<LF>] │...

- Page 89 Operator key test Transmit: <CR>[<LF>] Receive: <ACK><CR><LF> Transmit: <ENQ> Receive: xxxx <CR><LF> ││││ │││└─ Key 4 x = 0 –> Not pushed 1 –> Pushed │││ │││ ││└── Key 3 ││ │└─── Key 2 │ └──── Key 1 RS232 test Transmit: <CR>[<LF>] Receive:...

-

Page 90: Example

5.2.3 Example "Transmit (T)" and "Receive (R)" are related to Host. Request for gauge identification <CR> [<LF>] Positive acknowledgement E: <ACK> <CR> <LF> Request for data transmission S: <ENQ> Gauge identifications E: TPR,CMR <CR> <LF> Request for gauge statuses <CR> [<LF>] Positive acknowledgement E: <ACK>... -

Page 91: Maintenance

6 Maintenance The product requires no maintenance. Cleaning the TPG 261 For cleaning the outside of the TPG 261, a slightly moist cloth will usually do. Do not use any aggressive or scouring cleaning agents. DANGER DANGER: mains voltage Contact with live parts is extremely hazardous when liquids penetrate into the unit. -

Page 92: Troubleshooting

. key If the problem persists, is displayed. Possible cause and remedy/ acknowledgement The TPG 261 has been turned on too fast after power off. Acknowledge with the key. If the watchdog is set to the TPG 261 acknowledges the message automatically after 2 s (→... -

Page 93: Repair

8 Repair Return defective products to your nearest Pfeiffer Vacuum service center for repair. Pfeiffer Vacuum assumes no liability and the warranty becomes null and void if repair work is carried out by the end-user or third parties. BG 5195 BEN / A (2011-05) TPG261.oi... -

Page 94: Storage

9 Storage Caution Caution: electronic component Inappropriate storage (static electricity, hu- midity etc.) can damage electronic compo- nents. Store the product in an antistatic bag or con- tainer. Observe the corresponding specifica- tions in the technical data (→ Disposal WARNING WARNING: substances detrimental to the environment Products or parts thereof (mechanical and... -

Page 95: Appendix

Appendix Conversion Tables Weights slug 2.205 68.522×10 35.274 0.454 31.081×10 14.594 32.174 514.785 slug 28.349×10 62.5×10 1.943×10 Pressures , Pa mbar Torr 10×10 10×10 7.5×10 9.869×10 , Pa 100×10 750.062 0.987 750.062×10 0.987×10 mbar 133.322 1.333×10 1.333 1.316×10 Torr 101.325×10 1.013 1.013×10 Pressure units used in... -

Page 96: B: Default Settings

The following values are activated when the default set- Default Settings tings are loaded (→ 55): default user 1×10 mbar 9×10 mbar normal 1.00 (log) 1.000 (lin) 1000 mbar 0×10 mbar mbar 9600 2 Digit Auto BG 5195 BEN / A (2011-05) TPG261.oi... -

Page 97: C: Firmware Update

Firmware Update If your TPG 261 firmware needs updating, e.g. for implementing a new gauge type, please contact your local Pfeiffer Vacuum service center. User parameters Most of the settings you may have defined in the Pa- rameter and Test mode will not be affected by a firm- ware update. - Page 98 In the following instructions, the index is used instead of the actual index. Unpack the self extracting file If you have not connected the TPG 261 to the COM1 interface: • Open the batch file … • … edit the interface …...

- Page 99 TPG 261 off. ware Wait at least 10 s before turning the TPG 261 on again in order for it to correctly initialize it- self. The TPG 261 is now ready for operation. To be...

-

Page 100: D: Literature

Literature Instruction Sheet Compact Pirani Gauge TPR 261 BG 5105 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland www.pfeiffer-vacuum.de Operating Instructions Compact Pirani Gauge TPR 265 BG 5177 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland www.pfeiffer-vacuum.de Operating Instructions Pirani-Messröhre TPR 280, TPR 281 BG 5178 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar,... - Page 101 Instruction Sheet Compact Cold Cathode Gauge IKR 261 BG 5113 BN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland www.pfeiffer-vacuum.de Instruction Sheet Compact Cold Cathode Gauge IKR 270 BG 5115 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland [10] www.pfeiffer-vacuum.de Instruction Sheet Compact FullRange™...

- Page 102 [15] www.pfeiffer-vacuum.de Operating Instructions Compact Capacitance Gauge CMR 361 … CMR365 BG 5136 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland [16] www.pfeiffer-vacuum.de Operating Instructions Compact Capacitance Gauge CMR 371 … CMR375 BG 5138 BEN Pfeiffer Vacuum GmbH, D–35614 Asslar, Deutschland [17] www.pfeiffer-vacuum.de...

-

Page 103: E: Index

Index – A – – G – A/D converter test Gauge connector Gauge control – B – gauge activation gauge deactivation Baud rate OFF threshold Gauge identification – C – Gauge parameters Calibration factor calibration factor Cleaning Degas Communication measurement range interface measurement value filter Conformity... - Page 104 – O – – S – OFF threshold Safety Offset Scope of delivery Operating modes sensor connector Measurement mode Serial interface overview connector Parameter mode Status messages Program transfer mode Storage Operation Switching function para- power off meters power on Switching functions 22, 35, 36 Symbols...

-

Page 105: Ec Declaration Of Conformity

EC Declaration of Conformity We, Pfeiffer Vacuum, hereby declare that the equipment mentioned below complies with the provisions of the Di- rective relating to electrical equipment designed for use within certain voltage limits 2006/95/EC and the Directive relating to electromagnetic compatibility 2004/108/EC. - Page 106 A P A S S I O N F O R P E R F E C T I O N Pfeiffer Vacuum stands for innovative and custom Leading. Dependable. vacuum solutions worldwide. For German engineering art, Customer Friendly. competent advice and reliable services.

Need help?

Do you have a question about the TPG 261 and is the answer not in the manual?

Questions and answers