Becker DVT 3.60 Operating Instructions

Vacuum pumps/compressors

Hide thumbs

Also See for DVT 3.60:

- Maintenance manual (21 pages) ,

- Operating instructions manual (6 pages)

Table of Contents

Advertisement

Quick Links

l

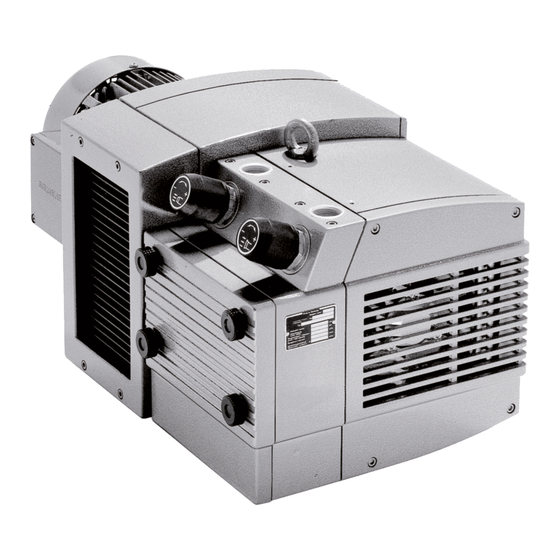

Vacuum pumps • Compressors

Application

These operating instructions apply to:

-Pressure vacuum pumps DVT 3.60-3.140

-Vacuum pumps KVT 3.60, 3.80, 3.100, 3.140

-Compressors KDT 3.60, 3.80, 3.100, 3.140

Safety Regulations

Please comply with Accident Preventi-

on Regulations VBG 16, Compressors, in particu-

lar Section IIIc "Installation" and IV "Operation"

plus VBG 4 "Electrical equipment and tools".

Pumps may only be converted or modified after

approval by the manufacturer.

Application

The pumps can be used to generate a vacuum

(KVT), overpressure (KDT) or combined (DVT).

Inlet air must be standard dry atmospheric air. Do

not use for pumping toxic or inflammable sustances.

The pumps work oil-free. Prevent suction of oil mist.

The specification is valid up to a height

of 800 m above sea level.

Transport and storage

Store pump in a dry area. Prevent condensation

caused by vapour.

Lift and transport only by using the ring screws.

Installation

It is recommended to install the radial compres-

sor with easy access for maintenance.

Clearance between compressors and adjacent

walls should be no less than 10 cm of free space

in order to ensure sufficient air flow for cooling.

COMBINED FLUID PRODUCTS COMPANY

Tel: 800-521-2083 ● Fax: 847-540-0513 ● Email:

DVT / KVT / KDT

3.60-3.80-3.100-3.140

Rotary vane vacuum pumps/compressors,

oilfree running, air-cooled

Contact Gebrüder Becker prior to installation

under noise insulation canopies.

Ambient temperatures must not exceed 45°C.

Connection and installation

Ensure correct dimensions (see Table) and clean

pipelines. Keep connections free from oil, grease,

water and any other contamination. With pipeli-

nes exceeding 5 m in length we recommend the

installation of non-return valves.

Keep connections free from oil, grease, water

and other contaminants.

Remove end caps at DA and SA. Do not connect

to pipeline yet.

Motor connection

Connect the radial compressor to the electricity supply

observing all applicable safety regulations. Comply with

EN 60204 T1.

Connect motor based on connecting diagram (in termi-

nal box) or ready-made plugs. This work should be car-

ried out by an experienced electrician only. Check for

connecting voltage and frequency.

Install motor circuit-breaker with Main switch and

set to nominal motor current. (For data see motor

rating plate).

Avoid switching of more than 10 times per hour.

Briefly start motor and check rotation

(arrow on casing). Exchange phases if rotation is

incorrect.

Commissioning

Connect pressure line at DA and inlet line at SA.

Set vacuum control valve VR or pressure control valve

DR to operating values (for values see table).

sales@combinedfluidproducts.com

Operating Instructions

Do not operate the compressor without safety

equipment against excessive pressure (for maxi-

mum values see rating plate). In case of permit-

ted compression end pressures of more than 1

bar additionally connect a pressure meter and

mark end pressure.

Maintenance

Maintain pump regularly to achieve the best ope-

rating results. Maintenance intervals will depend

on the pump´s use and ambient conditions.

Before commencing maintenance, remove

mains plug from socket to avoid unintentional restarting.

Air compression will generate high tem-

peratures at the compressors: Allow the pump

parts to cool before disassembly.

The filter cartridges are inserted behind the

enclosure cover GD. Clean depending on dust accumu-

lation. Blow out filter from inside to outside.

Replace blocked, oily or greasy cartridges.

Additional filters are available for operation in very dusty

environment.

Blow out dirt in cooling air channels KK by

compressed air.

The vanes are subject to wear due to abrasion from

the walls of the enclosure.

Check vane width every 3000 operating

hours or annually (for minimum widths see Table).

Remove side cover SD for this.

On replacement blow out enclosure by dry compressed

air.

● Vacuum and Compressed Air Specialists ● Since 1975

● Online Orders/Parts:

www.CFPWarehouse.com

Replace the grease loss in the rolling bearing due

to disassembly - 2g 'Amblygon 15/2' grease in

total.Grease is to be found behind GB or with

included grease gun.

DVT/KVT/KDT3.60-3.80:The roller bearings are

prelubricated for life and will not require mainten-

ance.

DVT/KVT/KDT3.100-3.140:Grease Roller bearings

at A and B after 2,000 hours of operation at both

of the grease nippels while the compressor is

running (3.100: 5g and 3.140: 7g).

Replace by original roller bearings only.

Repairing

Please return to Gebr. Becker.

D V T / KVT / KDT 3.60-3.80-3.100-3.140

● Web:

www.combinedfluidproducts.com

Advertisement

Table of Contents

Summary of Contents for Becker DVT 3.60

-

Page 1: Operating Instructions

Vacuum pumps • Compressors oilfree running, air-cooled Application These operating instructions apply to: Contact Gebrüder Becker prior to installation Do not operate the compressor without safety Replace the grease loss in the rolling bearing due -Pressure vacuum pumps DVT 3.60-3.140 under noise insulation canopies. - Page 2 Tabelle-Table-Tableau-Tabella-Tabla DVT/KVT/KDT ..3.60 ..3.80 ..3.100 ..3.140 Anschlußleitung bis 2m / 2m bis 10m . . .1" / 1 1/2" ..1" / 1 1/2" ..1 1/2" / 2" ..1 1/2" / 2" Pipework up to 2m / 2m up to 10m Tuyauterie jusqu’à...

Need help?

Do you have a question about the DVT 3.60 and is the answer not in the manual?

Questions and answers