Table of Contents

Advertisement

Quick Links

Your new Table Saw has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation,

and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator's manual.

Thank you for buying a Ryobi Table Saw.

SAVE THIS MANUAL FOR FUTURE REFERENCE

OPERATOR'S MANUAL

10 in. (254 mm) TABLE SAW

BTS20R

Advertisement

Chapters

Table of Contents

Summary of Contents for Ryobi Table Saw

- Page 1 Your new Table Saw has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance. WARNING: To reduce the risk of injury, the user must read and understand the operator's manual.

-

Page 2: Table Of Contents

Loose Parts List ... 10 Features ... 11-13 Operating Components ... 12 On/Off Switch ... 12 To Turn Your Saw On ... 12 To Turn Your Saw Off ... 12 To Lock Your Saw Switch ... 12 Blades ... 13 Assembly ... -

Page 3: Rules For Safe Operation

Servicing requires extreme care and knowledge and should be performed only by a qualified service technician. For service we suggest you return the tool to your nearest Ryobi AUTHORIZED SERVICE CENTER for repair. When servic- ing, use only identical Ryobi replacement parts. - Page 4 Safe operation of this power tool requires that you read and understand this operator's manual and all labels affixed to the tool. Safety is a combination of common sense, staying alert, and knowing how your table saw works. READ ALL INSTRUCTIONS KNOW YOUR POWER TOOL. Read the operator's manual carefully.

- Page 5 OFF and disconnecting the saw from the power source. PROVIDE ADEQUATE SUPPORT to the rear and sides of the saw table for wide or long work pieces. Use a sturdy "outrigger" support if a table extension more than 24 inches long is attached to the saw.

-

Page 6: Safety And International Symbols

Instructions for safe use of accessories are included with the accessory. DOUBLE CHECK ALL SETUPS. Make sure blade is tight and not making contact with saw or workpiece before connecting to power supply. MAKE SURE THE WORK AREA HAS AMPLE LIGHT-... -

Page 7: Extension Cords

ELECTRICAL ELECTRICAL CONNECTION Your Ryobi Table Saw is powered by a precision built electric motor. It should be connected to a power supply that is 120 volts, 60Hz, AC only (normal household current). Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. -

Page 8: Glossary Of Terms

The area over, under, behind, or in front of the blade. As it applies to the workpiece, that area which will be, or has been, cut by the blade. The distance that the tip of the saw blade tooth is bent (or set) outward from the face of the blade. Throw-Back Throwing of a workpiece in a manner similar to a kickback. -

Page 9: Phillips Screwdriver

Your Model BTS20R Table Saw is shipped complete in one carton and includes a rip fence, a miter gauge, a blade guard, wheels, and hub caps. Separate all parts from packing materials and check each one with the illustration and the list of Loose Parts to make sure all items are accounted for before discarding any packing material. -

Page 10: Loose Parts List

Description Rip Fence ... 1 Miter Gauge ... 1 Blade Guard Assembly ... 1 Wheels ... 2 Hub Caps ... 2 Washers ... 4 Shoulder Bolts ... 2 Large Wrench ... 1 Small Wrench ... 1 Bumper ... 2 Screws ... 4 Hex Key, 1/4 in. -

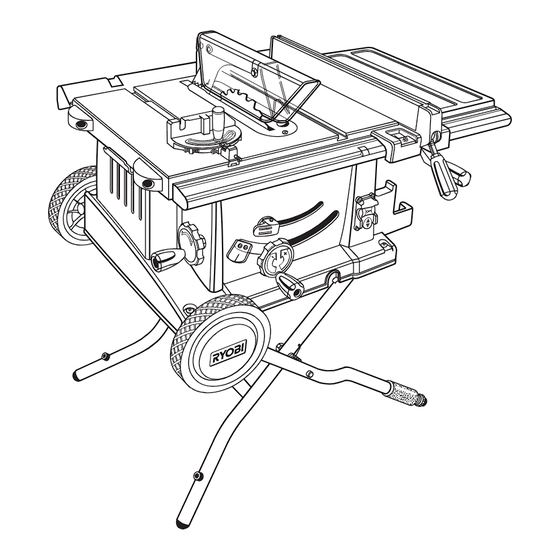

Page 11: Getting To Know Your Saw

• folding leg stand with wheels for ease of transportation These features provide ease of cutting with all types of wood. WARNING: Before attempting to use your table saw, familiarize yourself with all operating features and safety requirements. BLADE GUARD... -

Page 12: Operating Components

Then the teeth dig into the wood to help prevent or reduce the possibility of kickback. POWER SWITCH Your table saw is equipped with a power switch that has a built-in locking feature. This feature is intended to prevent unauthorized and possible hazardous use by children and others. -

Page 13: Features

BLADES It is recommended that you use a RYOBI 10 in. (254 mm) Combination Blade, which is provided with the BTS20R Table Saw. You will get maximum performance with the following features: • 36 precision ground, micro-grain carbide teeth • tensioning for 4,800 rpm This blade is provided with the saw. -

Page 14: Assembly

2 hub caps 4 flat washers 2 shoulder bolts Place the table saw on end. Secure the axle in place by inserting a screwdriver or large nail in the hole in the center of the axle. See Figure 7. Loosen bolts on each side of the axle by turning counter- clockwise. -

Page 15: Opening The Leg Stand

See 5. Push the leg stand towards the ground with your right hand and pull in the same direction with your left hand until the table saw is in an upright position. See 6 and 7. ASSEMBLY Page 15... -

Page 16: Closing The Leg Stand

Note: You can also refer to the blue label on the top of the table saw for tear-down procedures. Standing to the side of the table saw, grasp the table tilt handle with your left hand. Tilt the table saw to the your left and grab the grip with your right hand. -

Page 17: To Install Rip Fence

To reinstall the throat plate, drop blade below saw table and place throat plate in the opening. Push throat plate toward the rear of saw base to engage the spring clip. Snap the throat plate in place. Insert the throat plate screw and securely tighten. -

Page 18: Blade And Guard Assembly

Correctly align the blade and riving knife as shown, repeating above step as needed. Tighten attachment nuts securely. If riving knife is not positioned correctly with blade up, it could contact saw table when blade is lowered and restrict blade elevation. ASSEMBLY... -

Page 19: Throat Plate

Blade alignment with the riving knife can be adjusted for different blade thickness. Refer to Settings and Adjustments in the Operations Section. Before continuing, read To Check, Replace or Adjust the Blade Guard Assembly on page 23 to make sure of proper riving knife alignment. -

Page 20: Operation

Do not modify the plug; if it will not fit the outlet, have the correct outlet installed by a qualified electrician. Refer to the Electrical page of this manual. Note: This table saw is designed to cut wood and wood composition products only. CAUSES OF KICKBACK Kickback can occur when the blade stalls or binds, kicking the workpiece back toward you with great force and speed. -

Page 21: Types Of Cuts

Knock out any loose knots with a hammer before making the cut. Always provide proper support for the wood as it comes out of the saw. TYPES OF CUTS See Figure 19. There are six basic cuts: 1) the cross cut, 2) the rip cut, 3) the miter cut, 4) the bevel cross cut, 5) the bevel rip cut, and 6) the compound (bevel) miter cut. -

Page 22: Settings And Adjustments

SETTINGS AND ADJUSTMENTS TO REMOVE THE BLADE See Figures 20 - 22. Use the two wrenches supplied with the saw in this proce- dure to replace the blade. WARNING: Unplug your saw and make sure the blade guard assembly is installed and working properly to avoid serious personal injury. -

Page 23: To Check, Replace Or Adjust The Riving Knife And Blade Guard Assembly

It is held in place by two bolts and hex nuts at its base. The bolts are set in slots that permit front-to-back adjustment. WARNING: Failure to turn the table saw off, remove the switch key, and unplug the saw before servicing or working on it could result in accidental starting causing possible serious injury. -

Page 24: To Adjust The Blade Depth

1/4 in. but the lowest points (gullets) are below the top surface. See Figure 25. WARNING: Unplug the saw and make sure the blade guard assembly is installed and working properly to avoid serious personal injury. Raise the blade by turning the blade adjusting handle counterclockwise or lower it by turning the handle clockwise. -

Page 25: Heeling (Paralleling) The Blade To The Miter Gage Groove

See Figures 28 - 30 . WARNING: Make sure the switch is off, switch key is removed, and saw is unplugged. Failure to do so could result in accidental starting causing serious personal injury. Do not loosen any screws for this adjustment until you have checked with a square and made test cuts to be sure adjusments are necessary. -

Page 26: To Use The Outfeed Support

See Figure 31. The outfeed support slides to give the operator additional support for cutting long workpieces. With the table saw in the off position, stand behind the saw. Grasp the outfeed support with both hands and pull the outfeed support until it is fully extended. -

Page 27: To Make A Miter Cut

Set the miter gauge to 0˚ and tighten the lock knob. Place a support (the same height as saw table) behind the saw for the cut work. Make sure the wood is clear of the blade before turning on the saw. -

Page 28: To Make A Bevel Cross Cut

Make sure the wood is clear of the blade before turning on the saw. Let the saw blade build up to full speed before moving the miter gauge and the workpiece into the blade. Hold the workpiece firmly with both hands on the miter gauge and feed the workpiece into the blade. -

Page 29: To Make A Compound Miter Cut

Remove the throat plate. Raise the saw blade. Put the saw in angle mode by pushing the bevel locking lever to the right. Turn the blade adjusting handle until the blade indicator shows a 30° angle. Push the bevel locking lever securely to the left to lock the angle. -

Page 30: Operation

TO MAKE DADO CUTS A dado is a non-through cut and typically refers to a channel cut, both with the grain and across the grain. (The Ryobi part number for the dado set is 4650306.) Unplug your saw. -

Page 31: Maintenance

TO SET BLADE AT 0 OR 45 See Figure 40. The angle settings of your saw have been set at the factory and, unless damaged in shipping, should not require setting during assembly. After extensive use, it may need to be checked. -

Page 32: Troubleshooting

3. Adjust nut counterclockwise. 1. Replace or have blade sharpened. 2. Slow the feed rate. 3. Replace wood. 4. Call Ryobi Technical Service at 1-800-525-2579 1. Have blade resharpened. 1. Adjust positive stops. See page 31. - Page 33 NOTES NOTES Page 33...

-

Page 34: Extension Cord Caution

Ryobi Authorized Service Center. Be sure to provide all pertinent facts when you call or visit. Please call 1-800-525-2579 for your nearest Ryobi Authorized Service Center. You can also check our web site at www.ryobitools.com for a complete list of Authorized Service Centers.

Need help?

Do you have a question about the Table Saw and is the answer not in the manual?

Questions and answers

Как поднимать и опускать пильный диск?

I ordered a replacement handle for the blade raising function (the old one busted). How do I remove the part that is broken and install the replacement?